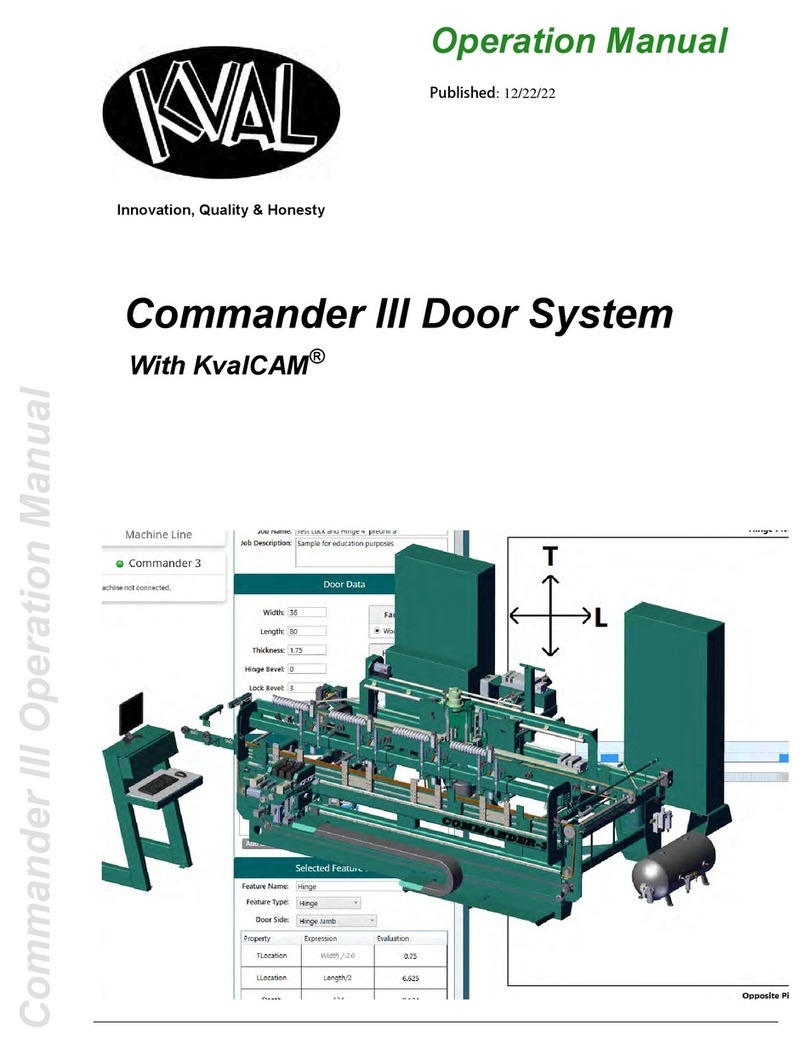

KVAL Commander III Manual

Using the Edit/View Button.................................................................2-10

Using the Clone Button.......................................................................2-10

Using the Delete/Restore Button........................................................2-11

Using the Diff Button...........................................................................2-12

About the Database Icon....................................................................2-13

About Revisions....................................................................... 2-14

Principle and Diff.................................................................................2-14

Revisions at the Door Job Library.......................................................2-14

Revisions at the Door Data Library.....................................................2-15

Revisions at the Door Feature Group Library.....................................2-15

About Door Job Creation......................................................... 2-17

About the Job Name Menu.................................................................2-18

About the Door Data Menu.................................................................2-18

About the Feature Tree Menu.............................................................2-19

Breakdown of a Feature Group and Features....................................2-19

About the Feature Tree Menu.............................................................2-20

About the Selected Feature Details Menu..........................................2-21

About the Selected Feature Details Menu (Child Level).....................2-22

About the Control Buttons...................................................................2-23

About the Job Preview Screen (2D and 3D).......................................2-24

2 D Screen..........................................................................................2-24

3 D Screen..........................................................................................2-25

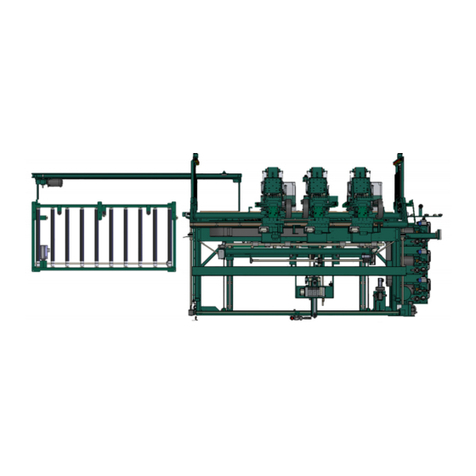

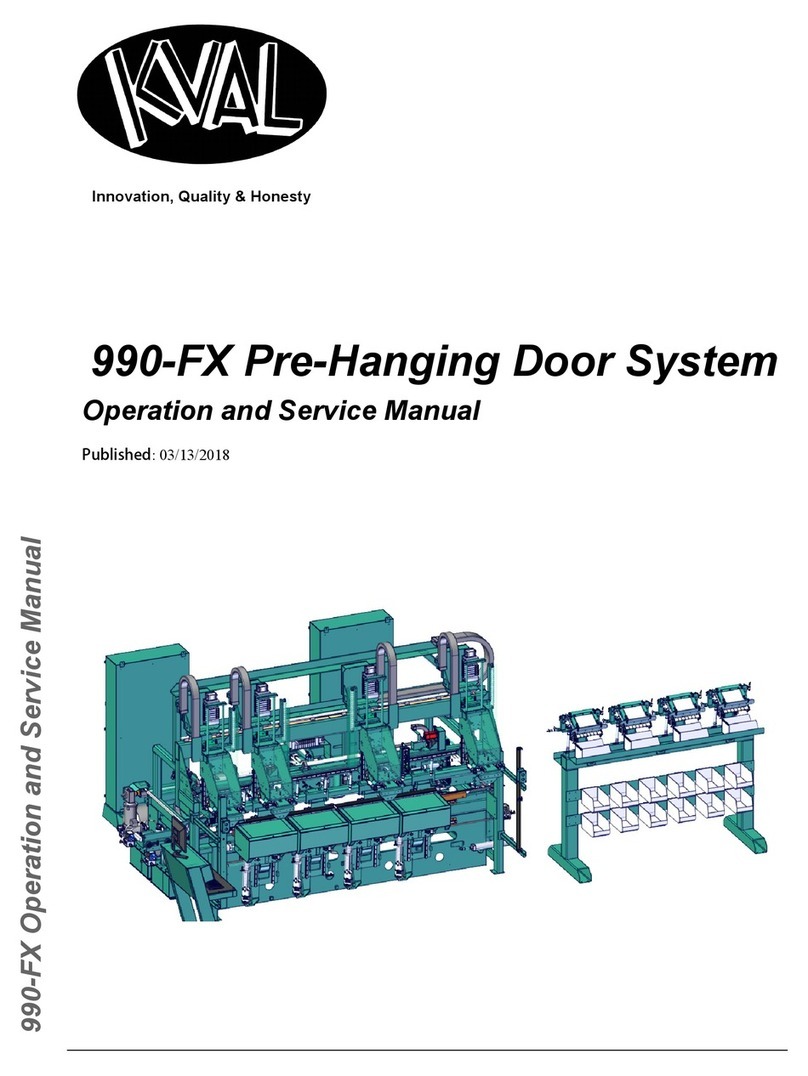

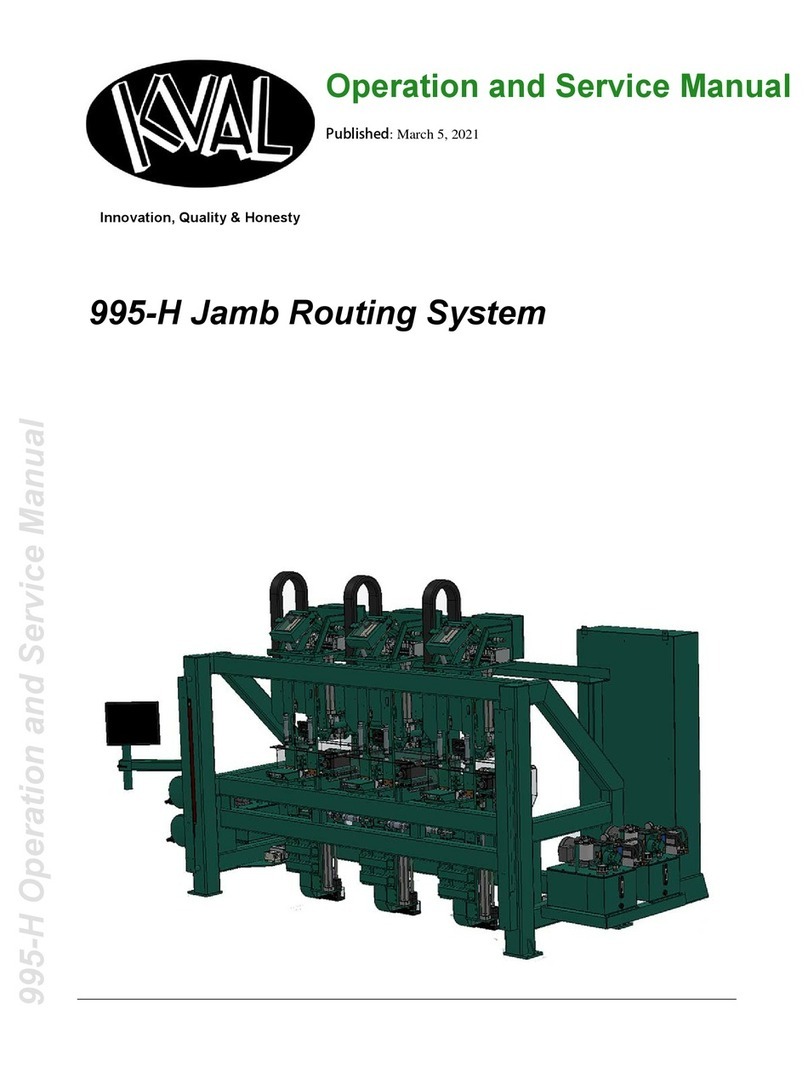

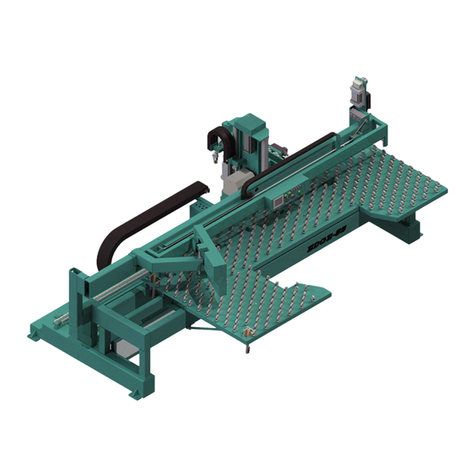

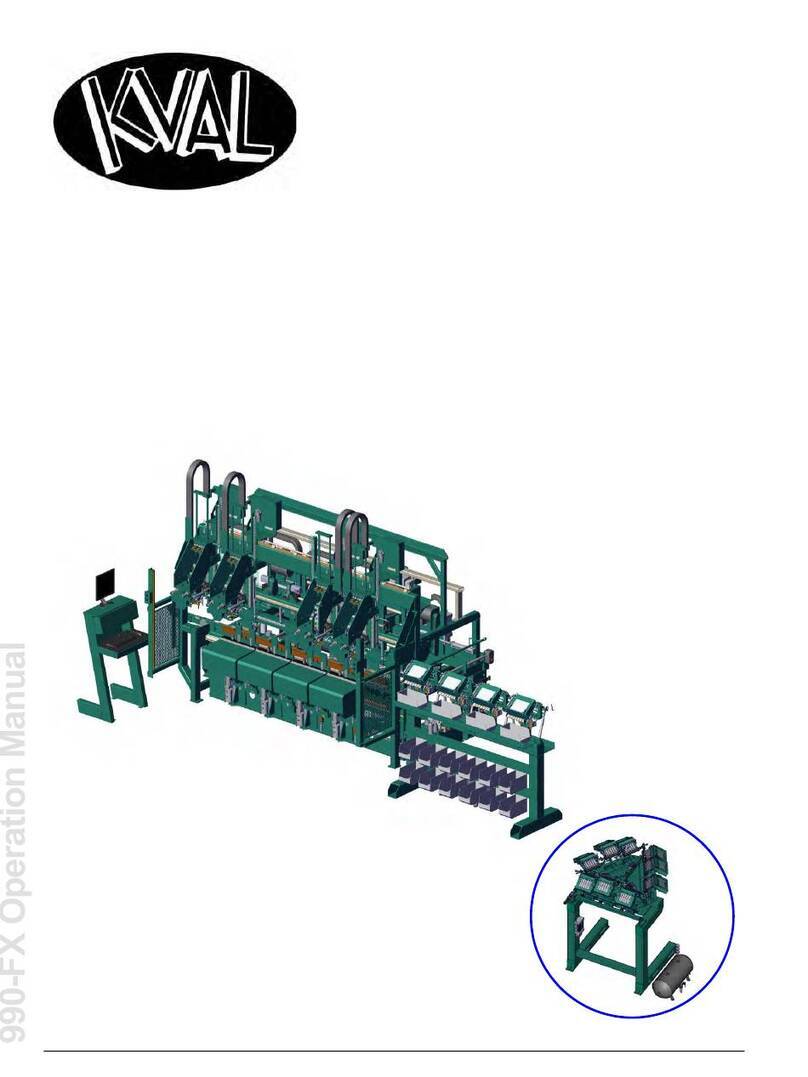

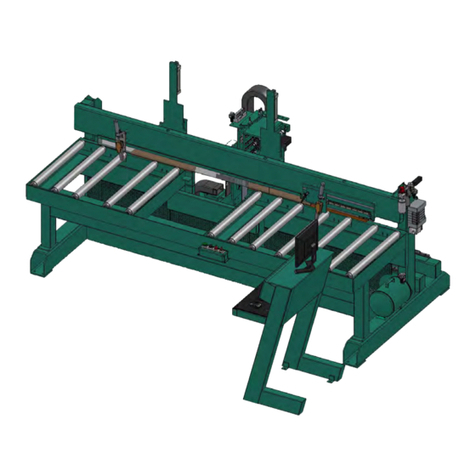

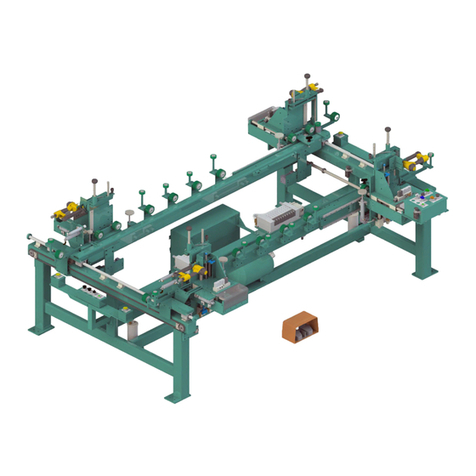

About the Machine Line Screen............................................... 2-26

Machine Line Screen..........................................................................2-26

About Backing up Data and Checking the Revision Status..... 2-30

Job Preview Examples ............................................................ 2-31

Door Face (Lock Preview)..................................................................2-31

Door Edge (Lock Preview)..................................................................2-32

Door Edge (Hinge Preview)................................................................2-33

About Validation....................................................................... 2-34

About the Validation Screen ...............................................................2-35

Outline ................................................................................................2-36

About the LiteCutout Feature Detail (DL-NCD Only)............... 2-37

Process...............................................................................................2-37

About the LiteCutout Screen...............................................................2-41

About the Work Area Coordinates......................................................2-42

Sample Oval Cut.................................................................................2-43

Common Terms ....................................................................... 2-45

Door Job.............................................................................................2-45

Door Data ...........................................................................................2-45