Bettcher AutoEdge User manual

Operating Instructions & Spare Parts List for the

BETTCHER®

Manual # 185321

Re-Issued: June 15, 2018

TMC #827

For Assistance, Write:

BETTCHER INDUSTRIES INC.

P.O. Box 336

Vermilion, Ohio 44089-0336

U.S.A.

Phone: 440/965-4422

Phone: 800/321-8763

Fax: 440/328-4535

Internet: http://www.bettcher.com

COMPANY CONFIDENTIAL

Information in this document is subject to change without notice.

No part of this document may be reproduced or transmitted in any form or any means, electronic or

mechanical, for any purpose, without the express written permission of Bettcher Industries Inc.

Written permission to reproduce in whole or part is herewith granted to the legal owners of the

Bettcher® AutoEdge with which these Operating Instructions have been supplied.

Operating Instructions in other languages are available on request. Additional copies of Operating

Instructions are available by calling or writing the local Representative or by contacting:

BETTCHER INDUSTRIES, INC.

P.O. Box 336

Vermilion, Ohio 44089-0336

U.S.A.

Telephone : 440/965-4422

(In The U.S.A.) : 800/321-8763

Fax : 440/328-4535

The Information Provided In These Operating Instructions Is Important To Your

Health, Comfort And Safety.

For Safe And Proper Operation, Read This Entire Manual Before Using This

Equipment.

Copyright 2018 by Bettcher Industries, Inc.

All Rights Reserved

Original Instructions

Page i

COMPANY CONFIDENTIAL

Table of Contents

Section 1……………Safety and Ergonomics

Section 2……………Designated Use

Section 3……………Unpacking and Installation

Section 4……………Instructions for Operation

Section 5……………Maintenance

Section 6……………Cleaning

Section 7……………Service Parts

Section 8……………Contact and Document Information

BETTCHER®

Page ii

COMPANY CONFIDENTIAL

COMPANY CONFIDENTIAL

Safety and Ergonomics

BETTCHER

Industries, Inc.

Manual No. 185321

June 15, 2018

Safety and Ergonomics

Operation and Maintenance Manual 1-1

Section 1

Safety and

Ergonomics

CONTENTS OF THIS SECTION

Safety Recommendations and Warnings ............................................................................... 1-2

Safety Features ...................................................................................................................... 1-4

Ergonomics and Environment................................................................................................. 1-4

COMPANY CONFIDENTIAL

BETTCHER

Industries, Inc. Safety and Ergonomics

1-2 Safety and Ergonomics

Operation and Maintenance Manual

Manual No. 185321

June 15, 2018

Safety Recommendations and Warnings

Any use in applications other than those for which the Bettcher® AutoEdge was designed and built may

result in equipment damage and/or serious injuries.

Warnings identify conditions that can cause serious bodily injury to the user.

Cautions identify conditions that are important to the operation, care and maintenance of the machine.

W A R N I N G

THE MANUFACTURER ASSUMES NO LIABILITY FOR ANY

UNAUTHORIZED DESIGN CHANGES, MODIFICATION, OR USE

OF PARTS NOT SUPPLIED BY THE MANUFACTURER

OR

THE USE OF PARTS NOT DESIGNED FOR USE ON THIS

SPECIFIC MODEL, AND INCLUDES CHANGES IN OPERATING

PROCEDURES MADE BY THE OWNER OR ANY OF HIS

PERSONNEL.

FOR SAFE AND PROPER OPERATION, READ THE ENTIRE

MANUAL BEFORE USING THIS EQUIPMENT.

W A R N I N G

ELECTRICAL SHOCK MAY OCCUR! ALWAYS DISCONNECT

UNIT FROM POWER SUPPLY PRIOR TO SERVICING.

COMPANY CONFIDENTIAL

Safety and Ergonomics

BETTCHER

Industries, Inc.

Manual No. 185321

June 15, 2018

Safety and Ergonomics

Operation and Maintenance Manual 1-3

Safety Recommendations and Warnings (Continued)

W A R N I N G

SHARP BLADE MAY CAUSE CUT INJURY! FOR PROPER

PROTECTION OF HANDS, PROTECTIVE GLOVES SHOULD BE

WORN WHEN OPERATING THIS EQUIPMENT AND DURING THE

HANDLING OF BLADES.

W A R N I N G

ELECTRICAL SHOCK MAY OCCUR! USE ONLY 3-WIRE

GROUND TYPE CONNECTOR. THIS MUST BE CONNECTED TO

A PLANT GROUND VIA A SUITABLE GROUNDED THREE

CONDUCTOR RECEPTACLE. AVOID USE OF THIS MACHINE IN

STANDING WATER.

W A R N I N G

EYE INJURY MAY OCCUR! NEVER OPERATE THIS MACHINE

WITHOUT THE EYE SHIELD IN PLACE AND PROPER EYE

PROTECTION WORN.

COMPANY CONFIDENTIAL

BETTCHER

Industries, Inc. Safety and Ergonomics

1-4 Safety and Ergonomics

Operation and Maintenance Manual

Manual No. 185321

June 15, 2018

Safety Recommendations and Warnings (Continued)

W A R N I N G

KEEP THE MACHINE AND SURROUNDING AREA CLEAN

FROM BUILDUP OF GRINDING DUST.

A BUILDUP OF METAL DUST CAN BE A FIRE HAZARD.

Safety Features

The Bettcher® AutoEdge Blade Sharpener is equipped with an eye shield to deflect grinding particles

away from the operator.

Ergonomics and Environment

This equipment should be operated while standing in a comfortable and secure position.

The noise emission value is less than 85 db.

NOTICE

The manufacturer assumes no liability for any unauthorized changes

in operating procedures or for unauthorized changes or modifications

made to the design of the machine or any factory-installed safety

equipment, whether these changes are made by the owner of this

equipment, by his employees, or by service providers not previously

approved by Bettcher Industries, Inc.

COMPANY CONFIDENTIAL

Designated Use

BETTCHER

Industries, Inc.

Manual No. 185321

June 15, 2018

Designated Use

Operation and Maintenance Manual 2-1

Section 2

Designated Use

CONTENTS OF THIS SECTION

Machine Specifications ........................................................................................................... 2-2

Electrical Specifications .......................................................................................................... 2-2

Designated Use ...................................................................................................................... 2-2

Machine Function ................................................................................................................... 2-2

COMPANY CONFIDENTIAL

BETTCHER

Industries, Inc. Designated Use

2-2 Designated Use

Operation and Maintenance Manual

Manual No. 185321

June 15, 2018

Machine Specifications

Weight 53.5 lbs. (20.0 Kg)

Overall size (with eye-shield) 14” wide x 18” deep x 22” high

(35.6cm x 45.7cm x 55.9cm)

Power cord length 6 feet (1.83 meters)

Electrical Specifications

Power Source:

115/230VAC / 1 Phase / 60/50 Hz 150W

Designated Use

The Bettcher® AutoEdge Blade Sharpener has been designed to sharpen only Bettcher Whizard®

Trimmer blades.

Machine Function

The Bettcher® AutoEdge Blade Sharpener is a precision grinding unit that is easy to operate and

maintain. It will produce consistently sharp blades when used properly.

With a blade installed in the blade holder, the cycle switch is pushed to start the automatic blade

sharpening cycle. The blade holder and grinder wheel will turn on and start rotating. The grinder wheel

will automatically move toward the blade and start grinding. The blade’s cutting surface is ground for a

short time to sharpen the cutting edge. A steeling device will automatically come in to steel the inside of

the cutting edge. The grinder wheel will continue to lightly grind the blade during the steeling

operation. When the sharpening process is complete, the steeling device and grinder wheel will

automatically retract to their home position and shut off.

The blade can then be removed and the sharpening process repeated for the next blade.

COMPANY CONFIDENTIAL

Unpacking and Installation

BETTCHER

Industries, Inc.

Manual No. 185321

June 15, 2018

Unpacking and Installation

Operation and Maintenance Manual 3-1

Section 3

Unpacking and

Installation

CONTENTS OF THIS SECTION

Unpacking .............................................................................................................................. 3-2

Included With Your Machine ................................................................................................... 3-2

Installation .............................................................................................................................. 3-3

Work Station and Lighting ...................................................................................................... 3-3

COMPANY CONFIDENTIAL

BETTCHER

Industries, Inc. Unpacking and Installation

3-2 Unpacking and Installation

Operation and Maintenance Manual

Manual No. 185321

June 15, 2018

Unpacking

Included With Your Machine

The following parts and assemblies are included with your Bettcher® AutoEdge Blade Sharpener.

Please check when unpacking and advise your local Bettcher Industries’ representative if the delivery is

incomplete.

Item

Number Description

1 Eye Shield

2 “Quad” Steeling Device Head

3 Blade Holder Base

4 Blade Holder Screw

5 Washer

6 Grinder Wheel

7 Utility Drawer

Not Shown Information Sheet (Part Number 185222)

Not Shown Operator’s Manual

Description Part Number

Tool Kit

(Includes the following): 185299

Dust Brush 120547

7/16 inch Nut Driver 120546

3/32 Hex Wrench 120545

5/32 Hex Wrench 173546

1

2

3

4 & 5

6

7

COMPANY CONFIDENTIAL

Unpacking and Installation

BETTCHER

Industries, Inc.

Manual No. 185321

June 15, 2018

Unpacking and Installation

Operation and Maintenance Manual 3-3

Installation

Work Station and Lighting

Place the Bettcher® AutoEdge on a bench surface of standard working position height. Appropriate

lighting should be available. Head and hands are to be kept at a safe distance from the grinder wheel

and blade during operation.

230V Machines Only: A plug is not provided with this machine. A way to disconnect, in the form of a

plug or switch, must be attached to the power cord to assure proper disconnect of all poles.

COMPANY CONFIDENTIAL

BETTCHER

Industries, Inc. Unpacking and Installation

3-4 Unpacking and Installation

Operation and Maintenance Manual

Manual No. 185321

June 15, 2018

THIS PAGE INTENTIONALLY LEFT BLANK

COMPANY CONFIDENTIAL

Instructions for Operation

BETTCHER

Industries, Inc.

Manual No. 185321

June 15, 2018

Safety and Ergonomics

Operation and Maintenance Manual 4-1

Section 4

Instructions for

Operation

CONTENTS OF THIS SECTION

Instructions for Operation ....................................................................................................... 4-2

Information / Operation Sheet:................................................................................................ 4-2

Attaching the Blade Holder ..................................................................................................... 4-2

Installing a Blade for Sharpening ............................................................................................ 4-3

Positioning the Steeling Device .............................................................................................. 4-4

Selecting the Steeling Head ................................................................................................... 4-5

Positioning the Grinder Motor ................................................................................................. 4-6

Grinder Wheel ........................................................................................................................ 4-7

Sharpening the Blade ............................................................................................................. 4-7

Removing the Blade ............................................................................................................... 4-8

Check Blade Wear .................................................................................................................. 4-9

COMPANY CONFIDENTIAL

BETTCHER

Industries, Inc. Instructions for Operation

4-2 Instructions for Operation

Operation and Maintenance Manual

Manual No. 185321

June 15, 2018

Instructions for Operation

Read Complete Operating Instructions Before Attempting to Sharpen any Blades.

C A U T I O N

THE BLADE HOLDER HAS A PILOT BOSS ON THE BOTTOM WHICH LOCATES ON THE

BLADE HOLDER BASE AND A BORE ON TOP WHICH LOCATES THE BLADE. CARE

SHOULD BE TAKEN NOT TO DAMAGE THESE SURFACES AS WELL AS THE DRIVE

SHAFT. ALWAYS CHECK THAT THESE SURFACES ARE FREE OF GRINDING DUST

PRIOR TO ASSEMBLY.

Information / Operation Sheet:

An information sheet (Part Number 185222) is provided with the sharpener that identifies the steeling

device position, steeling device head position, grinder motor position and blade holder to be used with

each blade model.

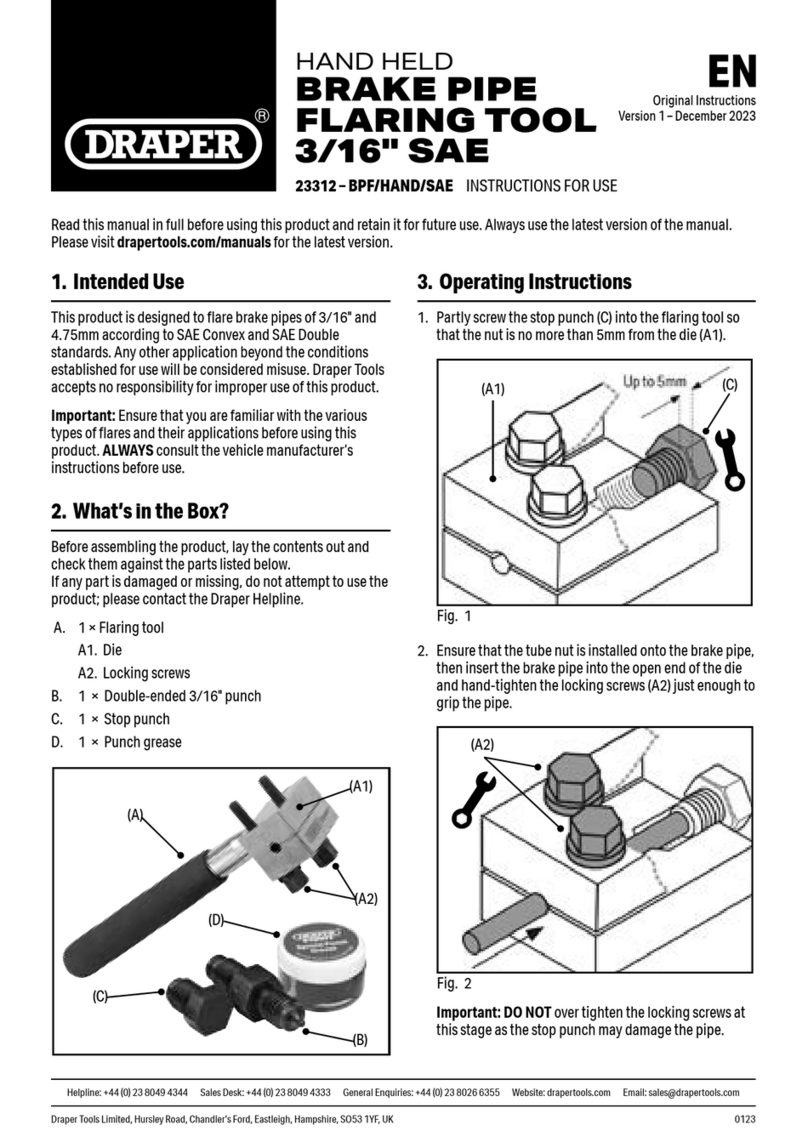

Attaching the Blade Holder

Refer to the information sheet for the model blade holder to be used. The blade model number and the

part number of the holder are etched on the face of the blade holder.

The blade holder base is attached to the blade holder drive shaft with two screws. This blade holder

base need not be removed once it has been installed.

IMPORTANT: Insure all mounting surfaces for the blade holder are clean.

Place the blade holder on the blade holder base. A pilot boss on the back of the blade holder locates into

the pilot bore of the base. Install the blade holder washer and screw through the center hole in the blade

holder. Do not tighten at this time.

Screw

Pilot Boss

on Back

of Blade

Holder

Pilot Bore on

Blade Holder

Base

Blade Holder

(Installed)

Screw and

Washer

COMPANY CONFIDENTIAL

Instructions for Operation

BETTCHER

Industries, Inc.

Manual No. 185321

June 15, 2018

Safety and Ergonomics

Operation and Maintenance Manual 4-3

Installing a Blade for Sharpening

W A R N I N G

SHARP BLADE MAY CAUSE CUT INJURY! FOR PROPER

PROTECTION OF HANDS, A PROTECTIVE GLOVE SHOULD BE

USED WHEN OPERATING THIS EQUIPMENT AND DURING

HANDLING OF BLADES.

Make certain the proper blade holder is installed.

Check that all inner surfaces of the holder are free of grinding dust.

Place the blade into the blade holder recess. Carefully hold the blade into the recess and tighten the

blade holder screw until you feel some resistance against the blade. Hold the outside diameter of the

blade holder base and tighten the blade holder screw to fully secure the blade in the blade holder.

Blade Holder

Recess for the

Blade

COMPANY CONFIDENTIAL

BETTCHER

Industries, Inc. Instructions for Operation

4-4 Instructions for Operation

Operation and Maintenance Manual

Manual No. 185321

June 15, 2018

Positioning the Steeling Device

Refer to the information sheet for the setting position of the blade model to be sharpened.

The steeling device slides on the steeling base and is secured in place by the lock-down knob. Loosen

the lock-down knob. Slide the steeling device assembly so that the indicator mark on the steeling device

body lines up with the number line position on the steeling position plate.

Tighten the lock-down knob.

The steeling device is secured in the down position by a spring plunger latch. The steeling device can be

pivoted out from the blade holder by pulling up on the steeling device handle.

Number Line on the

Steeling Position Plate

Indicator

Mark on the

Steeling

Device Body

Lock-Down Knob

Steeling Base

Spring Plunger Latch

COMPANY CONFIDENTIAL

Instructions for Operation

BETTCHER

Industries, Inc.

Manual No. 185321

June 15, 2018

Safety and Ergonomics

Operation and Maintenance Manual 4-5

Selecting the Steeling Head

Refer to the information sheet for the steeling head setting position of the blade to be sharpened.

The standard steeling head has four steeling rod positions lettered A, B, C and D. To position the

steeling head, pull it out fully and then rotate it so that the correct position letter is facing outward. The

steeling head will then slide back so that the steeling shaft key slides into the position slot.

The steeling head should slide freely on the shaft against the spring and be guided on the shaft key.

There are special steeling heads for non-standard blade models as indicated on the chart with lettered

positions E, F, --etc. These non-standard blade models are listed in Section 7; Service Parts.

To replace the steeling head, remove the steeling shaft screw and slide the spring and steeling head off.

Reverse this procedure to install the steeling head.

Position

Slot

Steeling

Shaft Screw

Position Letter

Steeling Rods

Steeling

Head

Assembly

Steeling Shaft Key

COMPANY CONFIDENTIAL

BETTCHER

Industries, Inc. Instructions for Operation

4-6 Instructions for Operation

Operation and Maintenance Manual

Manual No. 185321

June 15, 2018

Positioning the Grinder Motor

Refer to the settings chart for the appropriate grinder motor position of the blade to be sharpened.

Holding the grinder arm handle, loosen the screw inside the grinder arm lock knob, using a

7/16” (11mm) hex nut driver. The grinder arm is now free to slide along the motor position base.

Align the indicator line on the grinder arm’s bottom plate to the appropriate number line on the motor

position plate and tighten the lock knob screw, using the hex nut driver.

The lock knob can be loosened to swing the grinder arm down out of the way when changing blades,

without losing the motor set position. Swing the grinder arm back up against the lock knob post and

tighten the knob down to reposition the grinder arm in the grinding position.

Grinder Arm Indicator Line

Motor Position Number Line

Motor Position Base

Grinder Arm

Screw Inside of

Locking Knob

Lock Knob Post

Lock Knob

Grinder Arm

Grinder Arm Handle

COMPANY CONFIDENTIAL

Table of contents

Other Bettcher Power Tools manuals

Popular Power Tools manuals by other brands

DeWalt

DeWalt DCF899HP2 manual

Milwaukee

Milwaukee M12 FPD-602X Original instructions

DeWalt

DeWalt DC820, DC830, DC840 instruction manual

Strongway

Strongway 46270 owner's manual

Hitachi

Hitachi CG-HT Handling instructions

National Flooring Equipment

National Flooring Equipment 5200QL OPERATING & SERVICE MANUAL