Best Tugs BRAVO 5 User manual

BRAVO

USER MANUAL

5, 8, 12, & 18

Best Tugs

Because Your Pla ne Deserves It

252 West 3560 North

Spanish Fork, UT 84660

800.914.2003

INTRODUCTION

At Best Tugs™, we pride ourselves on building the most innovative

and advanced tugs in the world. We work diligently to ensure that

the quality and workmanship of your tug exceeds your expectations

and are confident that you will see the difference in every part of

your Best Tugs™experience.

We designed this guide to provide you the information needed to

make your experience even better… and while we are confident that

this guide will answer your questions, we are always here to chat

with you on the phone. You can reach us at 800-914-2003.

Thank you again for choosing Best Tugs™.

Best Aviation

Products

1

Please read these instructions

before beginning.

For any questions

call us at 800.914.2003

Tools Needed:

• Phillips Head

Screwdriver

(Drill/Impact is easiest)

• 7/16 Socket

1. The lid is spray-painted with a red “1”.

Remove the screws marked with red

paint. Remove the top lid from the

crate.

2. The end panel is spray-painted with a

red “2”. Remove the screws marked

with paint. Remove the panel from

the crate.

3. Remove the plastic wrap from

around the Control Arm. Remove

the L-Handle Pin from the control

arm BEFORE lifting the control arm

(FIG 1). Rotate the Control Arm into

the lowest operating position (FIG

2). Insert L-Handle Pin until the pin

is visible from both sides. See page

8 for more instructions on adjusting

the Control Arm.

4. On the lateral sides of the crate,

marked with a red “3” - Remove the

screws marked with red paint. These

screws are in a 2x4 board, which is

holding the control arm and tires

in place. NOTE: Make sure to hold

the boards as you remove screws to

keep them from falling onto the tug’s

cover.

5. Cut the strap holding the cardboard

box in place. This box holds the

accessories for your tug. Remove the

box from the crate.

UNCRATING INSTRUCTIONS

FIG 1

11

22

33

FIG 2

Note: Foam filed tires

have a screw in the tire

from the factory. It is safe

to remove the screw.

2

6. Using the end of the crate, stack the

2x4’s (step 4) on top of each other, as

illustrated. (FIG 3)

7. Place the removed end wall with the ½”

plywood resting on the 2x4’s to create a

ramp. (FIG 4)

NOTE: The B5 comes with two (2)

2x4 boards in the crate, while the

B8 and B12 come with three (3). Use

the third 2x4 board to support the

ramp, as shown in FIG 4 for the more

substantial B8 and B12 models. The third

board is not necessary for B5. If you

have a painted floor, we recommend

performing this step outside of the

hangar to avoid any possible scuffs or

scratches.

8. Turn the tug on by rotating the red

E-Stop on the end of the control panel

clockwise and pushing the master

switch to the “on” position.

9. Set the direction to “PULL” and slowly

twist the throttle to drive your tug out

of the crate. See page 11 of your User

Manual for further instructions on how

to operate tug safely.

UNCRATING INSTRUCTIONS

Continued

FIG 3

FIG 4

Please Email cool pictures of

your tug and plane to sales@

besttugs.com. You may see it

on our website or social media.

(By sending images, you expressly

permit us to use these images for

marketing purposes.)

A couple notes:

The twisting and lock-

ing slides are attached

to the QLF. They are list-

ed for reference purpos-

es. Be sure to remove

the L-Handle Pin before

rotating the control

arm into the operating

position. The contents

in your crate may vary

from the illustrations.

First Use

If you are using an Easy Load or Lazy Susan

configuration: the tug comes from the factory

with the tire cradle in a loaded position. Unlock

the hook and then physically pull the locking

hook back to release the cradle before physically

moving the ramp to the loading position. Note:

Before each use, double-check your loading

tray. Repeat the step of manually lowering the

ramp if needed.

3

External Charger

WHAT’S IN THE CRATE?

Cup Adapters

Air Hose and Pressure Gauge

Jump Start Cords

Twisting Slide Locking Slide

Items Depending On Aircraft

or Options on Tug

Standard Items

L-Handle Pin

(in base of control arm)

Wheel Chock Kit

Carabiner, Axle Strap, RGA Pin

Quick Lock Fork (QLF)

4

CONTROL PANEL FUNCTIONS

1. Emergency Stop Switch

Rotate clockwise to power on,

push in to turn off. CAUTION! Do

not turn off while in motion, un-

less an emergency stop is needed,

this aggressively shuts down the

system and locks parking brake.

2. Master Switch

Turns tug on and off. NOTE: Tug

will not turn on if E-Stop is de-

pressed.

3. Multifunction

Note: this switch controls mutually

exclusive options; it has three func-

tions unless you only have the EZ

Load. The Lazy Susan is a rotatable

EZ Load.

EZ Load

(Two Position Switch)

Up/Load Locks the cage in the

load position. Down/Unload re-

leases the cage

The Lazy Susan

(Three-Position Switch) Rotate/Up

releases the Lazy Susan turntable

The EZ load cage is also locked.

Load allows locking the rotation

when the pin aligns and locks

the EZ Load. Unload/Down the

turntable is locked, and the cage is

released.

Heli/Trailer Lift/High Lift

(Two Position Switch) controls up/

down motion. Motion starts when

you push on the switch and stops

when you release the switch, or

the Lift has achieved max travel up

or down. Note: When using the

High Lift: do not move your plane

in the elevated position while

turning.

4. Battery Charge Status

Recharge your tug when power

indicates 70% (while tug is at rest.)

When charging, turn your tug off.

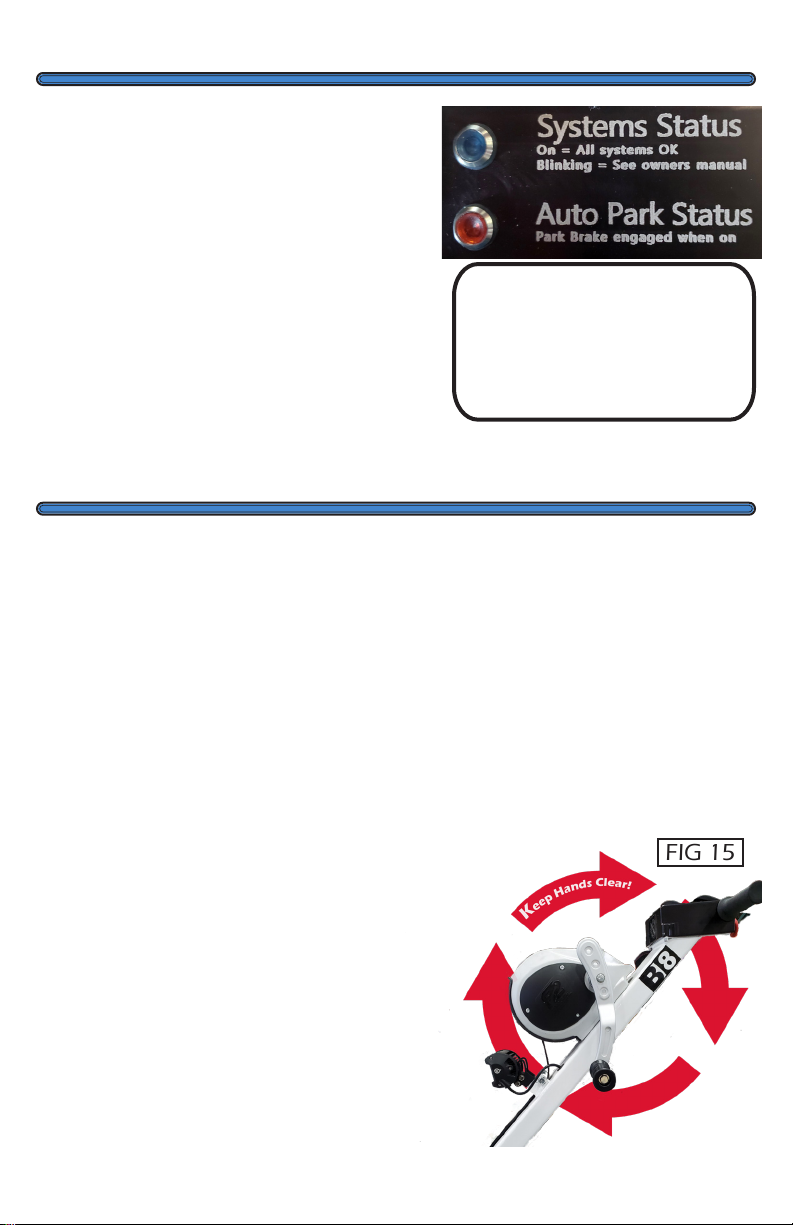

5. System Status Indicator

See Error Code Translations on

page 14 for flashing light transla-

tions.

6. Auto Park Indicator

The red light indicates that the

parking brake is set. The brake

engages when the tug comes to a

stop and remains “in-park” when

the system is powered down.

Note: Always use wheel chocks

7. Direction Control

Push/Pull

8. LED LIGHT (optional)

Make sure this switch is off while

the tug is charging.

9. Air Compressor (optional)

When hooking up the included

hose: Insert the air hose into the

fitting while pulling the sleeve on

the fitting away from the brass

elbow connection. Release the

fitting to lock air hose into place.

10. High/Low Setting

Use “HIGH” for maximum speed,

typically used for long-distance

movements. Use the “LOW” set-

ting when maneuvering in tight

or restrictive areas for better con-

trol and safety. No damage will

occur if the HIGH/LOW setting is

changed while in motion.

5

3

2

79

810

44

55

6

1

6

Please familiarize yourself with

how long it takes for your tug

to ramp up/down and stop;

the“coast” when slowing

is due to the software that

protects your nose gear from

unnecessary damage and

stress. Take the time to get used

to this feature and be aware of

it as you move your aircraft.

INITIAL USE

Adjusting the Control Arm

Your tug arrives fully assembled.

Before first use, set the control

arm to your preferred height. To

do this, be sure you have a good

hold on the control arm to make

sure it doesn’t fall onto the cover,

remove the L-Handle Pin at the

base of the control arm and

rotate the arm (FIG 5) until it is

at your preferred angle. (Most

users lower it to the bottom

position.)

Once you have decided on the

angle, line up the holes on the

base bracket with the holes on

the base of the control arm and

insert the L-Handle Pin until it is

visible from both sides. (FIG 6)

We strongly recommend using

your tug without an aircraft

attached to get used to the

controls and movements; this

is a very user-friendly system,

but it can take a bit of practice

to get familiar with initially.

Change the drive direction

(PUSH/PULL),

vary the speed by

slowly twisting the throttle as

you begin moving.

Make sure

you are comfortable with the

throttle, maneuverability, and

functionality of the tug before

moving your plane.

FIG 5

FIG 6

7

EZ Load/ Lasy Susan

The Cage on the Ez Load/Lazy

Susan needs to be adjusted to fit

your specific tire. After you load

your plane, adjust the width by

adjusting the two sliders on the

bottom of the Cage so that they

are close to the tire’s sidewalls.

Remove the pins and adjust the

sliders to the nearest hole, then

put the pins back in.

The size of the wheel that can be

loaded can be adjusted. Remove

the thumbscrews and adjust the

Cage so that it fits closely to your

tire diameter. We designed the

Cage to resist letting your tire

pop out of the Cage. If you have

not adjusted this feature, a tire

could pop out of a loosely fitted

Cage.

Warnings

Check the plane’s surroundings,

remove any obstructions, verify

that your path is clear, and

your propulsion systems (prop),

wings, and tail, clears. Please

verify that your wheel is secure

on the tug, including strapping

it down. Finally, remove the

wheel chocks. You are ready

to move your plane. Check

your plane’s POH to verify the

maximum turn radius for your

particular nose gear. The tug

can turn your plane at an angle

that may exceed the nose gear’s

maximum turn radius. Best

Tugs™assumes no responsibility

for any damage caused by

the tug operator misusing the

equipment. As the operator,

you have the responsibility

to be familiar with your tug,

your plane, and their specific

limitations.

Note: E-Stop means

EMERGENCY STOP. Not

power off, not stop my tug

from moving—It means Stop

now—I don’t care if my tug and

my plane’s landing gear are

damaged, because my plane

going through the hanger wall,

or trapping your body against

the hanger wall, is much more

expensive to repair.

When you shut down the tug

with the E-Stop, all that energy

in the motor controller has to

go somewhere, and it does—

destroying the controller over

time.

INITIAL USE

Continued

8

FIG 9

FIG 7

FIG 8

First Time Set Up (QLF/Wheel Chock Kit)

NOTE: Quick Lock Fork and Wheel Chock Kit

ARE NOT USED TOGETHER

Setting Up the Quick Lock Fork

If equipped with the standard ramp

TIP: It is easier to set up your QLF

if you give yourself plenty of slack in the strap.

1. Right Fork - Push the spring-loaded locking

slide on the right fork of the QLF to the left

until it locks into place. It is locked when the

slide does not return to the open position

on its own. (FIG 7) To release the slide, lift

the drop pin and allow it to return to its

original position.

2. Place the QLF over/in the nose gear

connection.

3. Left Fork - Lift the drop pin on the left fork

and rotate the slide until it fits firmly against

the nose gear. (FIG 8) The less slop and

wiggle, the better. Once the slide is fitting

snugly, release the drop pin and continue

twisting until it falls into place to lock the

slide. See FIG 10 and FIG 11.

Setting Up Wheel Chock

The wheel chock drops into the loading

tray between the two brackets. Line up

the holes on the RGA with the bracket

holes in the loading tray and insert the

pin. Make sure both ends of the pin are

visible and fully inserted. (FIG 12)

9

Pin Improperly Set

FIG 10

First Time Set Up (QLF/Wheel Chock Kit)

Continued

Switching from

Wheel Chock to QLF

Pull the long pin and remove the wheel

chock from the loading tray and take the

carabiner off the tow strap. Take the winch

strap in one hand and the QLF in the other.

Take the QLF pin out of its hole by pushing

the springing wedge down and removing

the pin. Slip the winch strap onto the pin

and push the pin to the original position.

(FIG 9) Line the strap loop up with the QLF

pin holes then push the pin back

through the strap and QLF holes. Ensure

the spring wedge holds the pin in place.

Now that your wheel chock is set up for

your specific plane, you are ready to winch

it into place and move your aircraft.

DO NOT USE QUICK LOCK FORK

AND THE WHEEL CHOCK KIT

AT THE SAME TIME

Pin Properly Set

FIG 11

FIG 12

See BestTugs.com for instructional videos on loading.

10

STRAP INSTRAP IN

STRAP INSTRAP IN

STRAP OUTSTRAP OUT

STRAP OUTSTRAP OUT

B5 Winch

FIG 13

Loading Your Plane (Standard Ramp)

STRAP INSTRAP IN

STRAP INSTRAP IN

STRAP OUTSTRAP OUT

STRAP OUTSTRAP OUT

B9 / B12 Winch

FIG 14

Note: If you are comfort-

able with your throttle,

you can choose to winch

the plane onto the tug

while very slowly driving

the tug forward, which

makes winching easier.

Keep wheels chocked if

you decide to use this

method.

Double-check your attachments to

make sure they are correctly attached,

and the setup steps followed.

1. Chock aircraft mains. Position tug

with nose wheel centered on the

ramp. Until you are comfortable

with the tug’s operation, turn the

tug off for the safest loading.

2. Put the winch in neutral/reverse

and pull enough slack in the strap

to attach QLF for wheel pant

planes or axle strap for retractable

gear aircraft.

3. Before you begin winching, flip

the switch (FIG 13) on the B5

winch to the forward position

(counter-clockwise (FIG 14) for B8

and B12-18) and winch the plane

onto tug’s loading tray.

11

Check the surroundings of the

plane, remove any obstructions,

including the wheel chocks.

Make sure the tug is in proper

mode (PUSH/PULL) then twist

the throttle to start moving.

Make sure you familiarize

yourself with how long it takes

for your plane to ramp up/down

and stop.

When slowing, the “coast”

is due to the software that

protects your nose gear from

unnecessary damage and stress.

(Note: E-Stop overrides the soft

auto-stop feature. You could

damage your plane and or tug)

Take the time to get used to the

soft auto stop feature and be

aware of it when moving your

aircraft.

We strongly recommend

moving your tug without aircraft

attached to get used to the

controls and movements. As you

are moving your plane, be sure

your nose gear can handle the

turns you are taking.

As the operator, you are

responsible for knowing the

limitations of your specific

aircraft.

Moving Your Plane

12

Parking

Unloading Your Plane (Standard Ramp)

Your tug has an automatic parking

brake that engages when you stop

your tug. A red light on the control

panel lights up to show the brake

has been appropriately set. When

you are ready to move, rotate the

throttle, and the brake disengages

automatically. NOTE: Tug’s parking

brake acts as a secondary brake,

always use wheel chocks to park

your aircraft safely.

If anything ever looksIf anything ever looks

wrong or like it maywrong or like it may

damage your aircraft,damage your aircraft,

please call us.please call us.

800.914.2003800.914.2003

Make sure the tug is in line with

the plane. Chock the aircraft

mains.

Crank the winch handle slightly

to release stress on winch direc-

tion selector; switch to unload/

neutral.

Select “PULL” on the control pan-

el and slowly drive tug

away from aircraft.

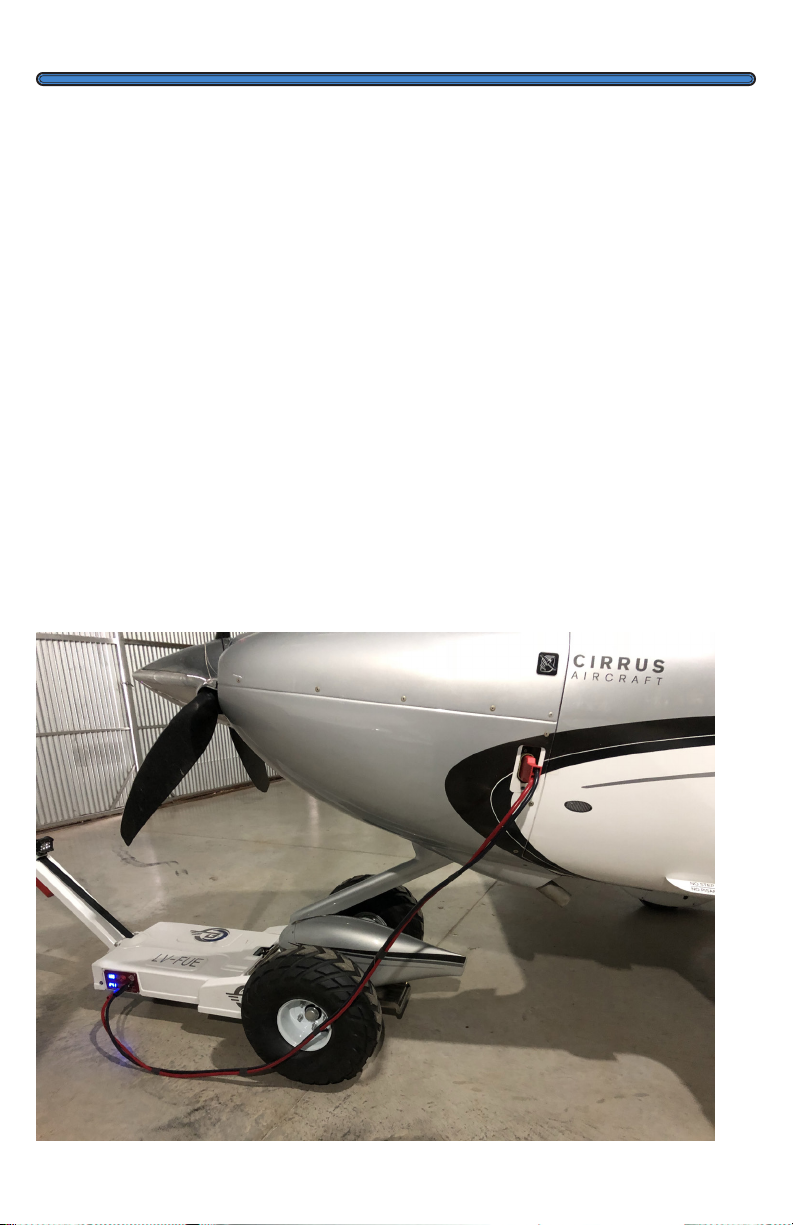

CAUTION

The winch handle rotates quickly

as your plane unloads from the

tug, keep hands clear (FIG 15)

Leave the slack left from unloading

the plane unspooled; this leaves

the attachment/strap ready to be

attached for your next flight.

FIG 15

Always use wheel

chocks when loading

and unloading your

plane.

13

Lazy Susan/EZ Load Operation

Your Cage can and should be

adjusted to more tightly fit your

wheel. Both the diameter (thumb-

screws) and width (slider) can be

adjusted. See Initial Use on page 7

for set up instructions.

If you have a Lazy Susan, lock the

rotation before loading or unload-

ing. Locked, the Lazy Susan now

behaves as an EZ Load. Be sure

your tug and aircraft are in line

with each other before loading/

unloading to avoid damage to your

tug/aircraft.

To lock the Lazy Susan so it cannot

rotate, engage the locking mecha-

nism by selecting Load or Unload/

Down, depending on what you

are going to do, and line up the

plane and tug until the locking

mechanism engages. You can not

unload a plane until the Lazy Susan

is aligned AND locked. To allow the

Lazy Susan to rotate—push Rotate/

UP, to disengage the locking mech-

anism.

In the Unload/Down switch posi-

tion (hold the silver button down

on older models), the EZ load

locking device releases when the

weight of the plane’s wheel shifts

from contacting the ramp and

presses against the back of the

Cage. Note: this is a safety feature

to prevent the tug from releasing

while you are pulling your tug.

Loading:

Make sure the ramp is down. If it

is not in the down position, select

Unload/Down and manually lower

the ramp. Drive the tug under your

wheel. When your plane is loaded

correctly, the ramp automatically

locks into the upright and locked

position.

Unloading:

Select Unload/Down on the rocker

switch (silver button on older mod-

els) to allow your plane to unload.

Carefully move the tug towards the

chocked aircraft; this causes the

nose wheel to contact the back of

the Cage, relieving pressure from

the ramp and disengages the lock-

ing device. Then as you pull away

from the plane, the tire pushes the

ramp open.

An advanced maneuver is; while

moving the plane towards you,

press the Unlock on the rocker

switch (silver button on older mod-

els) to allow the locking device to

release when the ramp pressure is

removed, then reverse the throttle.

The tug’s autothrottle allows the

plane to continue to move towards

you for a moment during the

autothrottle’s slow-down/reverse.

That lets your plane press against

the back of the Cage, removing the

pressure against the locking device,

and then you can pull the tug from

under your wheel.

14

Power Options

JumpStart: Provides High

cold-cranking amps to assist in

starting your engine (12 Vdc and 24

Vdc). This option uses power from

your tug’s batteries to assist your

aircraft’s batteries when starting

your plane. Note: Even when the

tug is off, the JumpStart panel is

live! (Although the readouts won’t

show until the tug is on.)

GPU: The Ground Power Unit is

used to power your avionics and

other lower power demand systems

in your aircraft from the standard

110 Vac wall connection. You have

28.5 Vdc at 25/50 Amps. Note: Do

not use the GPU to power air condi-

tioning or pitot tubes. Warning: bat-

tery damage is possible—the GPU

should not be used to charge either

the tugs or the aircraft’s batteries!

JumpStart + Boost: Press the

silver button to the right of the

JumpStart JumpStart panel, and the

tug gives you thirty minutes (from

the time you pushed the button.)

with over 28 Volts from the GPU

and all those amps from the batter-

ies providing power to the plane.

The disadvantage of using only the

JumpStart option is that you are us-

ing the tugs batteries that discharge

with time, and some planes require

over 28 Volts before they can rec-

ognize the external power source.

With the JumpStart plus Boost, you

can combine both sources of power

for an excellent source of current

at the correct voltage to start your

plane.

GPU PANEL

W/ EXPOSED 110 VAC PORT

JumpStart Panel

JumpStart Panel

w/Silver Boost Button

Plug the cable into your plane

first! Which service your plane

gets depends on which pow-

er panel you insert the cable.

See page 16

15

Tighten the wheel lugs once

a quarter to 70 ft/lbs. The

recommended tire pressure for inner

tube equipped tires is 45 PSI. The

caster wheel needs to be re-greased

every two years for continuous use.

Tighten chains every 12 months for

safe operation. To tighten chains,

remove the six (6) screws around

the perimeter of the cover, loosen

five (5) bolts on the motor mount.

Using a pry bar, tighten the chains by

pushing against the axle until there

is little to no slack in the chains, while

keeping chain tension, re-tighten

bolts. If you have any questions about

this process, give us a call.

Winch straps (on tugs equipped with

winches): Before each use, check

straps for damage or loose stitching.

If the strap is damaged, replace it

before use. Replace your winch straps

annually; there is cumulative UV

and oxidation damage that can be

invisible to the eye.

Best Tugs™ will replace your strap

once a year for free—as long as you

own your tug. Just pay shipping and

handling. Call sales at 800.914.2003

to order; exclusions

apply.

The Lazy Susan option needs to

have the central bolt tightened and

moving parts lube with lightweight

oil annually. It is found under the

Romeo and centered under the

Lazy Susan. Failure to maintain this

may cause the failure of the bearing

ring. Loosen the locking nut and

tighten the central nut until tight,

but not so tight that the Lazy Susan

cannot rotate. Re-tighten the locking

nut after you have completed the

adjustments.

If the Lazy Susan’s locking

mechanism fails to engage,

disconnect the wires (unplug the

pins) of the solenoid (Left side

when looking from the ramp side

and golden in color) and twist

counterclockwise to remove. On

older models, manually align the

Lazy Susan until you find the only

opening. Clean the opening below

of oils and debris. Replace the

solenoid and re-plug in the wires.

Store your tug in an area that is

dry and safe from the elements.

Electrical systems are not affected

by limited exposure to rain and

snow. We do not recommend

extended exposure.

If you do not plan on using your

tug for an extended period, leave

your tug plugged in so the smart

charger can take care of the

battery.

Always turn off your tug and

accessories.

Storage

Maintenance

16

Battery Care

Your tug has a smart charger

with trickle charge and battery

maintenance cycles. To charge,

plug the charger cord into the

tug, then the power cord into

a standard power outlet. You

cannot overcharge when using

the included charger.

Always turn off the master

switch when charging.

We suggest charging your tug

when the battery falls below

around 70% (at rest) for optimal

battery life (for sure before 30% at

rest). Note: The tug continuously

and instantaneously calculates

the state of charge, which is why

the percentage fluctuates while

moving your plane. We have seen

as low as a 10% charge displayed

when using a fresh battery and

moving a heavy plane. To read

the resting battery’s charge,

leave the tug at rest for at least

60 seconds. We have seen a 10%

drop from freshly charged just by

moving the tug in and out of the

hanger. The discharge rate is non-

linear.

If you notice shorter times needed

between charges, your batteries

are beginning to wear out.

Lead Acid batteries are

surprisingly delicate—damaged

by direct and indirect effects:

environmental, user induced,

misapplication, and on and on.

For instance, charging with

a voltage above 14.4 volts or

17

12 Volt 35 AH Sealed AGM Battery.

Battery Care

Continued

Acceptable brands include Duracell, UPG, Bright Way Group, Panasonic,

Interstate, and others. (The previous are registered trademarks of the respective companies.)

Length: 7.68 in

Width: 5.12 in

Height: 7.09 in

Volt age: 12

Lead Acid Type: Deep Cycle

Capacity: 35AH

Chemistry: Lead Acid

Lead Acid Design: AGM

Product Category: Sealed Lead Acid

Product Subcategory: Deep Cycle

Terminal Type: J

allowing the battery to discharge

completely are the two most

common ways to damage a lead-

acid battery.

Even new batteries can be

ruined in just a few weeks by

being discharged too much or

left uncharged for too long; for

this reason, Best Tugs cannot

warranty the batteries as we have

no control over the end-users’

actions.

Modern microprocessor-based

smart chargers use switching

circuits; they are lightweight and

designed to protect themselves

against reverse polarity

connection. They also have an

annoying feature of not charging

if the battery’s voltage is below

some arbitrary value.

If you left the tug on and it no

longer charges, a cheap 12-volt

car charger with a volt-meter is

your best option to try and restore

the battery. Note: Most local

battery/automotive stores carry

replacement batteries.

To recover the battery pack or

diagnose their condition:

• Connect a twelve (12) Volt

charger with a meter across

the terminals of each battery,

one battery at a time.

• If you get a reading of zero

(0) volts, a short circuit has

occurred, replace the battery.

• If your battery reads less than

10.5VDC when charging, then

the battery has a dead cell,

replace the battery

• The battery charger indicates

fully charged, but the voltage

is below 12.4VDC? The battery

is sulfated, replace the battery

soon.

Are all batteries fully Charged?

The tug should be able to resume

normal functions. If not, call us.

This manual suits for next models

3

Table of contents

Other Best Tugs Jack manuals