Best Tugs ALPHA A2 User manual

ALPHA

USER MANUAL

A2 and A3

Best Tugs

Because Your Pla ne Deserves It

252 West 3560 North

Spanish Fork, UT 84660

800.914.2003

INTRODUCTION

Best Aviation

Products

At Best Tugs™, we pride ourselves on building the most innovative

and advanced tugs in the world. We work diligently to ensure that

the quality and workmanship of your tug exceeds your expectations

and are confident that you will see the difference in every part of

your Best Tugs™experience.

We designed this guide to provide you the information needed to

make your experience even better… and while we are confident that

this guide will answer your questions, we are always here to chat

with you on the phone. You can reach us at 800-914-2003.

Thank you again for choosing Best Tugs™.

1

Please read these instructions

before beginning.

For any questions

call us at 800.914.2003

Tools Needed:

• Phillips Head

Screwdriver

(Drill/Impact is easiest)

• 7/16 Socket

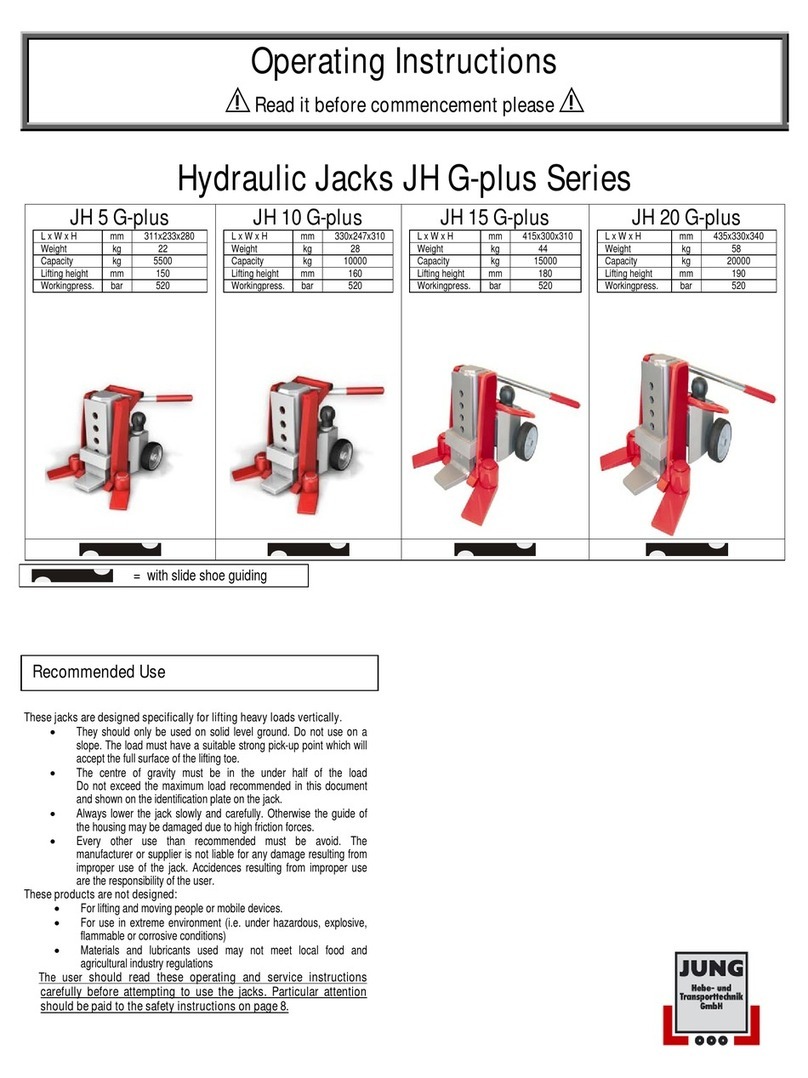

1. Start by removing the screws marked

with red paint from the lid marked

with red “1”. Remove the top lid from

the crate.

2. On side 4 (FIG 1) of the crate, cut the

two black retaining straps.

3. On the opposite end of the crate, the

required wall is marked with a red

“4” and stripes, remove the screws

securing the end wall to the crate.

Remove the end wall. (FIG 2)

4. In the crate, cut the band securing

the control arm.

5. Grab the tug’s handle and pivot the

tug up with the tug’s weight resting

on the tires.

6. Push the master switch to the “on”

position.

7. Left thumb pressure moves the tug

backward. Slowly increase pressure

on the throttle with your left thumb

and back your tug out of the crate.

FIG 2

33

11

22

44

FIG 1

UNCRATING INSTRUCTIONS

2

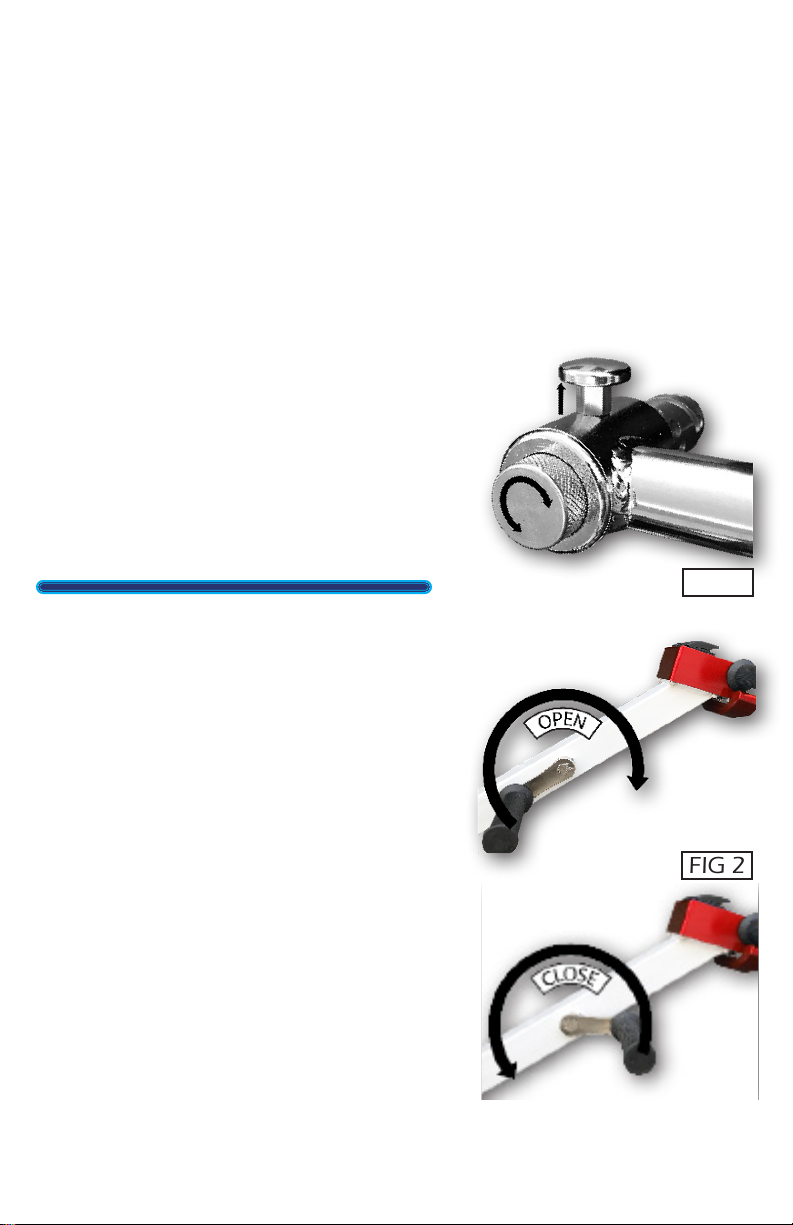

8. Once out of the crate, carefully

rotate your tug forward and rest the

aluminum base on the ground.

Be sure to place foam from the crate

or some other padding between the

aluminum base and the ground to

avoid scuffs. (FIG 3)

9. Remove the kickstand from inside of

the crate. With the provided 5/32

Allen wrench, screw the kickstand to

the back of the Alpha’s control arm.

10. Observing all safety precautions,

attach your Best Tugs™tug to your

aircraft.

11. Most importantly, enjoy your new

Best Tugs™ Tug!

Please Email cool pictures of

your tug and plane to sales@

besttugs.com. You may see

it on our website or social

media. (By sending images, you

expressly permit us to use these

images for marketing purposes.)

FIG 3

UNCRATING INSTRUCTIONS

Continued

Note: Foam filed tires have

a screw in the tire from the

factory. It is safe to remove the

screw.

3

WHAT’S IN THE CRATE?

Adapters may not be included depend-

ing on your plane type. If you have more

planes you’d like to move with your

tug, give us a call, and we can ship the

appropriate adapters out to you.

Quick Connect Pins - 3

Charger

AdaptersConnecting Arms

Items Depending on Aircraft

3

1

2

Storage slot when pivoting

4

1. POWER SWITCH

Turns tug on and

off. Do not leave tug

turned on for long

periods of time or while

charging to avoid

draining the batteries

2. LED LIGHT

Make sure this switch

is off while the tug is

charging.

3. HIGH / LOW (A3 only)

High will move your

plane at a higher

speed. Low is great

for safe movements

around your hangar.

4. OVER CENTER LOCK

The locking arm travels

in an arching motion.

When locking, make

sure the arm is fully

rotated down and

secured in place.

5. VARIABLE SPEED

THROTTLE

Right thumb pressure

moves tug forward,

left thumb pressure

moves tug backward.

6. DIGITAL READ OUT

Displays your tug’s

state of charge.

3

2

5

1

4

INITIAL USE

We strongly recommend using your tug without an aircraft attached to get used

to the controls and movements; this is a very user-friendly system, but it can take

a bit of practice to get familiar with it initially. Make sure you are comfortable

with the throttle, maneuverability, and functionality of the tug before moving

your plane.

CONTROL PANEL FUNCTIONS

6

5

First Time Set Up

Right Connecting Arm - Pull out Drop

Pin and spin the Slide out, so the open

end is as close as possible to the center

of the connecting arm. (FIG 1)

Left Connecting Arm - Repeat step

one process on left arm.

1. Rotate locking arm upwards to open

right connecting arm and move the

tug, position the Slides, so they are

close to the tow pin.

2. Close the arms. (FIG 2 & 3) Slides are

not expected to close on the tow pin

in this step.

3. Twist Slides until firmly attached to

the tow points. Correct set up should

leave very little to no slop on the

connection.

4. Wiggle tug slightly to confirm the

pins are firmly cupped and secured.

FIG 2

Drop PinDrop Pin

Please familiarize yourself with how long it takes for your plane to ramp up/down

and stop; that “coast” when slowing is due to the software that protects your

nose gear from unnecessary damage and stress. Take the time to get used to this

feature and be aware of it as you move your aircraft.

Check your plane’s POH to verify the maximum turn radius for your particular

nose gear. The tug can turn your plane at an angle that may exceed the nose

gear’s maximum turn radius. Best Tugs™ assumes no responsibility for any

damage caused by the tug operator misusing the equipment. As the operator,

you have the responsibility to be familiar with your tug, your plane, and their

specific limitations.

FIG 1

Check the plane’s surroundings, remove any

obstructions, verify that your path is clear, and

your propulsion systems (prop), wings, and tail

clear. Please verify that your wheel is secure on

the tug, including strapping it down. Finally,

remove the wheel chocks. You are ready to

move your plane.

Slide

6

Most users prefer their tug to pivot while

pulling their aircraft because it eliminates

the need to pick up and move the tug

when turning. The same feature that

makes pulling so incredibly easy can make

pushing your tug feel awkward at first; it

drives like backing up a trailer, meaning it

drives the opposite of where you turn.

Once you are used to the throttle, start/

stop speeds, and movements of the tug,

we strongly recommend you push/pull

your plane in an open area to familiarize

yourself with how your plane moves.

Pushing may take a few tries before you’re

comfortable, but once you find your

system, it is easy.

If you prefer to use your Best Tugs™ tug

with the pivoting base locked, place pin

3 back in the lock slot. Make sure the pin

seats as shown. (FIG 4)

Go to besttugs.com/pages/videos for

instructional videos and tips for moving

your plane.

1

Storage slot when pivoting

FIG 4

First Time Set Up

Continued

7

If anything everIf anything ever

looks wrong or likelooks wrong or like

it may damage yourit may damage your

aircraft,aircraft,

please call us.please call us.

800.914.2003800.914.2003

Loading Your Plane

Double check your plane to

make sure the tug is correctly

attached and the First Time Setup

instructions were followed.

1. Drive up to within one to two

feet of the airplane. Use locking

arm to open left connecting arm.

Turn power OFF and manually

push tug into position. We

strongly recommend following

this step in case you accidentally

bump the throttle while close to

your aircraft.

2. Position the tug with arms on

either side of the plane.

3. Insert the right arm into/onto tow

connection.

4. Use locking arm to close the left

connecting arm.

Moving Your Plane

Check the surroundings of the plane,

remove any obstructions, and verify you

have removed the wheel chocks. We

recommend slow and steady movements

when moving your plane. The right thumb

control moves the tug forward, and the left

thumb moves the tug backward. As you are

moving your plane, be sure your nose gear

can make the turns you are taking.

As the operator,

you are responsible

for knowing the

limitations of your

specific aircraft.

8

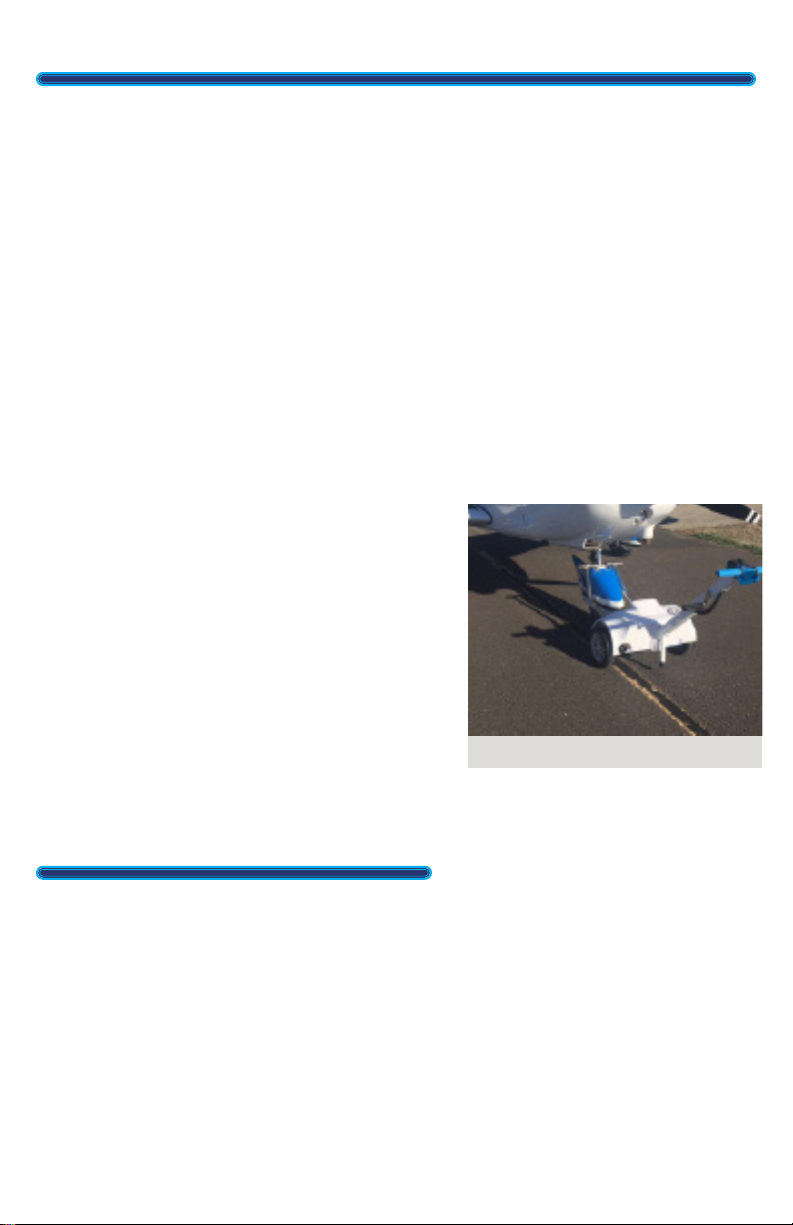

1. Chock the aircraft’s mains.

2. Make sure the tug is in line with

your plane.

3. Rotate locking arm upwards to

open the arms. (FIG 5)

4. Make sure the connecting arms

are going to easily clear your plane

as you pull the tug away from the

aircraft.

Switching Out Arms

1. Pull the detention pin holding the

connecting arm in place and slide

out connecting arm.

2. Insert new connecting arm,

reinsert pin.

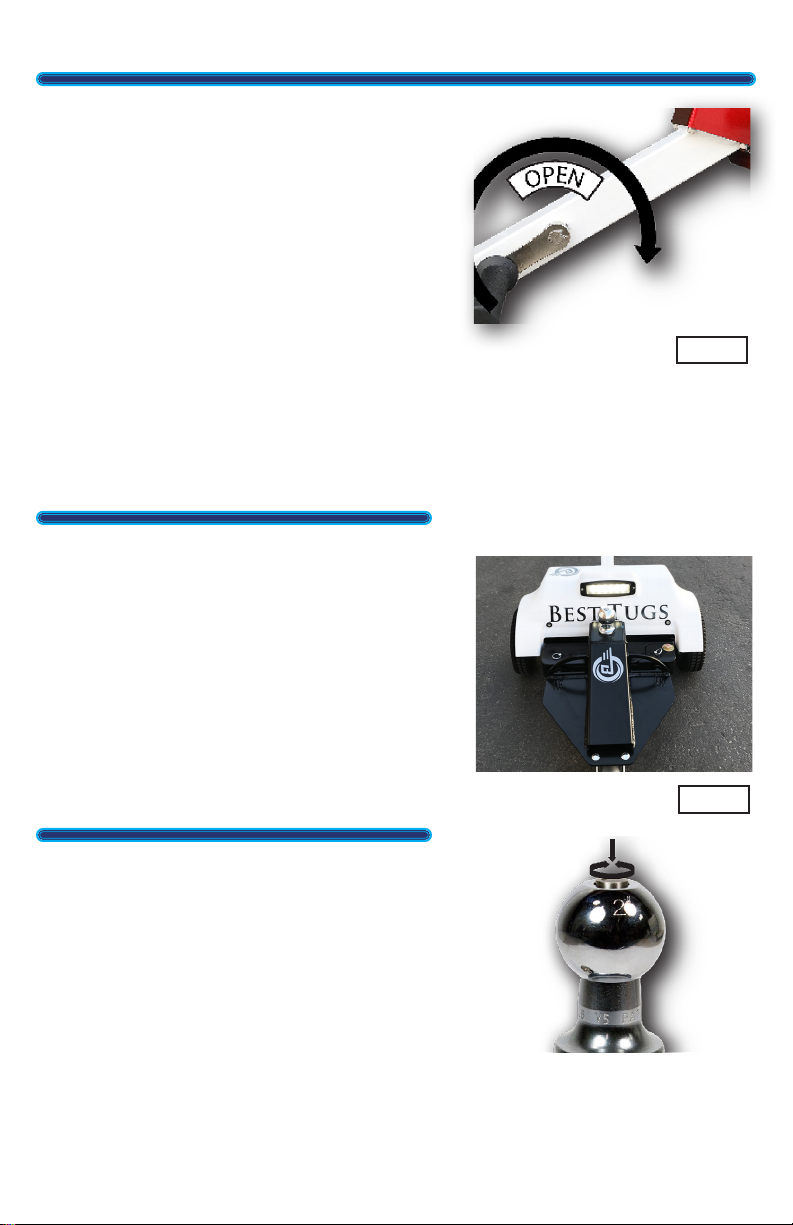

Attaching Trailer

Attachment (option)

1.

Remove both connecting arms with

accompanying pins from the tug.

2. IInsert trailer attachment

connections into connecting arm

slots. Insert pins to secure the

attachment in place. (FIG 6)

FIG 6

FIG 5

Unloading Your Plane

9

3. To change the ball size, push

down, and rotate the center of

the ball counter-clockwise (FIG

7), the center springs up, freeing

the ball. Put on the desired size,

push the center down, and

rotate clockwise to lock the ball

into place.

Storage

Store your tug in an area that is dry

and safe from the elements. Limited

exposure to rain and snow does

not affect the electrical systems.

However, we do not recommend

extended exposure.

If you do not plan on using your

tug for an extended time, leave

your tug plugged in, and our

smart charger can take care of the

battery. Always turn off your tug

and accessories.

Maintenance

Tighten the wheel lugs once

a quarter to 70 ft/lbs. The

recommended tire pressure for

inner tube equipped tires is 45

PSI. The caster wheel needs to

be re-greased every two years

for continuous use.

10

Battery Care

Your tug has a smart charger with trickle charge and battery maintenance cycles.

To charge, plug the charger cord into the tug, then the power cord into a standard

power outlet. You cannot overcharge when using the included charger.

Always turn off the master switch when charging.

We suggest charging your tug when the battery falls below around 70% (at rest)

for optimal battery life (for sure before 30% at rest). Note: The tug continuously

and instantaneously calculates the state of charge, which is why the percentage

fluctuates while moving your plane. We have seen as low as a 10% charge

displayed when using a fresh battery and moving a heavy plane. To read the

resting battery’s charge, leave the tug at rest for at least 60 seconds. We have seen

a 10% drop from freshly charged just by moving the tug in and out of the hanger.

The discharge rate is non-linear.

If you notice shorter times needed between charges, your batteries are beginning

to wear out.

Lead Acid batteries are surprisingly delicate—damaged by direct and indirect

effects: environmental, user induced, misapplication, and on and on. For instance,

charging with a voltage above 14.4 volts or allowing the battery to discharge

completely are the two most common ways to damage a lead-acid battery.

Even new batteries can be ruined in just a few weeks by being discharged too

much or left uncharged for too long; for this reason, Best Tugs cannot warranty the

batteries as we have no control over the end-users’ actions.

Modern microprocessor-based smart chargers use switching circuits; they

are lightweight and designed to protect themselves against reverse polarity

connection. They also have an annoying feature of not charging if the battery’s

voltage is below some arbitrary value. If you left the tug on and it no longer

charges, a cheap 12-volt car charger with a volt-meter is your best option to try and

restore the battery. Note: Most local battery/automotive stores carry replacement

batteries.

To recover the battery pack or diagnose their condition:

• Connect a twelve (12) Volt charger with a meter across the terminals of each

battery, one battery at a time.

• If you get a reading of zero (0) volts, a short circuit has occurred, replace the

battery.

• If your battery reads less than 10.5VDC when charging, then the battery has a

dead cell, replace the battery

• The battery charger indicates fully charged, but the voltage is below 12.4VDC?

The battery is sulfated, replace the battery soon.

Are all batteries fully Charged? The tug should be able to resume normal functions.

If not, call us.

11

Replacement Battery Specs.

12 Volt 18 Ah Sealed AGM Battery.

Acceptable brands include Duracell, UPG, Bright Way Group,

Panasonic, Interstate, and others.

(The previous are registered trademarks of the respective companies.)

Length: 7.17 in

Width: 3.03 in

Height: 6.57 in

Voltage: 12

Lead Acid Type: Deep Cycle

Capacity: 18ah

Chemistry: Lead Acid

Lead Acid Design: AGM

Product Category: Sealed Lead Acid

Product Subcategory: Deep Cycle

Terminal Type: M6 Nut and Bolt, NB, Nut, and Bolt.

Screw 3 Screw 4

FIG 8

Screw 2

Screw 1

To access the batteries,

take off the four (4) Allen

screws with a 5/32” wrench

which will release the cover.

(FIG 8)

12

Critical Cautions

Our tugs do not instantly stop. This feature is to protect your aircraft’s

landing gear. Failure to compensate for this soft stop can cause damage to

your aircraft. “Slowly” is the word to live by when you are in tight spaces or

loading the tug. We recommend practicing with the tug before using it on

your aircraft to allow familiarization with this soft stop feature. Exception:

E-Stop stops the tug NOW! An emergency stop can damage the landing

gear and damage the tug’s motor control module. The “E” in E-stop stands

for EMERGENCY.

Chock your mains! You don’t want to push your aircraft into the hanger

wall...

During operation, be aware of your surroundings. Never put your-

self between the tug and any object! A tug capable of pushing thousands

of pounds of aircraft can push you against an obstacle with thousands of

pounds of pressure. There is a risk of serious injury, death, or dismember-

ment. Proper operation is your responsibility.

Best Tugs™ tugs do not have secondary brakes. The motor/trans-

mission provides all braking. Your aircraft can roll freely if your transmission

fails. As the operator, it is your responsibility to keep your aircraft within safe

limits. Never move an aircraft on a slope or environment where the loss of

tug breaking would put you or your aircraft in danger.

Exceeding the parameters of the tug can cause future power train

failure. Best Tugs™ tugs load ratings are designed for hard flat and level

surfaces. Use on a slope drastically changes those parameters. The steep-

er the grade, the more energy it takes to move your plane—it is as if the

plane’s load parameter increased. The transmission’s gears have a superior

hardened surface; a one-time event that exceeds the tug’s parameters can

degrade that surface—eventually leading to total failure.

Rough surfaces, such as grass, can increase the rolling resistance of your

tires. The lower your tire pressure, the larger the tire’s contact patch, the

more extreme the tire deflection, resulting in more rolling resistance. It now

takes more energy to move the airplane—which is functionally equivalent (In

regards to the loaded weight charts) to the plane weighing more. Even a ten

percent under-inflation could cause your load to be over the limit—you have

just damaged the gears. Failure is now a matter of when—not if.

DC motors heat up from the inside out. If the casing is hot to your

13

touch, the internal components are probably red hot. The larger the aircraft,

the more energy it takes to move that load, causing heat buildup. Slopes and

rough terrain are like moving a larger aircraft causing more heat buildup.

Moving aircraft long distances also causes heat buildup. Excessive heat build-

up can damage the tug’s motor, drastically reducing the tugs life span. Best

Tugs™ tugs are designed for intermittent use. The larger the tug, with an

appropriately smaller than rated load, the longer a tug can be in continuous

usage. If you must move your aircraft a long-distance, slow down, or pause

now and then (See Loaded Weight Tables) to allow for heat dissipation.

Example 1: You have a tug you bought for your Cirrus SR22, and you do your

buddy a favor and move their King Air—you have just damaged the gears.

Failure is now a matter of when—not if.

Example 2: You used the same tug for your Cirrus SR22, and pulled it up a

3-degree slope—you have just damaged the gears. Failure is now a matter

of when—not if. It would be best if you had used a tug with a higher rating,

such as the commercial version. If you find that you have the wrong tug for

your plane’s environment, please call us and exchange it for the appropriate

model. We have a 30-day exchange policy; you only pay for the price differ-

ence and freight.

Did we mention that you need to chock your mains?

Critical Cautions

A2 Load & Duty Cycle

Degree 1,300 1,950 2,600

0.0 100 100 100

0.5 100 100 82

1.0 100 80 60

1.5 95 63 N/A

2.0 78 52 N/A

2.5 67 N/A N/A

3.0 58 N/A N/A

LOADED WEIGHT

A3 Load & Duty Cycle

Degree 1,800 2,700 3,600

0.0 100 100 100

0.5 100 100 78

1.0 100 76 57

1.5 90 60 N/A

2.0 75 N/A N/A

2.5 64 N/A N/A

3.0 55 N/A N/A

14

TROUBLESHOOTING

QUESTION SOLUTION

The tug was left

on and the

batteries are

dead

A cheap 12 volt battery charger (commonly found at

Walmart) can sometimes save the batteries. If recovery is

unsuccessful, replacement batteries can be purchased at

most battery/automotive stores in the U.S.

The master

switch is “on”

but the tug is not

moving.

There are two possible solutions.

1. The tug will turn off the computer after 20 minutes

of inactivity. To reset the computer, turn the tug’s

master switch off for three seconds and then back

on.

2. Make sure the red E-Stop is not pushed in. The tug

will not turn on unless E-Stop has been twisted out.

I started to move

my plane, but my

tug stopped, a

light is flashing.

See Error Code Translations on page 15 for details.

Optional Accessories

• LED Flood Lamp - A high Intensity LED light to assist in load-

ing and unloading your airplane. The control panel light switch

controls the action of the light when the main power switch is

on. Note: The main power must be on for the LED lamp to light

up.

• Extinguisher – Type BC. Class BC extinguishers handle both

Class B (flammable liquid) and Class C (energized electrical

equipment) threats. See the manual that comes with the extin-

guisher.

• Tundra Package – Better operation on grass fields. No user

interaction required. Proper air pressure must be maintained, or

the inner-tube could slip, ripping the valve stem out. Note: the

tires use a 3.00x4 inner-tube.

• Connecting Arms – options to connect the tug to various

airplanes. Call us at 1-800-914-2003 for more details

• Trailer Attachment - Call us at 1-800-914-2003 for more de-

tails

• Under Glow - LED accent lights. Depending on the selected

options, you have an on/off switch or remote control. Note:

Under-glow only functions when the tug is on.

15

Error Code Translations

Most codes are safely reset by turning the tug off, waiting five

seconds, then back on again. If system fails to reset please contact

Best Tugs™ at 800.914.2003 for assistance.

Blue LED Light off: System powered down after 20 minutes of no

use.

Blue LED Light on: Controller operational, no faults.

All codes have two parts. Count the sequence of flashes (*) to iden-

tify code.

Common codes are blue.

Flashes Meaning

1,1

* *

Aircraft Chocked or Brake Set

1,2

* **

Throttle Fault

1,3

* ***

Speed Limit Fault

1,4

* ****

Low Battery (Charge Required ASAP)

1,5

* *****

Over Voltage (Unplug tug before use)

2,1

** *

Main Contactor Driver Failed Open

2,3

** ***

Main Contactor Stuck, driver fail, or brake coil

2,4

** ****

Main Contactor Driver Failed Closed

3,1

*** *

HPD Fault

3,2

*** **

Brake on (Electromagnetic brake open or shorted)

3,3

*** ***

Pre-Charge Fault (Low Battery)

3,4

*** ****

Brake Off (Electromagnetic Brake open or shorted)

3,5

*** *****

HPD Fault (Throttle was engaged when tug was turned on)

4,1

**** *

Current Fault (controller failure, motor or wire failure)

4,2

**** **

Motor voltage (short in motor or wiring)

4,3

**** ***

EEPROM Failure

4,4 **** **** Power Section Fault

16

Warranty

Best Tugs™DOES NOT WARRANTY BATTERIES

Best Tugs™includes a one (1) year warranty on all parts, including

the drive train, from date of delivery. Warranty excludes labor and

the cost of shipping. Call sales if you want to purchase the optional

extended warranty.

This warranty does not apply to any Best Tugs™component(s)

that have damage caused by, misuse of the vehicle, accidents,

collision or object striking the vehicle, vandalism, fire, explosion,

water damage, customer-applied chemicals to painted surfaces,

improper handling or application, nor does it extend to Best Tugs™

parts which have been repaired or altered outside of Best Tugs™

provided maintenance of an authorized service representative.

Furthermore, any modification of Best Tugs™electrical system MUST

be pre-approved and documented in writing by Best Tugs™. Failure

to do so voids the unit’s electrical component warranty. Best Tugs™

parts which have been repaired or altered outside of Best Tugs™

provided maintenance of an authorized service representative as well

as any modification of a Best Tugs™tugs MUST be pre-approved and

documented in writing by Best Tugs™. Failure to do so voids the

warranty.

Exclusions may apply. Visit BestTugs.com for the full and overriding

Warranty. Exclusions may apply.

252 West 3560 North

Spanish Fork, UT 84660

Release Date: April 22, 2020

or call 1-800-914-2003

Sales Ext 2

Support Ext 3

Best Aviation

Products

This manual suits for next models

1

Table of contents

Other Best Tugs Jack manuals

Popular Jack manuals by other brands

AME

AME 14400 Instruction manual & parts breakdown

Tripp Lite

Tripp Lite Cat6 quick start guide

Power Fist

Power Fist 8879942 manual

Black Hawk Automotive

Black Hawk Automotive BH2128 Operating instructions & parts manual

Bend-Pak

Bend-Pak RJW Series Installation and operation manual

Metalworks

Metalworks 754752220 manual