© July 2017 Van Essen Instruments. All rights reserved.

Contents

1 Introduction.............................................................................................................................................1

1.1 Features..........................................................................................................................................1

1.2 System Overview...........................................................................................................................2

2 Getting Started........................................................................................................................................2

2.1 Supported Equipment..................................................................................................................2

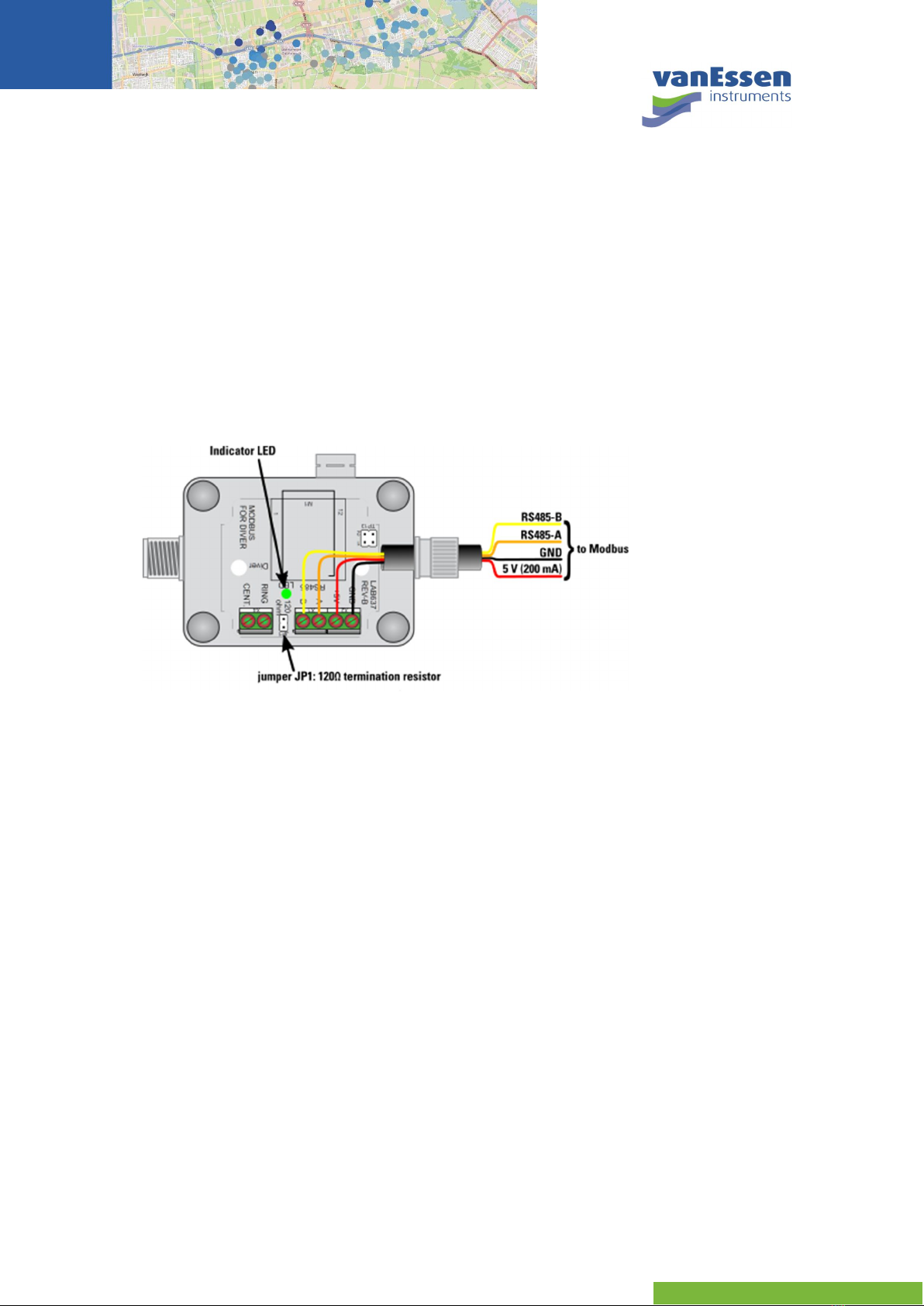

2.2 Installation.....................................................................................................................................3

2.3 Configuration.................................................................................................................................3

2.4 Transmission Mode.......................................................................................................................5

2.5 Operation.......................................................................................................................................5

3 Modbus Registers ....................................................................................................................................5

3.1 Reg. 30002, 30012: Firmware Version and Serial Number Diver-MOD.....................................5

3.2 Reg. 30220: Real-time Barometric Data from Diver-MOD.........................................................6

3.3 Reg. 40001: Change Slave Address of Diver-MOD ......................................................................6

3.4 Reg. 40002: Change Baudrate of the RS485 port .......................................................................6

3.5 Reg. 40003: Change Parity of the RS485 port.............................................................................7

3.6 Reg. 00001: Update Real-Time Data from Diver.........................................................................7

3.7 Reg. 00002: Get Diver Data ...........................................................................................................8

3.8 Reg. 00003: Update General Diver Information .........................................................................8

3.9 Reg. 00004: Force to accept new connected Diver ....................................................................8

3.10 Reg. 00011: Start/Stop Logging of Diver.....................................................................................9

3.11 Reg. 30241: Number of Records Recorded by Diver ..................................................................9

3.12 Reg. 30242: Maximum Number of Records for Diver.................................................................9

3.13 Reg. 30243: Remaining Battery Capacity Diver..........................................................................9

4 Reading Diver Data................................................................................................................................10

4.1 Header Information ....................................................................................................................10

4.2 Time Series Data..........................................................................................................................11

5 Appendix A – Specifications.................................................................................................................15

5.1 Casing...........................................................................................................................................15

5.2 Connections.................................................................................................................................15

5.3 Power Consumption...................................................................................................................15

5.4 Modbus.........................................................................................................................................15

5.5 Pressure........................................................................................................................................16

5.6 Temperature................................................................................................................................16

5.7 Environmental.............................................................................................................................16

6 Appendix B - Diver-MOD Register Map................................................................................................17

6.1 Coils – Status Registers...............................................................................................................17

6.2 Read Only Registers ....................................................................................................................17

6.3 Reading Diver Memory................................................................................................................18

7 Appendix C – Pressure Conversion Table ...........................................................................................22

8 Appendix D – Diver Equipment............................................................................................................23

8.1 Communication Cable................................................................................................................23

8.2 TD-Diver........................................................................................................................................23