Bertos E6ST Safety guide

E6ST | E10ST

E6MB | E10MB

MANUAL

Installation

ELECTRIC

COMBINATION OVEN

TRANSLATION OF THE

ORIGINAL INSTRUCTIONS

EN

Dear Installer

this manual contains all the information necessary for

correctly installing the appliance.

Please read it carefully before assembling the appliance

and store it safely for future reference.

If you do not fully understand any of the contents, please

contact the manufacturer for further information.

43

GENERAL INDEX

INSTALLATION WARNINGS..................................... 45

INSTALLATION .......................................................... 48

CONNECTIONS AND FINAL INSPECTIONS......... 58

................................................. 70

44

SECTION INDEX

MEANING OF PICTOGRAMS................................... 45

FOR WHOM THIS MANUAL IS INTENDED ........... 45

INSTALLATION WARNINGS..................................... 45

.......................... 47

Warnings

for installing the

appliance safely.

45

MEANING OF PICTOGRAMS

Indicates that caution is required

when carrying out an operation

described by a paragraph bear-

ing this symbol. The symbol also

indicates that the operator must

be fully informed in order to avoid

undesired or dangerous conse-

quences

To mitigate electrical risks, the

systems have been designed in

accordance with standard CEI

EN 60335-1. This sticker means

“high voltage” and identifies areas

where there are electrical hazards.

Hot surfaces: surfaces marked

with this symbol may be hot and

care must therefore be taken

when touching them

To avoid burns, do not place con-

tainers filled with liquid or food

that liquefies when heated to

higher levels than can be easily

observed.

Earthing

Identifies the terminals which,

when connected together, bring

the various parts of an appliance

or system to the same potential

(not necessarily earth potential)

Indicates that the paragraph

marked with this symbol must be

read carefully before installing, us-

ing and maintaining the appliance

FOR WHOM THIS MANUAL IS

INTENDED

• These instructions are mainly intended for

the installer and maintenance personnel,

who must read them carefully before in-

stalling the appliance.

• The installer is strictly forbidden

from carrying out operations other

than those outlined in these in-

structions.

• The machine’s end user CANNOT under

any circumstances carry out the opera-

tions intended for the installer.

• The term “APPLIANCE” hereafter refers to

the oven mod. E6ST, E6MB, E10ST, E10MB.

-

tions are valid for any model.

INSTALLATION WARNINGS

• Read this manual carefully before in-

stalling or carrying out special main-

tenance on the appliance. Store this

manual with care for future reference.

• All installation, assembly and non-routine

maintenance work must be performed

authorised by the manufacturer, in

compliance with the regulations in force

in the user country and the regulations on

systems and safety in the workplace.

• Wear appropriate personal protective

equipment during the installation.

• Before starting installation or routine or

special maintenance work, it is obligatory

to disconnect the appliance from the

electrical power supply.

• Before installing the appliance, check

that the systems are compliant with

indicated on the appliance serial plate.

• The installation area must be equipped

with all power supply and waste disposal

connections, and must be adequately

lit and meet all the hygiene and sanitary

requirements under current law.

46

•

which have not been expressly approved

and which do not comply with the

instructions in this manual could cause

damage, injury or death, and void the

warranty.

• Installation or maintenance that fails to

respect the indications in this manual may

cause damage, injury or death.

•

not involved with the installation may not

pass through or occupy the work space.

• The packaging material is potentially

dangerous. It must be kept out ofthe reach

of children and animals, and correctly

disposed of in compliance with local

regulations.

• The ratings plate provides essential

technical information that is of utmost

importance for any appliance maintenance

or repairs. Do not remove, damage or

modify the plate.

• The premises must meet the minimum

installation requirements set out by the

manufacturer.

• The appliance must be installed in

accordance with the methods and

requirements described in these

instructions, as well as the required

clearances.

• The installer must assess the installation

position of the appliance and associated

equipment to ensure that the various

components can be assembled and

disassembled easily and conveniently,

and ensure the necessary clearance and

access to the appliance for maintenance.

• Failure to follow these instructions may

cause damage, injury or death; voids the

warranty; and relieves the manufacturer of

all liability.

• The parts protected by the manufacturer

or one of its agents cannot be altered by

the installer.

• Install the appliance in areas:

• that meet the safety requirements laid

down in the regulations in force;

• with adequate ventilation. Make sure

that there is a continuous exchange

of air from outside to ensure proper

combustionandtopreventtheformation

of harmful volatile substances (danger

• Make sure:

• that the installation is carried out

bearing in mind the safety regulations

of the country of use;

• that the components used in the

installation that were not supplied by

the manufacturer comply with the

regulations in force in the country of use;

• that the ventilation openings (if present)

and the appliance drain (if present) are

not obstructed (e.g. by objects or walls).

• This sticker means “high voltage”

and identifies areas where there

are electrical hazards. Do not open

the compartments marked with this sym-

-

thorised by the manufacturer only. Failure

to observe this regulation invalidates the

warranty and may cause damage or injury

including death.

• Before making any replacements, activate

all envisaged safety devices and prevent

access to all devices that may cause a

hazard if activated.

• If worn components need replacing,

use only original spare parts. No liability

is accepted for damage to persons or

components resulting from the use of

non-original spare parts and work that

may alter safety requirements, without the

manufacturer’s authorisation.

• Theapplianceisdesignedtobepermanently

connected to the water mains (not using a

set of separable connectors).

• To connect directly to the mains, provide a

disconnect switch with omnipolar contact

separation so as to guarantee complete

disconnection in overvoltage category

III conditions, in accordance with the

installation regulations.

• If the power cable is damaged it must

be replaced by the manufacturer or their

authorised technical service or by a

any risk.

47

• The water supply to be connected to

the appliance must guarantee pressure

between 150kPA and 300kPA.

• Be careful when the oven door is opened

as hot steam may escape.

• Once the appliance has been

positioned, if any trays are more

sticker provided in the packaging must be

applied at that height.

PROTECTIVE EQUIPMENT (PPE)

• To prevent risks that may be generated

while installing the appliance, all operators

coming into contact with it must wear ap-

propriate personal protective equipment

(PPE), such as:

•

andfreeoflooseendsthatcouldbecome

entangled (if not already required by

the regulations for the environments in

which the appliance will be used);

• heat-resistant gloves;

• safety footwear (if not already required

by the regulations for the environments

in which the oven will be used);

• safety goggles.

Any unauthorised reproduction, even partial, of the contents of these instructions is expressly prohibited. These instructions, and

all attached documents, have been checked before sale. If errors or inaccuracies are found, please inform the manufacturer.

The manufacturer reserves the right to make changes to improve the appliances and accessories at any time without advance

notice. The measurements provided are approximate and not binding. In the event of disputes, this document was originally

written in Italian. The manufacturer is not responsible for any translation/interpretation errors.

48

SECTION INDEX

TECHNICAL DATA..................................................... 49

E6ST | E6MB..............................................................................................49

E10ST | E10MB..........................................................................................50

TECHNICAL AND ELECTRICAL DATA TABLE................................................51

CHECKING AND DISPOSING OF PACKAGING.... 52

DISPOSING OF PACKAGING .......................................................................52

CHECKING COMPONENTS..........................................................................52

TRANSPORTATION................................................... 53

GETTING STARTED .................................................. 54

REMOVING THE PROTECTIVE FILMS..........................................................54

REMOVING NON-COMPLIANT OBJECTS ....................................................54

INSTALLATION ROOM

................................................. 54

POSITIONING............................................................. 56

MINIMUM CLEARANCES ................................................

57

Appliance

installation

49

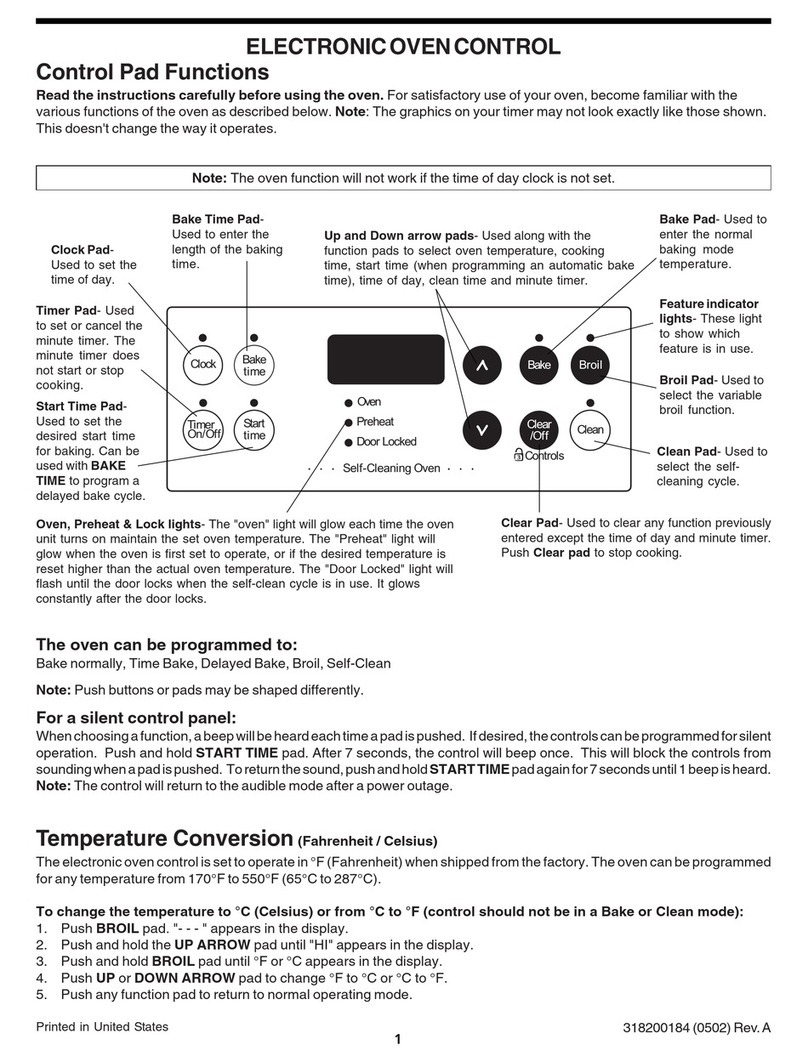

940 61

611

895

G

H

F

5575156

807

43 43

98 H20 OUT

184

807

205 600 133

238

102

168

162

E

D

B

C

A

56

260

Ø50 H2O

OUT

62

42

132

152

307

46

82

E6ST | E6MB

A Power supply 380-415V 3N 50/60Hz (or 220 240V3 50/60Hz)

C Detergent inlet

E Rinse aid inlet

F: Oven cavity steam discharge (steam outlet)

G: Cavity vent (inlet air)

H: Boiler wash charge

TECHNICAL DATA

50

82

56

260

Ø50 H2O

OUT

102

168

162

62

42

132

152

307

46

551031

56

807

43 43

611

895

205 600 133

238

98 H20 OUT

184

1087

940 61

FHG

A

B

C

D

E

E10ST | E10MB

A Power supply 380-415V 3N 50/60Hz (or 220-240V3 50/60Hz)

C Detergent inlet

E Rinse aid inlet

F: Oven cavity steam discharge (steam outlet)

G: Cavity vent (inlet air)

H: Boiler wash charge

51

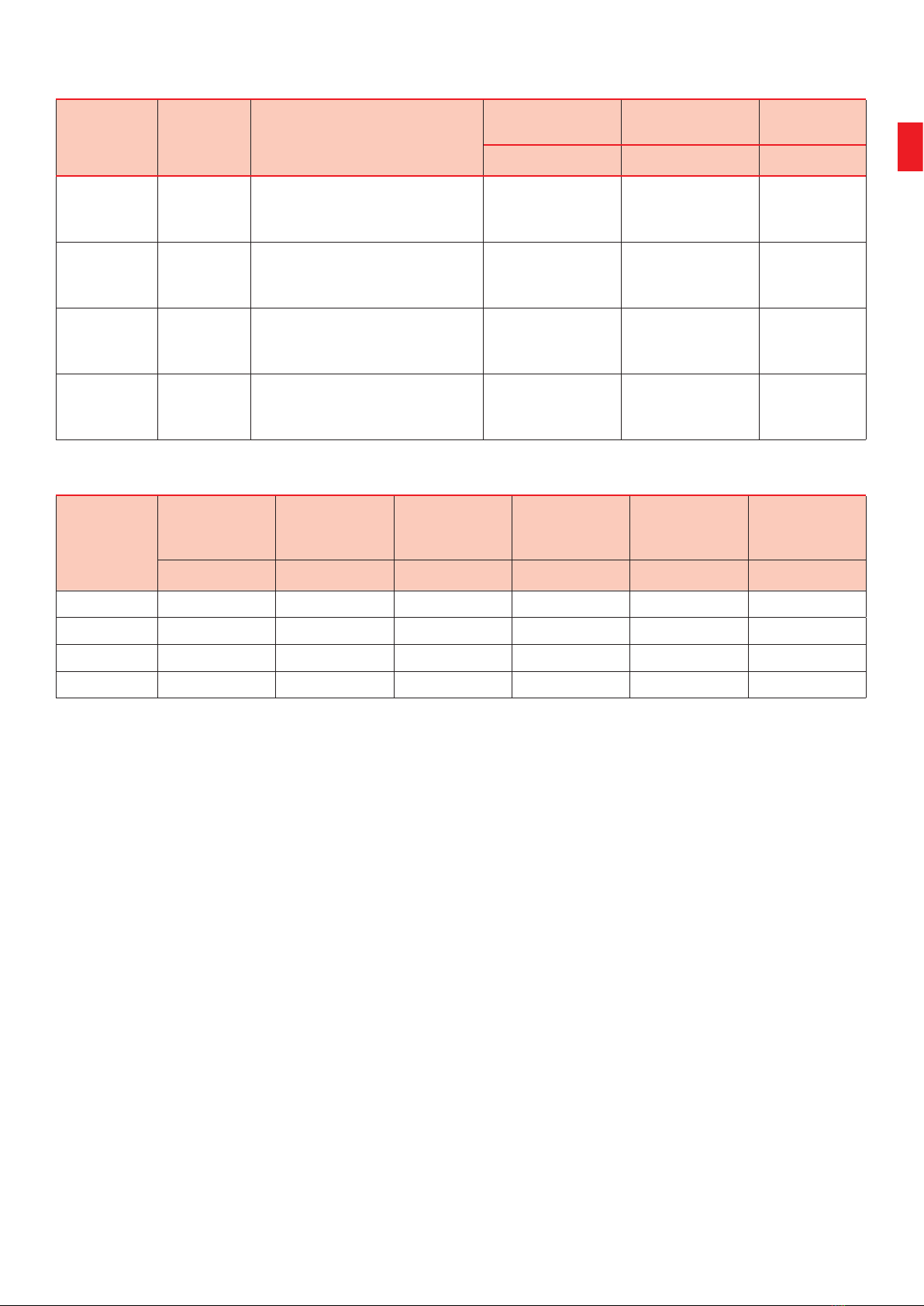

Model Berto’s

code Description Voltage Power cable

H07RN-F Frequency

[V] [mm²] [Hz]

E6MB 15040000

ELECTRIC OVEN 6 Trays

7” TOUCH controls

with BOILER and CLEANING

380-415V3N~

220-240V3~

5x2.5 mm²

4x4 mm² 50/60

E6ST 15080000

ELECTRIC OVEN 6 Trays

5” TOUCH controls

with CLEANING

380-415V3N~

220-240V3~

5x2.5 mm²

4x4 mm² 50/60

E10MB 15060000

ELECTRIC OVEN 10 Trays

7” TOUCH controls

with BOILER and CLEANING

380-415V3N~

220-240V3~

5x4 mm²

4x10 mm² 50/60

E10ST 15100000

ELECTRIC OVEN 10 Trays

5” TOUCH controls

with CLEANING

380-415V3N~

220-240V3~

5x4 mm²

4x10 mm² 50/60

Model

Installed

electric

power

Boiler cavity

power Width Depth Height Weight

[kW] [kW] [mm] [mm] [mm] [kg]

E6MB 10 9.6+9.0 895 940 (1000) 860 140

E6ST 10 9.6 895 940 (1000) 860 125

E10MB 18.5 18+9.0 895 940 (1000) 1140 160

E10ST 18.5 18 895 940 (1000) 1140 145

TECHNICAL AND ELECTRICAL DATA TABLE

52

1

2

01

PET

06

PS

PP+PET

CA

FOR

CA

CHECKING AND DISPOSING OF

PACKAGING

1

After unpacking and before moving the appliance to the

installation site, visually check it has not been damaged

during transport. If you notice any damage or anomalies,

do not proceed with the installation and promptly inform

the carrier or manufacturer.

Damaged appliances must not be returned to the

manufacturer without prior notice and without

having obtained prior written authorisation.

DISPOSING OF PACKAGING

area as it could hinder transport to the installation

site and cause a potential risk of entanglement and

must be properly disposed of according to the standards

in force in the country where the appliance is installed. If in

doubt, contact the local authorities for information on how

to dispose of it correctly.

2

below:

• Triple wall cardboard box: Recyclable | material: paper |

marking: PS06

• Pallet: Recyclable | material: wood | marking: FOR

• Polystyrene: Recyclable | material: polystyrene | marking:

PS06

• Cardboard corners and paper sheets: Recyclable | mate-

rial: paper | marking: PS06

• Straps: Non recyclable | material: Polypropylene (PP) and

Polyester (PET)

• Film: Recyclable | material: polyethylene terephthalate |

mark.: PET01

CHECKING COMPONENTS

The packaging must contain the following components

and/or accessories:

• countertop oven;

• instruction manual:

• declaration of conformity;

• warranty certificate.

Contact the manufacturer if anything is missing or

damaged.

generic packaging, depending on the model

visually check for damage

53

3

4

TRANSPORTATION

The appliance must be transported and lifted:

•in full compliance with laws on accident prevention

and the regulations in force and with the utmost care;

• by professionally enabled, authorised and trained per-

sonnel in good physical and mental condition;

•while using PPE (personal protective equipment

;

•while keeping the appliance vertical.

• after making sure there are no people or things in

the manoeuvring area that could get in the way;

• after making sure that the floor is perfectly smooth,

level, even, free of obstacles and not slippery.

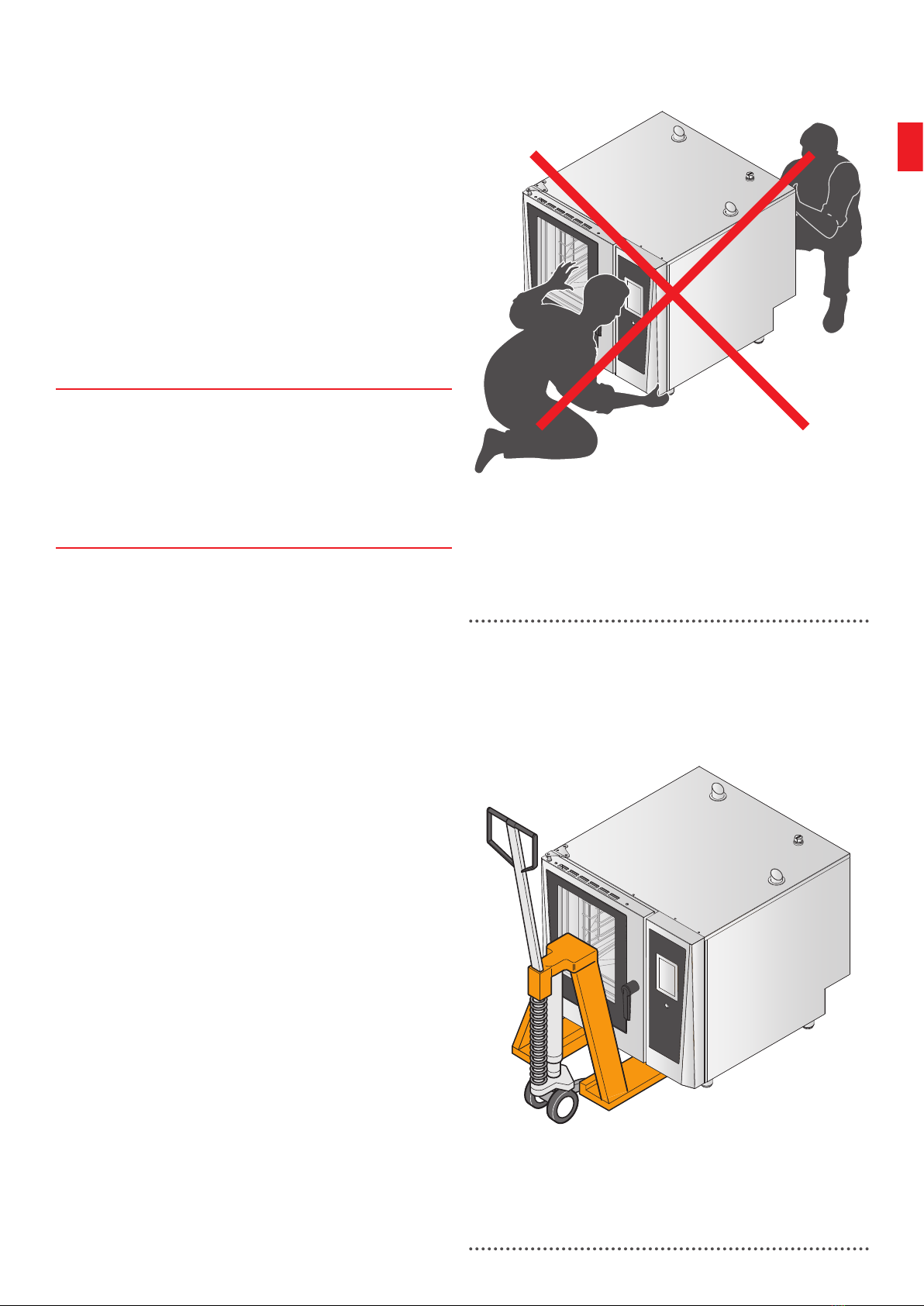

3

The appliances must NOT be moved manually, with

straps, or by dragging or pushing them.

The manufacturer shall not be held liable for any

inconvenience caused by transportation carried out in

any other conditions.

4

Insert the prongs at the front or rear using a pallet

jack suited to the weight of the appliance, taking care

not to damage its base.

Lift the appliance enough to move it easily and take

particular care to balance the weight as the centre of

gravity is not in the geometric centre of the appliance.

Take care with tilting during movements; always keep

the appliance vertical.

Lifting equipment (pallet jack, forklift, etc.) must be

suitable for the mass, dimensions and movements to

be carried out; when lifting any part, use a lifting device

with a load capacity at least 20% more than the weight

of the part to be transported.

use makeshift means to attach and lift parts of the

appliance.

these instructions.

incorrect oven transportation

correct oven transportation

54

5

6

Max 35°C/95°F

Min 5°C/41°F

Max 70%

GETTING STARTED

REMOVING THE PROTECTIVE FILMS

5

Clean any glue residue with an appropriate solvent

without using tools, abrasive detergents or acids that

could spoil the surfaces.

the reach of children and animals as they are potentially

dangerous. Dispose of them correctly in compliance with

local regulations.

REMOVING NON-COMPLIANT OBJECTS

Make sure that no non-compliant objects (e.g. bags,

manuals, etc.) are inside the oven cavity.

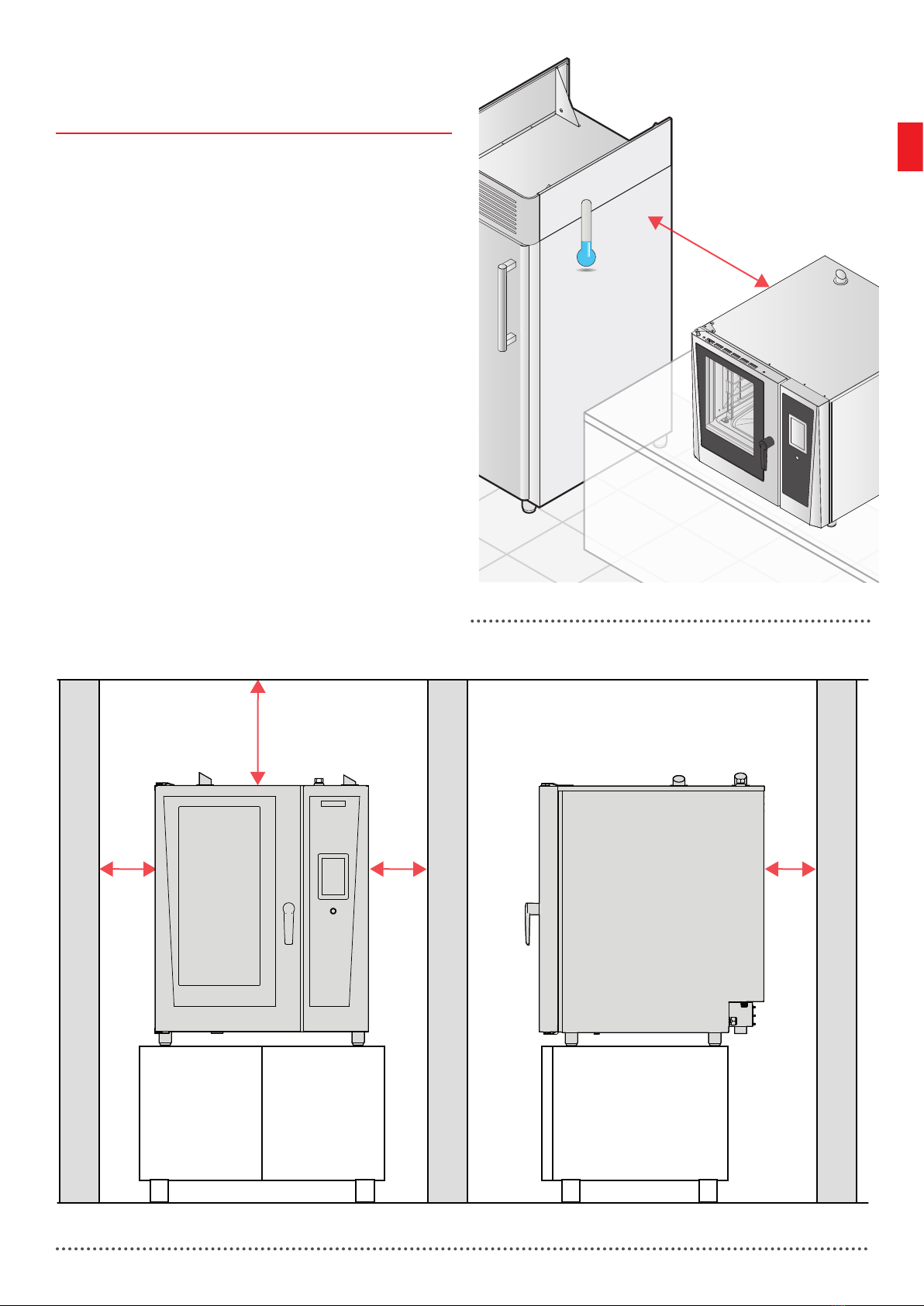

INSTALLATION ROOM

6

The appliance installation room must:

•have a smooth, perfectly level oor, which can with-

stand the weight of the appliance at full load.

•be sheltered from direct sunlight and the elements (e.g.

rain);

• be ventilated and have proper exchange of air: if

natural ventilation is not possible, forced ventilation may

be used.

•comply with the laws in force on system safety, work-

place safety and re prevention;

• not contain potentially explosive or ammable

materials or substances (e.g. gas cylinders, wooden

partitions, etc.) due to the risk of re and explosion;

• be designed solely for food storage;

• have a temperature between 5 °C and 35 °C;

• be equipped with all the necessary power supply (elec-

tricity, gas, water) and waste disposal connections (e.g.

evacuation of fumes);

• be adequately lit and meet all the hygiene and sanitary

requirements under current law.

installation room

getting started

55

The appliance must not be exposed to vibration, high frequency noise, dust or foreign materials, as such exposure

may cause deterioration or mechanical faults.

It must be easy to move the appliance for any extraordinary maintenance work. Make sure that any masonry work

after installation (e.g. building walls, replacing doors with narrower ones, renovations, etc.) does not obstruct

movement.

THE IMPORTANCE OF PROPER LEVELLING

The appliance is tted with feet that can be turned clockwise or anticlockwise to level it if the oor in the

installation room is not perfectly at.

Incorrect levelling may slow the ow in the drain circuit, resulting in limescale build-up or stagnation.

It may also lead to cooking fat being incorrectly distributed inside the trays with a risk of overow, which is

extremely dangerous during removal.

56

7

8 9

POSITIONING

7

The appliances must be placed solely on a

substructure provided by you or the manufacturer,

The structure must be:

• stable and perfectly level;

• unmoveable;

• heat resistant and not ammable;

• able to support the appliance weight at full load without

deforming or experiencing structural failure.

If using your own structure, for safety reasons we

recommend it not be too high, so that the top tray is

below a height of 160 cm. If this is not possible, the

sticker included in the packaging must be applied at a

height of 160 cm.

8

If using the manufacturer’s structure, fasten the oven to

it using the bracket provided.

9

After positioning the appliance, it must be levelled by

turning the support feet.

oven positioned on the manufacturer’s

substructure and tray tipping sticker

levelling the ovenfastening the oven to the substructure

57

10

11

5 cm

50 cm 50 cm

50 cm

70 cm

MINIMUM CLEARANCES

10

| 11

Position the appliance:

• so that you have easy access to electrical connections;

• approximately 70 cm from cold appliances (e.g. blast

chillers or refrigerators). If the indicated clearance can-

not be complied with, place an insulating reproof wall

between the two appliances that can withstand tem-

peratures of at least 150°C.

• leaving the clearances indicated in the gure from any

walls or other neutral appliances.

Always make sure that the chosen installation position

allows the door to be opened fully, and daily cleaning

and special maintenance (e.g. repairs) to be carried out.

Also check there are no curtains or other easily

(e.g. gas cylinders) near the appliance.

The appliance is not suitable for recessed

installation.

minimum clearances from other appliances

minimum clearances

58

SECTION INDEX

CONNECTIONS ......................................................... 59

SEE THE RATING PLATE..............................................................................59

ELECTRICAL CONNECTIONS.......................................................................60

PLUMBING CONNECTIONS.........................................................................62

INSTALLING DETERGENT AND RINSE AID TANKS.......................................63

EVACUATION OF FUMES........................................ 64

REPLACING PARTS ................................................. 64

FINAL INSPECTION.................................................. 65

ALARMS TABLE........................................................ 66

Connections and

inspections

59

E6MB

50/60

10

12

13

E6MB

21100/1234Z

E6MB

50/60

10

E6MB

21100/1234Z

E6MB

50/60

10

CONNECTIONS

All connections must be carried out by

qualied technicians authorised by the

manufacturer using personal protective equipment

(PPE) (e.g. gloves, safety footwear) in accordance

with the requirements and standards on systems

and workplace safety in force in the country of use:

failure to follow these instructions may cause damage

and injury, voids the warranty and relieves the

manufacturer of all liability.

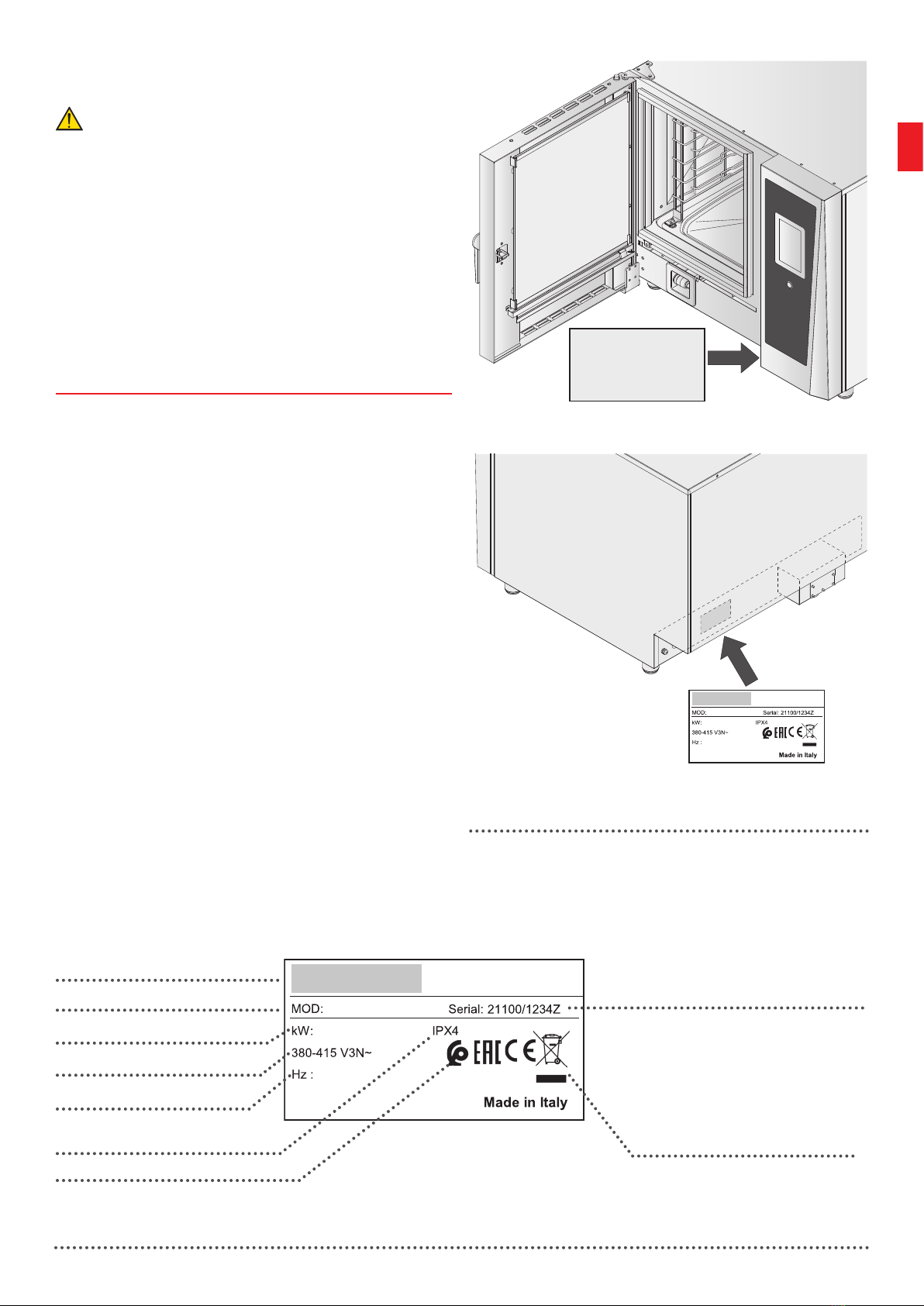

SEE THE RATING PLATE

12

| 13

Before making the connections, check the appliance

data to ensure it matches the system data; all data is

shown on the rating plate found on the back or inside

the door (in basic form).

The rating plate provides important technical

information. This information is essential in case of a

request for maintenance or repair to the appliance. Do

not remove, damage or modify it.

Manufacturer

Oven model Serial number | item number

The symbol indicates that the

product must not be disposed

of with other waste at the end

of its useful life, but must be

collected separately

Oven power

Power supply

Frequency

Protection rating

basic rating plate

full rating plate

reading the rating plate

position of rating plate

60

14

380-415V 3N 50/60Hz

220-240V3 50/60Hz

2

1

3

4

5

7

L3

N

L2

L1

6

ELECTRICAL CONNECTIONS

SAFETY PRECAUTIONS

• Before connecting, carefully read the safety warnings

at the beginning of this manual.

•Do not use adapters or multi sockets for the connec-

tion. Do not splice the power supply cable in any way.

•Do not coil the cable if it is too long and ensure it is not

kinked, pinched or blocking people’s transit.

• There must be an earth connection made using a

single, seamless cable, without interruptions (including

the circuit breaker). The yellow/green earth wire must be

at least 10 mm longer than the other wires.

CONNECTING TO THE ELECTRICITY MAINS

Appliances are supplied without a power supply

cable

a cable with a suitable cross-section and type to the

internal terminal board in accordance with that shown

in the wiring diagrams attached to the appliance. See

Technical and electrical data table page 51 for

information on the cable cross-section and type.

replaced solely by a qualied and authorised

technician. The cable can only be replaced by one with

the same characteristics (H07RN-F).

14

Connection procedure:

12open the right-hand panel;

3... 5loosen the cable gland and insert the power

cable;

6

7tighten the cable gland and close the oven’s

right-hand panel.

electrical power connection

This manual suits for next models

3

Table of contents