Bently Nevada 3300/46 User manual

-~

ARTISAN

®

~I

TECHNOLOGY

GROUP

Your definitive source

for

quality

pre-owned

equipment.

Artisan Technology

Group

Full-service,

independent

repair

center

with

experienced

engineers

and

technicians

on staff.

We

buy

your

excess,

underutilized,

and

idle

equipment

along

with

credit

for

buybacks

and

trade-ins

.

Custom

engineering

so

your

equipment

works

exactly as

you

specify.

•

Critical

and

expedited

services

•

Leasing

/

Rentals/

Demos

• In

stock/

Ready-to-ship

•

!TAR-certified

secure

asset

solutions

Expert

team

ITrust

guarantee

I

100%

satisfaction

All

tr

ademarks,

br

a

nd

names, a

nd

br

a

nd

s a

pp

earing here

in

are

th

e property of

th

e

ir

r

es

pecti

ve

ow

ner

s.

Find the GE / Bently Nevada 3300/46-07-04-00-00 at our website: Click HERE

•

.yi".a.m.cicils.

• • • • • • •

•

1)014-f =j

G. ./

I17

3300/46

RAMP DIFFERENTIAL

EXPANSION

MONITOR

OPERATION MANUAL

BENTLY

NEVADA

0

PART NO. 84413-01

Ramp Differential Expansion Monitor Operation

NOTICE

84413-01

READ THE FOLLOWING BEFORE INSTALLING OR OPERATING EQUIPMENT

Bently Nevada Corporation has attempted to identify areas of risk created by improper installation

and/or operation of this product. These areas of information are noted as WARNING or CAUTION

for your protection and for the safe and effective operation of this equipment. Read all instructions

before installing or operating this product. Pay particular attention to those areas designated by the

following symbols.

WARNING

High Voltage present

Could cause shock, bums

or death.

Do Not touch exposed

wires or terminals.

CAUTION

Machine Protection

Will Be Lost

In this document procedures are given only for channel A. Procedures for channel B are similar

except for the obvious substitution of corresponding switches, terminals, and indicators.

SYMBOLS

Special symbols are used in the manual to illustrate specifics in the step by step processes. For

example:

PRESS

+

FLASHING CONNECT DISCONNECT OBSERVE SCREWDRIVER

ii.

•

•

•

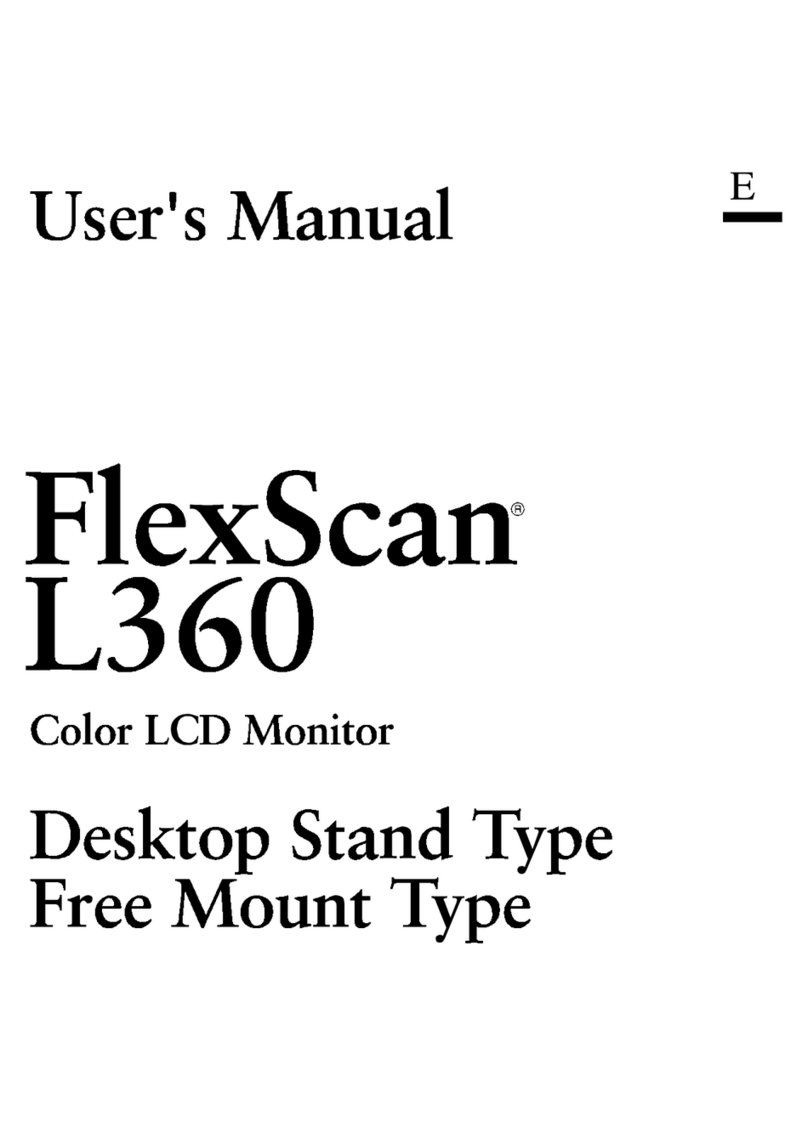

•Ramp Differential Expansion Monitor Maintenance

112 1 Test OK Limits

Figure 9

84414-01

1. Disconnect COM and IN wiring from the

channel A terminals on the Signal Input Relay

Module.

2. Connect the multimeter and the power supply.

3. Adjust the power supply voltage for -9 Vdc.

4. Verify that the channel A OK LED is on.

5. Increase the power supply voltage (more

negative) until the OK LED goes off (upper limit).

Verify that the upper OK limit is within the upper

OK voltage range (reference Table 8).

A\ CAUTION

Test will exceed alarm setpoint

levels causing alarms to

activate. This could result in

relay contact to change state.

See Danger Bypass section 10.

A\ WARNING

High Voltage present. Could

cause shock, bums or death.

Do not touch exposed wires or

terminals.

m••..

DIFFERENT I AL

EXPANSION tiON

P1

,1!

4COM

000 A (3)

1.0.V.tro ••••••cur...r.s

22

£26Z8LML 'ON HE ONIENNVW ES:EI a3M 66-80-03G

Ramp Differential Expansion Monitor Maintenance

12 Test OK Limits Cont.

6. Verify that the OK relay changes state (de-

energized). Note : all other channels in the

rack must be OK or bypassed in order for the

relay to change state.

7. Decrease the power supply voltage (less

negative) to -9 Vdc and verify that the OK LED

comes back on and the OK relay energizes (if

the Non-latching Not OK jumper is installed).

Press the RESET switch on the System

Monitor to reset latching Not OKs.

8. Gradually decrease the power supply voltage

(less negative) until the OK LED goes off

(lower limit). Verify that the lower OK limit is

within the lower OK voltage range (reference

Table 8 ).

9. Verify that the OK relay deenergizes.

10. When finished, disconnect the power supply

and multimeter and reconnect COM and IN

wiring to the channel A terminals on the Signal

Input Relay Module. Verify that the OK LED

comes on and the OK relay energizes (if the

Non-latching Not OK jumper is installed).

Press the RESET switch on the System

Monitor to reset latching Not OKs.

11. Repeat steps 1 through 10 for channel B.

1.11.111\

TABLE 8. OK Voltage Limits

,wwwwim. 84414-01

11•11:1

'lilt), 46

011-FE:ENT IAt_

ExpANSIC'; MONITOR

Transducer Type Lower OK Voltage Limits Upper OK Voltage Limits

11 mm

14 mm

25 35, d 50 mm

-3.25 Vdc to -3.35 Vdc

-1.65 Vdc to -1.75 Vdc

-1.30 Vdc to -1.40 Vdc

-19.68 Vdc to -19.88 Vdc

-18.20 Vdc to -18.40 Vdc

-12.40 Vdc to -12.60 Vdc

3Srnm?�c�es

23

41111.11mor

'd EiHnLZOL 'ON MA DNLONVW Pq:Ei om 66-80-2a

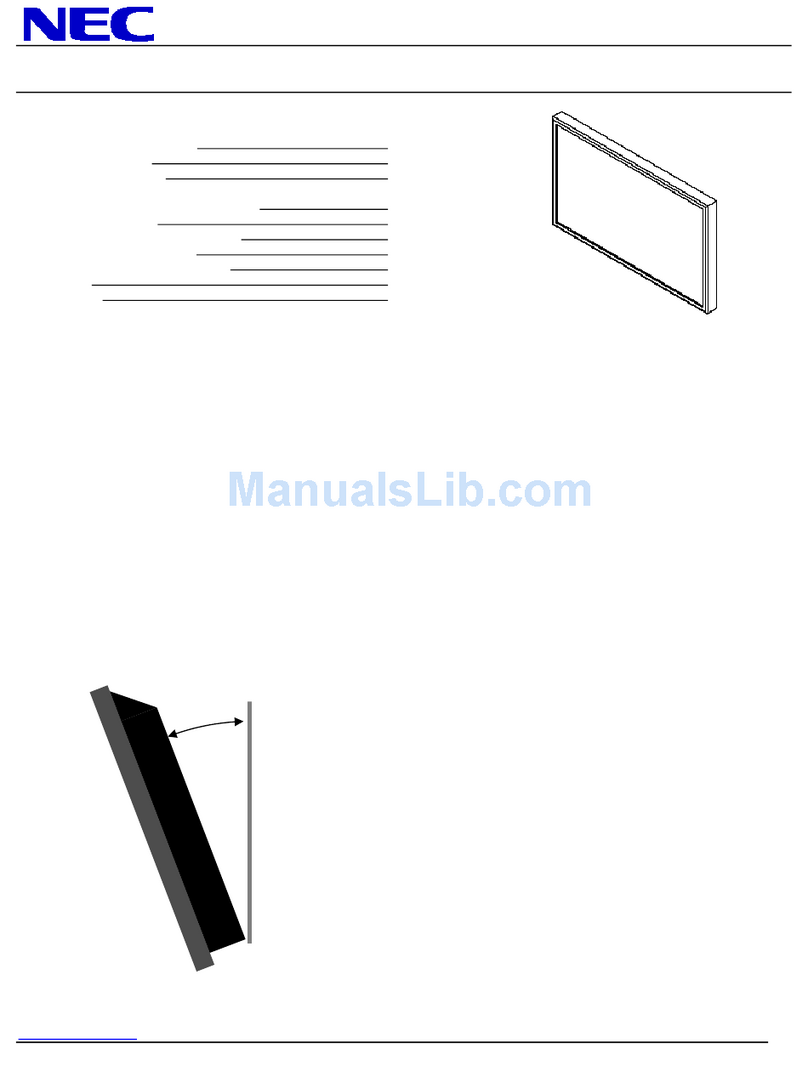

Ramp Differential Expansion Monitor Maintenance

LI id Calibrate Channels

Figure 1

1--'421*

°NAL

NeVZ.ZEi

Calibration Terminology:

[0.q1113,

CAG LOT

L— 1;rtt"

LEic...101

KI

CINIGUM I 101

61,4 V11.4.11CIR

WILMA

uVA, ,Pdi• PRIV •,

U2•11111/011:14

tways, Jr

3

84414-01

CAUTION

Monitoring will be bypassed

automatically during calibration.

Machine Protection will be lost

during calibration. See Danger

Bypass section 10.

4\WARNING

High voltage present could

cause shock, burns or death.

Do not touch exposed wires or

terminals.

TSF is defined as Transducer Scale Factor. 11 mm and 14mm = 100 mV/mil (3.937 V/mm), 25mm

and 35mm = 20 mV/mil (0.7874 V/mm), 50mm = 10 mV/mil (0.3937 V/mm).

MR is the range from the bottom of the meter to the top of the meter (in inches).

FUSV is the full upscale voltage.

ZPV is the zero position voltage.

is the ramp angle (see figure below and section 6 for ramp angle options).

CHANNEL A , CHANNEL

PROBE ) PROBE

"7:11r4

TABLE 9. Zero Position Voltage

Transducer Type Zero Position Voltage (WV)

01 (11mm)

02 (14mm)

03 (25mm)

04 (35mm)

05 (50mm)

-11.6 ± 0.65 Vdc

-10.0 ± 0_65 Vdc

- 6.5 ± 0.30 Vdc

24

170 'd C26N220/ 'ON Xdd ONIIDOW t 9:Ei UM 66-80-0K

•

•

•

Ramp Differential Expansion Monitor Maintenance 84414-01

Calibrate Channels FCont.

1. Disconnect COM and IN wiring from the

Channel A terminals on the Signal Input Relay

Module.

2. Connect a power supply and a multimeter to

COM and IN with polarity as shown in Figure

1on page 24.

3. Open front panel.

4. Short calibration terminals (CA) using a clip

lead (a jumper may be used if the monitor is

on an extender card). A test pattern will

appear on the display when the calibration

terminals are shorted and no calibration dip

switches are set. Both BYPASS LEDs will

come on.

5. Activate the Channel A zero adjust dipswitch (ZA)

by moving it to the left. Measure the voltage at

Test Point Channel A (TA) using the multimeter.

Adjust the power supply to ZPV (reference Table

9). Press the GAP switch and use the (t) and ( )

switches on the System Monitor to adjust the

voltage at TA to get +2.5 ± 0.03Vdc.

6. Deactivate the Channel A zero adjust dipswitch

(ZA) by moving it to the right. If the short is removed from the calibration

dipswitch is deactivated, the adjustment will not be stored.

7. Repeat steps 1-6 for Channel B substituting ZB and TB.

terminals before the

25

SO 'd EtHaiLML 'ON HE ONIENEN 99:EIQOM 66-80-03C

•

•

•

Ramp Differential Expansion Monitor Maintenance

113 I Calibrate Channels [Conti

8. Activate the Channel A gain adjust dip

switch (GA) by moving it to the left. The

Channel A bargraph will begin to flash.

Measure the voltage at Test point Channel A

(TA) using the multimeter. Adjust the power

supply to the Full Upscale Voltage (FUSV)

(reference Table 10).

9. Press the GAP switch and use the System

Monitor ('1') and (1) switches to adjust the

gain until the Test point Channel A (TA) is at

+5.0 ±0.05 Vdc and the BYPASS LED is on

steady (not flashing). The flashing BYPASS

LED indicates an overrange condition. If this

occurs, reduce the gain using the System

Monitor (1) switch.

10. Deactivate the Channel A gain adjust dip

switch (GA) by moving it to the right. If the

short is removed from the calibration

terminals (CA) before the dip switch is

deactivated, the adjustment will not be

stored.

11. Repeat steps 8 through 10 for Channel B

substituting GB and TB.

84414-01

26

90'd E2E6UOL 'ON XV.] ONIIENVW 99:EI 66-80-0a1

•

•

•

Ramp Differential Expansion Monitor Maintenance

113 I Calibrate Channels [Cont]

12. Activate the meter adjust dip switch (MA) by

moving it to the left. The differential

expansion signal will begin to flash on the left

LCD display.

13. Measure the voltage at test point Channel A

(TA) using the multimeter. Adjust both power

supplies to ZPV (reference Table 9). Press

the GAP switch and use the System Monitor

(T) and (1) switches to adjust the voltage at

TA to +2.5 ± 0.03Vdc.

14. Deactivate the meter adjust dip switch (MA)

by moving it to the right. If the short is

removed from the calibration terminals (CA)

before the dip switch is deactivated, the

adjustment will not be stored.

15. Remove the clip lead (jumper) from the

calibration terminals (CA).

TABLE 10. Formulas for Full Upscale Volts

84414-01

Full Upscale Volts (FUSV) Vdc

Single Ramp Option Probe A

Direction Dual Ramp Option Probe A or B

Probe B

Upscale Toward

Probe A

Upscale Away

From Probe A

ZPV +(0.5 sin 8 )(TSF)(MR) ZPV + (0.5 tan 8)(TSF)(MR)

ZPV -(0.5 sin 8)(TSF)(MR) ZPV - (0.5 tan 8)(TSF)(MR)

Example: A user has a 25mm probe and a 0.25-0-0.25 inch full scale range. The monitor is configured

for upscale toward probe A with dual ramp angles of 14 degrees.

(1 inch = 1000 mils, 1 V = 1000mV)

TSF = 20mV/mil

MR = 0.5 inches

FUSV = -6.5Vdc + (0.5 sin 14)(20mV/mil)(1V/1000mV)(1000mils/inch)(0.5inches) -5.29 Vdc

27

LO 'd £203/20L 'ON XV.4 ONIENNW 99:E1 aim 66-80-011

a

•

•

Ramp Differential Expansion Monitor Operation

FORWARD

84413-01

This document is for personnel who operate the 3300 Monitoring System. The procedures are

presented in step-by-step graphic format.

RELATED DOCUMENTS

3300 System Overview, 80177

3300 System Installation Instructions, 80172

3300 System Troubleshooting, 80173

3300/10 Power Supply, 80174

3300/01 System Monitor, 80175

3300/46 Ramp Differential Expansion Maintenance, 84414-01

Keyphasor® is a registered trademark of Bently Nevada Corporation

Proximitor is a registered trademark of Bently Nevada Corporation

Document No. 84413 . First Printing: May 1989 . Revision NC: May 1989

Copyright() 1989 Bently Nevada Corporation

All Rights reserved

No Part of this publication may be reproduced, transmitted, stored in a retrieval system nor translated into any human or

computer language, in any form or by any means, electronic, mechanical, magnetic, optical, chemical, manual, or otherwise,

without the prior written permission of the copyright miner,

Bently Nevada Corporation

P. O . Box 157

Minden, Nevada 89423 USA

Tele phon e 800-227-5514 702-782-3611

Tele mail /Tele x 7400983 BNC UC

Fax 702-782-9253

Copyright infringement is a serious matter under

United States of America and Foreign Copyright Laws

iii

Ramp Differential Expansion Monitor Operation 84413-01

Blank Page

iv

•

•Ramp Differential Expansion Monitor Operation

CONTENTS

84413-01

TITLE PAGE

Differential Expansion Monitor System 1

Monitor Options 2

3. Programmable Options 3

4. Monitor Functions 4,5

5. OK 6

6. Bypass 7

7. Alert 8

8. Danger 9

9. Read Channel Differential Expansion 10

•10. Read Gap Voltage 11

11. Read Setpoint Levels 12

12. Self Test 13-15

INDEX 16

•

SECTION

1.

2.

Ramp Differential Expansion Monitor Operation 84413-01

Blank Page

vi

•

•

•

•

•

•

Ramp Differential Expansion Monitor Operation 84413-01

1DIFFERENTIAL EXPANSION MONITOR SYSTEM

3300/48

DIFFERENTIAL

EXPANSION MONITOR

3

2

E,

N

A0

0

0

s—

'21-1

OK

DANGER

ALERT

BYPASS

•

A

B

0

•

ALERT

B

BUFFERED TRANSDUCERS

r

•CHANNEL A

RECORDER

OUTPUT

ALERT

RELAY

CONTACTS

SIGNAL INPUT RELAY

MODULE LOCATION

3300 RACK

OO

<1:=1

OO

PROXIMITOR

OO

C=i

O

PROXIMITOR

SIGNAL INPUT

CHANNEL

RECORDER

OUTPUT

DANGER

RELAY

CONTACTS

NOTE: CHANNEL B RECORDER OUTPUT ONLY ACTIVE DURING CALIBRATION

(V

CHANNEL B

PROBE <431P.

SHAFT

CHANBEL B

PROBE

SHAFT

`4(674€L ^

DUAL RAMP OPTION

CHANNEL A

PROBE

SINGLE RAMP OPTION

1

Ramp Differential Expansion Monitor Operation

TRANSDUCER

FULL SCALE RANGE INPUT ALARM RELAY

AGENCY

APPROVAL

3300/46 AA BB CC DD

01 = 5-0-5mm 01 = 11mm, 00 = NONE 00 =NOT REQUIRED

02 =0 - 10mm 100 mV/mil 01 = EPDXY 01 = CSA

03 =0.25-0-0.25 INCHES 02 = 14mm, SEALED 02 =BASEEFA

04 =0 - 0.5 INCHES 100 mV/mil 02 = HERMETI- 03 = FM

05 =10-0-10mm 03 = 25mm, CALLY SEALED

06 =0 - 20mm 20 mV/mil 03 = EPDXY

07 =0.5-0-0.5 INCHES 04 = 35mm, SEALED QUAD

08 =0 - 1.0 INCHES 20 mV/mil

09 =1.0-0-1.0 INCHES 05 = 50mm,

10 =0 - 2.0 INCHES 10 mV/mil

11 =25-0-25mm

12 =0 - 50mm

84413-01

2MONITOR OPTIONS

RAMP DIFFERENTIAL EXPANSION

MONITOR PART NUMBER

2

•

FIRST OUT ENABLED *

DISABLED

DANGER MODE LATCHING *

NONLATCHING

ALARM DELAYS 0.1 SECOND

1SECOND

3SECOND *

6SECOND

RECORDER OUTPUTS +4 TO +20 mA *

+1 TO +5 Vdc

0 TO -10 Vdc

NOT OK MODE NONLATCHING *

LATCHING

RAMP OPTION DUAL *

SINGLE

ALERT MODE LATCHING *

NONLATCHING

UPSCALE DIRECTION TOWARD PROBE A *

AWAY FROM PROBE A

METER RESPONSE TIME FAST *

SLOW

DANGER BYPASS SWITCH ENABLED

DISABLED *

RAMP ANGLE 4TO 45 DEGREES

(1 DEGREE

INCREMENTS) **

NOT OK MONITOR DEFEAT ENABLED

DISABLED *#

•

Ramp Differential Expansion Monitor Operation

I3 I PROGRAMMABLE OPTIONS

MONITOR FEATURE OPTION MONITOR FEATURE OPTION

84413-01

I

* AS SHIPPED FROM FACTORY

#REQUIRES NONLATCHING OK OPTION

** AS SHIPPED FROM FACTORY: 11/14mm = 7 deg, 25/35/50mm = 12 deg

•

3

Ramp Differential Expansion Monitor Operation 84413-01

4MONITOR FUNCTIONS

RAMP DIFFERENTIAL EXPANSION - The Ramp Differential Expansion Monitor provides continuous

monitoring of shaft growth relative to the machine case. Normal expansion direction can be toward

or away from the probe A.

PROBE GAP VOLTAGE - Probe gap is measured as a negative dc voltage that is directly proportional

to the gap distance between the face of a proximity probe and the surface being monitored. Probe

gap voltage for each channel is displayed on the front panel meter by pressing the GAP switch.

OK - When the Proximitor output voltage is within its upper/lower limits, the transducer is defined as

OK. The OK detection circuit controls the channel OK LED and the monitor relay drive to the system

OK relay. If the monitor has the latching Not OK option, a System Reset is required to reset the OK

function.

OK RELAY - The OK relay is located on the Power Input Module. Every channel in the rack must

be OK or bypassed to energize the OK relay.

ALARM - Pressing the ALERT and DANGER switches on the front panel of the monitor causes the

Alert (first-level alarm) or Danger (second-level alarm) setpoints to be displayed on the front

panel meter. ALERT and DANGER LEDs come on when the differential expansion signal level exceeds

preset levels for the selected time delay, and appropriate Alert and Danger alarm relay contacts are

activated.

FIRST OUT - Separate First Out circuits exist for Alert and Danger alarms. A monitor with First Out

option selected flashes the LONG or SHORT alarm LED if that particular alarm was the first alarm

since the last reset. Pressing the RESET switch acknowledges the First Out.

ALARM RELAYS - Monitor alarms can be programmed for either the latching or nonlatching mode.

In the nonlatching mode, the alarm resets automatically when the alarm no longer exists. In the

latching mode, the alarm condition must be reset manually by pressing the RESET switch on the front

panel of the System Monitor (or by closing external Reset contacts). The alarm will not reset if the

alarm condition still exists.

DANGER BYPASS - For maintenance functions, a Danger Bypass switch on the monitor circuit board

behind the front panel can be set to inhibit the Danger relay drive. This function causes the BYPASS

LEDs to be turned on. Other front panel functions are not affected. This function can be enabled by

installing a jumper on the monitor.

BUFFERED OUTPUT - The Channels A and B coaxial cable connectors on the front panel of the

monitor and terminals on the Signal Input Relay Module provide buffered signals from respective

channel transducers. These connectors can be used for connection of external equipment.

4

•

•

•

Ramp Differential Expansion Monitor Operation 84413-01

4MONITOR FUNCTIONS

RECORDER OUTPUT - Depending on the option selected, the recorder output levels proportional to

the measured differential expansion signal are 0 to -10Vdc, +1 to +5Vdc, or +4 to +20mA.

SELF TEST - The monitor has three categories of self test: Power-up, Cyclic, and User-invoked.

Power-up self test is performed automatically each time the monitor power is turned on. A series

of basic tests and transducer OK tests are performed.

Cyclic self test is performed automatically during monitor operation. Errors encountered during

cyclic tests disable the monitor, and flash error code on the LCD bargraph. If the error is

intermittent, the monitor will return to operation, but the error codes are stored for retrieval during

User-invoked self tests. Stored error codes are indicated by OK LEDs flashing at 5 Hz provided

that the channel is OK.

User-invoked test performs Power-up self test and allows error codes stored during cyclic tests

to be read and cleared. Stored errors are annunciated by flashing the OK LEDs at 5 Hz and

displaying the error codes on the front panel LCD bargraph.

Not OK Monitor Defeat - The Not OK Monitor Defeat function prevents faulty transducer wiring from

causing false alarms. If a transducer is determined to be Not OK, the channel OK LED goes off, the

Channel BYPASS LED comes on, the differential expansion signal is clamped to zero position,

alarming is disabled, and the OK relay deenergizes. If a channel's input signal returns to an OK

condition, the channel's OK LED will start flashing at 1Hz to indicate that the OK state is restored.

After ten seconds, the BYPASS LED will go off, and alarming is enabled. The RESET switch on the

System Monitor front panel must be pressed to stop the OK LED from flashing.

5

Ramp Differential Expansion Monitor Operation

LED DISPLAY

AB

CONDITION

OK

RELAY DRIVE *

•OK •CHANNEL A AND B IN OPERATING RANGE ON

•

0

OK

OK

0

•

RESPECTIVE CHANNEL A OR B TRANSDUCER

IN NOT OK CONDITION. * OFF *

0OK 0

MONITOR IN SELF TEST, OR BOTH

TRANSDUCERS IN NOT OK CONDITION OR

BYPASSED. *

OFF *

*

OK 0

FLASHING AT 5 Hz = ERROR ENCOUNTERED

DURING CYCLIC TEST. READ ERROR MESSAGE

SEE SECTION 12.

ON

•

OK

FLASHING AT 1 Hz = TRANSDUCER

HAS BEEN NOT OK SINCE LAST

RESET.

ON

•

84413-01

5OK

NOTE: EACH CHANNEL IN THE SYSTEM CONTROLS THE OK RELAY. THEREFORE, EITHER CHANNEL CAN CAUSE A

NOT OK RELAY CONDITION (DEENERGIZED RELAY)

*MONITOR CAN BE BYPASSED TO RESTORE RELAY OK CONDITIONS TO THE REST OF THE RACK

•

•

•

6

•

LED DISPLAY

LONG SHORT

CONDITION

•BYPASS •

MONITOR IN DANGER BYPASS MODE

SYSTEM IN POWER-UP MODE

USER-INVOKED SELF TEST IN PROGRESS

MONITOR BYPASSED

CALIBRATION MODE

*

BYPASS

*

MONITOR OVERRANGE DURING CALIBRATION

•

•

Ramp Differential Expansion Monitor Operation 84413-01

6BYPASS

7

This manual suits for next models

1

Table of contents

Other Bently Nevada Monitor manuals