SAFETY WORKING INSTRUCTIONS

1. Read instructions

Before the jack is used, these instructions must be read in their entirety by all

operating staff (i.e. all personnel who have received instructions to carry out the

liftingandtransportoperations).

2.Communicationand organisation

The communication between all operating stuff must be guaranteed, especially

when the visibility between each other is interrupted. One non-operating person

hastoberesponsibleforcontrolandclearadvicetoalloperatingpersonnel.

3. Danger Zone

The operatormust ensure thatotherpersonsshould remainatasafedistanceof

1.5 times the height of the load (i.e. clear of the danger zone). No unauthorised

personoranyonenotfamiliarwithitsoperationshouldattempttousethejack.

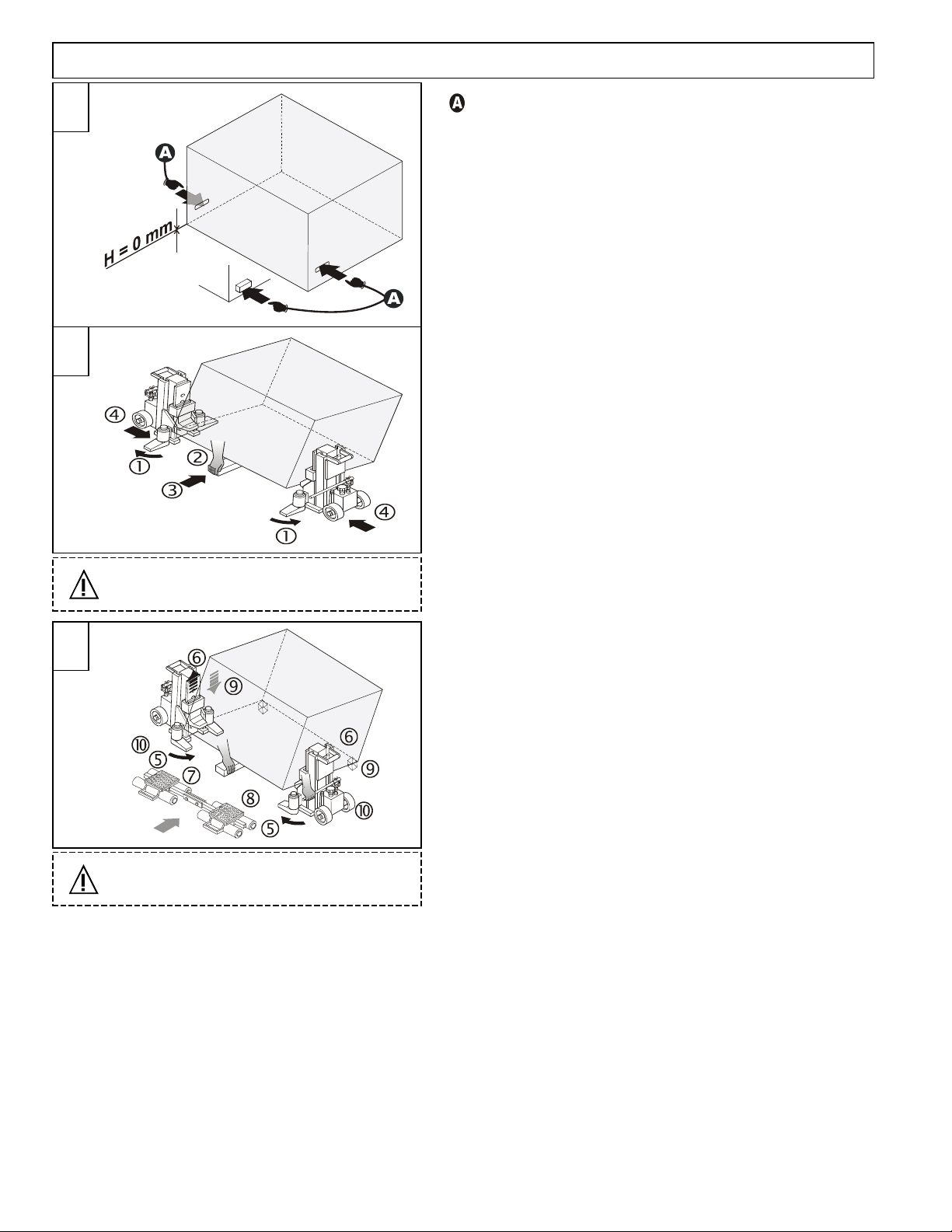

4.LoadandCentre ofgravity

The complete netweightandthepositionof the centre of gravity of theload have

tobefoundoutbeforeanyoperation.

Use of jacks and hydraulic pumps without knowing these facts is dangerous and

can be lead to damaged equipment and/or damage to the load and operating

personnel.

Thechoice ofanadequatejackcanbedonewiththisformula:

Minimumjackcapacity=(Loadweightinkg)x1. 25(securityfactor)

(I.e. load weight 4000 kg x 1.25 = 5000kg; the jack must have a minimum

capacityof5000kg.)

While using more than one jack with one load it is important that the jacks are

placed undertheload inpositionswhere itisguaranteedthatall ofthem will have

to lift the part of the weight. Therefore the part of the load plus security factor

must not exceed the capacity of the single jack. In order to place the jacks

correctly as requested it is absolutely necessary to know where the position of

thecentreofgravityislocated.

Lowering the jackswithout acentralpump the lowering speed hastobe slow and

absolutely synchronised on all jacks deployed. Forsecurity purposeuse of Jacks

withdifferentcapacitiesisn’tallowed.

5. Recommended use

These jacks are designed specifically for lifting heavy loads vertically. They

should be used on solid level ground only. Do not use on a slope or slippery

ground.

The loadmust be stable enough for lifting on a single pointand must not be tip

overwhile lifted.Thesurfacewherethejackwill beattachedmustbe suitablefor

lifting referring size, stability and non-slippery. Size means that there must be

enough room to lift up with the full surface of the lifting toe or top plate, only

partial connectionbetween the lifting surface ofjack and load is not enough.For

workingwith2ormorejacks werecommend theuse ofa centralpump whenthe

weight of the load:

1. exceedsthecapacityofonejackformorethen1.5x or

2. theheightofthe load exceedsthelengthof the sideoftheloadwhich is to

belifted.

While working with more than one jack the knowledge of the centre of gravity

determinesthepositionofthejacks. (See 4above“loadandcentreofgravity”).

Important: If the height of the load exceeds the length of the side being lifted

and/or the centre of gravity is located in the upper half of the load appropriate

precautionsmustbetakentopreventtheloadfromtipping.

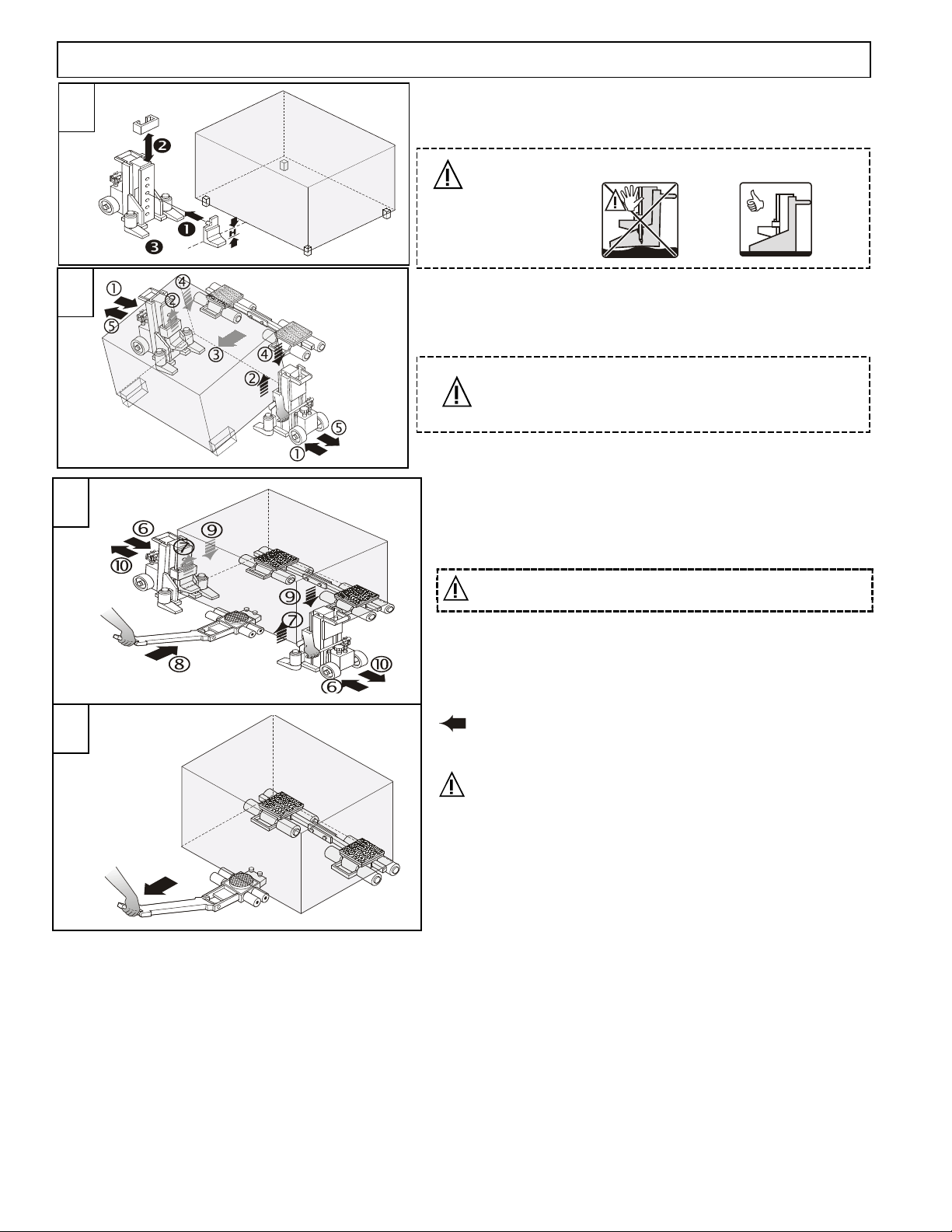

6. Liftingandlowering:

After preparing the a.m. steps the initial lifting should be done slowly and

carefully.Examine the load carefully after the first few mm of lift to ensure there is

no exceptional slipping or bending in the load. If this safety check is done, the

liftingoperationcanbecontinued.

Whenthejackisintheraisedpositionundertheload:

-No-one should attempt to work on or in the close vicinity of the load or

handleundertheload.

-The jack should not be left unattended when supported on the raised

jack.

-No unauthorised person oranyone notfamiliar with its operation should

attempttousethejack.

7. Liftingheight:

For security reasons the load has to be lifted and lowered step by step. Steps

causing more than 30 mmsofheight difference on one side have to be avoided.

Use suitable pads, i.e. hard wood or steel to secure the load when changing the

side. For your own safety do this when lifting tall loads with a high centre of

gravity.

PROTECTIVE EQUIPMENT

All members of operating personnel must wear safety footwear with steel

toecaps.

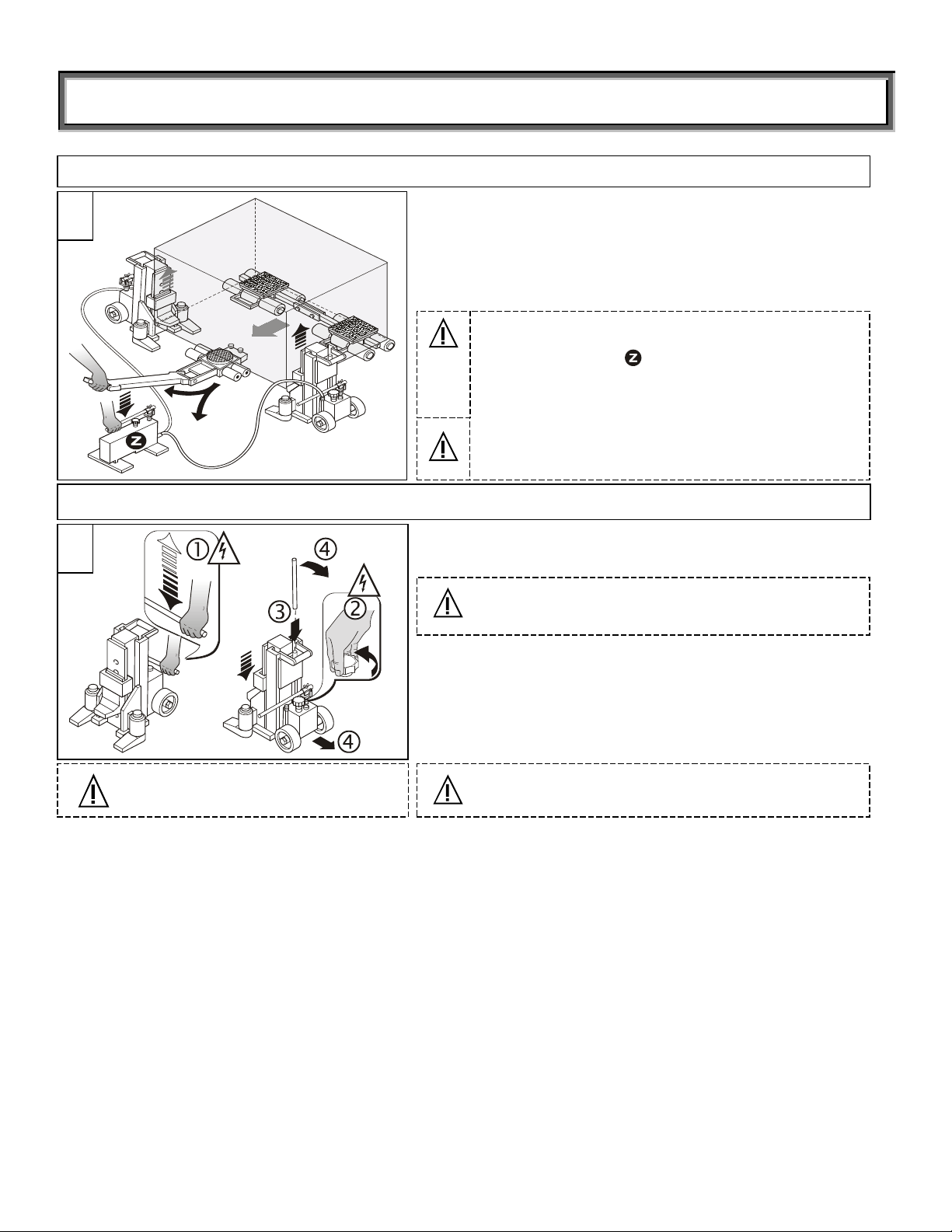

SAFETY MECHANISM

Each jack is fitted with a safety valve which restricts the permissible operating

pressure of its internal pump to 520 bar, thus limiting themaximum load to the

weightpermissibleforthedeviceinquestion.

WARNINGS

When working with 2 or more hydraulic jacks and 2 or more hydraulic pumps

on one load there is a danger that individual jacks could become overload and

damaged if lowering is performed unevenly. This could resultin the load being

dropped suddenly or tipped over, creating considerable risk of personal injury

totheoperatoraswellasriskingdamagetotheloadandanythingelse inwithin

the dangerzone.

It is of the utmost importance when working with a jack and while lowering the

load, that no part of the jack other than the lowering screw is touched. When

using single or multiple jacks neitherthe operator noranyone else shouldallow

any body part to enter the area beneath the load, beneath the lifting toe or

close to the jack body and slidingcolumn.When loweringthe load, the toe and

sliding column move in relation to the body of the jack and the floor, clothing

and operator’s body parts could be trapped and personal injury result if proper

caution is not exercised.

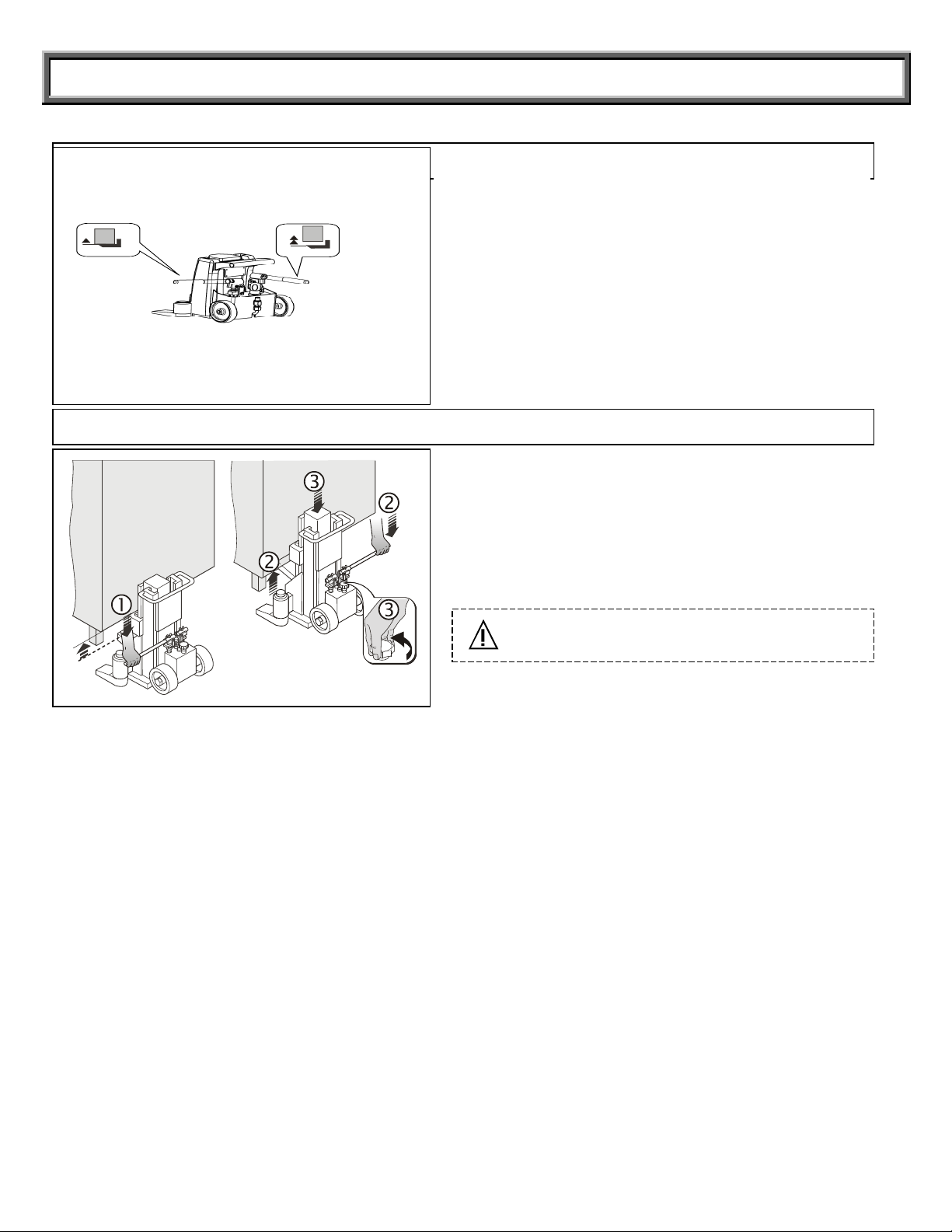

GENERAL SAFETY INSTRUCTIONS

Forsafeworkingitisnecessaryto knowthelocalgeneralsafetyregulationsof

your country. Furthermore you have to pay attention to the regulations

dependingtoyourbranchofindustry,operationalareaandoperationpurpose.

Jung-Equipmentisdesignedforuse underusualatmospherically conditions

andtemperaturesbetween-5° and 45° C.

AlloperationalpersonnelworkingwiththeJUNGequipment must beinstructed

regularlyinsafeworkingconditionsbyasecurityinstructororasafetyexpert.

Thismustbedonepersonallyastraining,deliveryofwritten regulationsor

manualsand/orannouncementonsignsisnotenough.

Beforeeachuseofthejackyoumustcheckthatitisingoodworkingcondition

andavalidinspectionbadgeisonthejack.

Ifthereisnobadgeorthe jackseemsobviouslydefective,i.e. deformationsor

cracksinthemainhousing,wearoroilleaksonmovingparts,the jacksshould

beinspectedbeforeuseandavalidcontrolbadgehastobeputon.