BERTHOLD TECHNOLOGIES LB 8300 User manual

Rod source shields

LB 8300

Operating manual

64217BA2

Rev.

No.:

00, 10/2017

BERTHOLD TECHNOLOGIES GmbH & Co. KG

Calmbacher Str. 22

75323 Bad Wildbad, Germany

www.berthold.com

Telephone +49 7081 177-0

Fax +49 7081 177-100

Table of contents Rod source shields LB 8300

4

64217BA2 Rev. 00, 10/2017

Table of Contents

1About this operating manual............................................................................. 6

1.1 Some prior remarks ...................................................................................................... 6

1.2 Storage .......................................................................................................................... 6

1.3 Target Group ................................................................................................................ 6

1.4 Validity of the Manual ................................................................................................. 7

1.5 Structure of the Manual............................................................................................... 7

1.6 Copyrights ..................................................................................................................... 7

1.7 Representation ............................................................................................................. 7

1.8 Symbols Used ................................................................................................................ 8

1.8.1 Structure of Warnings .................................................................................................. 8

1.8.2 Symbols used on the device......................................................................................... 9

2Safety manual ................................................................................................... 10

2.1 Proper use ................................................................................................................... 10

2.2 Ambient conditions during operation and storage................................................. 11

2.3 Qualification of the personnel .................................................................................. 11

2.4 Radiation Protection .................................................................................................. 13

2.4.1 Basic principles and regulations ................................................................................ 13

2.4.2 Exposure of employees to radiation ......................................................................... 14

2.4.3 Theft protection ......................................................................................................... 14

2.4.4 In the case of fire........................................................................................................ 14

2.6 Type plate of the source ............................................................................................ 15

3System Description ........................................................................................... 16

3.1 View............................................................................................................................. 17

4Installation........................................................................................................ 19

4.1 Safety Instructions ...................................................................................................... 19

4.2 Ambient conditions during assembly........................................................................ 20

4.3 Intermediate storage of the source .......................................................................... 20

4.4 Preparing the Installation .......................................................................................... 20

4.5 Checking the delivery................................................................................................. 20

4.6 Installation of the shield ............................................................................................ 21

4.7 Marking ....................................................................................................................... 26

5Usage ................................................................................................................ 27

5.1 Safety instructions ...................................................................................................... 27

5.2 Opening and closing the locking mechanism .......................................................... 27

5.3 Commissioning............................................................................................................ 29

6Maintenance and Repair .................................................................................. 30

6.1 Safety instructions ...................................................................................................... 30

6.2 Visual inspection......................................................................................................... 31

6.3 Leak test ...................................................................................................................... 31

6.4 Checking the locking mechanism.............................................................................. 33

6.5 Removing and installing the source.......................................................................... 34

6.5.1 Removing the source.................................................................................................. 34

6.5.2 Installing the source ................................................................................................... 37

6.6 Source replacement.................................................................................................... 39

6.6.1 Replacing the source .................................................................................................. 39

7Decommissioning.............................................................................................. 41

7.1 Safety instructions ...................................................................................................... 41

7.2 Disassemble the shield ............................................................................................... 42

Rod source shields LB 8300 Table of contents

7 64217BA2 Rev. 00, 10/2017

5

7.3 Disposal of radioactive substances ............................................................................ 43

7.4 Shipment of radioactive substances.......................................................................... 43

8Appendices ....................................................................................................... 45

8.1 Check lists for tests ..................................................................................................... 45

1 About this operating manual Rod source shields LB 8300

6

64217BA2 Rev. 00, 10/2017

1About this operating manual

1.1 Some prior remarks

The product is handed over to you by the manufacturer

BERTHOLD TECHNOLOGIES GmbH & Co. KG in a complete and functionally

reliable condition.

This operating manual illustrates how to:

•set up/install the product

•operate the product

•carry out maintenance on the product

•disassemble the product

•dispose of the product

Read these instructions thoroughly and completely before working with the

product. We have tried to compile all the information for safe and proper

operation for you.

However, should questions arise which are not answered in this manual, please

contact BERTHOLD TECHNOLOGIES GmbH & Co. KG.

Store the instructions where they are accessible for all users at all times.

1.2 Storage

This operating manual as well as all product-related documentation relevant to

the respective application must be accessible at all times during the life cycle near

the device.

1.3 Target Group

The product may only be installed, operated, maintained and repaired by trained

personnel.

This manual is directed at qualified specialist personnel who are familiar with

handling radioactive sources and heavy system components.

Specialist personnel refers to those who can assess the work assigned to them and

recognise possible dangers through their specialist training, knowledge and

experience as well as knowledge of the relevant regulations.

Rod source shields LB 8300 1 About this operating manual

64217BA2 Rev. 00, 10/2017

7

1.4 Validity of the Manual

The manual is valid from the delivery of the Berthold product to the user until its

disposal. Version and release date of this operating manual can be found in the

bottom of each page. An alteration service is not provided by the manufacturer

BERTHOLD TECHNOLOGIES GmbH & Co. KG.

The manufacturer reserves the right to make changes to this operating manual at

any time without stating reasons.

NOTICE

The current revision of this operating manual replaces all previous versions.

1.5 Structure of the Manual

This manual has been divided into chapters. The order of the chapters should

help you to familiarise yourself quickly and properly with the operation.

1.6 Copyrights

This manual contains copyright-protected information. None of the chapters may

be copied or reproduced in any other form without prior authorisation from the

manufacturer.

1.7 Representation

Identifier

Meaning

Example

Round brackets

Image reference

Connect the plug (fig. 1,

item 1)

1 About this operating manual Rod source shields LB 8300

8

64217BA2 Rev. 00, 10/2017

1.8 Symbols Used

1.8.1 Structure of Warnings

j

Signal word

Source and consequence

Explanation, if required

Measure

In case of emergency

•Warning symbols: (warning triangle) draws attention to the hazard

•Signal word: states the severity of the hazard

•Source: states the type and source of the hazard

•Consequence: describes the consequences if warning is ignored

•Measure: states how one can avoid the hazard.

•In case of emergency: states how to react in case of direct danger.

Warning levels used

In this manual, warning instructions in front of instructions for action refer to

risks of injury or damage to property. The hazard-prevention measures described

must be observed.

j

DANGER

Indicates an

imminent

, major hazard, which will certainly result in serious

injuries or even death if the hazard is not avoided.

j

WARNING

Indicates a

potential

hazard, which can result in serious injuries or even death

if the hazard is not avoided.

j

CAUTION

Refers to a

potentially dangerous

situation, which can result in medium or

minor physical injuries or damages to property, if it is not avoided.

NOTICE

If this information is not observed, deterioration in the operation and/or

property damage may occur.

Rod source shields LB 8300 1 About this operating manual

64217BA2 Rev. 00, 10/2017

9

IMPORTANT

Sections marked with this symbol point out important information on the

product or on handling the product.

Tip

Provides tips on application and other useful information.

1.8.2 Symbols used on the device

Ionising radiation

The shield is equipped with a radioactive source. Please note the handling

instructions. Please observe the transport instructions in this operating

manual.

2 Safety manual Rod source shields LB 8300

10

64217BA2 Rev. 00, 10/2017

2Safety manual

2.1 Proper use

The source with shield is used in connection with a detector and a suitable

evaluation unit provided by BERTHOLD TECHNOLOGIES to measure the radiation

intensity occurring during a radiometric measurement.

The shield was developed as shield/protective container for radioactive sources

and may be used exclusively for this purpose.

Usually, the shield contains a radioactive source. The notes on radiation

protection contained in the present manual as well as any statutory requirements

in this respect are to be strictly adhered to.

The following constitutes proper use:

•Adhering strictly to the instructions and operation sequences and not

undertaking any different, unauthorised practices which could put your safety

and the operational reliability of the shield at risk!

•Observing the provided safety instructions!

•Carrying out the prescribed maintenance measures or having them carried out

for you!

The following constitutes improper use and is to be avoided:

•Any non-compliance with the present operating manual for the supplied

products

•Applying conditions and requirements which do not conform to those stated

in the technical documents, data sheets, operation and assembly instructions

and other specific guidelines of the manufacturer.

•Using the product after any repair carried out by employees who have not

been authorized by BERTHOLD TECHNOLOGIES GmbH & Co. KG.

•Using the product in a damaged or corroded condition.

•Dismounting the unit while the radiation beam outlet is open (except for

situations in which the locking mechanism is defective and the beam outlet

can no longer be closed).

•Operation without the safety precautions provided by the manufacturer.

•Any modification to design and function, except for any activities provided for

and described in the present manual.

•Restructuring or changing the system components.

•Manipulation or avoidance of existing safety equipment.

BERTHOLD TECHNOLOGIES GmbH & Co. KG shall only accept liability for /

guarantee the correspondence of the product to its publicised specifications.

If the product is used in a way which is not described in this manual, the product's

protection is compromised and the warranty becomes void.

Rod source shields LB 8300 2 Safety manual

64217BA2 Rev. 00, 10/2017

11

2.2 Ambient conditions during operation and storage

The shield was specifically designed for use in rough ambient conditions. The

compliance with the operating conditions specified below contributes to

guaranteeing the permanent functionality of the shield and the prevention of

damage.

Shields containing radioactive substances and sources are to be stored in a

lockable storage room complying with the national requirements as regards the

storage of radioactive substances.

Furthermore, the following prescribed ambient conditions are to be observed:

•The minimum admissible operating/storage temperature is -40°C. Below this

temperature, the sealing rings of the shield may become brittle. In such case,

the leakproofness of the shield can no longer be guaranteed.

•The maximum admissible operating/storage temperature is +100°C. Above this

temperature, the sealing rings of the shield may be destroyed. In such case,

the leakproofness of the shield can no longer be guaranteed.

•The higher the dust and dirt content of the environment, the more likely

stiffness or an entire blockage of the locking mechanism is. For this reason, the

functional test intervals (see chapter 6) should be adjusted to the ambient

conditions.

•Highly combustible or explosive substances must not be kept in the vicinity of

shields in order to prevent a fire from spreading to the radioactive substances.

2.3 Qualification of the personnel

NOTICE

A minimum requirement for all work on or with the product would be

employees with general knowledge who are instructed by an expert or

authorised person.

At different parts in this manual, reference is made to personnel with certain

qualifications who can be entrusted with different tasks during the installation,

usage and maintenance.

The four groups this refers to are:

•Employees with general knowledge

•Experts

•Authorised persons

•Radiation Safety Officer

2 Safety manual Rod source shields LB 8300

12

64217BA2 Rev. 00, 10/2017

Employees with general knowledge

NOTICE

Employees with general knowledge must always be guided by one expert at

the very least. When dealing with radioactive substances, a radiation safety

officer must also be consulted.

Employees with general knowledge are e.g. technicians or welders who can

undertake different tasks during the transportation, assembly and installation of

the product under the guidance of an authorised person. This may also refer to

construction site personnel. The persons in question must have experience in

handling the product.

Experts

Experts are persons who have sufficient knowledge in the required area due to

their specialist training and who are familiar with the relevant national health

and safety regulations, accident prevention regulations, guidelines and

recognised technical rules.

Expert personnel must be capable of safely assessing the results of their work and

they must be familiar with the content of this manual.

Authorised Persons

Authorised persons are those who are either designated for the corresponding

task due to legal regulations or those who have been authorised by

BERTHOLD TECHNOLOGIES for particular tasks. When dealing with radioactive

materials, a radiation safety officer must also be consulted.

Radiation Safety Officer

In order to ensure proper handling and compliance with the statutory

requirements, the company has to appoint a radiation safety officer in

accordance with the applicable national law (in Germany:

Strahlenschutzverordnung [German radiation protection regulation]). The

radiation safety officer must implement the statutory radiation protection

requirements in order to protect employees against damage to their health

caused by handling radioactive materials.

NOTICE

Dangerous goods officers must not perform any activities as radiation

protection officers!

Radiation protection officers must have a special training with attendance of

an officially recognized course and appropriate professional experience.

Rod source shields LB 8300 2 Safety manual

64217BA2 Rev. 00, 10/2017

13

2.4 Radiation Protection

2.4.1 Basic principles and regulations

The amount of radiation absorbed by the body (exposure to radiation) is

determined by three parameters from which the basic radiation protection

regulations can be derived:

Distance

If work close to equipment containing

radioactive substances is required, the

largest distance possible is to be kept. In

particular, this shall apply for employees

which do not immediately participate in

such work.

Time

Any

work required in the vicinity of

radiometric measuring systems is to be

prepared carefully and to be organised

in a way that the work can be executed

as quickly as possible. Here, providing

the correct tools and aids is particularly

important.

Shield

W

hen mounting and dismounting the

shield, it is to be ensured in advance that

the radiation beam outlet is closed.

2 Safety manual Rod source shields LB 8300

14

64217BA2 Rev. 00, 10/2017

2.4.2 Exposure of employees to radiation

During installation, maintenance and decommissioning of the shield, employees

may be exposed to radiation.

In order to keep such exposure as low as possible, the shield with the source may

only be mounted and/or dismounted by authorized employees. Such authorised

staff is to be instructed as regards all rules of behaviour when handling

radioactive substances in advance.

It is to be ensured that the locking mechanism of the shield is closed and secured

in order to prevent the emission of unshielded radiation. Modification or damage

to the shield must be avoided at all times.

Work may only be executed according to the instructions and under the

supervision of the radiation safety officer, who furthermore has to calculate or

estimate the exposure of the employees to radiation in order to ensure that the

statutory dose rate limits are not exceeded.

2.4.3 Theft protection

Radioactive substances or equipment containing radioactive substances must be

secured in a way that they are protected against access by unauthorized persons.

In the case of firmly installed equipment containing radioactive substances, the

protection against unauthorized access is generally provided by the firmly

attached installation.

Shields with radioactive sources which are decommissioned for a certain period of

time must be dismounted and securely stored in a storage room complying with

the national regulations as regards the storage of radioactive substances.

Portable measuring systems must never be left unsupervised. When this

equipment is out of use, it is to be protected against access by unauthorised

persons.

2.4.4 In the case of fire

The shield material can melt and leak from the shield if exposed to very high

temperatures for an extended period of time. During and after a fire, there is a

risk of major long-time consequences for your health due to the incorporation of

lead as well as a risk of increased radiation exposure.

When planning the use of radiometric measuring systems, constructional

measures ensuring fire prevention are to be provided.

In the case of fire, these measures limit the access to this area.

Avoid the incorporation by keeping sufficient distance.

Notify BERTHOLD TECHNOLOGIES of the situation; you will promptly receive

information on immediate measures.

Rod source shields LB 8300 2 Safety manual

64217BA2 Rev. 00, 10/2017

15

2.5 Operator's obligations

The operator of the product must regularly train his personnel in the following

topics:

•Observation and use of the operating manual and the legal provisions.

•Proper use of the product.

•Observation of the plant security instructions and the operating instructions of

the operator

2.6 Type plate of the source

1

2

3

4

5

6

7

8

Date of manufacture of the source

Isotope

Activity [MBq]

Dose rate within 1 m distance [µSv/h]

Supplier of the source

Dose rate within 1 m distance [mrem/h]

Activity [mCi]

Source number

Fig.

1 Type plate of the source

3 System Description Rod source shields LB 8300

16

64217BA2 Rev. 00, 10/2017

3System Description

The rod source shield is intended as shield/protective container for radioactive

rod sources. The radioactive substance is contained in a leak-proof welded source

capsule and installed in the rod source shield. Apart from source and shield,

additional system components such as detectors and evaluation units are required

for a complete measuring system. Usage of these system components is not

subject of this operating manual. Please refer to the individual manuals of the

respective system components.

The shield container consists of a robust steel housing filled with lead. The

locking cylinder of the shield is pivoted. The provided lever rod can be used to

turn the locking cylinder to the two end positions. The radiation beam outlet is

thereby opened and closed.

The locking plate on the upper side of the shield ensures that the source cannot

be removed by unauthorized persons. Operators can secure the locking plate by

installing a padlock at the right-hand and the left-hand side.

The locking cylinder can be locked in both rotational positions (radiation beam

outlet open, radiation beam outlet closed) using fixing screws or a padlock.

Only the lower mounting plate and additionally the holes in the vertical bars

are permitted to mount the shield!

The rod source shield is available in different versions. You can find an overview

of all variants in the appendix (Technical Information).

The shield has the following functions:

•Shield radiation to a level that is non-hazardous for the operating personnel

•Locking the radiation beam outlet channel for transport and during

installation

•Protecting the integrated source capsule from mechanical damage and the

effects of the surrounding environment

Rod source shields LB 8300 3 System Description

64217BA2 Rev. 00, 10/2017

17

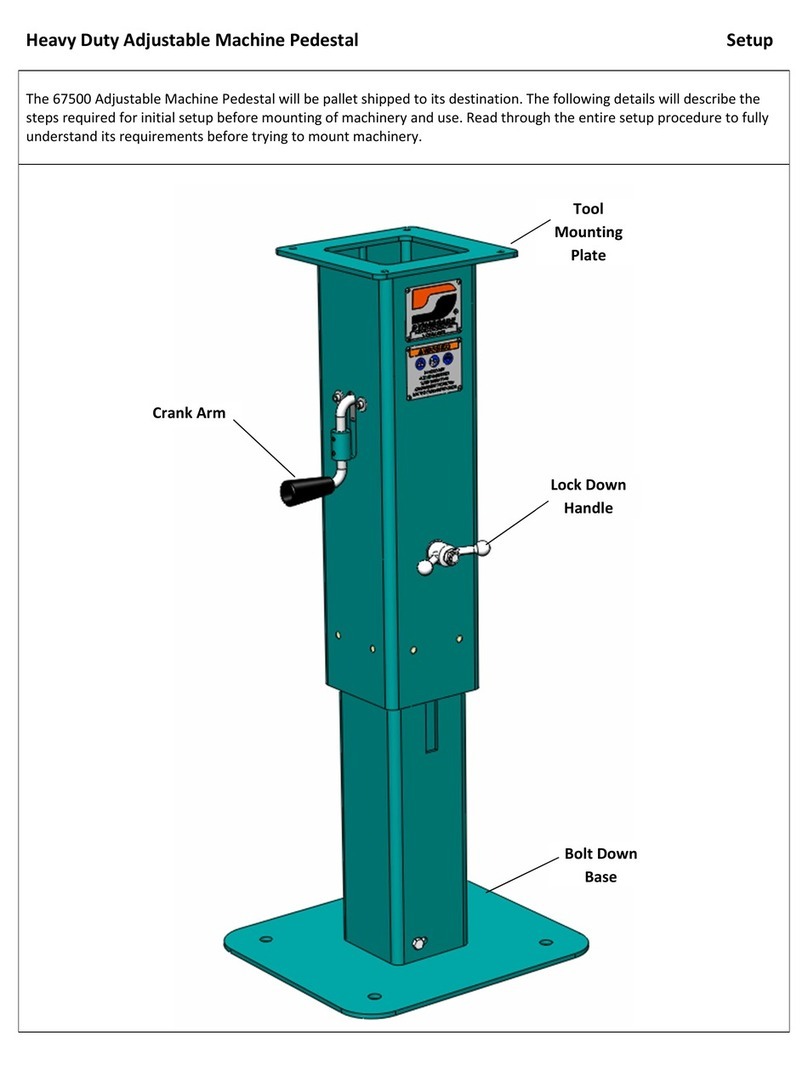

3.1 View

1

2

3

4

5

6

7

8

Ring nuts

Fastening bolts with padlock

Locking plate

Transport lock

Locking cylinder

Lever rod (auxiliary equipment used for turning the locking cylinder)

Padlock (secures the closed shield against rotation)

Mounting base

Fig.

2 Basic layout

3 System Description Rod source shields LB 8300

18

64217BA2 Rev. 00, 10/2017

1

2

3

4

Source holder

Source

Radiation beam outlet channel

Locking cylinder with shield material

Fig.

3 Sectional view (position CLOSE)

Rod source shields LB 8300 4 Installation

64217BA2 Rev. 00, 10/2017

19

4Installation

4.1 Safety Instructions

j

WARNING

Danger of injury by falling loads

Never stand underneath a lifted or suspended load, keep at a safe

distance.

Only use tested sling gear components appropriate for the transport

weight.

Exclusively use the provided fixing possibilities (lifting brackets) for

attaching the sling gear.

Observe the abient temperature during installation (4.2 Ambient

conditions during assembly)

Observe the marking for the centre of gravity on the outer packaging, if

applicable.

Wear head protection and safety shoes.

j

WARNING

Danger of injury caused by heavy and bulky system components

Heavy and bulky system components should only be handled using aids

and by a at least 2 persons.

Observe the guidelines for safe handling of heavy loads.

Ensure stability and use the provided fixing possibilities.

j

CAUTION

Danger caused by ionising radiation

Shields usually contain radioactive sources. An increased exposure to radiation

may lead to damage to health.

Consult the radiation safety officer responsible for your company.

Transport the source exclusively inside the closed and secured shield.

IMPORTANT

The applicable national regulations of the country of use have to be observed.

4 Installation Rod source shields LB 8300

20

64217BA2 Rev. 00, 10/2017

4.2 Ambient conditions during assembly

The assembly is made by two ring bolts (Fig. 2, item 1). The minimum permissible

temperature during assembly is -20 °C.

4.3 Intermediate storage of the source

If the source must be intermediately stored at the site of use between delivery

and installation, please observe the following notes:

Store the source exclusively inside a closed and secured shield.

Store the shield in a lockable and properly marked room. The storage room

must comply with the national requirements regarding the storage of

radioactive substances.

Accessible areas of increased radiation exposure must be marked and closed

off, if required.

4.4 Preparing the Installation

IMPORTANT

Size and position of the applicable measuring range are specified in the

project planning phase and determined by means of drawings, sketches or

written notes. During installation, these specifications must be strictly

observed since deviations may lead to malfunction of the measuring system.

To avoid an unnecessary exposure to radiation, the handling period of the source

(even if it is shielded) must be kept as short as possible during installation. It is

therefore recommended to perform the following steps prior to delivery of the

source:

•Installation planning (incl. estimation of radiation exposure)

•Instruction of the employees

•Organising and cleaning the installation site

•Preparing the required tools and hoisting devices

•Removing all obstacles which might hinder the installation of the shield or the

source

4.5 Checking the delivery

1. Check the delivery for completeness using the packing list.

2. Clean the parts, if required

3. In the case of damage, immediately notify the forwarding agent and the

manufacturer.

Table of contents

Other BERTHOLD TECHNOLOGIES Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

ABB

ABB HT563048 Operation manual

riverhawk

riverhawk IM-116 instruction manual

Chicago Dryer

Chicago Dryer AIR CHICAGO EXPRESS instruction manual

Donaldson Torit

Donaldson Torit PowerCore CPV-1 Installation and operation manual

Kval

Kval Commander III Operation manual

AFL Hyperscale

AFL Hyperscale L3 Mustang installation guide

Bosch

Bosch Rexroth Lohmann + Stolterfoht MOBILEX GFB 40 T2... operating instructions

ABB

ABB XAC25744 Operation manual

BENCH INDUSTRIES

BENCH INDUSTRIES 35472-2A owner's manual

Panasonic

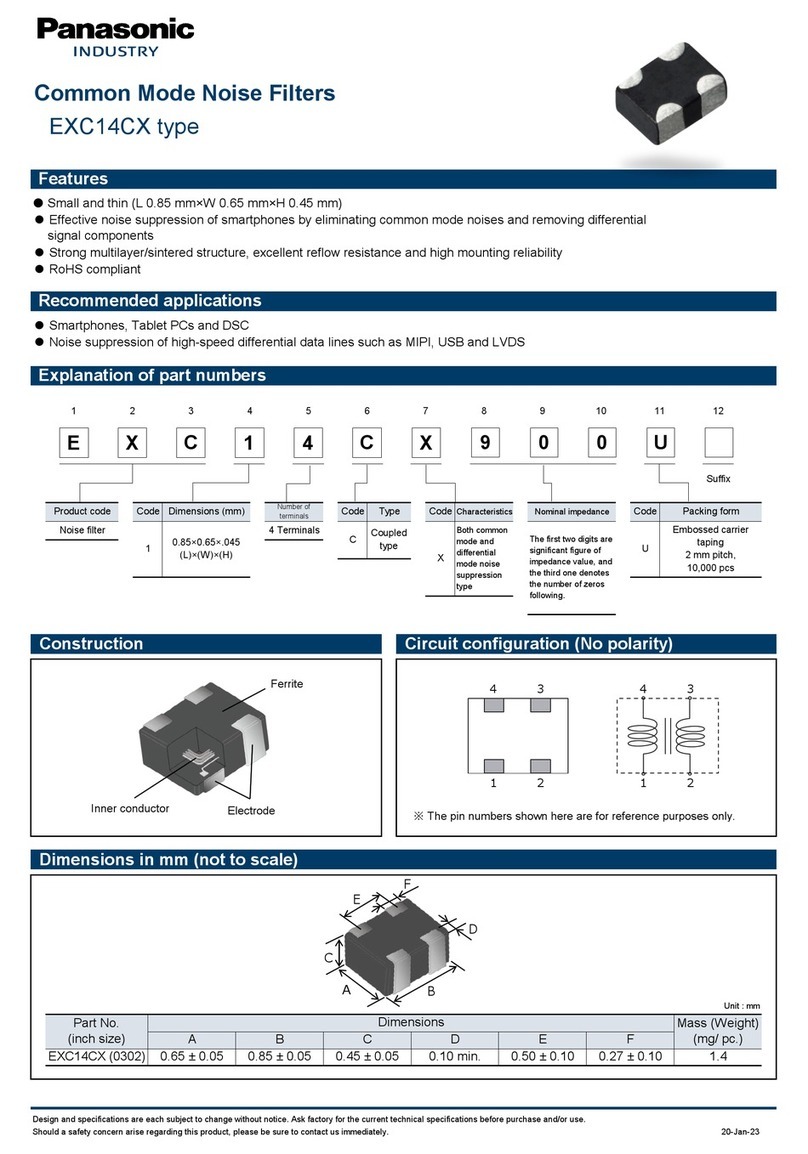

Panasonic EXC14CX quick start guide

Balluff

Balluff BIC 1B0-IT1A7-Q40KFU-SM4A4A user guide

SEI Industries

SEI Industries BAMBI BUCKET SMALL Series Operator's manual