beneq TFS 200 Technical manual

OPERATION INSTRUCTION

TFS 200

N815881

Rev. E

Created:

Toni Parvela, 2010-06-16 16:59:32

Page: 1 (33)

Updated:

ZZ, 2010-06-28 10:05:46

© Beneq 2020

OPERATION INSTRUCTION

TFS 200

OPERATION INSTRUCTION

TFS 200

N815881

Rev. E

Created:

Toni Parvela, 2010-06-16 16:59:32

Page: 2 (33)

Updated:

ZZ, 2010-06-28 10:05:46

© Beneq 2020

Table of contents

1Operating instructions ......................................................................... 4

1.1 General notes .................................................................................... 4

1.1.1 Scope of this manual............................................................. 4

1.2 Startup and shut down procedures/Emergency stop ................................. 4

1.2.1 Cold startup / Recovery from emergency stop ........................... 4

1.2.2 Shut down for a longer period of time ...................................... 5

1.3 Brief operator instructions (manual operations, HMI)................................ 5

1.4 Precursor delivery............................................................................... 7

1.5 Source loading and unloading procedures ............................................... 8

1.5.1 Liquid source ....................................................................... 8

1.5.2 Hot source, HS 500 ............................................................. 12

1.5.3 Hot source, HS 300 ............................................................. 13

1.6 Source adjustments .......................................................................... 16

1.6.1 The gas lines...................................................................... 17

1.6.2 The Ozone source ............................................................... 18

1.6.3 The liquid sources ............................................................... 19

1.6.4 The hot sources.................................................................. 20

1.7 Description of the flow system ............................................................ 21

1.7.1 The process gas flows.......................................................... 21

1.7.2 Gas flows for the instrumentation.......................................... 23

1.7.3 The vacuum system ............................................................ 23

1.8 Flow chart symbols ........................................................................... 23

1.8.1 Key components names ....................................................... 23

1.8.2 Diaphragm valves (DV)........................................................ 24

1.8.3 Solenoid valves (SV) ........................................................... 25

1.8.4 Axial valves (AV) ................................................................ 25

1.8.5 Needle valves (NV) ............................................................. 26

1.8.6 Hand valves (HV)................................................................ 26

1.8.7 Check valves (CV)............................................................... 26

1.8.8 Gate valves (GV) ................................................................ 26

1.8.9 Relief valves (RV) ............................................................... 26

1.8.10 Mass flow controllers (MFC) .................................................. 27

1.8.11 Flow indicators (FT)............................................................. 27

OPERATION INSTRUCTION

TFS 200

N815881

Rev. E

Created:

Toni Parvela, 2010-06-16 16:59:32

Page: 3 (33)

Updated:

ZZ, 2010-06-28 10:05:46

© Beneq 2020

1.8.12 Orifices and Capillaries (CA) ................................................. 27

1.8.13 Temperature sensors (TE) .................................................... 27

1.8.14 Heaters (H) ....................................................................... 28

1.8.15 Pressure transducers and indicators (PT,PIA)........................... 28

1.8.16 Filters ............................................................................... 29

1.9 Factory settings for flow components ................................................... 29

1.9.1 Orifices ............................................................................. 29

1.9.2 Needle valves..................................................................... 29

1.9.3 Gas inlet adjustments.......................................................... 30

1.10 Basic of process tuning ...................................................................... 30

1.10.1 Process tests...................................................................... 30

1.10.2 Underdosing test ................................................................ 31

1.10.3 Process time optimization: ................................................... 32

1.11 Heating and cooling system................................................................ 32

1.12 Residual risks................................................................................... 33

OPERATION INSTRUCTION

TFS 200

N815881

Rev. E

Created:

Toni Parvela, 2010-06-16 16:59:32

Page: 4 (33)

Updated:

ZZ, 2010-06-28 10:05:46

© Beneq 2020

1Operating instructions

1.1 General notes

1.1.1 Scope of this manual

The TFS 200 is designed to be a flexible ALD tool for research. It gives high freedom

for the process engineer to adapt it to daily needs. The flow system is easy to change

and it is possible to run many different types of recipes with TFS 200 system. The

high freedom of using and modifying the TFS 200 system makes it possible to run

this reactor even in undesirable mode. Thus, when changing the precursor tubing

and recipe, the process engineer has to fully understand the operation of the system.

This manual is built to be a handy set of information for the advanced user for getting

a good understanding of the reactor operation and for getting the most out of TFS

200 features. Simple daily operations are described in the chapter "Brief operator

instructions” of this manual.

1.2 Startup and shut down procedures/Emergency stop

1.2.1 Cold startup / Recovery from emergency stop

The cold startup procedure is the following:

-Check the overall condition of the system.

-Open any shutoff hand valves in the carrier gas, instrument gas, and process gas

inlets if closed.

-Turn on the tool main switch located in the electric cabinet.

-Wait approximately 1-2 min, PLC starts.

-Start TFS 200 HMI on the computer, log in to TFS 200 HMI using the valid username

and password.

-Acknowledge pop-up windows related to cold start. E-stop must be acknowledged

by pressing Ack Estop button from HMI top header.

Figure: Control page of TFS 200 HMI

OPERATION INSTRUCTION

TFS 200

N815881

Rev. E

Created:

Toni Parvela, 2010-06-16 16:59:32

Page: 5 (33)

Updated:

ZZ, 2010-06-28 10:05:46

© Beneq 2020

-Open cooling water shutoff Hand valves if closed.

-When the emergency routine is performed and acknowledged, the system runs the

startup routine automatically. The system runs the startup routine also when

powered up.

-The system is on idle state and ready to run. Alarms can be cleared from the alarm

window.

1.2.2 Shut down for a longer period of time

ALL PRECURSOR HAND VALVES SHOULD BE CLOSED AND CONTAINERS

SHOULD BE REMOVED! RISK OF PRECURSOR LEAKAGE!

Shut down for a longer period of time can be done when the tool is left unattended

for weeks.

Shut down procedure for a longer period of time, when the reactor is left in

atmospheric pressure.

-Pump down the reactor using the pump down button in the control window.

-Remove all precursor containers based on the unloading procedure.

-Vent the reactor using the vent button in the control window.

-Close user interface quit any other programs and shut down the computer.

-If the system is equipped with other than a rotary vane vacuum pump, shut down

the pump according to the pump user manual.

-Turn the power off from the main switch (all valves are closed, vacuum pump stops).

-Turn water and gas inlets off.

Shut down procedure for a longer period of time, when the reactor is left

under the vacuum.

-Pump down the reactor using the pump down button in the control window.

-Remove all precursor containers based on the unloading procedure.

-Set all MFC flows to 0 sccm.

-Close nitrogen main valve and vacuum valves. Keep the reactor under vacuum

condition.

-Close user interface quit any other programs and shut down the computer.

-If the system is equipped with other than a rotary vane vacuum pump, shut down

the pump according to the pump user manual.

-Turn the power off from the main switch (all valves are closed, vacuum pump stops).

-Turn water and gas inlets off.

1.3 Brief operator instructions (manual operations, HMI)

REACTION CHAMBER AND VACUUM CHAMBER PARTS MIGHT BE HOT WHEN

UNLOADING SUBSTRATES WITH TOP-LOADED REACTION CHAMBER! RISK

OF BURN INJURIES!

DO NOT TOUCH ANY PARTS OF THE MACHINE THAT ARE >60 °C! RISK

OF BURN INJURIES!

OPERATION INSTRUCTION

TFS 200

N815881

Rev. E

Created:

Toni Parvela, 2010-06-16 16:59:32

Page: 6 (33)

Updated:

ZZ, 2010-06-28 10:05:46

© Beneq 2020

For daily operation use the following procedures:

Preparation:

-Check the overall condition of the system.

-Check that the precursors are in the right positions.

Pumping down with top-loaded reaction chamber:

-Close the reaction chamber lid.

-Close the vacuum chamber lid.

-Run the pump down routine (by pressing the "Pump down" button in the control

window).

-Check that the machine status is in the IDLE state after the pump down routine

completed.

Pumping down with load lock:

With the load lock chamber installed, you can pump down either the load lock chamber

(in normal operation) or the vacuum chamber (after maintenance) when the gate

valve between the two chambers is closed. If the gate valve is open, both chambers

will be in the same pressure; pumping down or venting one chamber affects the other

chamber too. To pump down the vacuum chamber, follow the instructions of “Pumping

down with top-loaded reaction chamber”.

To pump down the load lock chamber:

-Close the load lock chamber lid.

-Make sure the substrate loader is pulled all the way back to home position.

-Make sure the gate valve is closed.

-Run the load lock pump down routine in the load lock window.

-Check that the machine status is in the IDLE state after the pump down routine

completed.

HANDLE THE VACUUM AND LOAD LOCK CHAMBER LIDS WITH CARE WHEN

OPENING AND CLOSING! RISK OF FINGER INJURY!

Loading/unloading the substrate (with the top-loaded reaction chamber):

-Run the vent routine if the reactor is under vacuum (by pressing the "Vent" button in

the control window).

-Open the vacuum chamber lid.

-Open the reaction chamber lid.

-Unload and/or load the substrate in the reaction chamber.

-Close the reaction chamber lid.

-Close the vacuum chamber lid (and HS 500 hot source lid if present).

-Run the pump down routine (by pressing the "Pump down" button in the control

window).

Loading the substrate through the load lock:

-Make sure that the vacuum chamber is in vacuum.

-The substrate carrier must be in the home position.

OPERATION INSTRUCTION

TFS 200

N815881

Rev. E

Created:

Toni Parvela, 2010-06-16 16:59:32

Page: 7 (33)

Updated:

ZZ, 2010-06-28 10:05:46

© Beneq 2020

-Vent the load lock from the load lock window.

-Open the load lock chamber lid.

-Load the substrate on the substrate carrier.

-Close the load lock chamber lid.

-Pump down the load lock chamber from the load lock window.

-Open the gate valve from the load lock window.

-Push the substrate carrier into the reaction chamber until it is in the front position.

-Lift substrate up by pressing the substrate lifter button. The button is lit when active.

-Pull back substrate carrier to home position.

-Lower substrate by pressing the substrate lifter button. The indication light of the

button goes off.

-Close the reaction chamber for the process by pressing the substrate holder button.

The button is lit when active.

-Close gate valve from the load lock window.

Unloading the substrate through the load lock

-Open the reaction chamber after the process by pressing the substrate holder button.

The indication light of the button goes off.

-Check the loadlock is in vacuum condition.

-Open gate valve from the load lock window.

-Lift substrate up by pressing the substrate lifter button. The button is lit when active.

-Push the substrate carrier into the reaction chamber until it is in front position

-Lower substrate to the carrier by pressing the substrate lifter button. The indication

light of the button goes off.

-Pull back substrate carrier to home position.

-Close gate valve from the load lock window.

-Vent the load lock from the load lock window.

-Open the load lock chamber lid.

-Unload the substrate.

Processing/Run recipe:

-Select and load the right recipe.

-Start the run (by pressing the "Start batch" button in the control window).

-Check that the temperature set values are right.

-Check that the pressure values are at the right level. To avoid precursor leaking from

the reaction chamber to the vacuum chamber, the pressure of vacuum chamber should

always be higher than the reaction chamber.

-Follow the instructions given by pop-up windows which are defined in the recipe, i.e.

the substrate and precursor temperatures reach to setting points, hand valves of

precursor containers are opened and etc.

1.4 Precursor delivery

RISK OF INJURY DUE TO HIGH PRESSURE FLUIDS AND GASES IN THE

PRECURSOR LINES! SAFETY GOGGLES IS RECOMMENED DURING THE

OPERATION.

In general, the precursor delivery can be described in several different ways, while the

three most common ways are the following:

OPERATION INSTRUCTION

TFS 200

N815881

Rev. E

Created:

Toni Parvela, 2010-06-16 16:59:32

Page: 8 (33)

Updated:

ZZ, 2010-06-28 10:05:46

© Beneq 2020

•Own vapor pressure

The precursor material is actually boiling when the pressure in the container is

dropping during the pulse. This method is most common for materials with the

vapor pressure of at least 10 mbar at source temperature.

•Carrier gas assisted delivery

The carrier gas and pulse valves are opened simultaneously. The carrier gas

flows through the precursor container making the flow of lower vapor pressure

precursor more efficient.

•Carrier gas assisted booster delivery

The carrier gas is first loaded into the container to increase the pressure inside

the container. Then the pulse valve is opened to release the mixture of carrier

gas and precursor vapor from the container. This is the most efficient way of

delivering a low vapor pressure material from the container. This method should

not be used for high vapor pressure materials since there is a risk of precursor

flowing to the carrier gas feeding line.

1.5 Source loading and unloading procedures

PRECURSOR RESIDUALS MIGHT BE STILL PRESENT IN THE LINES! EXTRA

PRECAUTIONS SHOULD BE TAKEN WHEN OPENING ANY CHEMISTRY

LINES OF THE SYSTEM! PROPER PURGING OF THE LINES IS NEEDED!

RISK OF PRECURSOR LEAK DUE TO WRONG ASSEMBLY OF PRECURSOR

CONTAINERS OR DURING INSTALLATION CONTAINER MIGHT FALL OVER

CAUSING LEAK TO THE ATMOSPHERE!

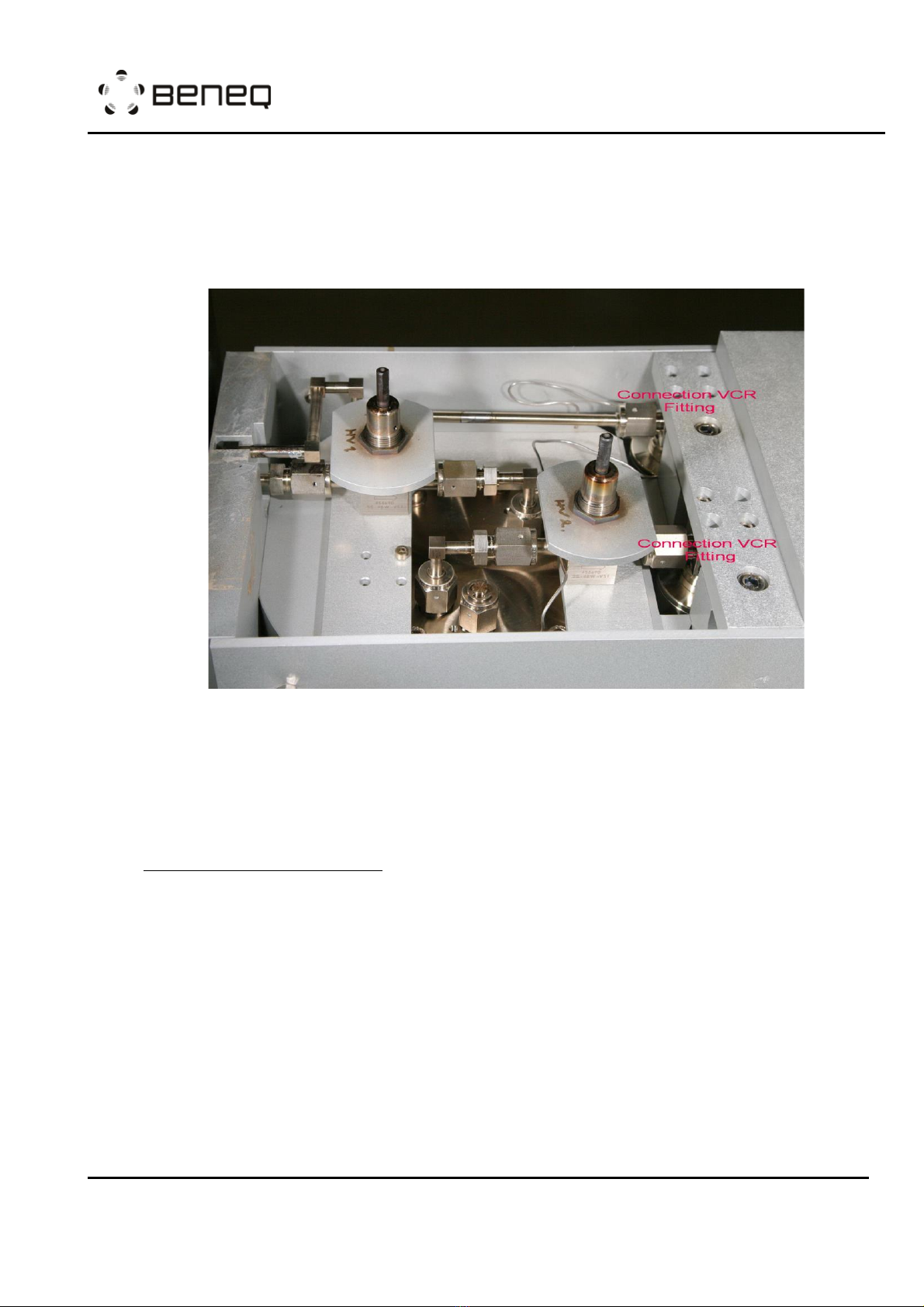

1.5.1 Liquid source

Liquid precursor materials are packed into metal containers. Liquid precursor

containers can be called “Liquid container with a single line”and “Liquid container

with dual lines”. “Liquid container with a single line”has only one connection with ¼"

VCR type metal fitting while the “Liquid container with dual lines” has two connections

with ¼" VCR type metal fittings. For all liquid containers, the material filling is a ½”

VCR fitting and the recommended maximum filling is 50% of the container capacity.

Liquid container with a single line

One hand valve is connected to the precursor outlet of the container.

PRECURSOR MATERIALS CAN BE DANGEROUS. PLEASE FOLLOW THE

CHEMICAL RELATED MSDS (MATERIAL SAFEY DATA SHEET).

HANDLE THE CONTAINERS WITH CARE DURING THE LOADING AND

UNLOADING PROCEDURES. ENSURE THE CONTAINER HAND VALVES ARE

CLOSED!

OPERATION INSTRUCTION

TFS 200

N815881

Rev. E

Created:

Toni Parvela, 2010-06-16 16:59:32

Page: 9 (33)

Updated:

ZZ, 2010-06-28 10:05:46

© Beneq 2020

Figure: Liquid container with a single line

Container loading

-Make sure that the container hand valve is closed.

-Remove the blind VCR caps from the container connectors and the TFS 200 feeding

line. (It is recommended to have caps plugged on the TFS 200 feeding lines when

source container is not in place.)

-Remove the used VCR gaskets.

-Place new VCR gaskets.

-Put the filled liquid source container to the right position in the aluminum support.

-Tighten the VCR fittings.

-Pump down the reactor into vacuum if not done already.

-Check that the machine is in an IDLE state.

-Leakage test VCR connections.

-Make sure the reaction chamber sealed well (there is the pressure difference

between reaction and vacuum chambers).

-Run container loading routine from either “control page” or “precursor page”of TFS

200 HMI based on the position of the liquid container.

NOTE: if the container is already under the vacuum, it is not necessary to

have Micropulsing in routine.

OPERATION INSTRUCTION

TFS 200

N815881

Rev. E

Created:

Toni Parvela, 2010-06-16 16:59:32

Page: 10 (33)

Updated:

ZZ, 2010-06-28 10:05:46

© Beneq 2020

Figure: Control page of TFS 200 HMI

Figure: Precursor page of TFS 200 HMI

Container unloading

-Make sure that the container hand valve is closed.

-Pump down the reactor to vacuum if not done beforehand.

-Make sure the reaction chamber sealed well (there is the pressure difference

between reaction and vacuum chambers).

-Run container unloading routine from either “control page” or “precursor page”of

TFS 200 HMI based on the position of the liquid container.

-Open the VCR fitting between machine and container.

-Remove the container.

-Plug the open fittings on both machine and container with blind VCR caps.

OPERATION INSTRUCTION

TFS 200

N815881

Rev. E

Created:

Toni Parvela, 2010-06-16 16:59:32

Page: 11 (33)

Updated:

ZZ, 2010-06-28 10:05:46

© Beneq 2020

Liquid container with dual lines

Two hand valves are connected to the container, one to gas inlet and one to precursor

outlet. Hand valves are connected to each other by a purge flow valve HV-SLx which

is used only when the container is removed/installed.

Figure: Liquid source precursor container (Left) and the connections to TFS 200

(Right). Red marks show the fittings that are opened and fastened when the

container is removed and installed. The purge valve is in the middle.

Container loading

-Make sure that container hand valves are closed.

-Make sure that purge valve HV-SLx is in purge position (valve handle is in position

open).

-Remove the blind VCR caps from the container connectors and the TFS 200 feeding

line. (It is recommended to have caps plugged on the TFS 200 feeding lines when

source container is not in place.)

-Remove the used VCR gaskets.

-Place new VCR gaskets.

-Put the filled liquid source container to the right position in the aluminum support.

-Tighten the VCR fittings.

-Pump down the reactor into vacuum if not done already.

-Fully open the needle valve (NV-PLx, where x is the liquid source number).

-Check that the machine is in an IDLE state.

-Leakage test VCR connections.

-Make sure the reaction chamber sealed well (there is the pressure difference

between reaction and vacuum chambers).

-Run container loading routine from either “control page” or “precursor page”of TFS

200 HMI based on the position of the liquid container.

-Close the purge valve HV-SLx.

-Adjust back the needle valve setting.

OPERATION INSTRUCTION

TFS 200

N815881

Rev. E

Created:

Toni Parvela, 2010-06-16 16:59:32

Page: 12 (33)

Updated:

ZZ, 2010-06-28 10:05:46

© Beneq 2020

NOTE: if the container is already under the vacuum, it is not necessary to

have Micropulsing in routine.

Container unloading

-Make sure that the container hand valve is closed.

-Pump down the reactor to vacuum if not done beforehand.

-Fully Open the needle valve (NV-PLx).

-Turn purge valve HV-SLx to purge position (valve handle position open).

-Make sure the reaction chamber sealed well (there is the pressure difference

between reaction and vacuum chambers).

-Run container unloading routine from either “control page” or “precursor page”of

TFS 200 HMI based on the position of the liquid container.

-Open the VCR fittings between machine and container.

-Remove the container.

-Plug the open fittings on both machine and container with blind VCR caps.

1.5.2 Hot source, HS 500

HOT SURFACES AT HOT SOURCE PARTS WHEN HEATING THEM UP ABOVE

100°C. RISK OF BURN INJURY!

PRECURSOR MATERIALS CAN BE DANGEROUS. PLEASE FOLLOW THE

CHEMICAL RELATED MSDS (MATERIAL SAFEY DATA SHEET).

HANDLE THE CONTAINERS WITH CARE! DO NOT OVERHEAT PRECURSOR

MATERIALS RISK OF UNCONTROLLED OVERPRESSURE BUILD UP IN THE

CONTAINER!

Semi-inert hot source (solid source) HS 500 has the capability to operate at

temperatures up to 500°C. This is possible because the pulsing is made by inert gas

valving. On the other hand, it is not possible to load/unload this type of hot source

without breaking the vacuum in the reactor.

This source type is designed to be used for very low vapor pressure materials. The

precursor delivery method is always carrier gas assisted pulsing mode.

HS 500 source cartridge loading

-Run vent routine from TFS 200 HMI to increase the pressure in the vacuum chamber

and HS 500 to atmospheric pressure.

-Fill the source cartridge (under glove box if needed).

-Open the source back flange and push the cartridge into the source tube.

-Close the back flange as far it goes without pressing the spring loaded hot source

cartridge.

-Set MFC-NOP and MFC-NOV flow to 1000 sccm for purging the HS 500.

-Wait 1 minute.

-Set MFC-NOP and MFC-NOV flow to 300 sccm.

OPERATION INSTRUCTION

TFS 200

N815881

Rev. E

Created:

Toni Parvela, 2010-06-16 16:59:32

Page: 13 (33)

Updated:

ZZ, 2010-06-28 10:05:46

© Beneq 2020

-Push the back flange completely closed and lock it by pressing the handle gently.

-Pump down the reactor to vacuum

HS 500 source cartridge unloading

-Ensure that HS 500 is cooled down

-Run the vent routine from TFS 200 HMI to increase the pressure in the vacuum

chamber and HS 500 to atmospheric pressure.

-Open the source back flange and pull out the used cartridge.

1.5.3 Hot source, HS 300

HOT SURFACES AT HOT SOURCE PARTS WHEN HEATING THEM UP ABOVE

100°C. RISK OF BURN INJURIES!

PRECURSOR MATERIALS CAN BE DANGEROUS. PLEASE FOLLOW THE

CHEMICAL RELATED MSDS (MATERIAL SAFEY DATA SHEET).

HANDLE THE CONTAINERS WITH CARE! DO NOT OVERHEAT PRECURSOR

MATERIALS RISK OF UNCONTROLLED OVERPRESSURE BUILD UP IN THE

CONTAINER!

The HS 300 can be heated up to 300°C and is designed for liquid and solid precursor

materials that need heating to reach sufficient vapor pressure. Precursor pulsing can

be done using either material's own vapor pressure or different ways of carrier gas

assisted pulsing. These methods are described in more detail in Chapter 1.4.

The recommended maximum filling of the precursor container is 150 ml. After

precursor filling, the container pressure can be different compared to normal process

pressure. As an example: if the precursor filling has been done at atmospheric

pressure and the deposition process will be done at vacuum, the higher pressure

from the container will cause higher flow into the reactor during the first pulses. This

may cause reactor contamination.

To avoid this, please follow the procedure:

HS 300 container loading

-Make sure that container hand valves are closed.

-Remove the blind VCR caps from the container connectors and the TFS 200 feeding

lines. (It is recommended to have caps plugged on the TFS 200 feeding lines when

source container is not in place.)

-Remove the used VCR gaskets.

-Place new VCR gaskets.

-Put the filled HS 300 container to the right position.

-Tighten the VCR fittings.

-Pump down the reactor into vacuum if not done already.

-Check that machine is in IDLE state

-Leakage test VCR connection.

-Make sure the reaction chamber sealed well (there is the pressure difference

between reaction and vacuum chambers).

OPERATION INSTRUCTION

TFS 200

N815881

Rev. E

Created:

Toni Parvela, 2010-06-16 16:59:32

Page: 14 (33)

Updated:

ZZ, 2010-06-28 10:05:46

© Beneq 2020

-Run source loading recipe of the HS 300 container. If it can not be found in the

recipe list, please contact Beneq. An example is shown below,

---------------------------------------------------------------------------------------------

*Recipe Loading Hot source 1 Precursor

*Recipe for purging hot source 1 line after attaching the container to the machine

*Based on flow chart N502400

*Program start

SPROG

*Open the N2 main valve and chamber flow valve and make sure filling valve is closed

OPEN DV-SN1,DV-NV2

CLOSE DV-NV1

*Check the vacuum level

WUNTIL PT-P1<10 10s

*Open main vacuum valve

OPEN DV-VP1

*Set flows

FLOW MFC-NOVS=300

FLOW MFC-NOPS=600

*Close pulse valves

CLOSE DV-PL1,DV-BL1

CLOSE DV-PL2,DV-BL2

CLOSE DV-PL3,DV-BL3

CLOSE DV-PL4,DV-BL4

CLOSE DV-PH1,DV-BH1,DV-BHA1

CLOSE DV-PH2,DV-BH2,DV-BHA2

CLOSE DV-PH3,DV-BH3,DV-BHA3

*Close process gas valves

CLOSE DV-PN1,DV-PN2

CLOSE DV-PG1,DV-PG2

CLOSE DV-PG6,DV-PG7,DV-PG8

CLOSE DV-PG1C,DV-SG02,DV-PG6C,DV-PG7C

*close precursor hand valves

WRITE M7

WUSER YES

*confirm that all precursor hand valves are closed

WRITE M22

WUSER YES

*Purge hot source 1 line

OPEN DV-PH1,DV-BH1

WTIME 1min

REPEAT 8

PULSE DV-BHA1 10s

WTIME 2min

REND

CLOSE DV-PH1,DV-BH1

*Prepare for processing

WRITE M6

WUSER YES

*mircopulsing to evacuate canister

REPEAT 80

PULSE DV-PH1 50ms

WTIME 1s

REND

REPEAT 100

PULSE DV-PH1 100ms

WTIME 1s

REND

*close precursor hand valves

WRITE M7

OPERATION INSTRUCTION

TFS 200

N815881

Rev. E

Created:

Toni Parvela, 2010-06-16 16:59:32

Page: 15 (33)

Updated:

ZZ, 2010-06-28 10:05:46

© Beneq 2020

WUSER YES

*Purge hot source 1 line again

OPEN DV-PH1,DV-BH1

WTIME 1min

CLOSE DV-PH1,DV-BH1

*end program

EPROG

---------------------------------------------------------------------------------------------

Figure: HS 300 container with the feeling lines. Red marks show the fittings that

are opened and fastened when the container is removed and installed.

NOTE: Preferably use metal (copper) seals in the top flange. If using

polymer seals, make sure seal material is compatible with the chemical and

the temperature used. A new container is always filled with Air. Please open

the container before transferring it into the glove box for chemical filling.

HS 300 container unloading

-Ensure that HS 300 is cooled down.

-Make sure that the container hand valve is closed.

-Pump down the reactor into vacuum if not done beforehand.

-Make sure the reaction chamber sealed well (there is the pressure difference

between reaction and vacuum chambers).

-Run source unloading recipe of the HS 300 container. If it can not be found in the

recipe list, please contact Beneq. An example is shown below,

---------------------------------------------------------------------------------------------

*Recipe Unloading Hot source 1 Precursor

*Recipe for purging hot source 1 line after detaching container from the machine

*Based on flow chart N502400

*Program start

SPROG

*Open the N2 main valve and chamber flow valve and make sure filling valve is closed

OPEN DV-SN1,DV-NV2

OPERATION INSTRUCTION

TFS 200

N815881

Rev. E

Created:

Toni Parvela, 2010-06-16 16:59:32

Page: 16 (33)

Updated:

ZZ, 2010-06-28 10:05:46

© Beneq 2020

CLOSE DV-NV1

*Check the vacuum level

WUNTIL PT-P1<10 10s

*Open main vacuum valve

OPEN DV-VP1

*Set flows

FLOW MFC-NOVS=300

FLOW MFC-NOPS=600

*Close pulse valves

CLOSE DV-PL1,DV-BL1

CLOSE DV-PL2,DV-BL2

CLOSE DV-PL3,DV-BL3

CLOSE DV-PL4,DV-BL4

CLOSE DV-PH1,DV-BH1,DV-BHA1

CLOSE DV-PH2,DV-BH2,DV-BHA2

CLOSE DV-PH3,DV-BH3,DV-BHA3

*Close process gas valves

CLOSE DV-PN1,DV-PN2

CLOSE DV-PG1,DV-PG2

CLOSE DV-PG6,DV-PG7,DV-PG8

CLOSE DV-PG1C,DV-SG02,DV-PG6C,DV-PG7C

*close precursor hand valves

WRITE M7

WUSER YES

*confirm that all precursor hand valves are closed

WRITE M22

WUSER YES

*Purge hot source 1 line

OPEN DV-PH1,DV-BH1

WTIME 1min

REPEAT 8

PULSE DV-BHA1 10s

WTIME 2min

REND

CLOSE DV-PH1,DV-BH1

*end program

EPROG

---------------------------------------------------------------------------------------------

-Open the two VCR fittings between machine and container.

-Remove the container.

-Plug the open fittings on both machine and container with blind VCR caps.

NOTE: Always make sure you are not overheating the precursor in the

container. Some precursors may contain for example water or other volatile

components that may be released during heating. This kind of precursors

may generate overpressure in the container when it is heated. Use pure

chemicals and monitor the pressure build-up during the first heating. The

risk of uncontrolled pressure builds up in the container! Risk of damaging

the source and uncontrolled precursor release!

1.6 Source adjustments

The TFS 200 ALD system has three main types of sources; gas, liquid (cold) and hot

sources. For hot sources, there are two different source constructions, HS 300 and HS

500.

OPERATION INSTRUCTION

TFS 200

N815881

Rev. E

Created:

Toni Parvela, 2010-06-16 16:59:32

Page: 17 (33)

Updated:

ZZ, 2010-06-28 10:05:46

© Beneq 2020

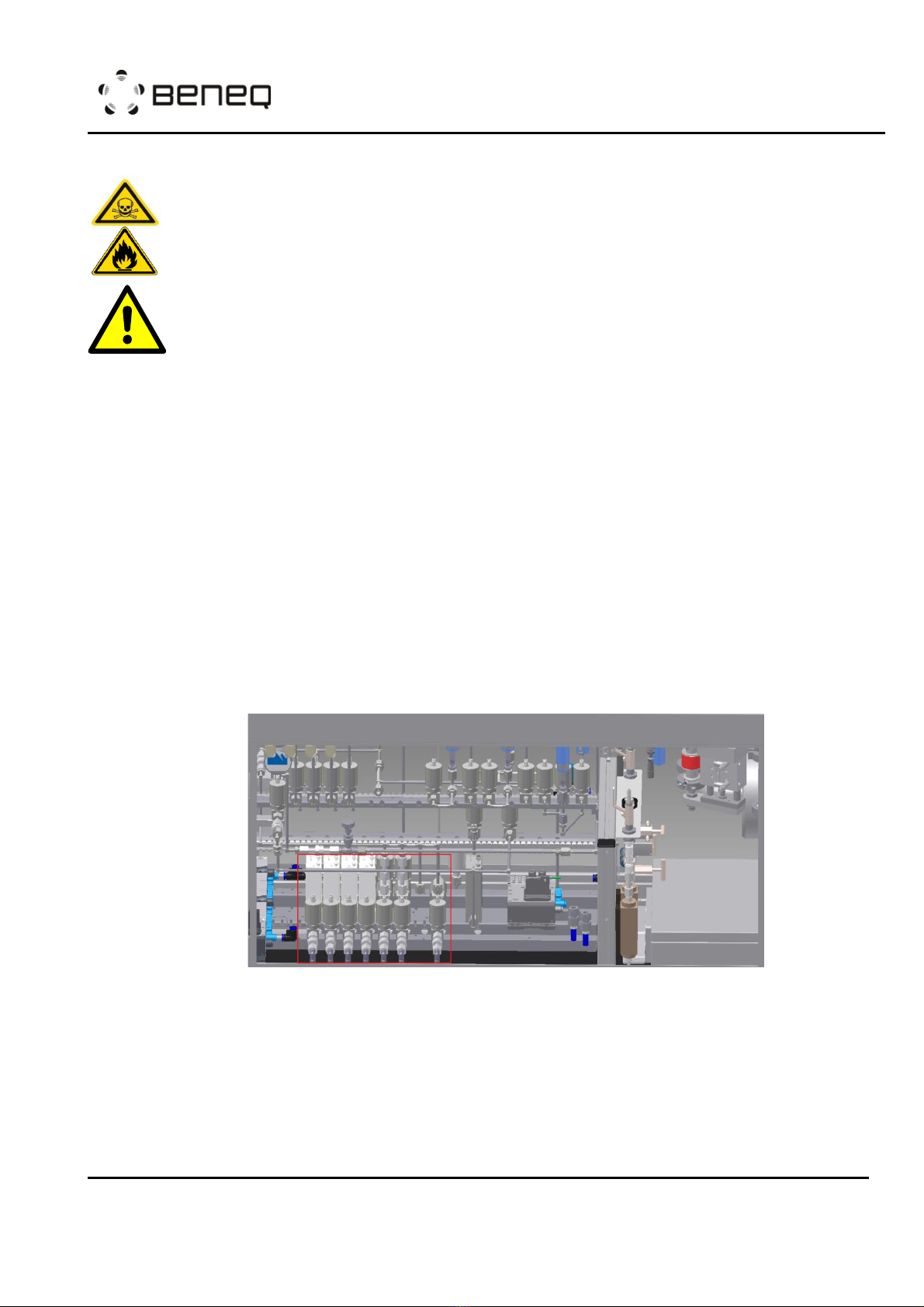

1.6.1 The gas lines

RISK OF TOXIC AND FLAMMABLE GAS LEAK TO THE ROOM ATHMOSPERE!

EXTRA PRECONSCIOUS STEPS SHOULD BE TAKEN ACCORDING TO MSDS,

LOCAL LAW, HEALTH AND SAFETY REGULATIONS!

RISK OF NON-COMPATIBLE REACTIVE GASES TO BE SWITCHED ON

SIMULTANEOUSLY DURING PROCESS!

The TFS 200 is equipt with gas lines for both thermal and plasma ALD operation as

shown in the figure below. For thermal ALD operation, the gas lines are not equipped

with mass flow controllers (MFC) for each gas line and usually the MFC controlled gas

lines are used for plasma gases that are not pulsed during the deposition. Plasma

gas lines are equipped with a pressure switch which prevents the pulsing valves to

be operated in case that the plasma gas feeding line is not under vacuum.

The precursors from the gas sources are delivered to the reactor by all-welded ¼"

SS tubes. The VCR type connection point is inside the machine frame.There is a

pulsing valve in the gas line, which leads the gas into the feeding line. The gas flow

is restricted with a flow orifice, which is located in the inlet connector of the pulsing

valve. The feeding lines of gas lines can be grouped in different ways. Plasma gases

are mixed to a common feeding line which goes to the plasma electrode through the

top lid of the vacuum chamber. Gas lines for thermal ALD are grouped into up to 3

separate feeding lines, which all have separate inlet connectors at the bottom of the

vacuum chamber.

Figure: The area marked with red, starting from the left side it shows four Plasma

lines equipped with MFCs, two flammable/toxic gas lines and a normal gas line.

Both thermal and plasma gas lines can be further separated into two types: a) Normal

gas line and b) Flammable/toxic gas line. The normal gas line is usually used for

gasses such as N2, O2, H2and the flammable/toxic line is used for gasses such as

NH3, H2S, WF6and more. For both types, software interlocks are used in cases of non-

combatible gasses which doesn’t allow the operation of the pulsing valves at the

same time. Both types of gas lines include line filters, inlet check valves for

OPERATION INSTRUCTION

TFS 200

N815881

Rev. E

Created:

Toni Parvela, 2010-06-16 16:59:32

Page: 18 (33)

Updated:

ZZ, 2010-06-28 10:05:46

© Beneq 2020

preventing flow from the TFS 200 to the facility system in a fault situation, pusling

vavles and orifices for flow adjustment. The flammable/toxic gas line is equipted with

more safety features such as double interlock valves on the gas supply, double

interlock pressure switches on the vacuum chamber for vacuum level monitoring and

interlocked to material feeding valves, check vavles on the purging line for preventing

the gas flowing back to the nitrogen line.

1.6.2 The Ozone source

RISK OF OZONE LEAK TO THE ROOM ATMOSPHERE DUE TO LEAKING

FEEDING TUBES, OZONE DESTRUCTOR DOES NOT WORK PROPERLY!

RISK OF OZONE RESIDUALS PRESENT IN THE VENTILATION LINE! EXTRA

PRECONSCIOUS STEPS SHOULD BE TAKEN ACCORDING TO MSDS, LOCAL

LAW, HEALTH AND SAFETY REGULATIONS!

The ozone source is enclosed within a ventilation cabinet as shown in the figure below.

Oxygen is fed into the ozone generator which generates the ozone to be used for the

ALD process. Due to the short limiting lifetime of ozone, there are both inlet and

outlet connections for the ozone line. This allows ozone to circulate through the

source tubes. During pulsing, the pulse valve will take enough material from the

circulation.

Figure: Ozone source cabinet

An ozone destructor is included in the source tube for destroying the bypass flow of

ozone and sending the residual O2by-product to the facilitie’s ventilation line. In

addition, the ozone cabinet is equipt with an ozone detector which is used to trigger

an alarm in case of ozone leakage caused within the ozone cabinet. A fatal alarm

would be triggered if the level detected by the ozone sensor is above a preset value

which will automatically close all process valves.

After the chemical reactions within the Reaction Chamber, excess gasess flow

through the exhaust line to the pump and then to the facilitie’s ventilation line. There

OPERATION INSTRUCTION

TFS 200

N815881

Rev. E

Created:

Toni Parvela, 2010-06-16 16:59:32

Page: 19 (33)

Updated:

ZZ, 2010-06-28 10:05:46

© Beneq 2020

is a possible risk that ozone residuals may enter the ventilation line and in this case

an ozone destroyer should be installed in the ventilation line of factory to eliminate

this risk.

1.6.3 The liquid sources

RISK OF PRECURSOR LEAK TO THE ATMOSPHERE DUE TO VERY HIGH

PRESSURE OF N2 CARRIER GAS! FEEDING N2 WITH HIGH PRESSURE IN

THE CONTAINER MIGHT CAUSE LEAKING OF THE PRECURSOR!

The liquid sources are designed for precursor materials that have enough vapor

pressure at room temperature for vacuum processing. The source containers are

located in a temperature-stabilized aluminum block. Normally the temperature is

adjusted to about 19-20°C for ensuring that the vapor pressure does not change

according to room temperature changes. Furthermore, the lower source temperature

minimizes the risk of condensation in the tubing between the source material

container and the reactor. The temperature is kept constant either by a separate

chiller (option) or other sources of cold water. The cooling liquid is circulating inside

the aluminum block.

The most common way to use this kind of high vapor pressure source is "pulsing by

own vapor pressure". In this case, the precursor vapor pressure is higher than the

pressure in the reaction chamber feeding tube. By opening the pulsing valve of the

liquid source (DV-PLx, x is the number of sources), the precursor vapor flows into

the reaction chamber. The needle valve (NV-PLx) or orifice is used to adjust the flow

to the right dosage level. The dose is also affected by pulse time and source

temperature.

If the precursor vapor pressure is not significantly greater than the feeding tube

pressure, it is possible to run this source in the "carrier gas assisted delivery" mode.

In this case, both container valves of DV-PLx and DV-BLx are opened simultaneously,

and thus the carrier gas is mixed with the precursor material. The dose is dependent

on the precursor vapor pressure, the total pressure of the container, reaction

chamber feeding tube pressure and the carrier gas flow rate. Precursor vapor

pressure is a physical value depending on source temperature. Flow is adjusted by

the mass flow controller and the overall pressure of the container can be adjusted by

the needle valve. Reaction chamber feeding tube pressure is dependent on all MFC

flow rates. This means that the dosing can be increased by opening the needle valve

or increasing the MFC flow rate. The dose is also affected by pulse time and source

temperature.

If the precursor vapor pressure is significantly lower than system pressure, the

“Carrier gas assisted booster delivery”mode can be used. This delivery type is based

on two steps: a) increasing the container pressure by pulsing nitrogen through the

DV-BLx valve and b) pulsing the mixture of carrier gas and precursor into the

chamber by opening the DV-PLx valve.

OPERATION INSTRUCTION

TFS 200

N815881

Rev. E

Created:

Toni Parvela, 2010-06-16 16:59:32

Page: 20 (33)

Updated:

ZZ, 2010-06-28 10:05:46

© Beneq 2020

1.6.4 The hot sources

RISK OF BURN INJURIES! HOT SOURCES AND SARROUNDING PARTS

MIGHT BE HOT! USE PROTECTIVE HEAT SHIELD WHEN OPERATING!

RISK OF UNCONTROLLED PRECURSOR FLOW DUE TO OVERHEAT OF

PRECURSOR MATERIAL TO THE TEMPERATURES WHERE ITS VAPOR

PRESSURE EXCEEDS REACTOR PRESSURE!

RISK OF PRECURSOR LEAK TO THE ATMOSPHERE DUE TO VERY HIGH

PRESSURE OF N2 CARRIER GAS! FEEDING N2 WITH HIGH PRESSURE IN

THE CONTAINER MIGHT CAUSE LEAKING OF THE PRECURSOR!

There are two types of hot sources: HS 300 and HS 500.

Hot source HS 500

This hot source type utilizes the most commonly used and robust technology for

reaching high source temperature. This is mainly needed for materials with low vapor

pressure (most of them are solid). The flow system is always the "purge assisted"

type. The inert carrier gas flows are used to prevent leakage from hot source volume

to the reaction chamber volume (and vice versa) between pulses. The dosing can be

adjusted by changing precursor vapor pressure (Source temperature change), by

changing the carrier gas flow rate and by changing the pulse time.

Hot source HS 300

When the precursor material needs moderate heating, it is possible to use this hot

source type. The flow system is very similar to the liquid source and the delivery

methods can be found in Chapter 1.4. The source can be heated up to 300°C. It is

designed for both liquid and solid precursor materials.

When using this source type in "own vapor pressure” mode, the temperature should

be high enough to get precursor vapor pressure above the system pressure. There

are no adjustable needle valves integrated into the hot source. This means that the

pressure should be only slightly above the system pressure for minimizing the

overdose of precursors. The dose can be adjusted by pulse time and source

temperature.

Using “carrier gas assisted booster delivery”mode, the chemical decomposition of

the low vapor pressure precursors can be avoided. This type of delivery mode can be

done by pulsing the carrier gas valve to increase the container pressure and then by

opening the pulsing valve to release the carrier gas and precursor mixture to the

reaction chamber. The dose of the precursor can be adjusted by changing the

precursor temperature or by changing the length of the carrier gas/precursor pulse.

Typically, the carrier gas/precursor pulse ratio is kept constant. The relatively long

time is often needed to generate enough pressure in the container.

Table of contents

Popular Industrial Equipment manuals by other brands

Nordson

Nordson ColorMax Customer product manual

Siemens

Siemens LITHOSTAR Multiline Repair instructions

Jäger

Jäger S62-M360.06 S5 manual

Bühler technologies

Bühler technologies BWT Series Installation and operation instructions

Surewerx

Surewerx VPT Series owner's manual

Siemens

Siemens SIRIUS 8WD4428-0BC operating instructions