4

2. SYSTEM DESCRIPTION

WATER SUPPLY REQUIREMENTS

Minimum Maximum

Water Pressure 25 psi (1.72 bar) 70 psi (4.83 bar)

Water Temperature - 100ºF (37.78ºC)

** Recommended water pressure is between 25 psi (1.72 bar) and 70 psi. (4.83 bar).

If pressure exceeds 70 psi, it is recommended that a 40 psi pressure regulator (part

#98394-00) is used.

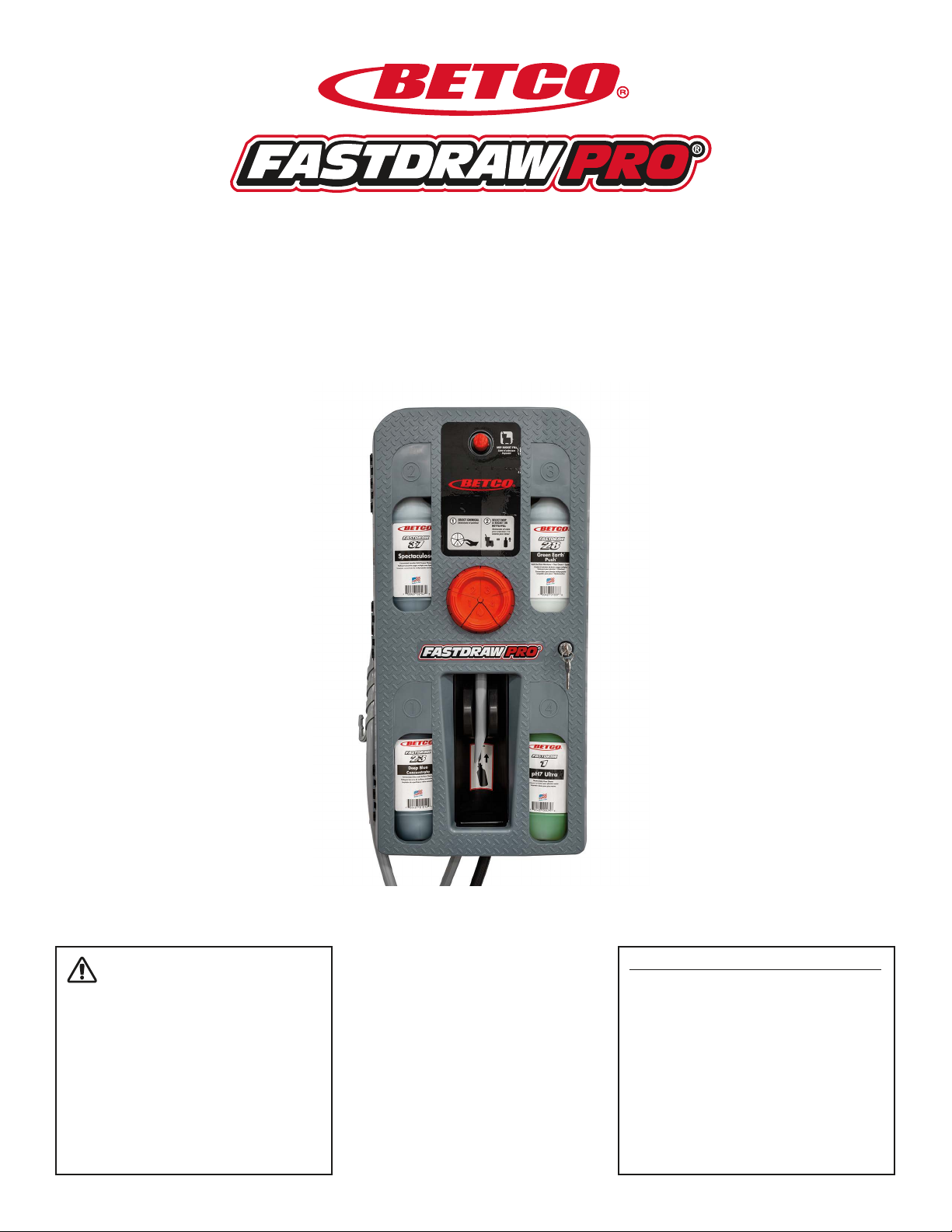

FASTDRAW PRO®is the most robust and convenient four (4) product system in the industry; designed innovative features that help users perform

their jobs faster and better. The following is just a short list of features and benefits in this system:

• Solid durable construction – Dispenser will handle the rigors of heavy wear-n-tear.

• Three-point locking – Secure locking system that prevents theft and pilferage.

• Mounting options – The dispenser can be mounted in a corner or a flat wall.

• Metering tips – No metering tips are needed. Each Betco refill comes with pre metered inserts.

• Bottle or Bucket Fill – Each bay in this dispenser can fill bottles (1 GPM), mop buckets (4 GPM), or automatic scrubbers (4 GPM)

• One-Hand bottle fill – Filling quart bottles has never been easier; simply slide the quart bottle on the tube and push forward.

• Backflow prevention – Dispenser comes in either Action Gap or Airgap which are ASSE and IAPMO approved.

• Viewing window – Each chemical bay has one large window to easily identify the type of product as well as how much of each product is

remaining.

3. PRE-INSTALLATION REQUIREMENTS

WARNING: INSTALLATION MUST MEET ALL APPLICABLE PLUMBING CODES AND REGULATIONS ESTABLISHED BY NATIONAL, CITY, COUNTY,

PARISH, PROVINCIAL OR OTHER AGENCIES. IT IS POSSIBLE THAT PLUMBING CODES AND REGULATIONS REQUIRE THAT A CERTIFIED

INSTALLATION CONTRACTOR OR ENGINEER PERFORM THE PLUMBING INSTALLATION.

• Thoroughly read the entire technical manual prior to the installation of the dispenser.

• Know what products are required for use in maintaining the facility.

• Make sure all components outlined in the parts schematic are in the carton.

• Use water supply lines from tap water outlets with a minimum of 25 PSI, not to exceed 70 PSI, and water temperature must not exceed 100°

Fahrenheit.

• Make sure the mounting surface can hold a 40lb. vertical load.

• If flat wall mounting near a corner, allow 12” to the left of the dispenser to open the door properly.

• Install the unit close to a floor drain or sink whenever possible.

• As with all chemical management systems, place it in an area that can be secured from unauthorized personnel. FASTDRAW PRO®has one locking

door to prevent tampering or theft.

4. TOOLS REQUIRED FOR INSTALLATION

• Hammer

• Tape Measure

• Drill with 9/32” drill bit

• Medium Phillips head screwdriver

• Pencil

• 2 ft level