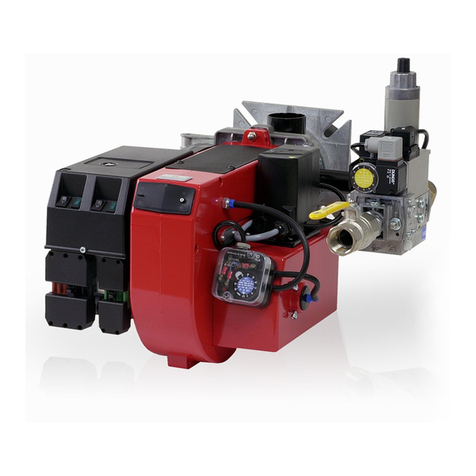

GENERAL INSTRUCTIONS

Adjustment of burner

The burner is from the factory pre-set to an average value that must then

be adjusted to the boiler in question. All burner adjustments must be made

in accordance with boiler manu-facturers instructions.These must include

the checking of ue gas temperatures, average water temperature and

CO2or O2concentration.

General instructions The installation of the gas burner must be carried out in accordance with

current regulations and standards. The installers of gas burners should

therefore be acquainted with all regulations and ensure that the instal-

lation complies with the requirements. The installation, mounting and

adjustment should be made with the greatest care and only the correct

gas should be used.

Operating instructions The operating instructions accompanying the burner should be left in a

prominent position in the boiler room.

Instructions The user should be thoroughly in-structed in the function of the gas burner

and the whole installation. The supplier must instruct the user.

Inspection and maintenance Daily inspection is advisable.

Start up After the burner has been tted to the boiler and the electric connection,

the leakage control, the venting and the electric function test have been

carried out, the burner will be ready for start-up.

Howerer, study the sections dealing with adjustments of multi-bloc,

combustion air and combustion head. Open the ball valve and switch on

the main switch. If the burner starts the actual adjustment can be made.

Adjustment of burner head The burner is equipped with an adjustment device changing the po si tion

of the brake plate in the burner head. This is used to adjust the cor rect

pressure drop over the combustion device in order to obtain a good

pulsation free combustion.

Which position to use depends on input and overpressure in the boiler. A

general rule is that the lower capacity the smaller the opening between

brake plate and combustion device.

Commissioning of installation

Control of the combustion. The combustion quality is checked by means

of a ue gas analysis device. Adjust the burner to appr. 20% excess air

in accordance with the table. Check the ue gas temperature. Calculate

the efciency. Check also the actual gas volume on the gas meter so

that the correct input is achieved.

Service

Service should only be carried out by qualied personnel. Replacement

parts should be of the same make and approved by the same authori-

ties as the original. If the burner is converted to re another gas quality

it must be re-commissioned. If town gas is to be red the combustion

head must be converted and the gas train adjusted to suit (e.g.a larger

gas armature or a different spring in the governor may be required).

172 305 28-1 12-01

Gas quality CO2% 02% max. CO2%

lambda 1,2

Natural gas 10,0 3,5 11,9

LPG 11,5 3,5 13,9