Beta Marine Beta 10 User manual

CALIFORNIA – Proposition 65 Warning: Diesel engine exhaust and some of its constituents are known

to the state of California to cause cancer, birth defects and other reproductive harm.

Operator’s

Maintenance

Manual

Operator’s

Maintenance

Manual

Heat Exchanger

& Keel Cooled

Small Diesel Engine Range: Beta 10,

Beta 14, Beta 16, Beta 20 & Beta 25

Heat Exchanger

& Keel Cooled

Small Diesel Engine Range: Beta 10,

Beta 14, Beta 16, Beta 20 & Beta 25

Engine Details IMPORTANT

- Please fill in details at moment of purchase - it really will

help you! (and it will really help us specify the correct spare parts for you).

Engine Type: Power: bhp Speed: rpm

BETA WOC NO: K

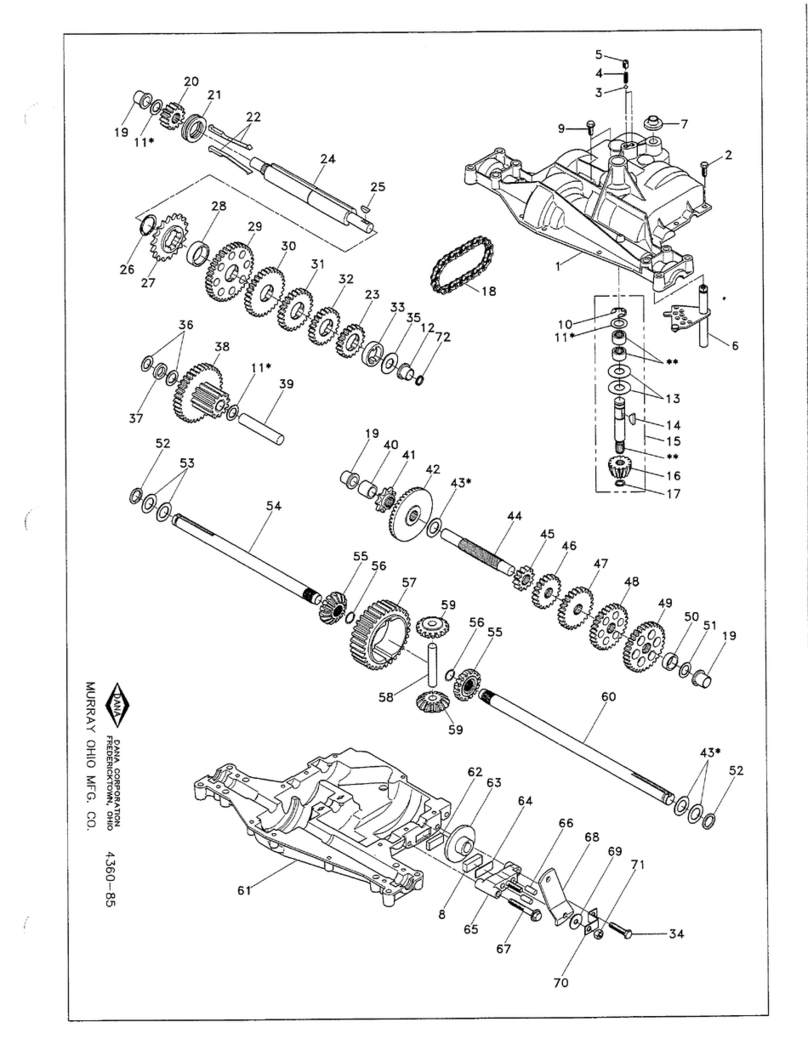

Gearbox Type:

Purchased From:

Invoice No.:

Date Commissioned:

Specification / Special Details:

1

My engine details (to be completed now) Inside front cover

Introduction

Engine identification 2

Initial receipt of the engine 2

Engine storage 2

Safety precautions 3

Technical specifications 4

Section 1: Installation guidelines

Engine mounting 5

Engine alignment - drives, flanges, flexible couplings 6

Exhausts and mounting exhausts 7 & 8

Fuel supply and "leak off" 9

Cooling - sea water inlet system 10

Cooling - keel cooling system 10 & 11

Calorifier connections (if fitted) 12

Electrical Installation 13

Section 2: Guidelines for operation of the engine

Important checks prior to initial use 14

Initial start-up and bleeding the fuel system 14

Starting and stopping 15 & 16

Section 3: Maintenance & Service guidelines

Maintenance schedule 17 & 18

Lubrication - checking and changing oil 19 & 20

Fuel system - fuel/water separator, fuel lift pump, fuel filter 21

Cooling - fresh water system, heat exchanger 22

Sea water pump, heat exchanger 24

Belt tensioning adjustment 25

Air filter inspection / replacement 25

Electrical maintenance 26

Laying up - winterising 26

Troubleshooting 28

Torque settings 39

Wiring diagrams and general arrangement drawings index 40

Exhaust Emission - Declaration of Conformity 71 & 72

Exhaust Emission - Durability 73

Fast Moving Parts Listing 76, 75 & 74

Maintenance record Inside back cover

Contents

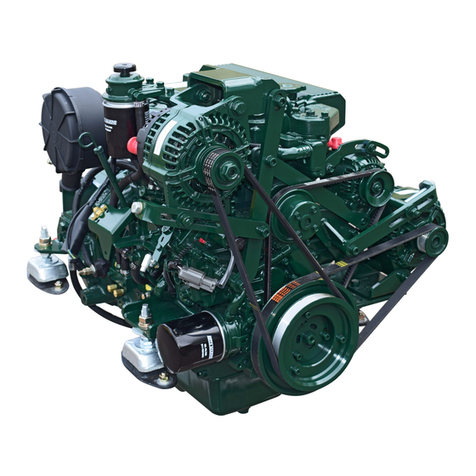

Engine Identification

NOTE: In all communications with the

distributor or Beta Marine, the W.O.C.

and engine number must be quoted.

Beta 10, Beta 14, Beta 16,

Beta 20 and Beta 25

The engine serial number is stamped above the fuel lift

pump on the starboard side of the engine, and is shown on

the rocker cover label.

Initial Receipt of the Engine

A full inspection of the engine must be made immediately

on delivery to confirm that there is no damage. If there is

any damage then write this clearly on the delivery note and

inform your dealer or Beta Marine within 24 hours. A

photograph would always help.

Engine Storage

The engine must be stored in a dry, frost free area and this is

best done in its packing case. If storage is to be more than

six months then the engine must be inhibited (contact your

dealer or Beta Marine). Failure to inhibit the engine may

result in the formation of rust in the injection system and the

engine bores, this could invalidate the warranty.

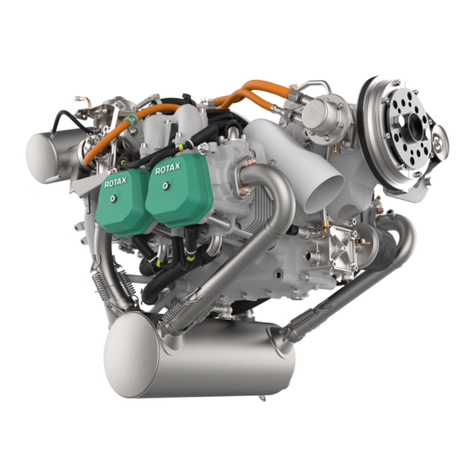

OPERATION AND MAINTENANCE MANUAL FOR THE FOLLOWING

BETA MARINE ENGINES BASED ON KUBOTA MINI SERIES

2

1

2

This manual has been compiled to provide the user with important information and recommendations to ensure trouble free

and economical operation of the engine.

As manufacturers we have obviously written this “Operators Maintenance Manual’ from our ‘involved technical viewpoint’

assuming a certain amount of understanding of marine engineering. We wish to help you, so if you do not fully understand

any phrase or terminology or require any explanations please contact Beta Marine Limited or its distributors and we will be

pleased to provide further advice or technical assistance.

All information and recommendations given in this publication are based on the latest information available at the time of

publication, and are subject to alteration at any time.

The information given is subject to the company’s current conditions of Tender and Sale, is for the assistance of users, and

is based upon results obtained from tests carried out at the place of manufacture and in vessels used for development

purposes. We do not guarantee the same results will be obtained elsewhere under different conditions.

Beta 10, Beta 14, Beta 16,

Beta 20 & Beta 25

3

A Keep the engine, gearbox and surrounding area clean,

including the area immediately below the engine

B Drives - Power Take Off Areas

i) Gearbox Output Flange

The purpose of a marine diesel propulsion engine is to

provide motive power to propel a vessel. Accordingly the

gearbox output shaft rotates at between 280 and 2400

rev/min. This flange is designed to be coupled to a

propeller shaft by the installer and steps must be taken to

ensure adequate guarding.

ii) Forward End Drive

Engines are supplied with unguarded belt drives to power

the fresh water pump and battery charging alternator.

The installer must ensure that it is not possible for injury

to occur by allowing access to this area of the engine.

The three pulleys run at high speed and can cause injury

if personnel or clothing come in contact with the belts or

pulleys, when the engine is running.

iii) Power Take Off Shaft (Engine Mounted Option)

Shaft extensions are available as an option and rotate at

between 850 and 3600 rev/min. If contact is made with

this shaft when the engine is running, injury can occur.

C Exhaust Outlet

Diesel marine propulsion engines emit exhaust gases at

very high temperatures - around 400 - 500°C. Engines

are supplied with either wet exhaust outlet (water

injection bend) or dry outlet (dry exhaust stub) - see

option list. At the outlet next to the heat exchanger /

header tank, the exhaust outlet can become very hot and

if touched, can injure. This must be lagged or avoided by

ensuring adequate guarding. It is the responsibility of the

installer to lag the exhaust system if a dry system is used.

Exhaust gases are harmful if ingested, the installer must

therefore ensure that exhaust lines are led overboard and

that leakage in the vessel does not occur.

DFuel

i) Fuel Lines

Diesel engines are equipped with high pressure fuel

injection pumps, if leakages occur, or if pipes fracture,

fuel at a high pressure can harm personnel. Skin must be

thoroughly cleaned in the event of contact with diesel

fuel.

ii) Fuel Supply Connections

Engines are supplied with 8mm compression fittings. The

installer must ensure that when connections are made,

they are clean and free of leaks.

EOil

The Beta propulsion unit is supplied with 2 dipsticks, one

for the engine and one for the gearbox. Ensure dipsticks

are returned and secure after checking, if not oil leaks can

cause infection when touched. All oil must be removed

from the skin to prevent infection.

F Scalding

An engine running under load will have a closed circuit

fresh water temperature of 85° to 95°C. The pressure

cap on the top of the heat exchanger must not be

removed when the engine is running. It can only be

removed when the engine is stopped and has cooled

down.

G

Transportation / Lifting

Engines are supplied on transportable pallets. Lifting eyes

on engines are used for lifting engine and gearbox

assembly only, not the pallet and associated kit.

GENERAL DECLARATION

This machinery is not intended to be put into service until it

has been incorporated into or with other machinery. It is the

responsibility of the purchaser / installer / owner, to ensure

that the machinery is properly guarded and that all necessary

health and safety requirements, in accordance with the laws

of the relevant country, are met before it is put into service.

Signed:

J A Growcoot, C.E.O,

Beta Marine Limited

NOTE: Recreational Craft

Where applicable, the purchaser / installer / owner and

operator must be responsible for making sure that the

Recreational Craft Directive 94/25/EC is complied with.

Safety Precautions!

Maximum Angle of Installation: Maximum 15° flywheel up or flywheel down when static; or up to 25° when heeling.

Rotation: Anti-clockwise on flywheel, clockwise on output gearbox flange for use with right hand propeller in ahead, on

mechanical gearboxes. Hydraulic gearboxes can be left or right handed. Diesel fuel must conform to BS2869-1970 class A1

or A2. The fuel must be a distillate and not a residual oil or blend.

Lubricant:

Engine - engine oil must meet API Classification CF (CD or CE), See section 2 for details

Gearbox - see gearbox operator’s manual for the gearbox oil type and capacity

Oil pressure - minimum (tickover) 0.5 bar

Power outputs: These comply with BS EN ISO 8665:1996 crankshaft power

Note: Declared Powers to ISO8665:1996

1. The declared powers are at the same engine speed as the ISO 3046 figures. This speed is the speed related to the

outputs / powers shown.

2. Declared powers are at the gearbox coupling (coupling to the propeller shaft) as per EN ISO 8665:1995 clause 3.2.1

with standard specifications as per our current price lists. Additional accessories or alternative gearboxes may affect the

declared powers.

3. Operation at parameters outside the test parameters may affect the outputs / powers which in any case are subject to the

ISO tolerance bands.

Standard Engines Beta 10 Beta 14 Beta 16 Beta 20 Beta 25

Cylinder 22233

Bore (mm) 67 67 72 67 72

Stroke (mm) 68.0 68.0 73.6 68.0 73.6

Displacement (cc) 479 479 599 719 898

Combustion 3 Vortex

Cooling Water

Starter voltage (V) 12 12 12 12 12

Starter output (kW) 0.8 0.8 0.8 0.8 0.8

Starter alternator output (Amps) 40 (standard)

Glow plug resistance (each) 1Ω1Ω1Ω1Ω1Ω

Engine speed (RPM) at full load 3,000 3,600 3,600 3,600 3,600

Power output to ISO3046 (BHP) 10.0 13.3 16.7 20.0 24.8

Declared power ISO8665 (kW) 7.4 8.7 11.0 13.1 16.3

Compression Ratio 23.0:1 23.0:1 23.0:1 23.0:1 23.0:1

Fuel timing BTDC 21° 21° 21° 21° 21°

Capacity of standard sump approx. (litres) 2.0 - 2.5 2.0 - 2.5 2.4 - 2.9 3.1 - 3.8 3.7 - 4.5

Capacity of shallow sump approx. (litres) 2.2 2.2 2.6 3.4 3.8

Nett dry weight with gearbox (kg) 89 90 95 104 113

Fuel Diesel fuel oil A1 / A2

Coolant 33%-50% maximum antifreeze:water

Coolant capacity approx.. (H/E litres) 2.25 2.25 2.25 3.00 3.25

Min. recommended battery capacity 12V, 40Ah 12V, 40Ah 12V, 40Ah 12V, 75Ah 12V, 75Ah

4

Technical Specifications

5

Installation Recommendations

The installation details are basic guidelines to assist installation, however due to the great diversity of marine craft it is

impossible to give definitive instructions. Therefore Beta Marine can accept no responsibility for any damage or injury incurred

during the installation of a Beta Marine Engine whilst following these guidelines.

Section 1

• All engines shall be placed within an enclosure separated

from living quarters and installed so as to minimise the

risk of fires or spread of fires as well as hazards from toxic

fumes, heat, noise or vibrations in the living quarters.

• Unless the engine is protected by a cover or its own

enclosure, exposed moving or hot parts of the engine that

could cause personal injury must be effectively shielded.

• Engine parts and accessories that require frequent

inspection and / or servicing must be readily accessible.

• The insulating materials inside engine spaces shall be

non-combustible.

•Ventilation - It is important that the engine compartment

has adequate ventilation, and this is your responsibility.

If there is no ventilation the engine can overheat and

damage can be caused. As a general statement an engine

will produce radiated heat - approximately equal to 1/3of

the engine output power. Also the 45 & 100 amp battery

charging alternators create lots of heat. (A symptom of

overheating problems is often black belt dust).

If you have any doubts about the temperature of your

engine compartment please check with a thermometer

on a hot day, the maximum temperature in the engine

compartment should less than 60°C - the cooler the

better! Engine compartment ventilation is normally best

with two holes; an inlet allowing colder air to enter near

to the alternator and drive belts and a second outlet

(a third bigger than the inlet) for the hot air to rise and

ventilate out from the top of the engine compartment.

Adequate ventilation must be included with all

installations.

•General - Keel Cooled Engines, sometimes overheating is

caused by:

(a) Not fully venting the engine cooling system of air. It is

necessary to remove all air from the cooling system -

including the “skin” tanks and (if fitted) the Calorifier and

associated piping.

(b) Incorrectly sized “skin” tanks that have been sized for

‘usual’ canal use, rather than maximum engine output

that can sometimes be required on fast flowing rivers.

An additional “skin” tank may need to be fitted; please

refer to our website.

Engine Mounting

To ensure vibration free operation, the engine must be

installed and correctly aligned on substantial beds, extending

as far forward and aft as possible, well braced and securely

fastened to form an integral part of the hull.

The engine must be installed as low as possible on the

flexible mount pillar stud. This will limit vibration and extend

the life of the flexible mount. To assist with engine

replacement we offer ‘Special Engine Feet’ manufactured to

your dimensions, as an optional extra to suit your existing

engine bearers and shaft alignment/installation.

Warning

(1) Do not set the engine feet high up the flexible mount

pillar stud. This will cause excessive engine movement

and vibration. Pack under the flexible mount with steel

shims securely bolted into the engine bearer.

(2) The pillar stud on the flexible mount is secured into

position by the lower locknut, do not forget to tighten

this. Also ensure that the stud is not screwed too far

through the mounting body so that it can touch the

bearer. This will cause vibration and knocking noises

which are very hard to find!

3

Alignment

To obtain accurate alignment the flexible mountings must be

adjusted until alignment is attained, and the mountings must

then be locked in position.

The engine/gearbox unit has to be aligned with the propeller

shaft in two ways. The traditional engine alignment method

involves measuring with either feeler gauges or a DTI (Dial

Test Indicator) mounted on a magnetic foot so that they are

aligned within 0.125mm (0.005”).

6

Engine Installation at an Angle

Beta Marine propulsion engines can be installed at angles up

to a maximum of 15° flywheel up or flywheel down when

static, or can be run at up to 25° when heeling. When our

engines are installed at varying angles of inclination the

normal markings on the dipstick should be disregarded.

It is probably better to totally drain the lubricating oil from the

sump, replacing the oil filter with a new one; then add the

recommended amount of lubricating oil – noting its position

on the dipstick – and then marking the dipstick. If in doubt

ask Beta Marine.

4Angular Mis-alignment

Angular Mis-alignment

Engine / gearbox

flange

Propeller

shaft

Angular Alignment

The engine mountings and the couplings must now be tightened in position and the alignment re-checked.

5Parallel Mis-alignment

Parallel Mis-alignment

Engine / gearbox

flange

Propeller

shaft

Parallel Alignment

Exhausts

We recommend care when designing your exhaust system. The most important aspect is to ensure that the engine will not

‘hydraulic lock’ - by allowing cooling water into the combustion chamber through the exhaust system.

The basic criteria is when your engine is installed below the water line, the potential for water entering the engine is

considerably increased. The important position that must be measured is from the water line to the point at where the cooling

water is injected into the exhaust - this should measure 30 cms above the water line.

In yachts, engines are mostly installed low down and often below the water line. There are several ways to avoid cooling water

entering the engine:

(a) Syphoning of cooling water can occur when the rubber

impellor of the sea water pump becomes worn. If our

standard injection bend is too low then we can offer a

high-rise injection bend that adds 15 cms to the height.

If this is still not enough then you have to fit an

‘antisyphon’ valve at least 30 cms above the water line.

These valves need to be checked regularly as they have

been known to block up with time.

(b) We recommend that you always fit a waterlock / silencer

to stop any water in the exhaust system back filling the

engine. The water lock should always be fitted at least

30 cms from the injection bend and about 15 cms below

the injection bend. The waterlock should have sufficient

capacity to hold an exhaust system full of water - draining

into it.

(c) We recommend that you always create a ‘gooseneck’

with the exhaust hose (or purchase a propriety one) by

raising the exhaust hose 40 cms above the waterline

before exiting the transom at least 5 cms above the

waterline. This will stop any waves pushing seawater

down the exhaust.

(d) Keep exhaust systems to a minimum length and have

gradual bends (NOT right angle elbows). Exhaust back

pressure should be as low as possible; it is increased by

long exhaust length and sharp bends. Back pressure

should be measured; with the complete exhaust system

connected and the engine running at full speed. The

correct measuring point is before the injection bend (at

the manifold flange).

Beta 10 to Beta 25 maximum 70 mmHg;

Beta 30 to Beta 60 maximum 80 mmHg,

and Beta 75 to Beta 105 maximum 90 mmHg.

(e) Wet Exhaust hose should be matched to the injection

bend diameter.

Beta 10 to Beta 60 is 50 mm internal diameter;

and Beta 75 & Beta 90 is 60 mm internal diameter.

(f) An engine correctly installed in accordance with this

handbook will meet the emission requirements of the

RCD (Recreational Craft Directive).

7

Flexible Output Couplings

A flexible coupling should be mounted on the gearbox output flange and is strongly recommended in almost every case.

Flexible couplings do not accommodate bad alignment, they are designed to absorb torsional vibrations from the propeller

(transmitted along the propeller shaft).

Typical Yacht Exhaust Installation

Warning

(1) One of the most common problems with engine

installations (and often expensive), is ‘hydraulic lock’

(water entering the engine combustion chamber). Water

entering the pistons / combustion chamber can cause

bent con rods, emulsified engine oil and a wrecked fuel

pump! It’s best avoided!

(2) The diagram shows a typical exhaust installation. The

rubber hose connecting the heat exchanger to the

injection bend must be replaced by a hose of sufficient

length, connecting to a “T” piece or anti-syphon valve that

is above the maximum seawater level when heeled (at

least 30 cms / 12 inches above the water line) on the

centre line of the boat. The pipe then returns to the

injection bend and the seawater is pumped down the

exhaust pipe.

8

7

Silencer

8

Silencer

*measured on the centre line of the boat

If required - a cooling water feed (approx 1/4BSP)

must be taken from the engine side of the anti-syphon

valve for water lubrication of the cutlass bearing

40 cm

minimum

5 cm

minimum

Waterlock

Silencer

Normal

seawater

Level

Anti syphon valve or

T piece fitted here

Propeller Clearance: between tip of propeller blade and

underside of hull should be at least 10% (some say 15%)

of the propeller blade diameter to avoid ‘tip noise’

If a rope cutter is fitted, allow approximately 1/2”

for engine movement, see manufacturer’s literature

Maximum

seawater level

when heeled*

Standard Exhaust

High Rise Exhaust

30 cm

minimum

6

Dry Exhaust System

a) An engine correctly installed in accordance with this

handbook will meet the emission requirements of the

RCD (see back of manual).

b) Keep exhaust systems to a minimum length and have

gradual bends (NOT right angle elbows). Exhaust back

pressure is increased by longer exhaust length and

sharp bends. Back pressure should be measured; with

the complete exhaust system connected and the engine

running at full speed; and should NOT exceed 70 mm

Hg (3.1 inches Hg). The correct measuring point is

before the dry exhaust bellows (at the manifold flange).

We can supply a Manometer kit for testing ‘Back

Pressure’.

c) The dry exhaust system installed in a canal boat or work

boat should be 1

1/2

” minimum internal diameter.

The engine is fitted with a 1

1/2

” BSP male connector

stub as standard - Valid for exhaust systems up to 3

metres in length. A flexible exhaust bellows and dry

exhaust silencer should be used. It is up to the installer

to work out his own pipe run but care should be taken

as follows:

• Never use a flexible exhaust bellow as a bend, it will

crack, always keep them straight.

• Ensure that rain water cannot enter the exhaust port

and run back down the system, flooding the silencer

and eventually the engine. (See drawings below).

• The system should be lagged if there is any danger of

the crew getting near it.

• A dry exhaust system will give off considerable heat

and suitable ventilation must be provided.

Ensure exhaust raises then falls to outlet

9

Engine Connections

Actual Connector: Required Pipe Size:

Fuel supply and fuel leak-off connections are 8 mm OD piping for both, a flexible section is required

8 mm conex with olives

Heat Exchanger - Yachts

Seawater cooling pump connections are is 22 mm OD Sea water pump inlet = 22 mm ID hose

Exhaust water injection bend is 50 mm OD Flexible rubber exhaust pipe of correct quality = 50 mm ID hose

Keel Cooling - Narrowboats

Keel cooling connections are 22 mm OD copper pipe Engine inlet and outlet = 22 mm ID hose

Keel cooled exhaust stub is

1

1/2

”

BSP male thread

1

1/2

”

BSP female thread flexible exhaust pipe

Fuel Supply & Leak Off

Fuel tank

Stop tap / valve Fuel / water

separator

Fuel filter

Fuel lift pump

Fuel injection

pump

Engine (All Fuel Connections Supplied)

Flexible Fuel

Connections

to be used

Fuel injectors

9

Vent

Notes:

1) A fuel/water separator must be installed.

2) The mechanical fuel lift pump is fitted to all engines as

standard, but if a suction head of 0.25m or more is

required, then an electric fuel lift pump must be fitted

(ask your dealer or Beta Marine).

3) It is very important that the excess fuel from the injectors

is fed back to the fuel tank and not back to any point in

the supply line. This will help prevent air getting into the

system.

4) The fuel return (leak off) pipe must loop down to be level

with the bottom of the tank before it enters the top of the

tank - see drawing. This prevents fuel ‘drain down’.

5) Fuel lines and hoses connecting the fuel tank to the

engine, must be secured, separated and protected from

any source of significant heat. The filling, storage,

venting, fuel supply arrangements and installation must

be designed and installed so as to minimise the risk of

fire. When connecting the engine to the fuel supply and

return lines, flexible fuel hoses must be used (next to the

engine) and must meet the requirements set in standard

ISO7840:1995/A1:2000 and/or as required by your

surveyor / authority.

6) Any fuel leaks in the system when static are likely to

cause poor starting and erratic running and must be

corrected immediately. These leaks will allow air to be

sucked in when the engine is running.

Canal Boats with Keel Cooling

The Beta 10 to Beta 25 propulsion engines are available

with keel cooling if required. The keel cooling supply

and return pipes are 22mm diameter; requiring flexible

rubber hoses with a 22mm bore. These rubber hoses

should be designed and manufactured as hot water

heater hoses suitable for operation up to 100 degrees

centigrade.

Narrowboats: With keel cooling the coolant (same fresh

water / antifreeze solution as heat exchanger cooling)

flows around the engine and also the keel cooling tanks,

before returning to the engine. These keel cooling tanks

are normally welded into the ‘swim’ of the narrowboat,

using the 8mm steel plate hull as one side of the tank to

transfer the engine heat to the canal water. The required

surface area for keel cooling our engines in narrowboats

is as detailed.

10

1. It is very important that the seawater inlet should have

a strainer system either built into the sea cock or a high

level system with visual inspection glass (as shown)

mounted just above the water line.

2. The inlet sea cock should be 1” BSP to which a 7/8”

/ 22 mm hose connector can be fitted. The sea water

pump is 22 mm OD to suit the 22 mm ID hose.

3. Good access to the inlet sea cock is essential so that

plastic bags or seaweed trapped in the intake can be

poked out.

4. All pipe work should have approved marine grade

stainless steel hose clips. Any loose clamps or bad

connections can cause flooding and sinking of the vessel

5. If water is required for stern tube lubrication then this

should be taken from a ‘T’ piece in the pipe going from

the heat exchanger outlet to the water injection bend.

6. Scoop type water pickups should never be used, as water

will be forced through the pump and into the exhaust

system whilst the vessel is sailing. This is very dangerous

as the exhaust will eventually fill and sea/raw water will

back up into the engine through the exhaust valve.

Catastrophic failure will result as soon as the engine is

restarted. Note: The maximum lift of the sea water pump

is 2m when primed.

Seawater Inlet System (Heat exchanger Cooled Engines)

Your engine is fitted with a gear driven sea water pump which sucks in seawater (raw water) to cool the closed circuit system

via the heat exchanger.

Water Level

10

12

Water Level

Exposed

Surface Area

11

11

Steel Tanks Steel Tanks

Engine Model Size (ft) Size (m

2

)

Beta 14 3.5 0.33

Beta 16 4.0 0.38

Beta 20 5.0 0.46

Beta 25 6.3 0.59

Beta 30 7.5 0.70

Beta 35 8.8 0.82

Beta 38 9.5 0.88

Beta 43 10.8 1.00

Beta 50 12.5 1.16

Beta 60 15.5 1.43

Efficient keel cooling tanks are side mounted, see

illustration. The ideal keel cooling tank should have:

a) The ‘baffle’ continuously welded to the outer skin

and should be close fitting to the inner skin.

b) The tank should be thin in section (30mm to

40mm) as it is the heat transfer to the canal or river

water that is important.

c) The tank must have air bleed valves fitted on the

top at both ends of the tank.

d) The hot water feed enters at the top of the tank

and the engine return comes out of the bottom.

The keel cooling tank size should have

a surface area exposed to the canal

or sea water of:

0.25 x the bhp of the engine = the square

feet of cooling area required (for steel hulls)

Important: If you boat has a hydraulic drive,

you will need to increase the surface area by

approximately 30% percent.

If you have any questions about keel cooling please refer

to our design guidelines detailed on our website, or ask us.

12

Calorifier System

All Beta ‘Green Line’ engines are fitted with ‘Calorifier Connections’ to allow the hot coolant from the closed cooling system to

circulate through a calorifier tank, which in turn heats up domestic water. Photos are shown below.

1. The big problem with a Calorifier is removing all the air

from the piping /system. If you cannot get the air out,

then the Calorifier will not work!

2. Try and keep the supply and return pipes either horizontal

or sloping down in a continuous fall. This avoids air

pockets being created.

3. If your calorifier is installed above the engine then a

‘Remote Header Tank kit’ must be fitted.

4. Extra care must be taken when first filling the calorifier

system with coolant (a solution of water plus 30% to

50% antifreeze) as the header tank may appear to be full

but it soon disappears into the calorifier pipe work. Run

the engine off load for 10 minutes then check the level as

described in ‘Filling the Fresh Water System’. Also check

to see if the pipe going to the calorifier is getting warm

after 15 minutes. Top up the water level as required and

run for another 10 minutes, then repeat.

5. If the water level is steady but no warm water is getting

to the calorifier then very carefully open the calorifier

bleed valve (see manufacturers instructions) or if none is

provided then very carefully loosen the jubilee clip

securing the supply pipe to the calorifier. Air should

escape. Refasten securely when no further bubbles are

seen.

Caution:

Do not do this when the engine is hot as

scalding hot water may be forced out of the pipe under

pressure.

a

Heat Exchanger Cooled Version

14

a

16

Calorifier

return

15

Calorifier

supply

13

Keel Cooled Version

Heat Exchanger Calorifier System

13

Electrical Installations

Beta Marine has 6 control panels: A, AB, ABV, ABVW B or C.

The Beta 10 to Beta 25 use the A, ABV, ABVW, B and C

control panels.

The engine harness is common to all.

1. These control panels must not be installed where sea

water spray can get at them. A suitable flap or cover

must be fitted. The ABVW panel is fully waterproof.

2. Control Panels must be fitted in a location where the

helmsman can either see or hear the alarm system.

3. For standard wiring diagrams, see back of manual.

4. Our standard wiring harness has a 3 metre loom.

As an optional extra, Beta can provide various lengths of

extension looms for runs of over 3m, but this kit includes

a start relay to overcome the voltage drop. (See drawing

300-58520). Care must be taken when pushing the two

halves of the plug together to ensure that individual pins

do not fall out. To prevent corrosion and assist in

assembly we recommend that the plug is packed with

petroleum jelly (Vaseline) and then carefully pushed

together.

The plastic boots should cover both halves and overlap.

A cable tie is then put around to hold the two halves in

position and help prevent any ingress of water.

5. All cables must be adequately clipped and protected from

abrasion.

6. Electrical systems shall be designed and installed so as to

ensure proper operation of the craft under normal

conditions of use and shall be such as to minimise risk of

fire and electric shock.

7. Attention shall be paid to the provision of overload and

short circuit protection of all circuits; except engine

starting circuits, supplied from batteries.

8. Ventilation shall be provided to prevent the accumulation

of gases, which might be emitted from batteries. Batteries

shall be firmly secured and protected from ingress of

water.

9. All electrical equipment must be protected from sea water.

Sea water or rust in the starter will invalidate the

warranty.

Typical Starter Motor Ratings

Starters used in Kobuta engines have the following

standard capacities:

Engine Starter Capacity (kW)

Less than 700cc 0.8 - 1.0

700 to 1,500cc 1.0 - 1.4

1,500 to 3,000cc 1.4 - 2.0

Over 3,000cc 2.0 - 2.5

Suggested Minimum Engine Starter

Battery Size

Engine Typical Battery Typical C.C.A

Capacity (AH) Cold Cranking

at a 20hr Rate Amperage

Beta 10, Beta 14, 35 - 50 AH 350 - 400

Beta 16, Beta 20

Beta 25, Beta 28,

Beta 35, Beta 38, 65 - 75 AH 450 - 540

Beta 43

Beta 50, Beta 60 100 - 120 AH 580 - 670

Beta 75, Beta 90 150 - 180 AH 1050 - 1200

Keyswitch Terminations

The standard panel keyswitch can be used to tap off a

switched positive ignition feed to power additional gauges. In

this way these gauges will only be live whilst the engine is

running, the engine is starting or the heaters are being used.

For silver keyswitches, the terminal to achieve this ignition

switched positive is marked ‘AC’. For black keyswitches, the

terminal to achieve this ignition switched positive is marked

‘15/54’. For panels without any keyswitch, gauges can be

driven from the 1 mm2brown wire which terminates at

11 way connector terminal 4. This is a lower power switched

positive, any additional power required from this connection

must be feed through a relay, as noted below.

Note: these keyswitch terminals are rated at 10 amps

maximum, since they are already utilised for panel and

alternator feeds Beta Marine recommend any additional

requirements from these terminals must be fed through a

relay. This relay should then be connected to it’s own fused

positive supply directly from the engine battery. Beta drawing

202-06421 illustrating the wiring of a typical electric fuel lift

pump with ignition switched relay is included in this manual.

14

Guidelines for Operation of Engine

Important Checks Prior to Initial Use

1. Generally, a new engine has the oil and anti-freeze

removed after the works test. Fill the engine with the

correct oil and antifreeze (see sections on Engine oil and

Cooling). Check gearbox oil level - see gearbox ‘Owners

Hand Book’.

2. Ensure the engine is free to turn without obstructions.

3. Ensure battery is fully charged and connected with the

battery isolator in the ‘ON’ position.

4. Ensure "Morse" speed and gearbox cables are fitted

correctly and that cable travel lengths are correct. Gear

selection lever - all mechanical gearboxes: care must be

taken to ensure that the remote control cable is adjusted

so that the selector lever on the gearbox moves full travel

and is brought "hard up" against its end stop in both

directions. Failure to achieve the correct adjustment will

reduce efficiency of the clutch and may cause slippage at

low revs. Warranty will not be accepted on gearboxes

returned in the warranty period for failure due to incorrect

adjustment.

5. Open the sea water cock - carefully checking there are no

water leaks.

6. Bleeding the fuel system for initial start up.

a) The fuel system must have all the trapped air carefully

‘bled’ out; starting at the fuel tank and progressively

working through to: the fuel/water trap, the fuel filter,

to the fuel injection pump.

b) Open the fuel tank stop tap/valve and then bleed the

fuel/water separator of air as shown in manufacturer’s

literature.

c) Fuel should now arrive at the fuel lift pump.

d) Open the fuel bleed screw on top of the fuel filter by

1 to 2 turns, (see photo 18).

e) Move the hand priming lever on fuel lift pump up and

down (see photo 17) until fuel with “no bubbles”

comes out of the fuel filter bleed screw (see photo

18). The hand priming lever normally has about 90°

travel; but the camshaft lobe may block this travel

requiring you to rotate the engine to obtain full

travel.

f) Shut/tighten the bleed screw.

g) Open the bleed screw on the fuel injection pump and

again ‘bleed’ through to the injection pump. Continue

to hand prime for 30 seconds to push fuel and any

remaining air through the fuel pump. Clean all areas

thoroughly of fuel with tissue paper.

7. Ensure engine is out of gear and set to 1/3throttle -

see "single lever control" instructions/manual.

8. Start engine (see normal starting). Note the engine may

have to be turned over with the starter for a few seconds

before it fires. Do not run the starter for more than 20

seconds. If the engine has not started after 20 seconds

there is probably still air in the fuel system; disengage the

starter and continue to hand prime the engine with the

fuel lift pump lever for a further 30 seconds, then repeat.

If engine does not start after 3 attempts then allow 5

minutes for the starter to cool down before repeating 6 (c)

to 8. Note: The starter motor windings can be burnt out

with continuous cranking.

Section 2

17

18

Fuel bleed screw

Warning

Caution - To avoid personal injury:

• Do not try to start the engine until you know how

to stop the engine.

• Do not bleed a hot engine as this could cause fuel

to spill onto a hot exhaust manifold creating a danger

of fire.

• Do not mix petrol / gasoline or alcohol with diesel fuel.

This mixture can cause an explosion.

• Do not get diesel fuel or oil on the flexible mounts

- they will deteriorate rapidly if soaked in these.

• All fuel must be removed from skin to prevent

infection.

15

To operate the engine: with the engine out of gear, set speed

control lever to 1/3 throttle.

1) Turn key anti-clockwise to ‘HEAT’ position and hold for

ten seconds.

2) Turn key clockwise to ‘RUN’ position. At this stage the

instrument panel should illuminate:

• Green lamp for panel ‘power on’ should illuminate.

• Buzzer should sound.

• Red lamp for ‘low oil pressure’ should illuminate.

• Red lamp for ‘high engine temperature’ should not

illuminate (when engine is cold / cool / warm). This lamp

will only ever illuminate if the engine is over temperature.

• Red lamp for ‘no starter battery charge’ should illuminate.

• Red lamp for ‘no domestic battery charge’. Only fitted with

panels AB and C and will illuminate only if 2nd ‘domestic’

alternator is fitted.

3) Turn to ‘START’ position and engine will motor, hold in

position until engine fires (see initial start-up section for

maximum time starter can be used).

4) Release key (when engine has started) to ‘RUN’ position.

• All red warning lamps should extinguish and buzzer should

stop sounding. The oil pressure lamp may take a few

seconds to switch off and the charge fail lamp may remain

on until engine rpm is increased to approximately 1,000rpm

if the engine was started on tickover.

• Green lamp for ‘panel power on’ should still function.

• If the ‘charge fail’ lamp remains on then “blip” the engine

speed up to 2000 rev/min and it will go out (split charge

relay drain).

Beta Control Panels - A, AB, ABV, B and C Deluxe - with keyswitch.

Beta Control Panel ABVW - Keyless (without keyswitch)

This panel controls the engine with three water resistant push

buttons instead of a keyswitch, and is less prone to damage

and corrosion from sea water spray.

To operate the engine: with the engine out of gear, set speed

control lever to 1/3 throttle.

1) Press and hold ‘HEAT’ button for ten seconds maximum.

• Green lamp for panel ‘power on’ should illuminate.

• Buzzer should sound.

• Red lamp for ‘no starter battery charge’ should illuminate.

• Red lamp for ‘high engine temperature’ should not

illuminate (when engine is cold / cool / warm). This lamp

will only ever illuminate if the engine is over temperature.

• Red lamp for ‘low oil pressure’ should illuminate.

2) Press ‘START’ button and hold in position until engine

fires (see initial start-up section for maximum time starter

can be operated). Release button (when engine has

started)

• All red warning lamps should extinguish and buzzer should

stop sounding. The oil pressure lamp may take a few

seconds to switch off and the charge fail lamp may remain

on until engine rpm is increased to approximately 1,000rpm

if the engine was started on tickover.

• Green lamp for ‘panel power on’ should still function.

3) To stop the engine press the ‘STOP’ push button, hold in

until engine stops. This button also switches the power off

to the gauges, engine and ‘power on’ lamp.

4) To re-start the engine, simply repeat steps from ‘1’ above,

there is no need to switch battery isolators off whilst

remaining on board.

5) If leaving the boat, isolate start battery from engine and

panel, to prevent accidental start up of engine and stop

power leakage.

Normal Starting

19

20

16

Stopping

Every propulsion engine is fitted with a stop solenoid.

To stop the engine simply press stop push button, hold in

until engine stops, then turn key from ‘RUN’ to ‘OFF’ position.

Do not turn the key to the off position when the engine is

running, this will not allow the alternator to charge the

battery.

Warning!

Do not leave the key in ‘HEAT’ position for more than

15 seconds - this will damage the heater plugs and

eventually lead to poor starting.

When leaving the boat for an extended period:

• Turn off sea-cock (heat exchanger cooled engines).

• Turn off battery isolator.

Notes for all panel types: Do not depress the stop button

for more than ten seconds as this will lead to overheating

and failure of the solenoid. These engines are equipped with

a mechanical stop lever in the event of electrical system

failure. This lever is located on the starboard side of the

engine above the speed control lever. See illustration below.

Move the stop lever aft to stop the engine then return it to the

run position.

21

Speed lever

Stop lever

17

Maintenance Schedule

Daily or every 8 hours running

• Check engine oil level.

• Check gearbox oil level.

• Check coolant level.

• Check battery fluid.

• Check drive belt tension

• Ensure raw water inlet strainer is clear.

• Check stern gland lubrication (if used).

• Drain off any water in fuel/water separator.

After the first 25 hours running

• Change gearbox lubricant (See separate gearbox manual).

• Check that all external nuts, bolts and fastenings are tight.

See table for torque values. Do NOT over tighten. Special

attention should be paid to the flexible mount lock nuts,

these should be checked for tightness, starting with lower

nut first in each case. If the lower nuts are found to be

very loose, then the alignment of the shaft to the gearbox

half coupling should be re-checked. Poor alignment due

to loose flexible mount nuts will cause excessive vibration

and knocking.

• Check the belt tension on any second alternators fitted

and adjust, see page 11.

• Check ball joint nyloc nuts for tightness on both gearbox

and speed control levers. Grease both fittings all over.

After first 50 hours

• Change engine lubricating oil.

• Change oil filter.

• Check for leaks on header tank tubestack. Tighten end

cap bolt if required.

• Drain off any water in fuel/water separator.

Every 150 hours

• If shallow sump (option) is fitted, change engine

lubricating oil and filter.

Every year or 250 hours if sooner

• Change engine lubricating oil (standard sump)

• Change lubricating oil filter

• Check air cleaner element

• Check sea water pump impeller and change if worn.

• Check wasting anode condition, replace when necessary.

In some environments this may be six monthly or less.

• Remove heat exchanger tube stack, by undoing the bolt

each end of the tube stack. Remove end cover, pull out

tube stack and clean. Replace rubber ‘O’ rings and re-

assemble. Top up with antifreeze. Immediately engine is

started check for leaks.

• Spray the key switch with WD40 or equivalent to

lubricate the barrel.

• Check that all external nuts, bolts and fastenings are tight.

See table for torque values.

• Check ball joint nyloc nuts for tightness on both gearbox

and speed control levers.

Every 750 hours (In addition to 250 hours maintenance)

• Change air cleaner element.

• Change fuel filter.

• Change antifreeze.

• Change gearbox oil.

• Check electrical equipment, condition of hoses and belts,

replace as necessary.

Section 3

18

Maintenance Schedule

Daily or After After Every Every Year Every

every 8hrs first first 150hrs with or 250hrs 750hrs

running 25hrs 50hrs shallow sump if sooner

Check engine oil level

Check gearbox oil level

Check engine coolant level

Check battery fluid

Check drive belt tension

Ensure raw water inlet

strainer is clear

Check stern gland lubrication

Drain off any water in fuel /

water separator

Change gearbox oil See separate gearbox manual

Check all external nuts, bolts and

fastenings are tight. Check belt

tension. Check for leaks

Change engine oil

Change oil filter

Lubricate keyswitch on control

panel with “vaseline” or WD40

Check coolant ”sacrificial” zinc

anode and replace if necessary

- sometimes frequently

Check general condition

Remove heat exchanger tube stack

and replace rubber O-rings

Check sea water pump impeller

and change if worn

Check air cleaner element

and change if required

Change air cleaner element

Change diesel fuel filter

Change gearbox oil

Drain and replace engine

coolant / anti-freeze

Other manuals for Beta 10

2

This manual suits for next models

4

Table of contents

Other Beta Marine Engine manuals

Beta Marine

Beta Marine BV1903 User manual

Beta Marine

Beta Marine Beta 50 User manual

Beta Marine

Beta Marine Beta 14 User manual

Beta Marine

Beta Marine BV1305 User manual

Beta Marine

Beta Marine Beta 14 User manual

Beta Marine

Beta Marine Beta 43 User manual

Beta Marine

Beta Marine Beta 10 User manual

Beta Marine

Beta Marine Beta 10 User manual