Trio UNIPLAY Instruction Manual

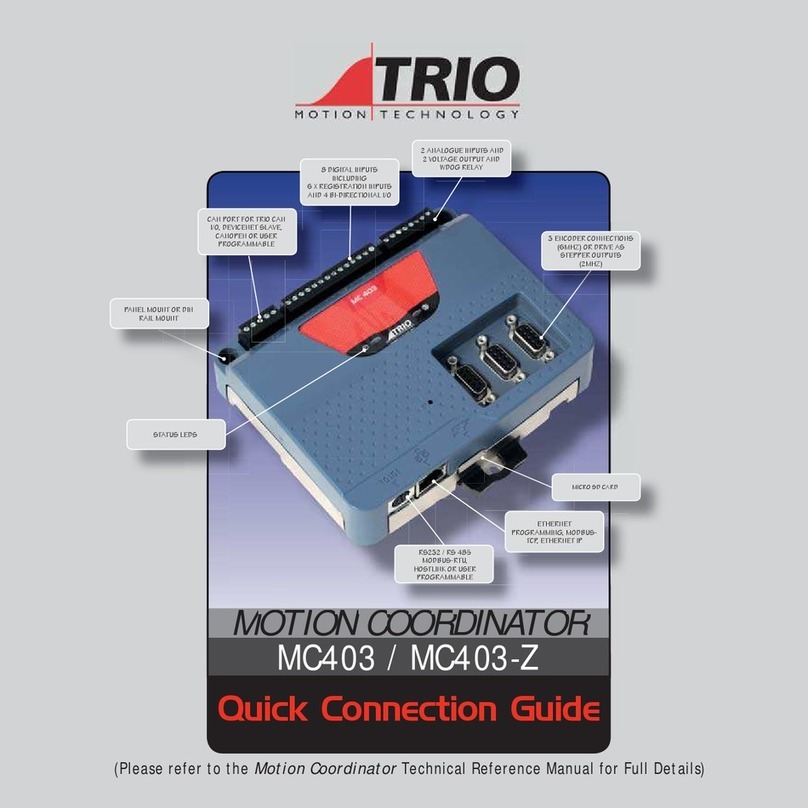

(Please refer to the Motion Coordinator Technical Reference Manual for Full Details)

HMI

UNIPLAY

Quick Connection Guide

H

H

IPLAY

H

M

H

M

PLAY

MI

M

I

INSTALLATION ENVIRONMENT

The UNIPLAY is designed for industrial use. The temperature operating range is 0 to 50 °C It may not be

suitable for using in certain outdoor applications. Please consult the factory for advised usage in outdoor

applications.

NEMA Rating

The UNIPLAY front bezel is NEMA 4 rated. When installed properly in a NEMA 4 panel, the NEMA 4 rating of

the panel will not be compromised. This means that fluids will not enter the panel during wash downs.

Electrical Environment

The UNIPLAY 7 / 10 has been tested to conform to European CE requirements. This means that the

circuitry is designed to resist the effects of electrical noise. This does not guarantee noise immunity in

severe cases. Correct wire routing and grounding will insure proper operation.

Mechanical Environment

Avoid installing units in environments where severe mechanical vibration or shocks are present.

Environmental Considerations

• The UNIPLAY are to be used indoors as built in displays. Make sure that the display are installed

correctly and that the operating limits are followed.

• Do not operate the unit in areas subject to explosion hazards due to flammable gases, vapours or dusts.

• The unit should not be installed where large temperature variations and/or high humidity is present. This

will cause condensation in the device.

• Do not install UNIPLAY in environments where have inflammable gases.

MOUNTING

Care should be taken when locating equipment behind the unit to ensure that a.c. power wiring, PLC output

modules, contactors, starters and relays, and any other source of electrical interference are located away

from the back of the unit. Particular note should be taken to the position of variable speed drives and

switching power supplies. Their input and load cables should be screened to a central star earth point.

Making a NEMA-4 Mounting Panel Details

The unit can be mounted into panels with a depth of 105mm. It is recommended that

the unit be mounted on the front panel of a steel enclosure, through an appropriate opening.

Allow a clearance of 25mm around the sides of the unit for mounting hardware. Allow

clearance for cable connections to the back of the unit. Unit depth may vary according to

cable type used. Typically, plan a depth to accommodate at least 105mm behind the

panel. This device should be mounted in the vertical position and for use on the flat surface

enclosure.

NEMA-4 Mounting

Put the unit through the panel cut out (See drawings at the back of this guide). Slide the clamps (packed

with product) into every hole provided around the case. Tighten the clamping screws in an even pattern

until the unit is secured in the panel. Screw torque: 3.5-4.7 Nm. This ensures a waterproof seal

and prevents the panel from being deformed.

VESA Mounting

There are 4 holes on back panel for atatching the VESA mount. The screw: M4 0.7mm, length:

shorter then 8.0mm, and screw torque: 4.7 Nm.

DO NOT OVER TIGHTEN MOUNTING CLAMPS!

To seal to NEMA-4 specifications, all supplied mounting clamps must be used and panel cannot

flex more than 0.253mm.

POWER CONNECTIONS

Make sure that all local and national electrical standards are met when installing the unit.

Contact your local authorities to determine which codes apply.

Power Requirements

The UNIPLAY is powered by d.c. power only. The specified voltage range is 24±20% Volts d.c. This insures

compatibility with most controller d.c. systems.

The power conditioning circuitry inside the unit is accomplished by a switching power supply. The peak

starting current can be as high as 2A.

Fusing Requirements

If the display does not come on within 5 seconds of power up, switch off the power. An internal fuse will

prevent damage if the polarity of the d.c. power is incorrect. Check wiring to insure proper connections and

try to power up again.

High Voltage

An Internal fuse will prevent damage for over voltage condition however it is not guaranteed.

D.c. voltage sources should provide proper isolation from main a.c. power and similar hazards.

Emergency Stop

A Hard-wired EMERGENCY STOP should be fitted in any system using an UNIPLAY to comply with ICS Safety

Recommendations.

Supply Voltage Condition

Do not power the UNIPLAY and inductive d.c. loads, or input circuitry to the controller, with the same

power supply.

The 24 Vd.c. output from some controllers may not have enough current to power the UNIPLAY.

Wire Routing

Wire lengths should be minimized (Maximum length :500m shielded, 300m unshielded).

Wires should be run in pairs with a neutral or common paired with a signal line.

If wiring is to be exposed to lightning or surges, use appropriate surge suppression devices.

Keep a.c., high energy, and rapidly switching d.c. wiring separate from the 3 signal wires.

Fit ungrounded d.c. supplies with a resistor and capacitor in parallel to earth ground. This provides a path

for static and high frequency dissipation. Typical values to use are 1MΩand 4700pF.

To prevent the UNIPLAY from becoming damaged or having noise output issues, after turning

the device off, please wait 10 seconds before turning the device on again.

Connection

To make a connection, strip about 10mm of insulation off the end of the wire, turn the

connector screw counterclockwise until the gap is wide open, insert the wire all the

way in, and turn the screw clockwise until tight. Connect positive d.c. line to the +24V

terminal and the d.c. ground to the 0V terminal.

Grounding Requirements

A CHASSIS GROUND MUST BE USED.

The d.c. ground is not directly coupled to Earth ground internally. It is not advisable to ground the d.c.

negative return to chassis ground as poor site earthing can introduce noise into a system, but if necessary

an earth connection should be made, from the power supply return point to the central star earth point.

Ground conductors should be as short and as wide in size as possible. The conductors must always be large

enough to carry the maximum short circuit current of the path being considered. Ground conductors should

be connected to a tree from a central star earth ground point. This ensures that no ground conductor

carries current from any other branch.

CE Requirements

To make an UNIPLAY comply with EMC directives, and to reduce susceptibility to electrical interference, a

separate #14 AWG ground wire should be taken to the chassis ground terminal of the power connector. This

ground connection should be run directly to the central star earth connection point.

GND

+24v

SAFETY GUIDELINES

The system designer should be aware that devices in Controller systems could fail and thereby create an

unsafe condition. Furthermore, electrical interference in an operator interface, such as an UNIPLAY, can

lead to equipment start-up, which could result in property damage and/or physical injury to the equipment

operator.

COMMUNICATIONS CONNECTIONS

The communication ports are located on the underside of the UNIPLAY. COM1, COM2, USB host, USB client

and SD card ports are not used.

Ethernet:

A 1:1 or cross-over Ethernet cable may be used to connect the UNIPLAY screen to a Motion Coordinator or

Ethernet switch.

Speaker:

An external speaker / buzzer may be used for greater keypress feedback. Connection is via a 3.5mm mono

jack plug.

DIP switch settings:

SW1 SW2 SW3 SW4 Mode

ON OFF OFF ON Touch Screen Calibrate mode

OFF ON OFF ON Hide HMI System Setting Bar

OFF OFF ON ON Boot Loader mode

OFF OFF OFF ON Normal

OFF OFF OFF OFF Not Supported

SW4 is used for adjusting LCD parameters, please keep it in the manufacturer default position,

otherwise incorrect screen display may be occurred.

SOFTWARE INSTALLATION

No software installation is required to use the UNIPLAY Industrial HMI system. Installation of any

additional software on the device by users will invalidate the warranty.

ON

1 2 3 4

USING THE UNIPLAY:

UNIPLAY HMI’s work with the Trio 4xx Motion Coordinator range. Motion Perfect 3 is used to create

operator HMI screens which are transferred to the UNIPLAY HMI by the Motion Coordinator at runtime.

Trio recommend using a USB powered switch

CONFIGURATION RUNNING

Default controller address: 192.168.0.250

Default HMI IP address: 192 168.0.251

To change the controller IP address the HMI requires, use Motion Perfect v3.

DIMENSIONS AND PORTS

A DIP switch & reset button G Com1 RS485, Com3 RS485, Com3 RS232

B Fuse H Com1 RS232, Com2 RS232

CPowerconnector I Ethernetport

D VESA 75mm screw holes J USB Host port

E Line out K USB Client port

F SD card slot

UNIPLAY 7

200.35mm

146.35mm

138mm

192mm

42.55mm

R2mm

CUTOUT DIMENSIONS

A

C

B

D

E GF H I KJ

UNIPLAY 10

270.97mm

212.97mm

201mm

259mm

50mm

R2mm

CUTOUT DIMENSIONS

A

C

B

D

E GF H I KJ

quick start v1-July 2012

Trio Motion Technology Ltd. Trio Motion Technology LLC Trio Shanghai Trio India

WWW.TRIOMOTION.COM

Table of contents

Other Trio Industrial Equipment manuals