3

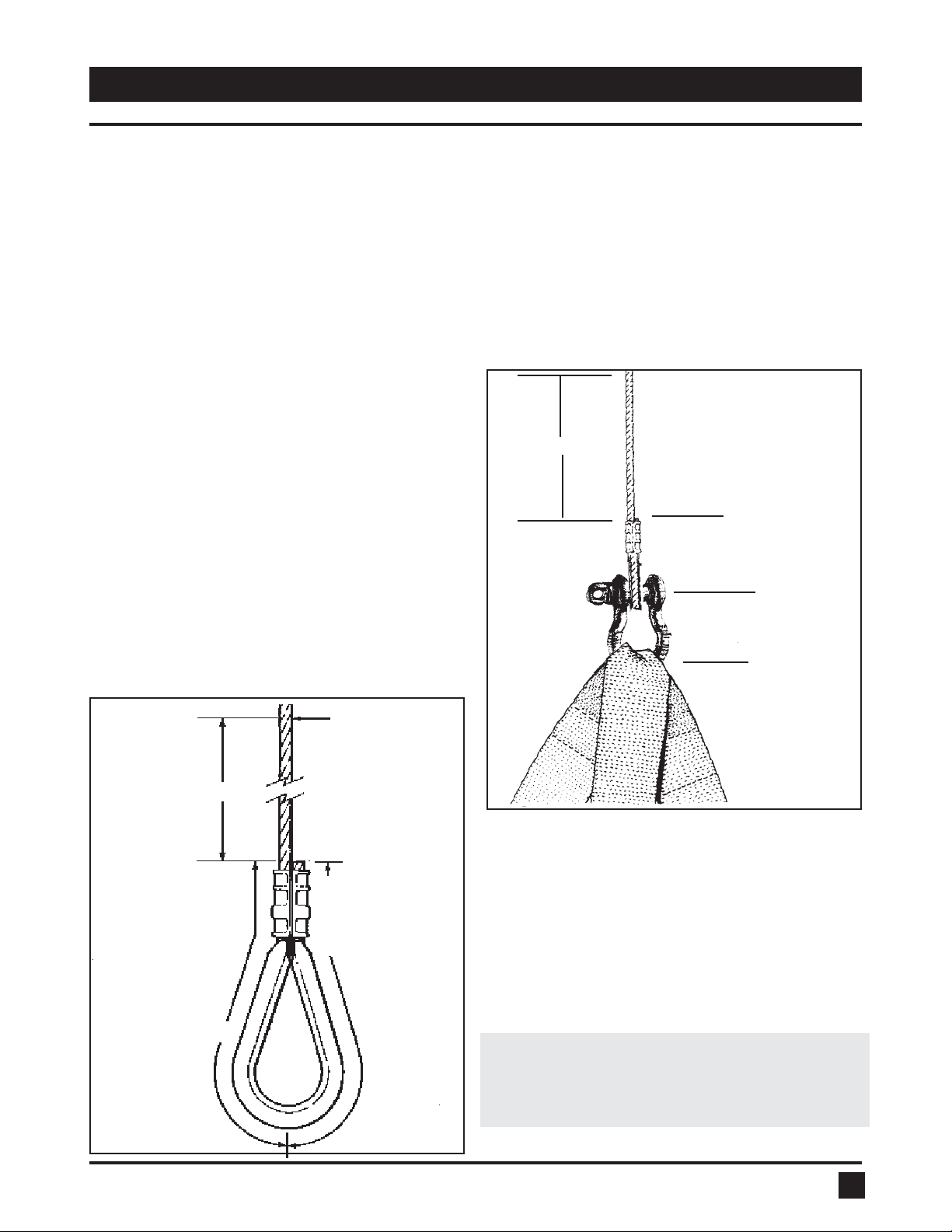

3.1 Attaching to Cargo Hook

The Bambi Bucket is rigged for a lateral cargo hook.

Correct attachment is indicated when the name plate on

the control head faces forward in flight; this ensures that

the ballast on the Bambi will face forward in flight.

CAUTION: It is IMPORTANT that the ballast faces

forward In flight. This will avoid twisting of the

suspension lines and possible jamming of the

trip line.*

There are two different styles of control head used on the

Bambi Bucket. The head used on Models 6072-4453

has a moveable yoke which can be rotated by 90 degrees.

The yoke is machined to orient in either direction.

If your helicopter has a longitudinal hook, rotate the

shackle yoke unit at the top of the head by 90 degrees.

This will place the name plate on the control head forward

in flight.

The head used on Models 5566-HL9800 is rigged for a

lateral cargo hook. It has a fixed top shackle. If your

helicopter has a longitudinal hook, use a second shackle

attached to the head shackle. This will effectively rotate

the attachment point by 90 degrees.

CAUTION: If using a second shackle on Models

HL5000-HL9800, it must have a load rating

equivalent to the top shackle supplied with the

head. Using a shackle with a lower load rating

could result in a shackle failure.

For either style of head, if using a swivel hook, operate in

the locked position to assure that the ballast is always

facing forward in flight.*

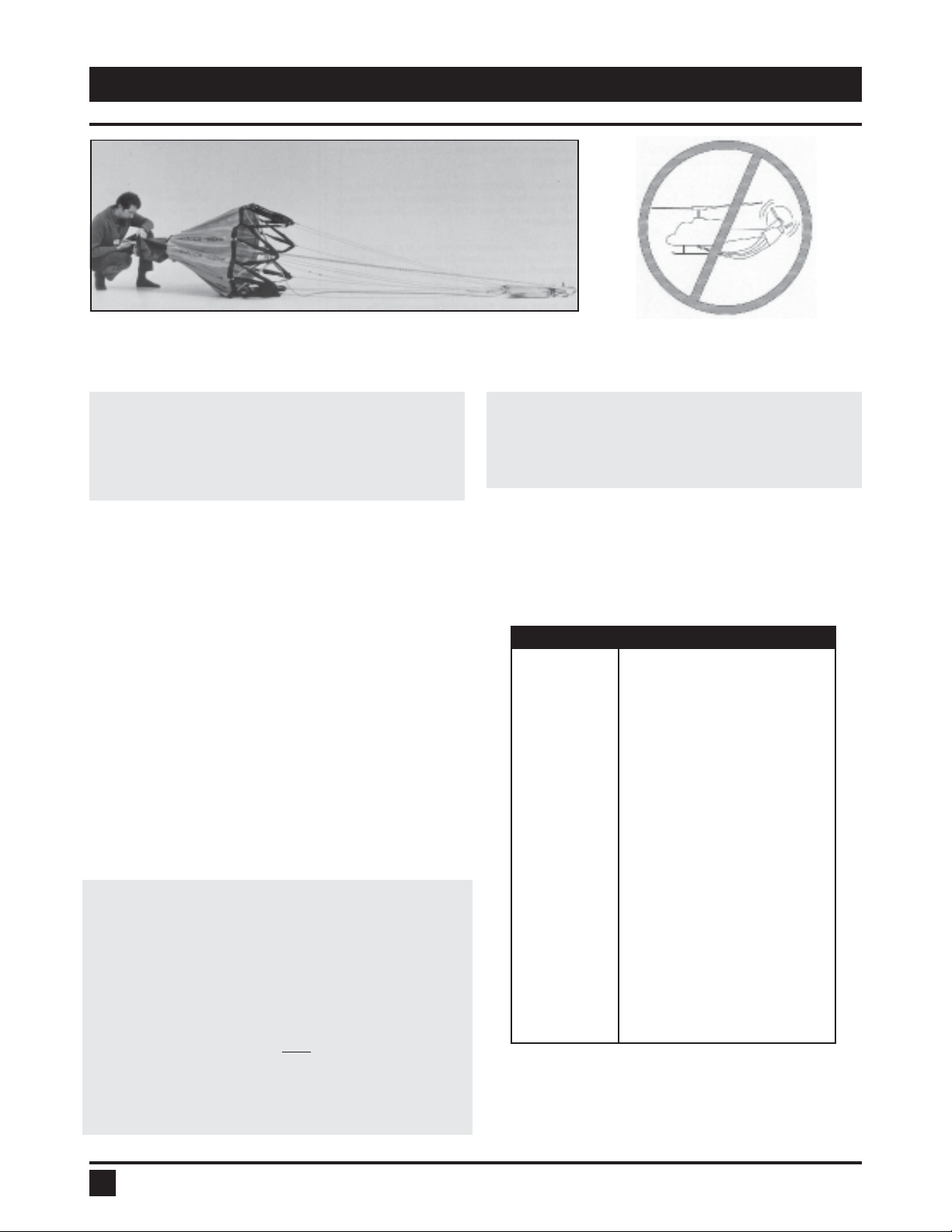

Caution: The Bambi Bucket may not be suitable

for a direct hook-up to the cargo hook. The

actual hook-up will be different for various

aircraft, and operators must comply to all

instructions and bulletins supplied by the

aircraft manufacturer. It is the operator's

responsibility to ensure that the Bambi Bucket

is correctly fitted to the helicopter.

3. DEPLOYING THE BAMBI BUCKET

3.2 Connecting Power

NOTE: To operate the solenoid and release the

water use a momentary contact switch rated only for

5.5 amps at 24 VDC. A suitable switch is available from

SEI. Alternatively, a lower rated switch may be used

with a relay--see suggested wiring diagram Section 17.

The solenoid has a 10% duty cycle. This means it is not

intended to be operated more than 10% of the time.

Operating the solenoid continuously will result in solenoid

failure.

The control head of the Bambi Bucket comes equipped

with a short length of two wire electrical cable. A popular

wiring hookup involves fitting a common household plug

to the end of the cable. To complete the wiring hookup:

1. Connect a 110 volt household plug to the wire

supplied on the control head.

2. Make a 12 AWG or heavier two wire interconnecting

electrical cable long enough to run from the bucket cable

to the accessory plug on the belly of the helicopter (leave

enough length for the control head to swing freely).

3. Attach the mating household plug to one end of the

interconnecting cable.

4. To check for continuity in the connections, push the

momentary contact switch. A clicking sound should be

heard from the control head.

5. With the engine running, test for a minimum of 24 VDC

at the breakaway plug (12 volts for 6072). If the voltage

is lower than 24 volts, use a heavier gauge wire for the

interconnecting cable. Re-test to confirm a minimum of

24 VDC at the breakaway plug.

The purpose of the household plugs is to offer a clean

“breakaway” if the Bambi Bucket has to be jettisoned

from the aircraft in an emergency. It is suggested that

the household plugs be lightly taped together with vinyl

tape while in use to ensure that wind action does not

separate the plugs. Current draw is only 5.5 amps. (24/

28 VDC)or 5.0 amps for 6072 (12-14 VDC).

*EXCEPTION: If you are using a swivel with an electri-

cal connection, then it is acceptable for the bucket to

be flown without the ballast facing forward. The Bambi

Bucket has been tested with the Canam Aerospace

swivel, and performs very well despite rotating in flight.

The swivel also prevents the suspension lines from

twisting up after dipping the bucket.