Ram stroke....................................................................180mm

Max height - ram to table...............................................340mm

Min height - ram to table................................................190mm

Table aperture ...............................................................115mm

Table depth....................................................................140mm

Table width ....................................................................335mm

Overall height..............................................................1060mm

Weight ............................................................................50.5kg

Gauge included....................................................................No

4. ASSEMBLY

4.1. Unpack the product and check contents. Should there be any damaged or missing parts contact your supplier immediately. Take care to

ensure safety when removing uprights from packing as the units are very heavy.

4.2. Use the parts diagram as your guide to assembly. Lay all parts and assemblies out before beginning. The following procedure is

recommended:

4.3. Identify and lay out parts. Bolt the cross legs to the bottom of the pre-assembled main frame.

4.4. Bolt the ram supporting plate or plates to the head of the main frame. NOTE. If your model has a top and bottom plate which attach to

either side of the frame head, screw the nuts finger tight only at this stage.

4.5. Remove the plastic protection ring from the ram thread and apply a suitable thread locking compound, screw the ram into the support

plate until it is tight, thread the locking ring onto the ram on the lower side of the support plate and tighten.

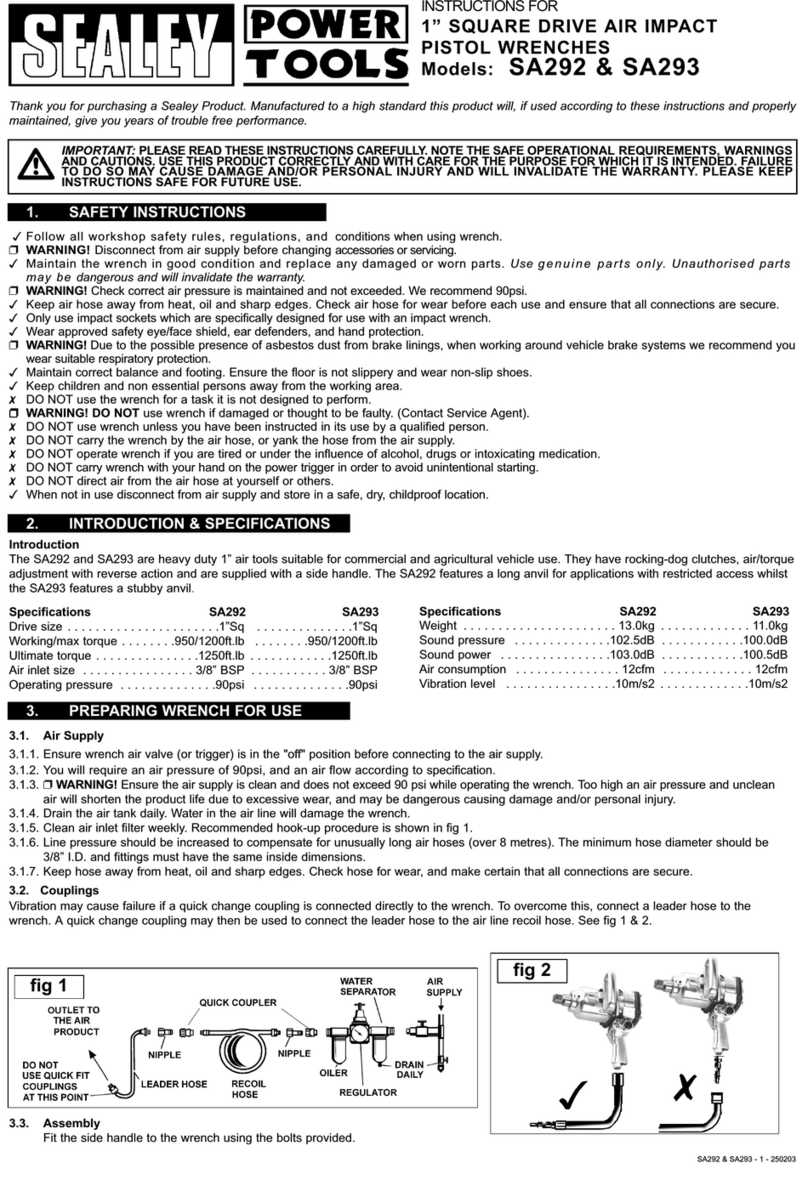

4.6. Attach the pump according to model:

4.7. Should your model have a separate pump assembly plate, check side of main frame to locate assembly holes. If you have a choice

of left or right attachment, assemble the plate according to your operational requirement.

4.8. Attach the pump to the pump plate or to the appropriate attachment bars incorporated in the main frame using the bolts provided.

4.9. The pump can be stowed on the side of the main frame when not in use by hanging it on the hook provided.

4.10. Remove the plastic safety bung from the end of the pump hose and connect the hose to the ram inlet valve.

4.11. Insert the work table support pins through the holes in the main frame. Taking firm hold of the table, tip it into a diagonal position so

hat it can be introduced between the mainframe uprights and carefully lower it back to a horizontal position to rest on the support

pins.

WARNING! Take care not to allow the working table to drop onto the pins and ensure your hands and fingers are clear of the

working table when lowering. OPERATION

5. INSTALLATION.

5.1. Securely attach the press to a flat, firm, level surface taking into account clearance for working pieces. Should you wish to mount a bench

press on a workbench or surface, ensure the bench is flat and level and is strong enough to support the press and any workpiece during

operation.

5.2. Before operating the press, purge the hydraulic system in order to eliminate any air that may have built up during transit. Open the

release valve and pump the handle several times. Should the system malfunction at any time, repeating this process may resolve the

problem.

▲ DANGER! Models are purpose designed to withstand greater loads than the hydraulic units can develop. For safety reasons, always

ensure the workpiece and press tools are secured on the table and will not flex or suddenly “give way” causing danger to operator

or the component. Also ensure you have read and understood section 1 safety instructions.

6. OPERATION

6.1. Check that the hydraulic unit is fully closed ready for operating.

6.2. Position the working table at the required operating height by inserting the support pins into the appropriate holes in the main frame.

6.3. Screw the required adaptor to the ram and if required identify the matching cutout on the arbor plate to be used.

6.4. Position the arbor plate or press tools to be used onto the work table and align beneath the ram. Place workpiece onto the work table

or arbors and align beneath the ram as required. Note: Care must be taken to ensure an arbor does not fall from the press work table.

If necessary hold the configuration in position with clamps.

6.5. Operate the pump slowly until the ram is close to or just touching the workpiece. Before applying real pressure to the workpiece

recheck the alignment with the ram and ensure that the workpiece and press tools are supported in such a way that they cannot flex to

breaking point. DO NOT exceed the stroke indicated on the label or the red mark on the piston and DO NOT apply off centre loads.

6.6. When work is complete release the pressure using the knob with four lugs and the piston and the ram head will retract automatically.

NOTE: Always keep the piston retracted after use to avoid corrosion.

7. MAINTENANCE

NOTE: Maintenance and repair must only be carried out by qualified person. Contact your Sealey stockist for details.

7.1. When the press is not in use, the hydraulic unit ram must be fully retracted to minimise corrosion. Remove the handle to inactivate the

press.

7.2. Lubricate all moving parts at regular intervals.

7.3. Always keep the press clean, dry, and protected from harsh conditions.

7.4. Should you need to replace the oil, ensure the hydraulic unit ram is fully retracted. An excess of oil will render the press inoperative.

7.5. Use only appropriate Sealey hydraulic jack oil (Sealey Part Number: HJO500MLS/HJO5LS). DO NOT use brake fluid.

7.6. Purge the system to remove any air.

7.7. Check your model parts information for spares.

Original Language Version

© Jack Sealey Limited YK10BLG.V2 Issue 2 07/11/18