Bently Nevada 19045 User manual

Part Number TW8029303

Rev. D (08/07)

Bently Nevada™ Asset Condition Monitoring

Installation Manual

DC-LVDT/Housing Assembly

Model 19045, 19046, 19047

DC-LVDT/Housing Assembly Model 19045, 19046, 19047 Installation Manual

ii

Copyright 1978. Bently Nevada LLC.

All rights reserved.

The information contained in this document is subject to change without notice.

Contact Information

The following ways of contacting Bently Nevada are provided for those times when you

cannot contact your local representative:

Mailing Address 1631 Bently Parkway South

Minden, Nevada USA 89423

USA

Telephone 1.775.782.3611

1.800.227.5514

Fax 1.775.215.2873

Internet www.ge-energy.com/bently

iii

Additional Information

Product Disposal Statement

Customers and third parties, who are not member states of the European Union, who are

in control of the product at the end of its life or at the end of its use, are solely

responsible for the proper disposal of the product. No person, firm, corporation,

association or agency that is in control of product shall dispose of it in a manner that is

in violation of any applicable federal, state, local or international law. Bently Nevada LLC

is not responsible for the disposal of the product at the end of its life or at the end of its

use.

DC-LVDT/Housing Assembly Model 19045, 19046, 19047 Installation Manual

iv

Contents

1. DESCRIPTION ...................................................................................................1

2. INSTALLATION .................................................................................................5

3. MAINTENANCE ..............................................................................................11

4. RECOMMENDED SPARE PARTS ...................................................................12

5. APPENDIX - SPECIFICATIONS ......................................................................13

Section 1 - DESCRIPTION

1

1. DESCRIPTION

GENERAL

The DC-LVDT (LVDT) transducer used with Bently Nevada Corporation (BNC)

instruments provides a linear dc output voltage over a specific range of core

movement. This output, connected to the BNC Case Expansion Indicator, is used

to measure the expansion of a machine case as operating conditions vary. The

LVDT is connected mechanically between a reference point on the machine

foundation and a point on the machine that exhibits the measured expansion.

Input power to the LVDT is supplied from the BNC instrument to which it is

connected. Circuitry within the LVDT body converts the machine expansion

measurement (core position) to the required output signal. The BNC instrument

accepts the signal and produces a meter indication of expansion measurement.

DC-LVDT/Housing Assembly Model 19045, 19046, 19047 Installation Manual

2

LVDT HOUSING ASSEMBLY OPTIONS

Table 1-1. LVDT Housing Options

CATALOG NO ASSEMBLY

19045 - AXX

01 DC-LVDT Housing Assembly with Model 500

HR-DC LVDT

02 DC-LVDT Housing Assembly with Model

1000 HR-DC LVDT

19046 – AXX

01 DC-LVDT Housing Assembly with Model

2000 HR-DC LVDT

02 DC-LVDT Housing Assembly with Model

2000 HR-DC LVDT

19047 – AXX

01 DC-LVDT Housing Assembly with Model 2000 HR-DC

LVDT @ 9.25 in. span, max*

02 DC-LVDT Housing Assembly with Model 2000 HR-DC

LVDT @ 12.00 in. span, max*

*19047-01 option can span up to 9.25 inches maximum, the -02 option can span

up to 12.00 inches. Total travel (range), however, is determined by the position of

the riders on the slide bar. (See table in Figure A-4.)

Section 1 - DESCRIPTION

3

FUNCTIONAL DESCRIPTION

A functional block diagram of the LVDT internal circuitry is shown in Figure 1-1.

The 24 Vdc supply power is connected to LVDT lead wires. This voltage drives an

oscillator to produce an alternating current. The alternating current is applied to

the primary of the differential transformer. The transformer has two secondary

windings, 180° out of phase, that are coupled to the primary by the movable core.

Core position determines the output voltage amplitude of each secondary. The

secondary outputs are applied to a demodulator which produces a dc voltage

signal. This signal varies in amplitude and polarity from negative, to zero (null), to

positive as the core moves through its operating range in a toward-LVDT

direction. Figure 1-2 is a graph of the output signal of the DC-LVDT models used

with BNC instruments. Output voltage is zero when the core and housing null

centers coincide.

Figure 1-1. DC-LVDT Functional Block Diagram

DC-LVDT/Housing Assembly Model 19045, 19046, 19047 Installation Manual

4

Figure 1-2. DC-LVDT Output versus Core Position

Section 2 - INSTALLATION

5

2. INSTALLATION

RECEIVING INSPECTION

Visually inspect exterior and interior to determine if any shipping damage has

occurred. (Figures A-2, A-3, and A-4 illustrate the fasteners that retain the housing

cover.)

If shipping damage is apparent, file a claim with the carrier and submit a copy to

BNC. The transducer housing assembly model number and appropriate option

numbers listed in Table 1-1 should be included with all correspondence. The user

will be advised concerning repair or replacement in accordance with the

guarantee.

OPERATING DIRECTION

Correct function of the LVDT instrument system requires that the transducer be

properly oriented to the measured machine movement according to the direction

option of the instrument; Toward-LVDT or Away-From-LVDT.

The direction option specifies the direction of LVDT core motion that produces

upscale meter movement at the instrument. Refer to the Option Table of the

instrument manual for the direction option. Figure 1-2 defines the toward-LVDT

direction; away-from-LVDT is opposite. Regardless of the instrument direction

option, core motion toward the LVDT produces a positive-going transducer

output signal.

DC-LVDT/Housing Assembly Model 19045, 19046, 19047 Installation Manual

6

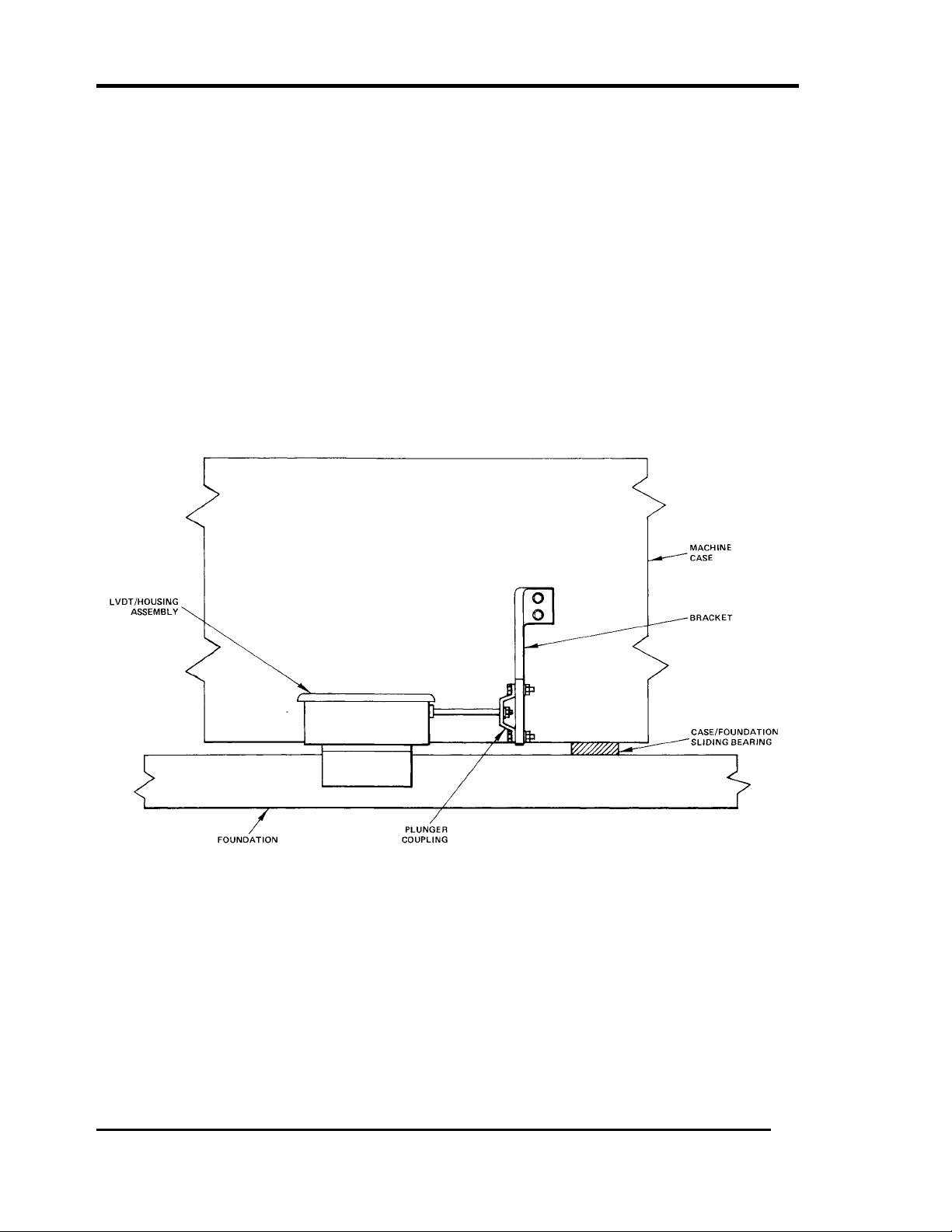

MECHANICAL LINKAGE

The maehine-LVDT linkage design is determined by the user. A typical case

expansion measurement linkage is illustrated in Figure 2-1. In general, linkage

design should conform to the following guidelines.

1. Linkage must not bind throughout the travel range.

2. Linkage weight must not be borne by the LVDT.

3. Adjustment provision is required to calibrate the LVDT output.

4. The LVDT plunger must be nonmagnetic material. (Series 300 nonmagnetic

stainless steel is used in the supplied plunger.) Magnetic material will

distort the LVDT output.

Figure 2-1. Typical CE Linkage

Section 2 - INSTALLATION

7

LVDT MOUNTING

Generally, configurations for the LVDT installations will vary; however, for all

installations, brackets or other structural members used to mount the LVDT

assembly must be rigid. If the bracket is flexible, undesireable relative motion

between the LVDT and observed machine part may result. Brackets must support

the LVDT so that the core axis aligns with the movement of connecting linkage.

Assembly installation is as follows.

a. Mount the LVDT housing to the designated mounting location. (Refer to

Figures A-2, A-3, and A-4, outline of LVDT housing assemblies, for

dimensions and component locations.) Housing mounting holes are

determined by the user.

b. Attach the connecting linkage between the machine and LVDT plunger.

Assure that linkage supports are properly aligned, linkage is free from

binding, and travel is unobstructed throughout the measurement range.

c. Check that the LVDT/housing assembly components are secure and housing

is free of foreign material. Final adjustment is performed after completing

electrical installation.

CAUTION

TO PREVENT LOSS OF MACHINE

PROTECTION, SECURE THE PUSH ROD

AND THE CORE PIN USING GLUE.

RECOMMENDED, LOCTITE

THREADLOCKER 242 (BNC PART NO,

04576130).

DC-LVDT/Housing Assembly Model 19045, 19046, 19047 Installation Manual

8

POWER AND SIGNAL CONNECTIONS

Connections between the LVDT and the instrument signal module are shown on

the interconnect diagram contained in the instrument manual. Cabling is

generally fabricated at the userTs facility, unless a specific request is made to

have BNC supply it. It is recommended that three-wire shielded cable be used for

these connections to avoid erroneous indications due to noise interference.

CAUTION

Be certain the transducer output and drive

voltage conductors do not become cross-

wired. An OK indication may be obtained, but

the equipment will not be operational.

Prolonged cross-wired connection can

change the output stage characteristics,

resulting in uncalibrated performance.

The COM connector at the transducer should not be used as the shield ground.

Ground the shield at the SHLD terminal of the signal module located in the

instrument rack. Grounding the shield at both ends is not recommended.

Precautions should be taken to keep electromagnetic interference away from the

cable by observing the following instructions.

1. Do not route transducer cables with power cables and other noise

sources.

2. Use steel conduit between the transducer and instrument rack assembly.

Section 2 - INSTALLATION

9

ADJUSTMENT

Adjustment requires measuring the LVDT output with the linkage set at the zero-

expansion point. Perform all adjustments as accurately as possible. The user may

construct a gaging tool, if desired, to aid in accurately adjusting the LVDT core

position during calibration. Table 2-1 lists recommended equipment for

adjustment. If LVDT power (-24 Vdc) is available from the instrument, the DC

Power Supply is not necessary.

LVDT linkage adjustment is performed in the following manner.

a. Disconnect the linkage at the machine case attaching point.

b. Supply the specified transducer power to the LVDT from the BNC instrument

or, if necessary, from the DC Power Supply. Check the voltage at the + and -

PWR terminals at the terminal block.

c. Connect the DMM to SIG and COM at the terminal block.

d. Manually adjust core position until the DMM displays 0.00 Vdc.

e. Move the LVDT core as follows:

If full scale expansion is toward-LVDT, move core away from the LVDT

exactly half the meter range of the indicator.

If full scale is away-from-LVDT, move core toward the LVDT exactly half the

meter range of the indicator.

The core is positioned for correct output signal at zero expansion of the

machine case. Mark or secure the core at this position.

f. Adjust the linkage carefully (with LVDT core at the zero-expansion position

set in step e) until the machine end of linkage is located at the zero-

expansion position of the attaching point on the machine case. Secure the

linkage adjustments.

g. Check the meter at the instrument to assure that linkage movement

produces the proper upscale/downscale meter response.

h. Connect the linkage to the machine case.

DC-LVDT/Housing Assembly Model 19045, 19046, 19047 Installation Manual

10

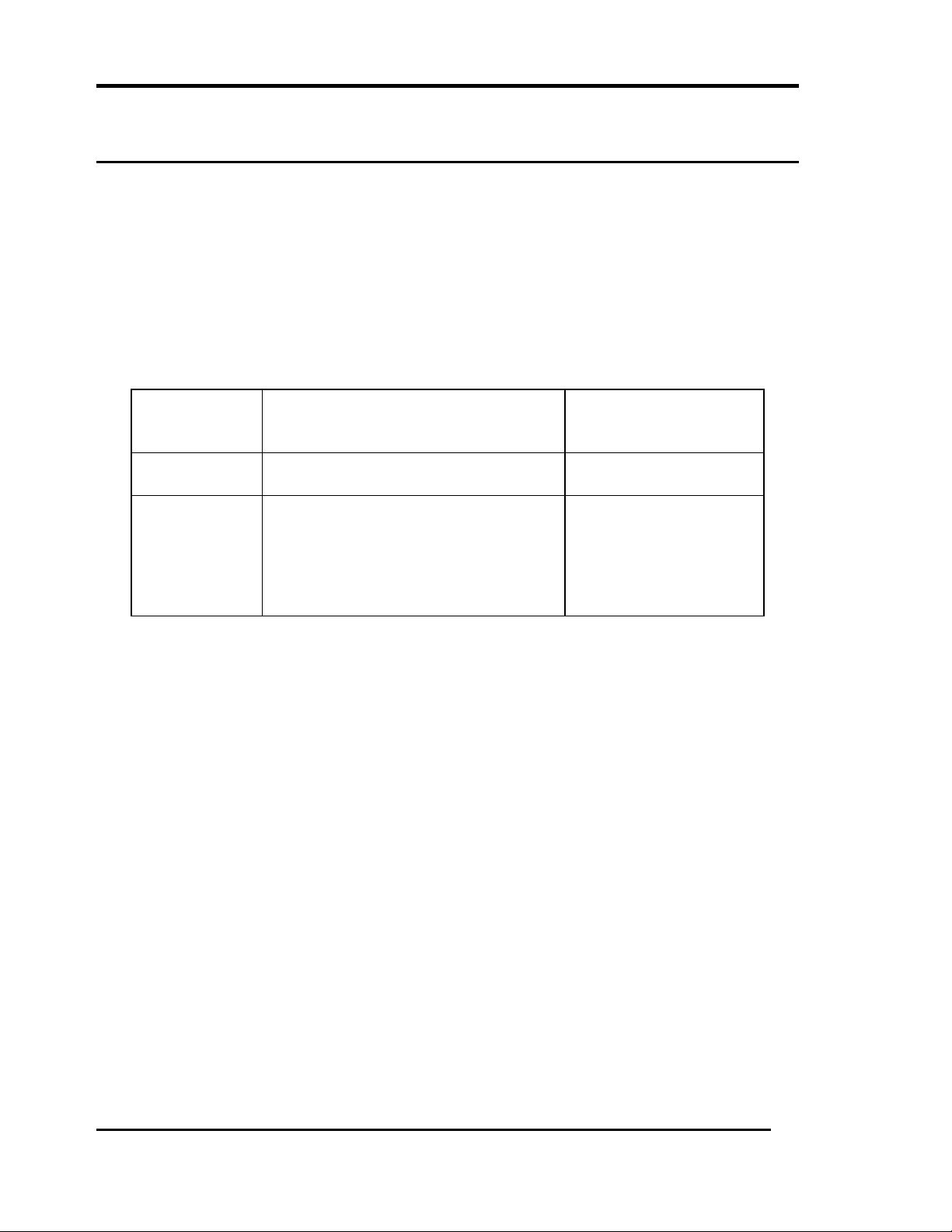

Table 2-1. Recommended Installation Equipment

RECOMMENDED EQUIPMENT EQUIPMENT SPECIFICATIONS

Hewlett-Packard HP970A 3-1/2 digit display with:

Digital Multimeter (DMM) 0 to ±1000 Vdc

0 to 1000 Vac

0 to 1000 mA dc

0 to 1000 mA ac

0 to 10 megohms

DC Power Supply 24 Vdc with less than

0.1% ripple and less than

3% regulation.

Section 3 - MAINTENANCE

11

3. MAINTENANCE

GENERAL

It is recommended that the user schedule inspections according to the

environment in which the transducer operates and the likelihood of wear or

damage.

TROUBLESHOOTING

The following troubleshooting procedure verifies proper LVDT performance. This

procedure should be followed in the order given.

a. Using the DMM, measure the voltage between the LVDT PWR ( + and - )

supply terminals at the housing terminal block. The DMM should

indicate between 22 and 26 volts. If the indication is not within this

range, the power supply from the instrument or associated wiring is

faulty. Restore power to the LVDT. If a proper voltage indication is

obtained, proceed to step b.

b. Disconnect the LVDT plunger from the linkage and manually position

the core to the null position. Refer to the Specifications and related

drawings for necessary dimensions.

c. Connect the DMM to the LVDT SIG and COM terminals. The voltage

shouldmeasure0Vdc±0.5 volt.

d. Measure the LVDT outputs with the core positioned at each extreme of

the measurement range that is specific to the LVDT model installed.

Move the core half the total range in each direction from the zero-

voltage core position. The voltages must correspond (within 5%) to the

scale factor listed for the specific LVDT in the manufacturers test data.

e. If the LVDT checks are satisfactory, check field wiring and, if necessary,

instrument performance.

PERIODIC INSPECTION

Linkage Integrity

Examine the linkage for looseness, misalignment, interference, corrosion, or other

detrimental conditions. Repair as necessary.

Mechanical Zero-Expansion Calibration

Check that placing the machine-to-LVDT linkage at the zero-expansion position

places the LVDT core at the correct point of travel. Refer to the Adjustment

paragraph in Section 2 for determining core position.

DC-LVDT/Housing Assembly Model 19045, 19046, 19047 Installation Manual

12

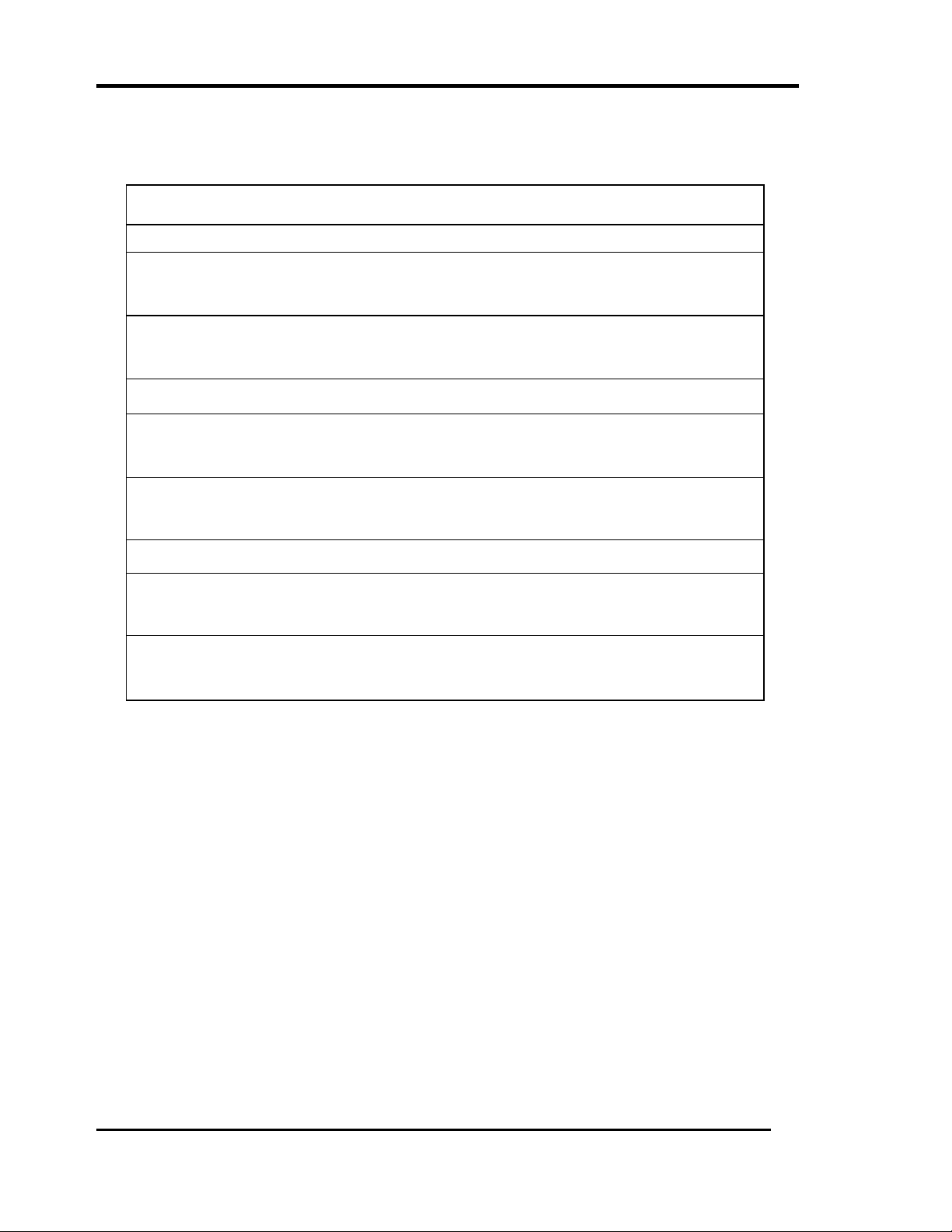

4. RECOMMENDED SPARE PARTS

Bently Nevada Corporation recommends that at least one of each type LVDT

transducer used in the instrument system be kept on hand as a spare. The

recommended spare parts for field maintenance are listed below. If the

instrument system is located in a remote area or is used on an extremely critical

application, several spares may be desired.

To order replacement units, specify the complete part number according to the

following table.

QTY*

PER LVDT

DESCRIPTION PART NUMBER

1DC-LVDT Housing Assembly See Table 1-1

1Model 500 HR-DC LVDT

Model 1000 HR-DC LVDT

Model 2000 HR-DC LVDT

00218500

00218501

00218502

*User option to stock either the Assembly or the LVDT only.

Section 5 - APPENDIX - SPECIFICATIONS

13

5. APPENDIX - SPECIFICATIONS

DC-LVDT TRANSDUCER

Input Power (nominal) -24 Vdc, 25 mA

Environmental Limits

Operation -18°C to +71°C

Storage -54°C to +93°C

Shock 250 g for 11 ms

Vibration 10 g @ 0 to 2 kHz

Construction

Body Series 400 magnetic stainless steel

Coil Laminated glass-epoxy

Lead Wire 24-gage stranded copper, Teflon insulated,

12 inches (31 mm)

Output

Ripple Less than 1% full scale

Linearity ±0.5% full range

Stability 0.125% full scale

Scale Factor

Temp. Coefficient 0.07%/°C

DC-LVDT/Housing Assembly Model 19045, 19046, 19047 Installation Manual

14

MODEL

500 HR-DC 1000 HR-DC 2000 HR-DC

Output

Scale Factor (nominal)

V/in (V/mm) 8.8 (0.35) 10.2 (0.40) 3.6 (0.14)

Linear Range ± 0.5 ± 1.0 ± 2.0

inches (mm) (±12.5) (±25.4) (±51)

-3 dB Frequency

(core movement) 20 Hz 15 Hz 10 Hz

Output Impedance

(nominal) 7 k ohm 7 k ohm 7 k ohm

Min Load Resistance 50 k ohm 100 k ohm 200 k ohm

Physical (See Figure A-l)

Body Length (A) 6.75 (171) 8.1 (206) 11.5 (292)

Body Diameter (B) 0.812 (20.6)

Body End to

NuU Center (C) 2.73 (69.3) 3.41 (86.6) 4.99 (126.7)

Core Length (D) 3.15 (80) 4.25 (108) 5.30 (135)

Core Diameter (E) 0.25 (6.4)

Plunger Length As required for application

Diameter 0.25 (6.4)

Thread 6-40 NF core end; 6-32 linkage end.

Material 300 Series nonmagnetic stainless steel.

HOUSING (19045, 19046, 19047) ASSEMBLIES

Dimensions/Construction See Figures A-2, A-3, and A-4.

Design Specification NEMA 3

Mounting Fastener Locations Optional per customer requirements.

Section 5 - APPENDIX - SPECIFICATIONS

15

Figure A-l. DC-LVDT Dimension Identification

DC-LVDT/Housing Assembly Model 19045, 19046, 19047 Installation Manual

16

This manual suits for next models

3

Table of contents

Other Bently Nevada Recording Equipment manuals