Benton Harbor 3147396 User manual

IMPORTANT:

Read and save

these instructions.

IMPORTANT:

Installer: Leave Installation Instructions

with the homeowner.

Homeowner: Keep Installation Instructions

for future reference.

Save Installation Instructions for local

electrical inspector’s use.

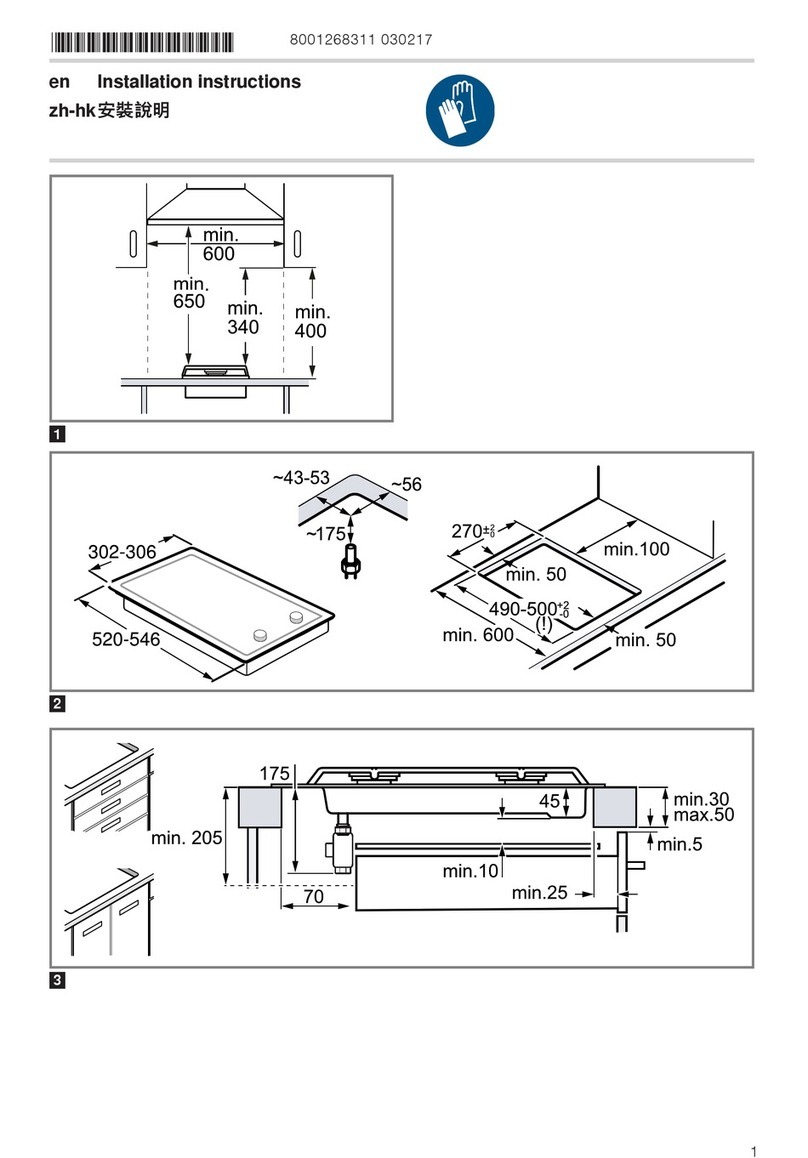

30” Set-In

Electric Range

Grounded electrical outlet is required.

See Electrical requirements.

Cabinet opening dimensions that are

shown must be used. Given dimensions

are minimum clearances and provide

required 0” clearance.

Important: Observe all governing codes

and ordinances.

Before you start...

Countertop preparation:

Front edges: You may need to shave or

cut the trim of formed or metal front-

edged countertops to clear the 30”

width of cooktoc>.

Read Electrical aid Carpentry instructions.

Proper installation isyour responsibility. A

qualified technician should install this

range. Make sure you have everything

necessary for correct installation. It isthe

customer’s responsibility to make sure that

the countertop has been properly

prepared, and to contact a qualified

electrical installer to assure that electrical

installation iscorrect.

ir countertop

extends more

than l-1/8”

beyond cabinet

iront, additional

notching ol

edge is required

to clear step of

end cap.

Electrical Shock Hazard

lt is the customer’s responsibility:

l

To contact a qualified electrical

installer.

l

To assure that the electrical

installation is adequate and in

conformance with National Electrical

Code, ANSVNFPA 70 - latest edition’

and all local codes and ordinances.

Failure to do so could result in electrica

shock or other personal injury.

Personal Injury Hazard

To eliminate the risk of burns or fire,

avoid installing cabinet storage above

the cooking surface. If cabinets are

already installed, reduce the hazard of

reaching over a heated cooking

surface by installing a range hood.

The range hood should extend a

minimum of 5 inches out from the

bottom front of the cabinets.

Reaching over a heated cooking

surface could result in a serious bum.

width - 30”

I L

T

3

Overall

height -

31-7/8~~

Recessed

heiB

ht -

Jl- 12” “F’or minimum

clearances to the

top of cooktop

see Note.

waiil

1

.

I I

k-

19-5/a”+ k

1-i/an

max.

25’ countertop

Cabinet

tront

---------

Side view of

cabinet cutout

Depth - 22:3/4”\

nust be level

------ front and I

28-w

min.

ronr IO back.1 ~~a~~~go~~~g ~

between 29-112”

dim. and opening

width equally

e spaced both sides.

\ II

is recomtiend&J, -

I if available. -

I

I 1

1

I T t

**Note: 30” min. clearance between the

top d cooktop and the bottom ol an

unprotected wood or metal cabinet.

24” min. clearance if protected by not

less than l/4” flame retardant millboard

covered with not less than No. 28MSG

sheet steel. .015” stainless steel, or .024”

aluminum or .020” copper.

I

718”

min.

required

between

cutout and e.

I

36”

countertop

height

I required on both

rear corners of

countertop cutout.

Front view of Top view of

cabinet cutout cabinet cutout

(see Step 7) during transit. Any method of

securing the range isadequate as long

as it conforms to the standards listed

above.

Four-wire power supply cord must be

used in a mobile home installation. The

appliance wiring will need to be revised.

See Electrical requirements, Figure 3,

Panel B.

Copies of the standards listed may be

obtained from:

l

National Fire Protection Assocition

Batterymarch Park

Quincy, Massachusetts 02269

locate eiectriciai

supply junction

box on cutout

Tools needed for

installation:

Electrical

Electrical Shock Hazard

l

Electrical ground is required on this

appliance.

l

Do Not ground to a gas pipe.

l

Do Not have a fuse in the neutral or

grounding circuit. A fuse in the

neutral or grounding circuit could

result in an electrical shock.

l

Check with a qualified electrician if

you are in doubt as to whether the

appliance is properly grounded.

Failure to follow these instructions

could result in serious injury or death.

If codes permit and a separate grounding

wire is used, it is recommended that a

qualified electrician determine that the

grounding path is adequate.

A

n

A threewire or four-wire, single

phase, 120/240+0lt, 60 Hz,AC only

electrical supply (or three-wire or four-wire

120/208-volt if specified on the serial/rating

Dlate) isreauired on a seoarate circuit.

fused’on b&h sides of the line. A time-

delay fuse or circuit breaker is

recommended. The fuse size must not

exceed the circuit rating of the appliance

as specified on the serial/rating plate. The

serial/rating plate islocated on the frame

behind the oven door.

B

n

THERANGE MUSTBECONNECTED

WITHCOPPERWIREONLY.

L The flexible armored cable

extending from the appliance should be

connected directly to the junction box.

Locate the junction box to allow two to

three feet of slack in the cable between

the junction box and the appliance so

that the range can be moved if servicing

isever necessary. Do Not cut the

conduit.

requirements

F

n

A U.L.-listed conduit connector must

be provided at each end of the power

supply cable (at the appliance and at

the junction box).

H A wiring diagram is located on

the right hand side of non-self-cleaning

ranges. A Tech Sheet islocated behind

the lower air grille on self-cleaning

ranges.

C

n

Wire shes and connections must

conform to the requirements of the National

Electrical Code, ANSVNFPA 70 - latest

edition’ and all local codes and ordinances

for the kilowatt rating of the range.

D

w The aooliance should be connected

directly to the’fused disconnect or circuit

breaker box through flexible, armored or

non-metallic sheathed cable with copper

grounding wire.

Panel A

Electrical

connection

Electrical Shock Hazard

l

Electrical ground is required on this

appliance.

l

Do Not connect to the electrical

supply until appliance is

pemwnently grounded.

l

Disconnect power to the junction

box before making the electrical

connection.

l

This appliance must be connected

to a grounded, metallic, permanent

wiring system, or a grounding

connector should be connected to

the grounding terminal or wire lead

on the appliance.

Failure to do so could result in a fire,

personal injury or electrical shock.

This appliance is manufactured with

white (neutral) power supply wire and a

cabinet-connected green grounding

wire twisted together.

Connect the appliance cable to the

junction box through the U.L.-listed

conduit connector. Complete electrical

connection according to local codes

and ordinances.

A. Where local codes permit...

connecting the cabinet-grounding

conductor to the neutral (white) junction

box wire:

Cable tram

Junction power wwiy

bOX

253

I

Red

wires, A

a

White

wires

Bare o?n

green wire conduit

Figure 1

Cable tram connec

range tor

Grounded Neutral

1.Disconnect the power supply.

2. Connect together 3 wires: green and

white appliance cable wires and the

neutral (white) wire in junction box.

3. Connect the two black wires together;

then the two red wires together. See

Figure 1.

B.Where local codes Do

Not permit...

connecting the cabinet-grounding

conductor to the neutral (white) junction

box wire:

Junction Cable from

_^...^. -..--I.

green

wires ‘\ iJ.L.4

Cable from conduit

range connector

Figure 2 Ungrounded Neutral

1,Disconnect the power supply.

2.Separate the green and white

appliance cable wires.

3.Connect the white appliance cable

wire to the neutral (white) wire in the

junction box.

4.Connect the two black wires; then the

two red wires. See Figure 2.

5.Connect the green grounding wire to a

grounded wire in the junction box.

C. If connecting to a four-

wire electrical system:

DO NOT connect the cabinet-grounding

conductor to the neutral (white) junction

box wire.

Junction Cable tram

bo;ee’y White

3

gree n

wires

I+-

y Black wires

; Cabe U.L.-listed

Figure 3

conduit

from range connector

1.Disconnect the power supply.

2. Separate the green and white

appliance cable wires.

3. Connect the white appliance cable

wire to the neutral (white) wire in the

junction box.

4. Connect the two black wires; then the

two red wires. See Figure 3.

5. Connect the green grounding wire to

the grounding wire in the junction box.

n

Now start...

wlth oven in kitchen.

1

H Remove shipping materials, tape,

and protective film from range. Do Not

remove shipping base at this time.

2

H Remove the racks and other parts

from inside the oven. Remove air grille

taped to top or side of range.

Q

n

Self-cleaning models: Insert a nail

or a 5/32” diameter item in the hole in

each of the hinges. Close the door as far

as possible. Lift oven door off of the

hinges and set aside.

Non-self-cleaning models: Open door to

the broil “stop” position and lift door

upwards to remove.

Floor Damage

Before moving range across floor,

check that range is on shipping base

or slide range onto cardboard or

hardboard.

Failure to follow these instructions may

result in damage to floor covering.

4

m Move range close to cabinet

cutout. Make electrical connection.

See Electrical requirements and

Electrical connection sections, Panels A

and B,for details.

Personal Injury Hazard

Because of the weight and size of this

range, two or more people are

needed to move and safely install it.

Failure to do so could result in

personal injury.

c

g H Remove and discard shipping

base. Lift range up into cabinet

opening using the oven opening as an

area to grip.

6

n

Center range in cabinet cutout.

Loosen screws and insert spacers

(shipped in literature bag) on each side

of the control console. If range does not

fit properly, check spacers. The spacers

may need to be cut to fit under the

countertop. Mark with a pencil where

each spacer needs to be cut. Loosen

both screws to remove spacers. Cut

across top of each spacer. Replace

spacers and tighten screws. Check that

range fits properly on countertop.

Panel 6

To reduce the risk of tipping the

appliance, the appliance must be

securely fastened to the cabinet using

the four screws that are provided.

/

n

Secure range to cabinet using

the four screws through the mounting

holes in the front frame of the oven,

8

n

Put air grille into place under the

oven door. Be sure louvers in air grille

point down, flange isat bottom, and

mounting holes are at top. Slide air grille

into position. Attach grille with 3 black

metal screws. (White models may use

chrome screws.)

9

V

n

Self-cleaning models: Fit both

corners of oven door over ends of

hinges. Push door evenly and

completely onto hinges. Remove nails

from hinges. If door does not close, you

have not pushed door completely onto

hinges.

Non-self-cleaning models: Fit both

corners of oven door over ends of

hinges. Push door evenly and

completely onto hinges. If door does

not close, you have not pushed door

completely onto hinges.

10

n

Turn power supply on.

1

unit

11

nn

Push in and turn each surfacePush in and turn each surface

control knob to ‘HI” position. Checkcontrol knob to ‘HI” position. Check

the operation of the cooktop elements

and indicator lights.

12

n

Check the operation of the

oven bake elements:

If you have oven and temperature

selector control knobs: Set the oven

selector knob to “BAKE.” Set the oven

temperature control to 350°F. The bottom

element should glow red and the

indicator light should be on. The upper

element should become hot but not

glow red. The oven indicator light goes

off when the oven ispreheated.

If you have electronic controls: Push the

“BAKE” pad. “350“” and “BAKE” will

appear in the display. Push the

“START/ENTER”pad. ‘Lo”,” “HEAT” and

“BAKE” will appear in the display; then

n170”.” The bottom element should glow

red and the upper element should

become hot but not glow red. As the

temperature rises,the temperature in the

display will increase in 5” increments until

the oven reaches the set temperature.

When the oven reaches 35O”F,press the

“OFF/CANCEL” pad.

13

n

Check the operation of the

oven broil element.

If you have oven and temperature

selector control knobs: Set the oven

selector and the oven temperature

control knobs to “BROIL.” The top

element should glow red and the

indicator light should be on. Set the oven

selector and oven temperature control

knobs to “OFF.”

If you have electronic controls: Push the

“BROIL” pad. “500”” and “BROIL” will

appear in the display. Pressthe

“START/ENTER”pad. ‘500”,” “BROIL” and

“HEAT” will appear in the display. The top

element should glow red. Pressthe

“OFF/CANCEL” pad.

To get

the

most efficient

use

from

yournewrange,

readyourUseandCureGuide.

KeepInstallationInstructions

andGuideclosetorungefor

eusy

reference.

Numbers

correspond

to steps.

Panel C

If the range does

not operate...

Firstcheck that the circuit breaker isnot

tripped or the house fuse blown. A more

detailed troubleshooting checklist is

provided in the Use and Care Guide.

For cleaning and

maintenance...

If removing the range isever necessary

for cleaning or maintenance, disconnect

the electrical supply to the range.

Remove screws holding range to cabinet

and pull range out only as far as

necessary to disconnect the electric

supply cable. Remove the range to

complete cleaning or maintenance.

Move range back into operating position.

Replace screws and secure range to

cabinet. Reconnect the electric supply.

Personal Injury/Product

Damage Hazard

Do Not step, lean or sit on the range

door.

Failure to follow these instructions could

result in personal injury and/or product

damage.

Part No. 3147396 Rev. B

01994

Printed on recycled paper.

10%post consumer waste/

50% recovered materials.

Benton Harbor, Michigan 49022

If you need

assistance..

Check your Use and Care Guide for a

toll-free number to call or call the dealer

from whom you purchased this

appliance. The dealer islisted in the

Yellow Pages of your phone directory

under “Appliances - Major - Service and

Repair.” When you call, you will need the

range model number and serial number.

Both numbers can be found on the

serial/rating plate located on the frame

behind the oven door.

Printed in U.S.A.

Table of contents