Beta Prusa DualX User manual

Assembly Instructions Beta Prusa DualX 13/05/14

Assembly Instructions

Beta Prusa DualX

3D Printer

Version 2.6

Date 13/05/14

Pa e 1 / 72

Assembly Instructions Beta Prusa DualX 13/05/14

General data about the assembly instructions for an incomplete machine

according to appendix VI of the EG machinery directi e 2006/42/EG

Manufacturer:

Wen er & Krautwasser GbR - 2PrintBeta

Reisstrasse 5

78467 Konstanz

Description of the machine:

Identification: Beta Prusa 3D printer

Type: DualX with two printheads

Year: 2014

Conditions that must be met for the incomplete machine so that it can properly, and

without compromisin the safety and health of peoples, be assembled with other

parts to form a complete machine:

Condition 1: Let an expert check the electrical connections of the machine.

Information over the undersi ned:

Name: Dominik Wenger

Function: Shareholder Wenger & Krautwasser GbR

11. 4.2 14

_________________________________________

Date, Signature

This work is licensed under a Creative Commons Attribution-NonCommercial 3.0 Germany License.

Pa e 2/ 72

Assembly Instructions Beta Prusa DualX 13/05/14

Con ratulations on purchasin a Beta Prusa 3D Printer!

Please read the followin assembly instructions carefully and keep the document on a safe

place. Please follow carefully all instructions and lookout for the warnin symbols.

Table of Contents

SAFETY INSTRUCTIONS....................................................................................................................................4

ASSEMBLY OF THE FRAME..............................................................................................................................5

STEP 1.1

.................................................................................................................................................................

6

STEP 1.2

.................................................................................................................................................................

7

STEP 1.3

.................................................................................................................................................................

9

STEP 1.4

...............................................................................................................................................................

1

STEP 1.5

...............................................................................................................................................................

11

STEP 1.6

...............................................................................................................................................................

12

STEP 1.7

...............................................................................................................................................................

13

STEP 1.8

...............................................................................................................................................................

14

STEP 1.9

...............................................................................................................................................................

17

ASSEMBLY OF THE AXES................................................................................................................................18

STEP 2.1

...............................................................................................................................................................

19

STEP 2.2

...............................................................................................................................................................

21

STEP 2.3

...............................................................................................................................................................

24

STEP 2.4

...............................................................................................................................................................

26

STEP 2.5

...............................................................................................................................................................

28

STEP 2.6

...............................................................................................................................................................

3

STEP 2.7

...............................................................................................................................................................

32

ASSEMBLY OF THE EXTRUDERS..................................................................................................................35

STEP 3.1

...............................................................................................................................................................

36

STEP 3.2

...............................................................................................................................................................

38

STEP 3.3

...............................................................................................................................................................

39

STEP 3.4

...............................................................................................................................................................

41

ASSEMBLY OF PRINT BED AND EXTRAS....................................................................................................42

STEP 4.1

...............................................................................................................................................................

43

STEP 4.2

...............................................................................................................................................................

44

STEP 4.3

...............................................................................................................................................................

45

ASSEMBLY OF THE ELECTRONICS..............................................................................................................48

STEP 5.1

...............................................................................................................................................................

49

STEP 5.2

...............................................................................................................................................................

52

STEP 5.3

...............................................................................................................................................................

54

STEP 5.4 (OPTIONAL)

...........................................................................................................................................

69

STEP 5.5 (OPTIONAL)

...........................................................................................................................................

71

Pa e 3/ 72

Assembly Instructions Beta Prusa DualX 13/05/14

Safety Instructions

Only assemble a Beta Prusa 3D printer accordin to the assembly instructions written here.

Please take notice of the followin Symbols and Notices. They are structured into dan er

levels accordin to ISO 3864-2.

DANGER

Refers to an imminent Danger.

If the information is not followed, it can result in death or serious injury

(in alidity).

Indicates a possible dangerous situation.

If the information is not followed, it can result in death or serious injury

(in alidity).

ATTENTION

Indicates a potentially dangerous situation.

If the information is not followed, damage to property or light to

medium personal injuries are possible.

NOTICE

Indicates general notes, useful operator tips and operating

recommendations which do not affect the safety and health of

personnel.

Pa e 4/ 72

WARNING

Assembly Instructions Beta Prusa DualX 13/05/14

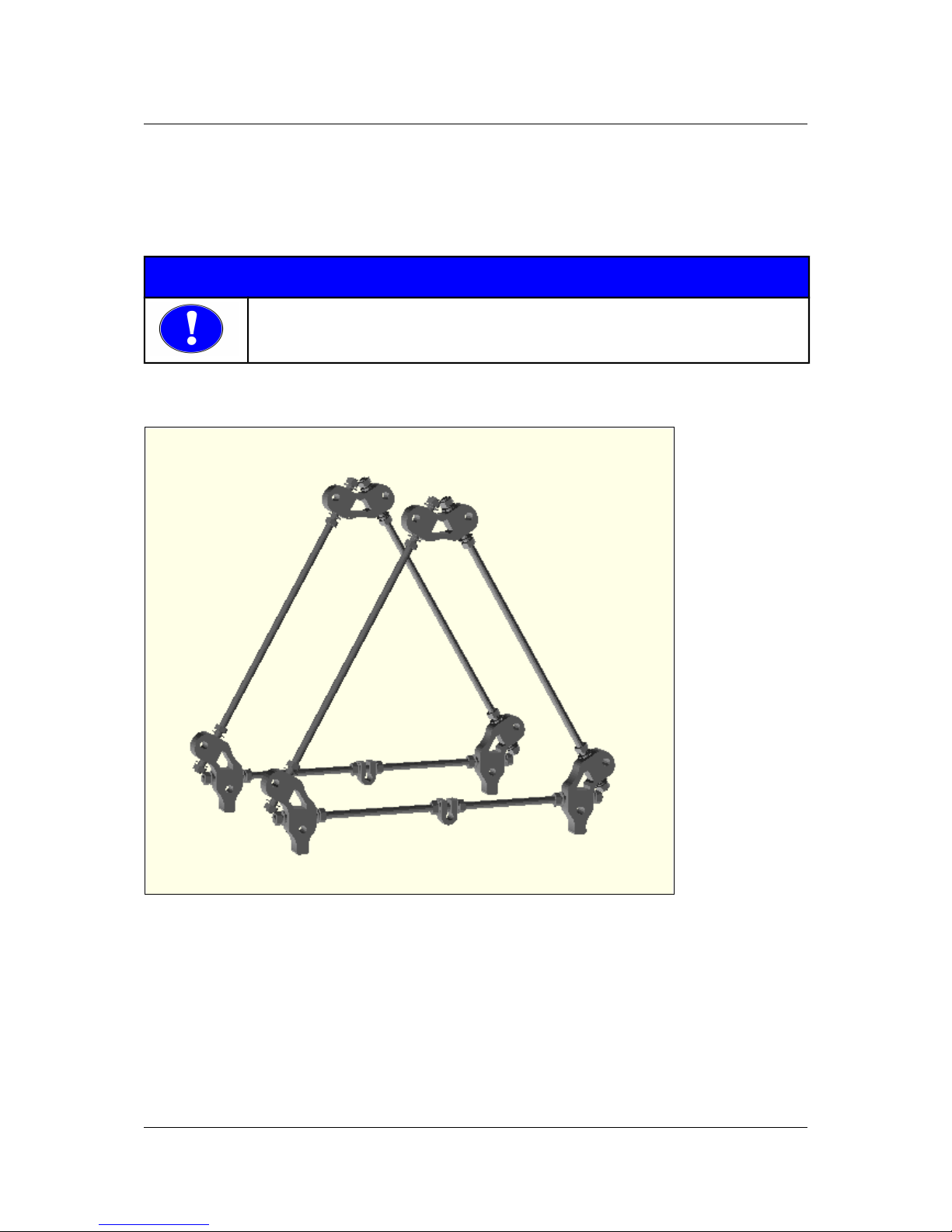

Chapter I

Assembly of the Frame

Pa e 5 / 72

Assembly Instructions Beta Prusa DualX 13/05/14

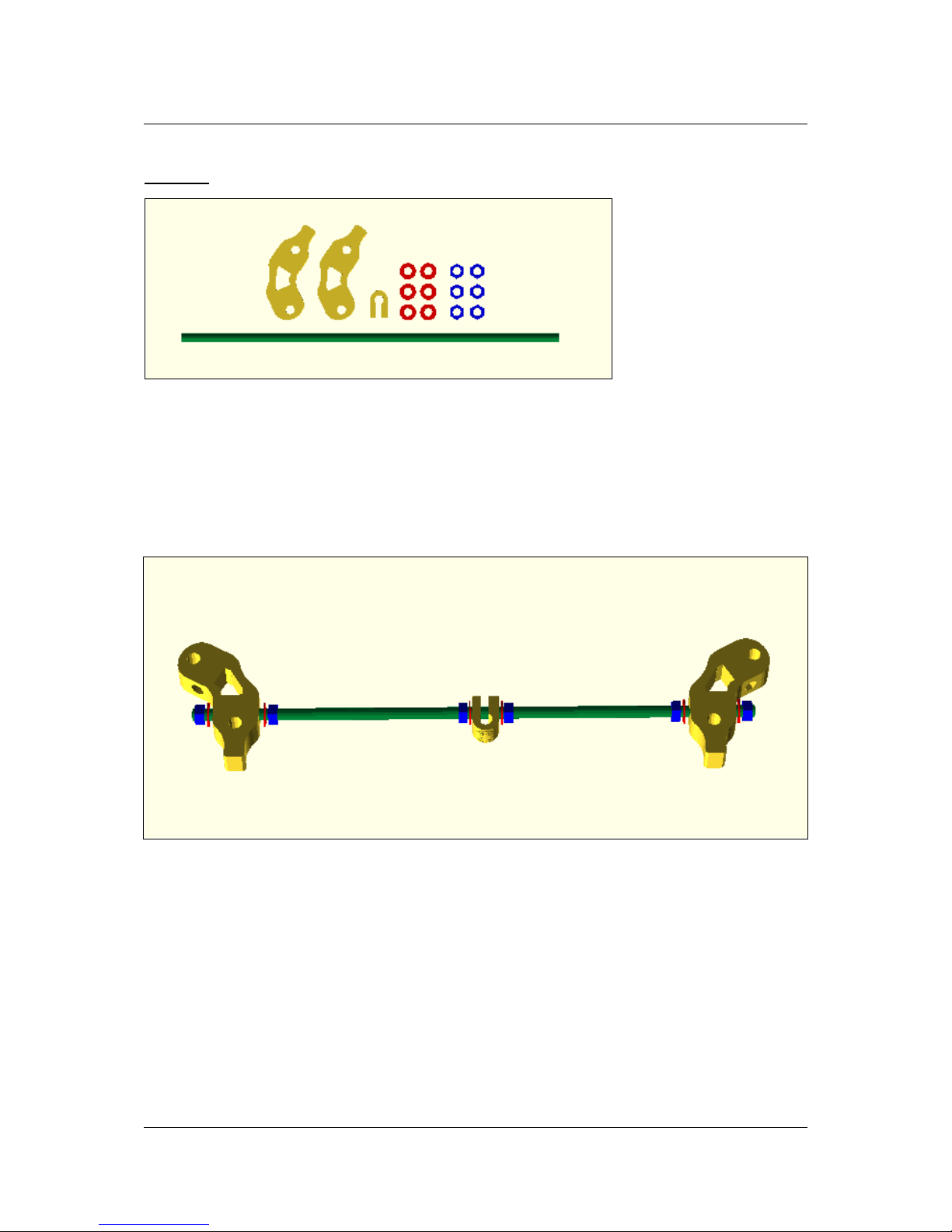

Step 1.1

Needed parts for step 1.1

The followin parts are needed for this step:

2x Frame vertex with foot

1x Bar clamp

6x Washer M8

6x Nut M8

1x Threaded rod M8 x 370 mm

Assembly Step 1.1

Assemble the bar clamp between two frame vertices like its shown in the picture above.

Don't completely fasten the nuts yet.

Pa e 6/ 72

Assembly Instructions Beta Prusa DualX 13/05/14

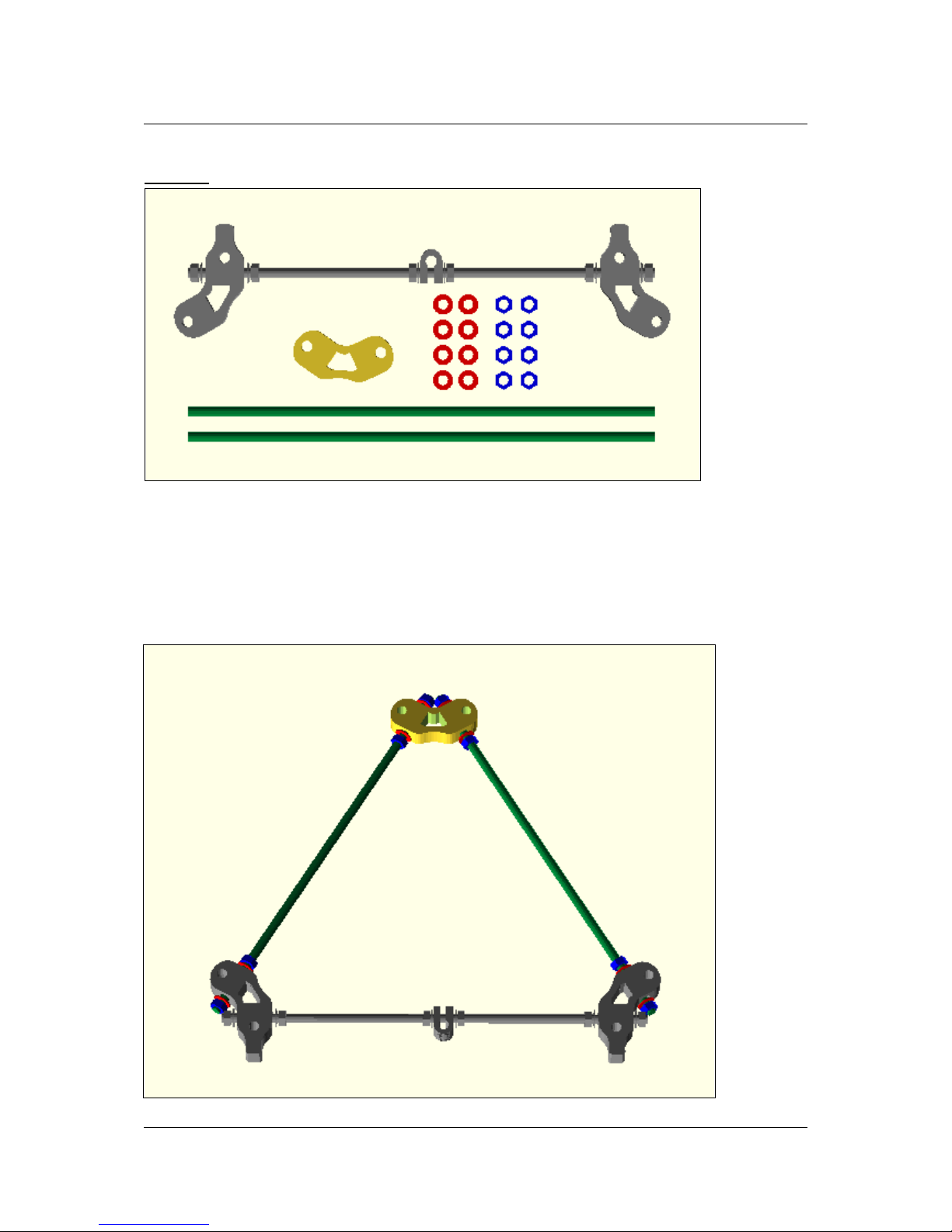

Step 1.2

Needed parts for step 1.2

The followin parts are needed for this step:

1x Pre-assembled part from step 1.1

1x Frame vertex without foot

8x Washer M8

8x Nut M8

2x Threaded rod M8 x 370 mm

Assembly Step 1.2

Pa e 7/ 72

Assembly Instructions Beta Prusa DualX 13/05/14

Connect the part from step 1.1 with the frame vertex and the rods to a trian le.

Make sure that all sides of the trian le are exactly the same len th. The distance between

the outer ed es of the plastic parts should be 291 mm.

Repeat the previous two steps and build a second trian le.

NOTICE

Make sure all sides of both triangles are exactly the same length.

Now fasten all nuts on the frame vertices.

Assembly of step 1.2 repeated

Pa e 8/ 72

Assembly Instructions Beta Prusa DualX 13/05/14

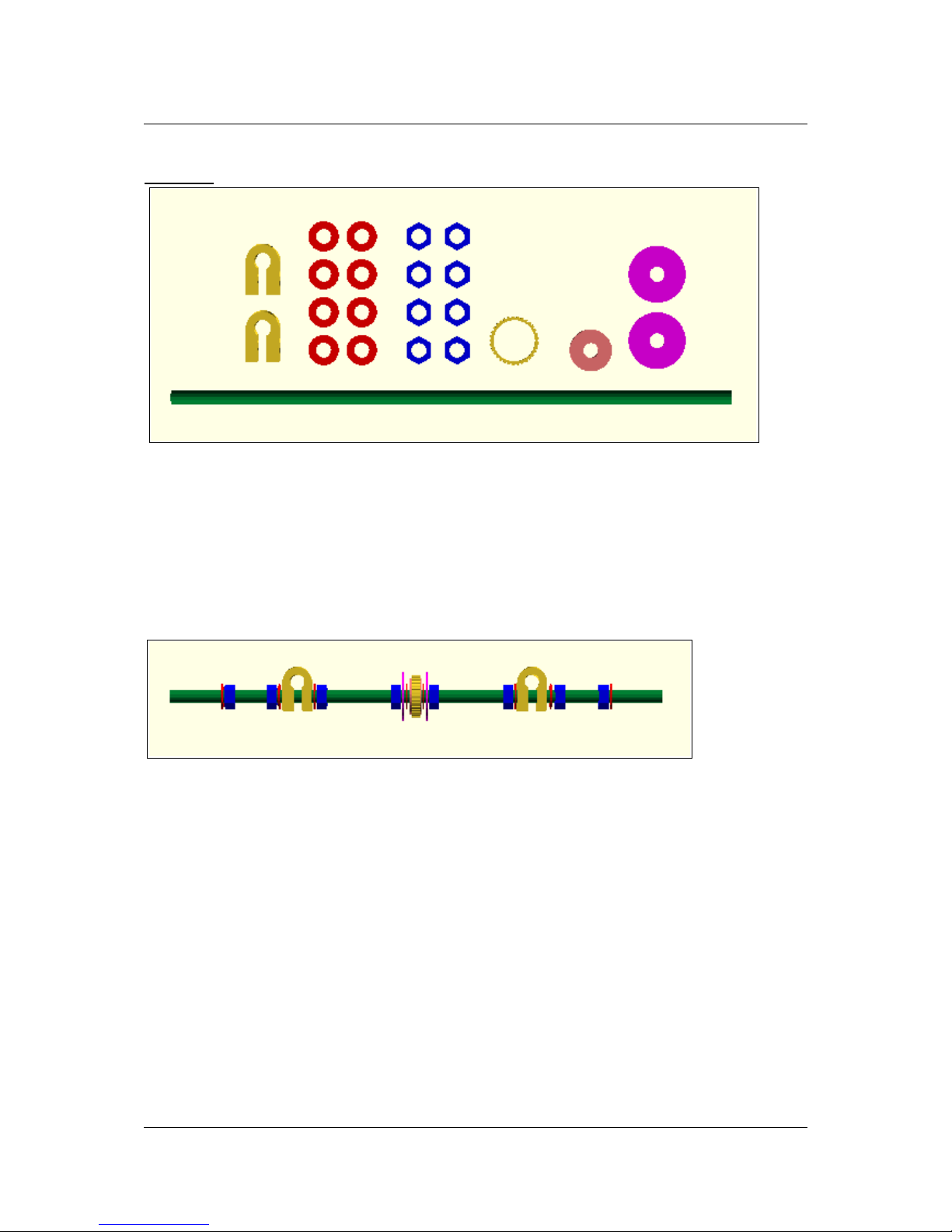

Step 1.3

Needed parts for step 1.3

The followin parts are needed for this step:

4x Washer M8

4x Nut M8

1x Threaded rod M8 x 294 mm

Assembly Step 1.3

Position the nuts and washer on the threaded rod as shown in the picture above.

Pa e 9/ 72

Assembly Instructions Beta Prusa DualX 13/05/14

Step 1.4

Needed parts for step 1.4

The followin parts are needed for this step:

1x Belt uide

2x Bar clamp

10x Washer M8

2x Bi Washer M8

8x Nut M8

1x Bearin 608ZZ

1x Threaded rod M8 x 294 mm

Bearing 608zz in belt guide

Press the 608ZZ bearin into the belt uide until it's in the middle of the uide.

Assembly step 1.4

Position the parts on the threaded rod as shown in the picture above.

Pa e 10/ 72

Assembly Instructions Beta Prusa DualX 13/05/14

Step 1.5

Needed parts for step 1.

The followin parts are needed for this step:

2x Bar clamp

8x Washer M8

2x Bi Washer M8

8x Nut M8

1x Belt uide

1x Bearin 608zz

1x Threaded rod M8 x 294 mm

Assembly step 1.

Position the parts on the threaded rod as shown in the picture above.

Pa e 11/ 72

Assembly Instructions Beta Prusa DualX 13/05/14

Step 1.6

Needed parts for step 1.6

The followin parts are needed for this step:

2x Washer M8

2x Nut M8

1x Threaded rod M8 x 294 mm

Assembly Step 1.6

Position the parts on the threaded rod as shown in the picture above.

Pa e 12/ 72

Assembly Instructions Beta Prusa DualX 13/05/14

Step 1.7

Needed parts for step 1.7

The followin parts are needed for this step:

4x Nut M8

4x Washer M8

2x Threaded rod M8 x 440 mm

Assembly Step 1.7

Position the parts on the threaded rod as shown in the picture above.

Pa e 13/ 72

Assembly Instructions Beta Prusa DualX 13/05/14

Step 1.8

Needed parts for step 1.8

The followin parts are needed for this step:

1x Y motor holder

2x Z motor holder

20x Washer M8

16x Nut M8

and all previously assembled parts

Assembly Step 1.8

Insert the two trian les from the outside into the prepared threaded rods and fix them

to ether with a washer and a nut each. The lon er threaded rods (440 mm) o into the frame

vertices without feet, the shorter ones (294 mm) in the Frame vertexes without feet like it's

shown in the picture above.

Pa e 14/ 72

Assembly Instructions Beta Prusa DualX 13/05/14

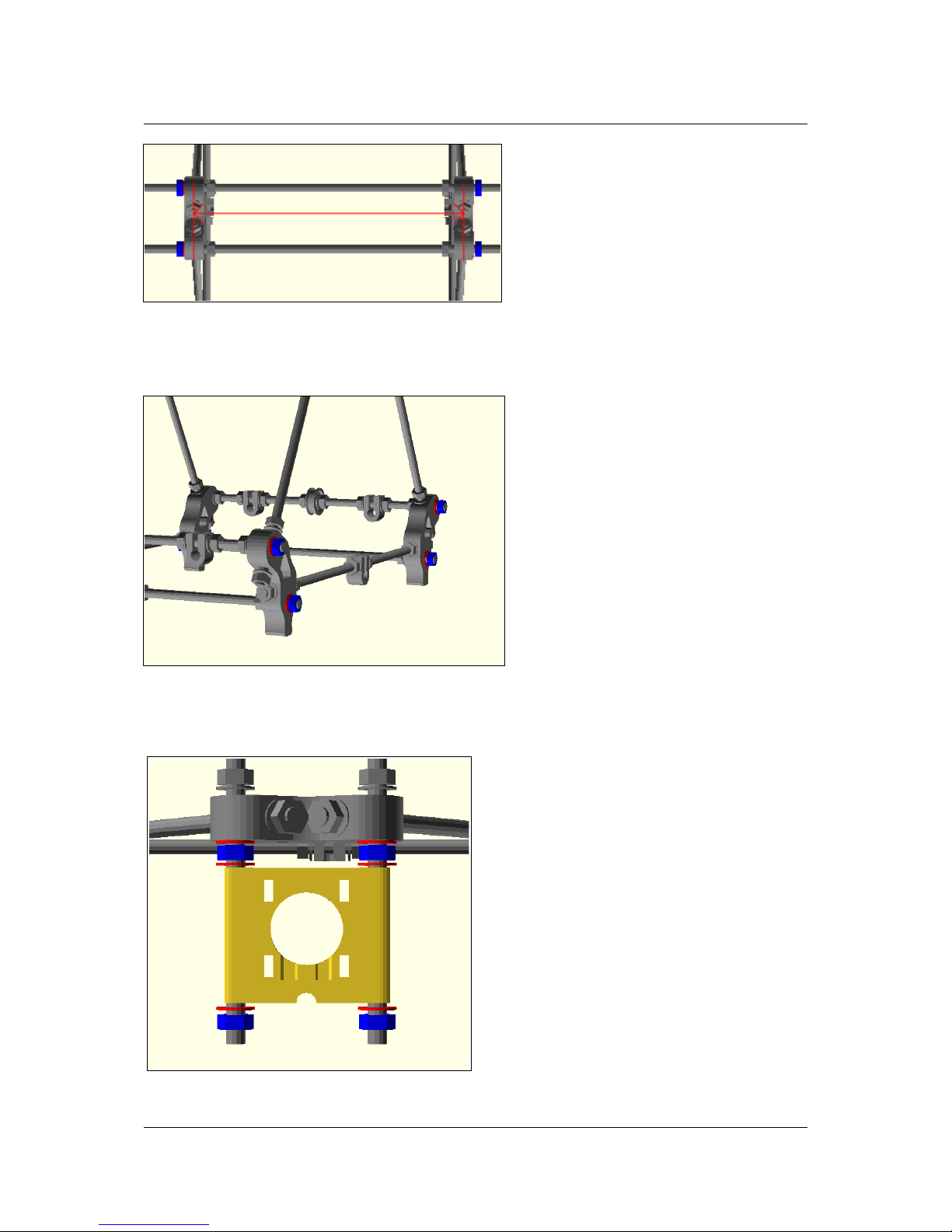

Distance between the frame triangles.

Measure the distances between the trian les, as shown above, on all three sides of the

frame.

Position of the nuts on the outside of the frame.

Now adjust the distance between the trian les by turnin the nuts on the frame vertices until

all distances are exactly the same. Make sure the trian les are as far out as possible, as

shown above. The distance between the bolts should be around 260 mm.

Assembly of a Z motor holder

Pa e 15/ 72

Assembly Instructions Beta Prusa DualX 13/05/14

Now push the Z motor holders, flat side down, onto the lon er rods as shown above. Secure

them with a washer and a nut each.

Assembly of the Y motor holder

At last, push the Y motor holder onto the rods, besides the belt uide and secure it with the

nuts on the threaded rods.

Pa e 16/ 72

Assembly Instructions Beta Prusa DualX 13/05/14

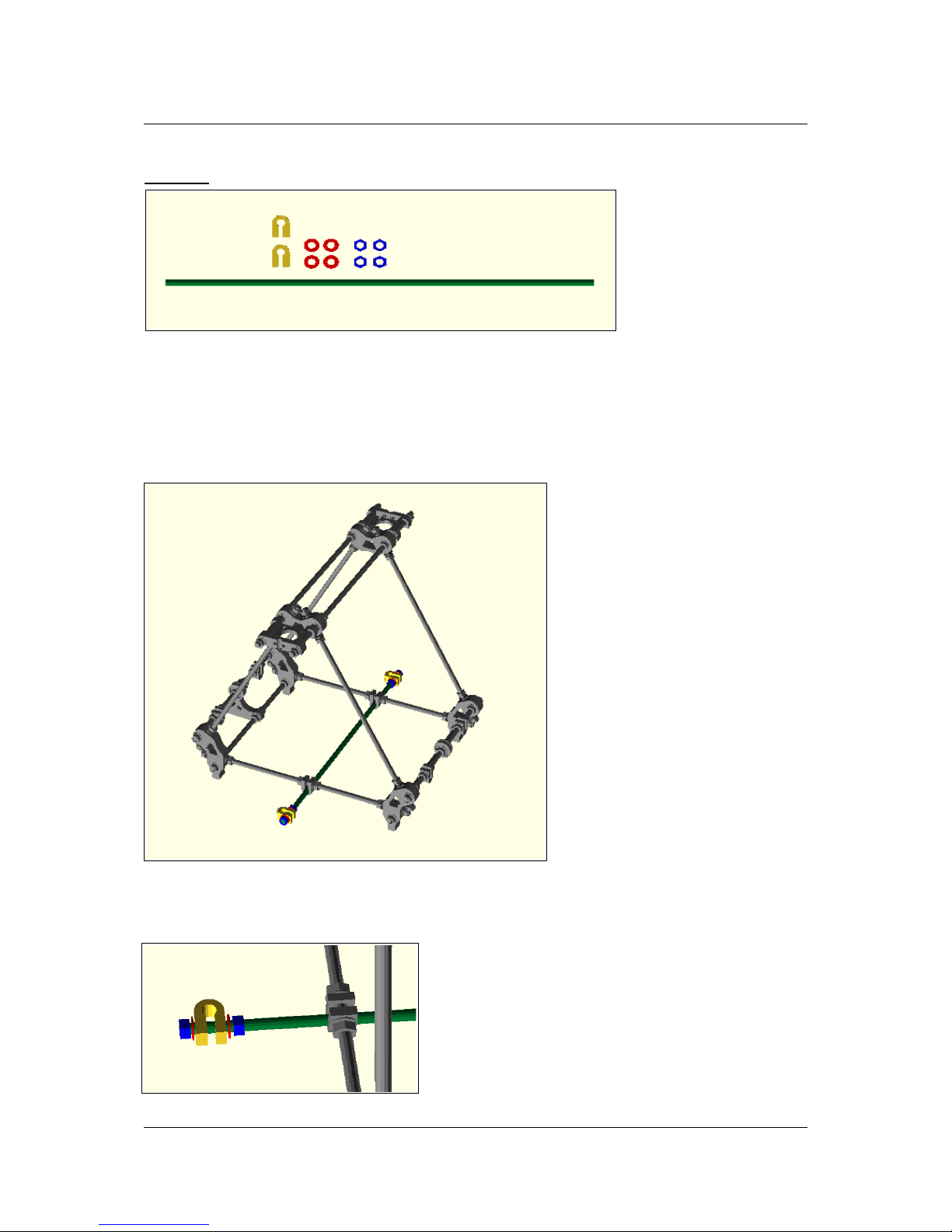

Step 1.9

Needed parts for step 1.9

The followin parts are needed for this step:

2x Bar clamps

4x Washer M8

4x Nut M8

1x Threaded rod M8 x 440 mm

and the structure from the previous step

Assembly Step 1.9

Push the threaded rod throu h the two bar clamps at the bottom of the frame and attach the

bar clamps on both sides with washers and nuts as shown in the picture above.

Assembly detail

Pa e 17/ 72

Assembly Instructions Beta Prusa DualX 13/05/14

Chapter II

Assembly of the Axes

Pa e 18 / 72

Assembly Instructions Beta Prusa DualX 13/05/14

Step 2.1

Needed parts for step 2.1

The followin parts are needed for this step:

1x Gear

4x Linear bearin SC8UU

1x Motor Nema17 with cable and plu

3x Washer M3

3x Screw M3 x 10 mm

1x Grub screw M3 x 8 mm

2x Smooth rod 8mm x 406 mm

and the structure from the previous step

Assembly Step 2.1

Pa e 19/ 72

Assembly Instructions Beta Prusa DualX 13/05/14

Push the smooth rods throu h the bar clamps on the frame and slide on the linear bearin s.

Do not fasten the nuts on the rod clamps yet.

NOTICE

Grease the linear bearings before using them. Don't forget to add the

linear bearings onto the smooth rods.

Assembly of the Y Axis motor

Push the ear onto the motor shaft and secure it with the 8mm rub screw. The ear has

holes with inte rated nuts for this. Make sure one rub screw is the flat side of the motor

shaft.

Now attach the motor to the Y motor holder with three M3 screws and washers as shown in

the picture above. Make sure the motor cables on the motor are pointin downwards.

Pa e 20/ 72

Table of contents