Jiangsu Ouring 3D Technology co.,Ltd

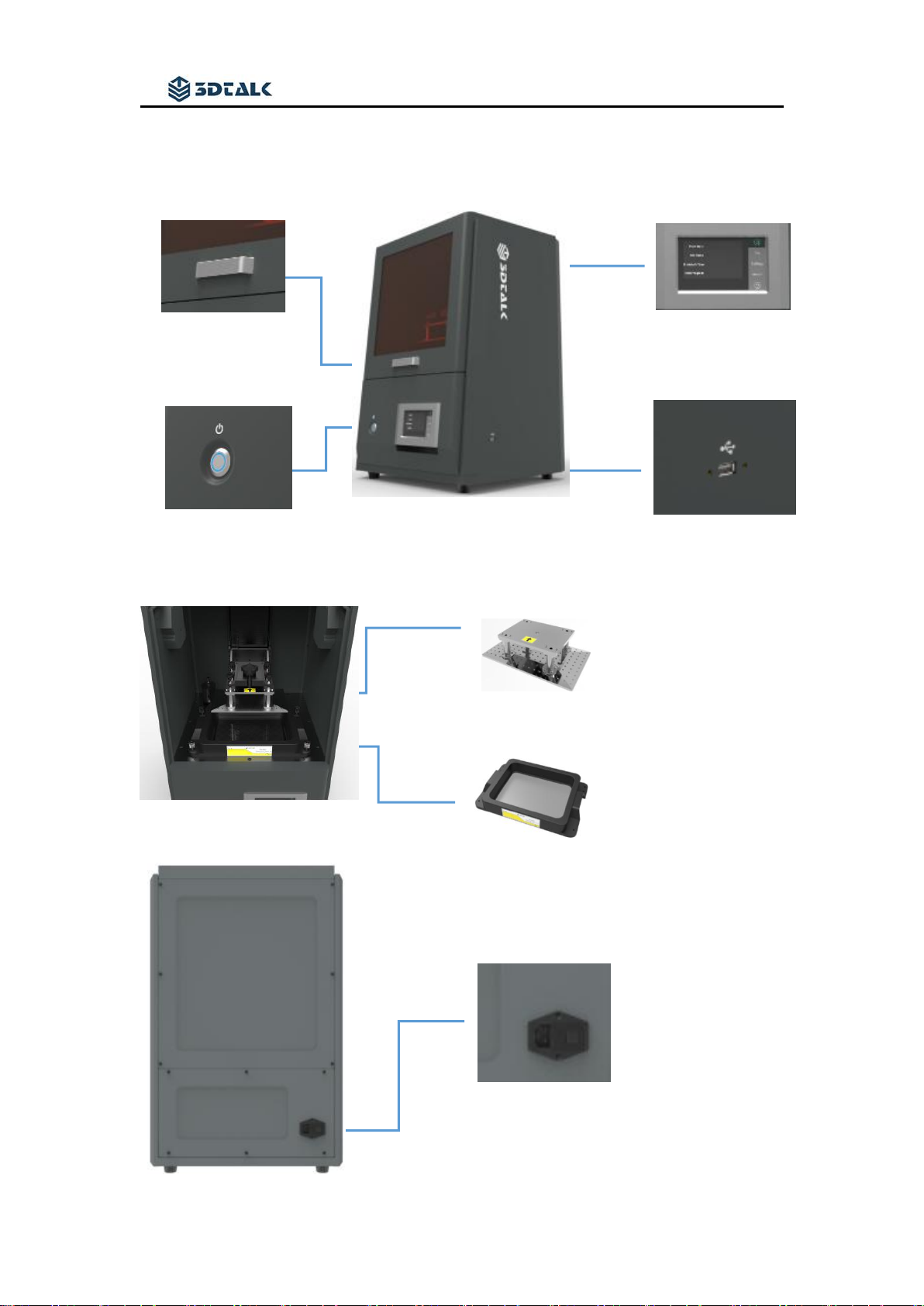

1. Product Description

General

3DTALK-DF100 series printer is a high-tech digital 3D resin printer developed

and produced by Jiangsu Ouring 3D Technology Co., Ltd. (referred to as

Ouring). Users of 3DTALK-DF100 are advised to read the product manual

carefully before start. Ouring reserves all rights. This manual is subject to

upgrade without prior notice.

Precautions

Note: Do not allow children to operate the printer without adult

supervision to avoid injury.。

Note: The printer should be placed on a horizontal table to avoid falling

or causing the resin flowing out from the vat.

Note: Do not place the printer in a damp or dusty environment, such as a

bathroom or transportation area.

Note: Please place and use the printer in a well ventilated environment.

A small amount of non-toxic odor will be produced during printing.

Having a well-ventilated area will ensure a more comfortable

environment

Note: Please lower the cabin door during printing. Do not use a metal

blade to clean the resin vat.

Note: To ensure the maximum print quality, please use original resin.

Note: Wear appropriate protective printer to avoid contact with resin. For

example: goggles, masks, protective gloves.

Note: Do not pour waste resin into the bottle and sink to avoid

contaminating the intact resin in the bottle and clogging the sewer,

please place the waste resin in a plastic bag and discard it in the sun

after cured.

Note: For unrecoverable problems, please contact the factory after-sales

staff or sales representative.