Bennett Marine AutoTrimPro User manual

Before Installation

Before performing installation, read the entire instructions and make

sure battery power is disconnected.

Required Tools and materials

Installation Instructions

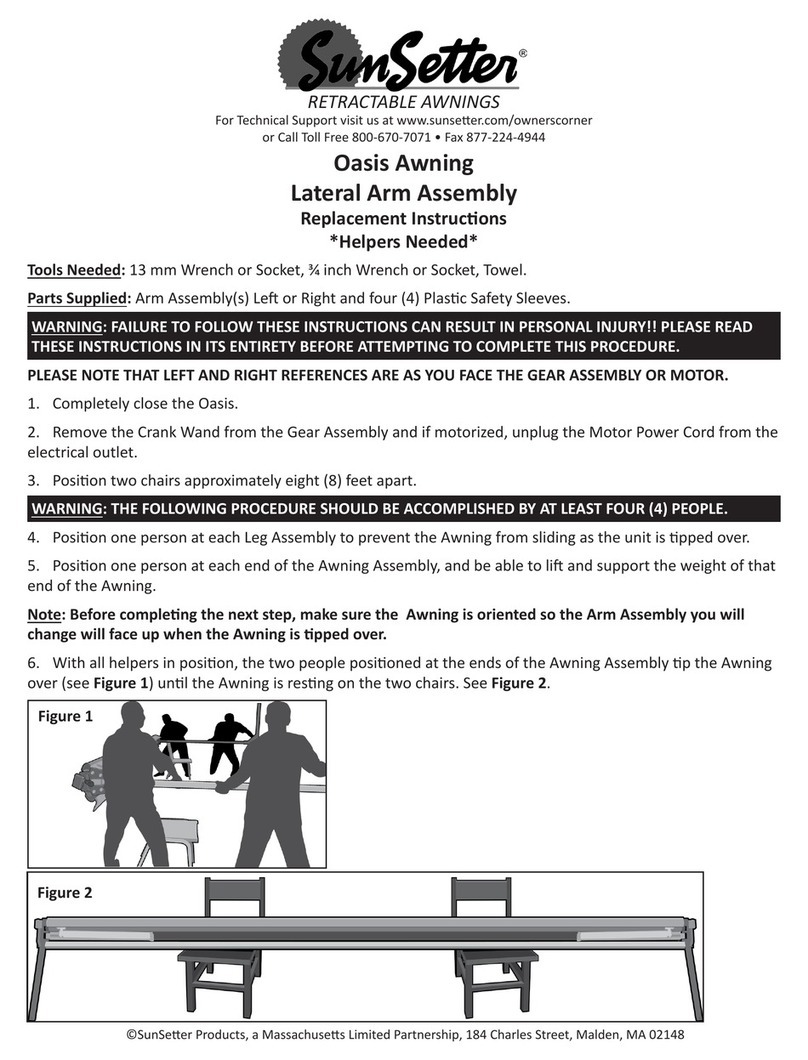

Installing New Upper Hinges with Sensors

Step 1 - Inside the transom, with tabs in full up position, locate the trim

tab hydraulic line. If there is no pipe nipple visible inside the transom,

you have a short through-transom tting connection,

(Figure 2). Unscrew and remove the actuator away from the transom and

use a 7/16"wrench to remove the tubing from the upper hinge.

Skip to step 3.

For standard installations, detach tubing from the brass elbow (some

uid will drip out). While holding the pipe nipples with vise grips,

unscrew the brass elbow using a 9/16" wrench. Do this procedure for

the port and starboard cylinders (see Figure 3).

Step 2 - Outside the transom, unscrew and remove the actuator away

from the transom. Remove the pipe nipple.

Step 3 - Start with the port side cylinder. Snap the white plastic clip

on the shaft protruding from the bottom of the cylinder.

is clip must be used to keep the spring inside the cylinder

compressed. Grasp the cylinder upper hinge with both hands and

unscrew it counterclockwise from the cylinder body (a small amount

of uid may spill).

Step 4 - Use care when handling sensor coils during assembly to

avoid damaging wires. Insert the metal rod into the piston,

pointed end down. Make sure

that the O-ring is in place in the

new upper hinge with sensor coil.

Screw the new upper hinge with

the red sensor wire onto the port

side cylinder while keeping the

metal rod inserted into the center

of the sensor coil (Figure 4).

Tighten the upper hinge hand tight. You will nish tightening the

cylinder in Step 7.

Step 5 - Remove the plastic clip from the piston and repeat steps

2 - 4 for the starboard cylinder. Use the upper hinge with the green

sensor wire for the starboard side.

Step 6 - Using the included template, drill a 5/16" hole in the

transom for the sensor wire (Figure 5). Screw the pipe nipple into the

actuator upper hinge. Tighten the nipple hand tight. en, with vise

grips, tighten two full turns …

NO MORE. Cover end of the

pipe nipple with masking tape.

If you have the short through-

transom tting, using a 7/16"

wrench, screw it in until the

tting is snug; the shoulder of

the tting will just touch the

plastic of the upper hinge.

Step 7 - Carefully feed the sensor wire through the 5/16" hole.

Apply sealant to the actuator upper hinge surface around the pipe

nipple, screw holes, and cable. Secure the actuator upper hinge to the

transom with mounting screws. Grasp the cylinder body with both

hands and tighten (clockwise) securely.

Step 8 - Inside the transom, remove masking tape from the pipe

nipples. Carefully wrap Teon tape around the male threads of the

pipe nipples. Holding the pipe nipples with vise grips (to prevent

them from turning) re-secure 90 degree elbows. Re-attach the

hydraulic tubing, tightening nut nger tight. Snug nut with 1/2"

wrench. Do not over-tighten. Note: If you have the short through-

transom ttings, omit this step. Repeat for the other side. Run the

red and green sensor wires to where you plan to mount the

ATP Helm Display.

Step 9 - Connecting the ATP Display

Refer to the “Installation of the ATP Helm Display” section on

page 7 of the ATP Hydraulic Installation & User’s Guide, and the

Connecting & Testing the System” section on page 8-9. Calibration

instructions as well as troubleshooting information can also be found

in the complete installation guide. A digital version of this manual

can be downloaded at BennettTrimTabs.com/ATP.

• 7/16", 1/2"

& 9/16" Wrench

• 5/16" Drill Bit

• Masking Tape

• 2" Hole Saw

• Teon Tape

• Wire Stripper

• Electric Drill

• Marine Grade

Sealant

• Vise Grips

• Wire Cutter

Figure 2

Hydraulic

Tubing

Short

hydraulic

tting

Transom

Figure 3

Nut

Brass

elbow

Pipe

nipple

Hydraulic Tubing

Transom

Figure 4

Figure 5

ATP Sensor Kit Installation Instructions

Have Questions?

We’re here to help

Call us at (954)427-1400

See the reverse side for the system diagram

and sensor wire hole drilling template

For information on installing a complete Bennett Hydraulic

Actuator, please visit BennettTrimTabs.com/Installation

ATP67-1

Ø 5/16

"

REVISIONS

ZONE

REV.

DESCRIPTION

DATE

APPROVED

DO NOT SCALE DRAWING

Actuator Mounting Template

SHEET 1 OF 1

UNLESS OTHERWISE SPECIFIED:

SCALE: 1:1

WEIGHT:

REV

DWG. NO.

A

SIZE

TITLE:

NAME

DATE

COMMENTS:

Q.A.

MFG APPR.

ENG APPR.

CHECKED

DRAWN

FINISH

MATERIAL

INTERPRET GEOMETRIC

TOLERANCING PER: ANSI Y-14

DIMENSIONS ARE IN INCHES

TOLERANCES:

FRACTIONAL

1/16

ANGULAR: MACH

BEND

TWO PLACE DECIMAL

.01

THREE PLACE DECIMAL

.005

APPLICATION

USED ON

NEXT ASSY

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

Bennett Marine Inc. ANY REPRODUCTION

IN PART OR AS A WHOLE WITHOUT THE

WRITTEN PERMISSION OF

Bennett Marine Inc. IS PROHIBITED.

5

4

3

2

1

Bennett Marine

550 Jim Moran Blvd

Deerfield Beach, FL 33442

Ø 5/16

"

REVISIONS

ZONE

REV.

DESCRIPTION

DATE

APPROVED

DO NOT SCALE DRAWING

Actuator Mounting Template

SHEET 1 OF 1

UNLESS OTHERWISE SPECIFIED:

SCALE: 1:1

WEIGHT:

REV

DWG. NO.

A

SIZE

TITLE:

NAME

DATE

COMMENTS:

Q.A.

MFG APPR.

ENG APPR.

CHECKED

DRAWN

FINISH

MATERIAL

INTERPRET GEOMETRIC

TOLERANCING PER: ANSI Y-14

DIMENSIONS ARE IN INCHES

TOLERANCES:

FRACTIONAL

1/16

ANGULAR: MACH

BEND

TWO PLACE DECIMAL

.01

THREE PLACE DECIMAL

.005

APPLICATION

USED ON

NEXT ASSY

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

Bennett Marine Inc. ANY REPRODUCTION

IN PART OR AS A WHOLE WITHOUT THE

WRITTEN PERMISSION OF

Bennett Marine Inc. IS PROHIBITED.

5

4

3

2

1

Bennett Marine

550 Jim Moran Blvd

Deerfield Beach, FL 33442

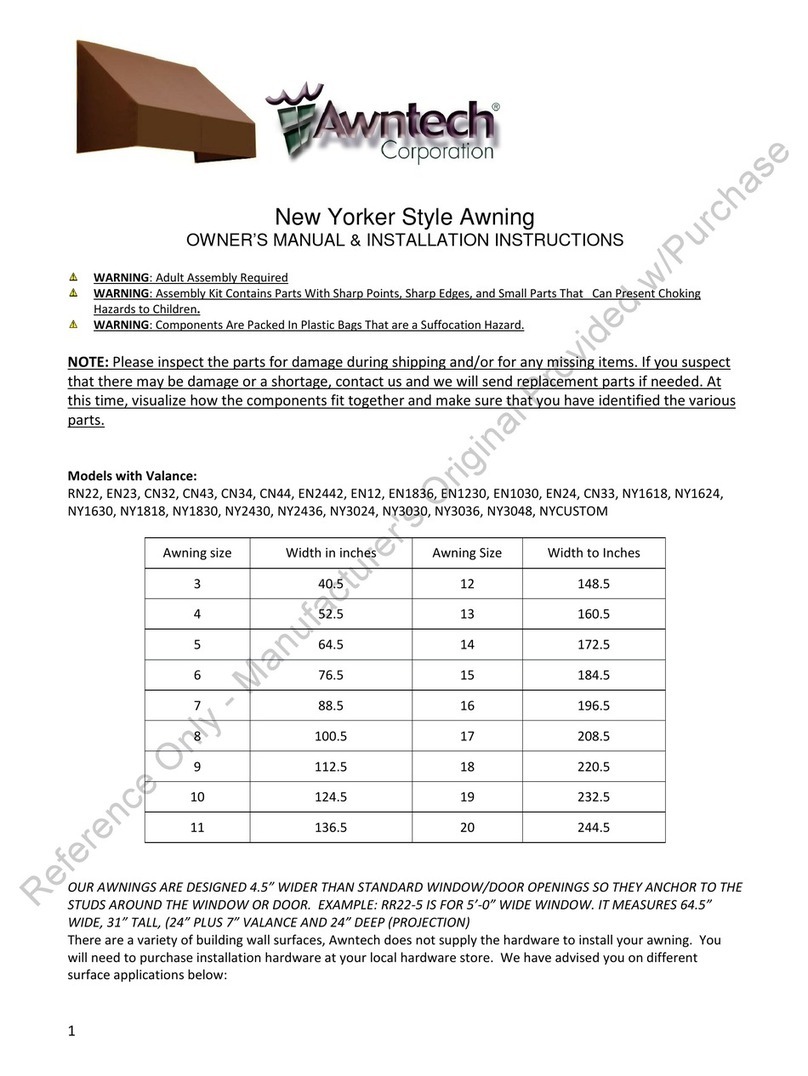

(954) 427-1400 BennettTrimTabs.com 550 Jim Moran Blvd., Deerfield Beach, FL 33442

Have Questions? We’re here to help.

ORANGE WIRE

CONNECT TO HELM POWER

GROUND

8

5

9

6

7

12

3

4

GROUND

ORANGE WIRE

CONNECT TO 20A (12V)

10A (24V)

PURPLE WIRE

CONNECT TO IGNITION

GROUND

No.

PART NAME

DESCRIPTION

1

ACT-XX

PORT Actuator

2

ACT-XX

STBD Actuator

3

SCBL22-S-DPLG-DRPT-X

STBD Sensor Extension

Cable

4

SCBL22-P-DPLG-DRPT-X

PORT Sensor Extension

Cable

5

ATPCTRLG4H

ATP Module

6

HPU-XX

Hydraulic Pump

7

RGYB-DPLG-DRPT-X

Pump Extension Cable

8

BQEDISEXTCABLE-X

Display Extension

Cable

9

ATP DISPLAYG4

Display

D

C

B

A

A

B

C

D

1

2

3

4

5

6

7

8

8

7

6

5

4

3

2

1

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

Bennett Marine Inc. ANY REPRODUCTION

IN PART OR AS A WHOLE WITHOUT THE

WRITTEN PERMISSION OF

Bennett Marine Inc IS PROHIBITED.

PROPRIETARY AND CONFIDENTIAL

NEXT ASSY

USED ON

APPLICATION

DIMENSIONS ARE IN INCHES

TOLERANCES:

FRACTIONAL

1/16

ANGULAR: MACH

BEND

TWO PLACE DECIMAL

.01

THREE PLACE DECIMAL

.005

INTERPRET GEOMETRIC

TOLERANCING PER: ANSI Y-14

MATERIAL

FINISH

DRAWN

CHECKED

ENG APPR.

MFG APPR.

Q.A.

COMMENTS:

DATE

NAME

TITLE:

SIZE

B

DWG. NO.

REV

WEIGHT:

SCALE: 1:12

UNLESS OTHERWISE SPECIFIED:

SHEET 1 OF 10

ATP Single / Single

DO NOT SCALE DRAWING

Bennett Marine

550 Jim Moran Blvd

Deerfield Beach, FL 33442

1. Port Actuator

2. Stbd. Actuator

3. *Stbd. Sensor Extension Cable

4. *Port Sensor Extension Cable

5. Control Unit

6. Hydraulic Pump

7. Pump Extension Cable

8. Display Extension Cable

9. ATP Display

* Optional

Classic

Single

Pump

Hydraulic

System

Stbd.Port

Templates must be

printed or copied at

100% scale. Be sure to

select “Actual Size” when

printing from a PDF file.

1"

AutoTrimPro

SYSTEM DIAGRAM

Other manuals for AutoTrimPro

4