Bettcher Whizard 210 Guide

Operating Instructions And Spare Parts List

UNIVERSAL BLADE SHARPENER

MODEL 210

(115 Volt)

For Assistance Contact:

BETTCHER INDUSTRIES, INC.

Post Office Box 336

Vermilion, Ohio 44089

Fax: 440-328-4535

Call: 1-800-321-8763

MANUAL NO. *113985

RE-ISSUED 06/15/2018

TMC # 828

www.bettcher.com

COMPANY CONFIDENTIAL

Operating BETTCHER Whizard®Universal Blade Sharpener Model 210, 115V

Instructions INDUSTRIES, INC. Rev. 05/17/2019

Page i

Information in this document is subject to change without notice.

No part of this document may be reproduced or transmitted in any form or any

means, electronic or mechanical, for any purpose, without the express written

permission of Bettcher Industries, Inc.

Written permission to reproduce in whole or part is herewith granted to the

legal owners of the Whizard® Universal Blade Sharpener Model 210, 115V

which with these Operating Instructions have been supplied.

Operating Instructions in other languages are available on request. Additional

copies of this Operating Instruction is available by calling or writing the local

Representative or by contacting :

BETTCHER INDUSTRIES, INC.

P.O. Box 336

Vermilion, Ohio 44089

U.S.A.

Telephone: 1-440-965-4422

(In the U.S.A.): 1-800-321-8763

Fax: 1-440-328-4535

The Information Provided In These Operating Instructions

Are Important To Your Health, Comfort And Safety.

For Safe And Proper Operation, Read This Entire

Manual Before Using This Equipment.

Copyright 2018 By Bettcher Industries, Inc.

All Rights Reserved.

Original Instructions

COMPANY CONFIDENTIAL

Operating BETTCHER Whizard®Universal Blade Sharpener Model 210, 115V

Instructions INDUSTRIES, INC. Rev. 05/17/2019

Page ii

Table Of Contents

SECTION 1.0 Machine Specifications 1

SECTION 2.0 Designated Use 1

2.1 Recommended Operation 1

2.2 Warning 2

SECTION 3.0 Function 2

3.1 Machine Functions 2

3.2 Safety Recommendations And Warnings 2

SECTION 4.0 Safety Features 3

SECTION 5.0 Ergonomics And Environment 3

SECTION 6.0 Unpacking 4

6.1 Included With Your Machine 4

SECTION 7.0 Installation 6

7.1 Work Station & Lighting 6

SECTION 8.0 Instructions For Operation 6

8.1 Attaching The Blade Holder 6

8.2 Attaching The Steeling Device 7

8.3 Installing Blade Into Blade Holder 7

8.4 Grinder Feed Control 8

8.5 Positioning Grinder To Sharpen Blade 8

8.6 Grinder Wheel 8

8.7 Sharpening The Blade 9

8.8 Lower Grinder After Sharpening & Steeling Blade 11

8.9 Removing The Blade 11

8.10 Check Blade Wear 12

8.11 Fault Detection And Correction 13

COMPANY CONFIDENTIAL

Operating BETTCHER Whizard®Universal Blade Sharpener Model 210, 115V

Instructions INDUSTRIES, INC. Rev. 05/17/2019

Page iii

Table Of Contents

(continued)

SECTION 9.0 Maintenance/Cleaning 14

SECTION 10.0 Spare Parts List

10.1 Cabinet Assembly 16

10.2 Grinder Motor Assembly 18

10.3 Drive Motor Assembly 20

10.4 Blade Holders 22

10.5 Steeling Devices 24

10.6 Grinder Wheels 26

10.7 Bettcher® Whizard® Blade Wear Gauges 27

10.8 Wiring Diagram` 28

SECTION 11.0 About These Operating Instructions 29

SECTION 12.0 Contact Address & Phone 30

COMPANY CONFIDENTIAL

Operating BETTCHER Whizard® Universal Blade Sharpener Model 210, 115V

Instructions INDUSTRIES, INC. Rev. 05/17/2019

Page 1

SECTION 1.0 Machine Specifications

General Information:

Weight: 45 lbs. (20 Kg)

Overall Size (With Eyeshield): 10” wide x 21” deep x 17.5” high

(254mm) x (534mm) x (445mm)

Power Cord Length: 6 feet

Electrical Specifications:

Grinder Motor: 115 VAC/1/50-60 Hz 1/10 HP 1.5 Amps

8000 RPM

Blade Drive Gear Motor: 115 VAC/1/50-60 Hz 1/50 HP 0.6 Amps

162 RPM

Power Source: 115 VAC / 1 Phase / 60 Hz

SECTION 2.0 Designated Use

2.1 Recommended Operation

The Whizard® Universal Blade Sharpener Model 210 was designed and built

to sharpen only Bettcher Whizard® blades.

COMPANY CONFIDENTIAL

Operating BETTCHER Whizard®Universal Blade Sharpener Model 210, 115V

Instructions INDUSTRIES, INC. Rev. 05/17/2019

Page 2

2.2 Warning

Any use in applications other than those for which the Whizard® Universal

Blade Sharpener Model 210 was designed and built may result in equipment

damage and/or serious injuries.

WARNING

THE MANUFACTURER ASSUMES NO LIABILITY FOR ANY

UNAUTHORIZED DESIGN CHANGES, MODIFICATIONS, OR

USE OF PARTS NOT SUPPLIED BY THE MANUFACTURER

OR

THE USE OF PARTS NOT DESIGNED FOR USE ON

THIS SPECIFIC MODEL, AND INCLUDES CHANGES IN OPERATING

PROCEDURES MADE BY THE OWNER

OR ANY OF HIS PERSONNEL.

FOR SAFE AND PROPER OPERATION, READ THE

ENTIRE MANUAL BEFORE USING THIS EQUIPMENT.

SECTION 3.0 Function

3.1 Machine Function

The Whizard® Universal Blade Sharpener is a precision grinding unit that is

easy to operate and maintain. As with any cutting device in meat packing,

the Whizard® is only as effective as the cutting edge is sharp.

Proper use of this sharpener will eliminate the guesswork as to whether or not

the blade edge is ground to the correct angle and is sharp. A properly

sharpened Whizard® blade will reduce operator fatigue and pay off big in

increased trimming yields.

3.2 Safety Recommendations And Warnings

WARNING

ELECTRICAL SHOCK MAY OCCUR! ALWAYS DISCONNECT

UNIT FROM POWER SUPPLY PRIOR TO SERVICING.

COMPANY CONFIDENTIAL

Operating BETTCHER Whizard®Universal Blade Sharpener Model 210, 115V

Instructions INDUSTRIES, INC. Rev. 05/17/2019

Page 3

3.2 Safety Recommendations And Warnings (Continued)

WARNING

SHARP BLADE MAY CAUSE CUT INJURY!

FOR PROPER PROTECTION OF HANDS, PROTECTIVE

GLOVES SHOULD BE WORN WHEN OPERATING THIS EQUIPMENT

AND DURING THE HANDLING THE BLADES.

WARNING

ELECTRICAL SHOCK MAY OCCUR!

USE ONLY 3-WIRE GROUND TYPE CONNECTOR.

THIS MUST BE CONNECTED TO A PLANT GROUND VIA

A SUITABLE GROUNDED THREE CONDUCTOR RECEPTACLE. AVOID

USE OF THIS MACHINE IN STANDING WATER.

WARNING

EYE INJURY MAY OCCUR!

NEVER OPERATE THIS MACHINE WITHOUT THE EYE SHIELD IN

PLACE AND PROPER EYE PROTECTION WORN.

SECTION 4.0 Safety Features

The Whizard® Universal Blade Sharpener Model 210 is equipped with an eye

shield to deflect grinding particles away from the operator.

SECTION 5.0 Ergonomics And Environment

This equipment should be operated while standing in a comfortable and secure

position.

The noise emission value is less than 75 dB(A).

COMPANY CONFIDENTIAL

Operating BETTCHER Whizard®Universal Blade Sharpener Model 210, 115V

Instructions INDUSTRIES, INC. Rev. 05/17/2019

Page 4

SECTION 6.0 Unpacking

6.1 Included With Your Machine

The following parts and assemblies are included with your Whizard®

Universal Blade Sharpener Model 210 except as noted. Due to the wide

variety of blade sizes and styles, the blade holder (Item 14) and the steeling

device (Item 6) must be ordered separately. Please check when unpacking

and advise your local Bettcher Industries representative if the delivery is

incomplete.

COMPANY CONFIDENTIAL

Operating BETTCHER Whizard®Universal Blade Sharpener Model 210, 115V

Instructions INDUSTRIES, INC. Rev. 05/17/2019

Page 5

6.1 Included With Your Machine (Continued)

Item Number Description

1 Eye Shield

2 Blade Holder Motor Switch

3 Grinder Motor Switch

4 Steeling Device Pin

5 Steeling Device Base

6 Steeling Device (Not Included)

7 Steeling Device Shaft (Included With Item 6)

8 Pedestal Knob

9 Positioner Plate

9A Positioner Arm

10 Positioner Shaft

11 Grinder Pivot

12 Grinder Motor

13 Grinder Wheel

14 Blade Holder (Not Included)

15 Blade Holder Pin (Included With Item 14)

16 Blade Holder Screws

Operating Instructions and Spare Parts Manual

COMPANY CONFIDENTIAL

Operating BETTCHER Whizard®Universal Blade Sharpener Model 210, 115V

Instructions INDUSTRIES, INC. Rev. 05/17/2019

Page 6

SECTION 7.0 Installation

7.1 Work Station & Lighting

Place the universal sharpener on a bench surface of standard working position

height. Appropriate lighting should be available. Head and hands to be kept

at a safe distance from the grinding wheel and blade during operation.

SECTION 8.0 Instructions For Operation

Read Complete Operating Instructions Before Attempting To Sharpen Any Blades.

8.1 Attaching The Blade Holder

Refer to Section 6.1 for item callouts.

The blade holders and steeling devices are labeled to indicate the model

blade(s) they are related to. See Sections 10.2 and 10.3.

CAUTION

THE BLADE HOLDER HAS A PILOT BORE ON THE BOTTOM WHICH LOCATES ON

THE DRIVE SHAFT AND A BORE ON TOP WHICH LOCATES THE BLADE. CARE

SHOULD BE TAKEN NOT TO DAMAGE THESE SURFACES AS WELL AS THE DRIVE

SHAFT. ALWAYS CHECK THAT THESE SURFACES ARE FREE OF DIRT AND DUST

PRIOR TO ASSEMBLY.

First lower the grinder (#12) to its rest position.

Hold the grinder pivot (#11) with your left hand and press in the knob of the

positioner shaft (#10) with your thumb to release the grinder from the

positioner arm (#9A).

Then slowly swing the grinder down until it comes to a stop.

Do not let the grinder drop freely.

COMPANY CONFIDENTIAL

Operating BETTCHER Whizard®Universal Blade Sharpener Model 210, 115V

Instructions INDUSTRIES, INC. Rev. 05/17/2019

Page 7

8.1 Attaching The Blade Holder (Continued)

Do not remove blade holder screws (#16) from the drive shaft.

Carefully guide blade holder (#14) straight onto the drive shaft.

With blade holder seated on the drive shaft, loosen blade holder screws (#16)

sufficiently to allow the blade holder to rotate until the screws are in line with

the countersunk holes of the slots.

Tighten blade holder screws (#16) down snugly. Do not over tighten.

8.2 Attaching The Steeling Device

Remove the steeling device pin (#4).

Place steeling device (#6) in slot of steeling device base (#5).

Align hole in steeling device with slot in steeling device base and insert

steeling device pin.

8.3 Installing Blade Into Blade Holder

WARNING

SHARP BLADE MAY CAUSE CUT INJURY!

FOR PROPER PROTECTION OF HANDS, A PROTECTIVE

GLOVE SHOULD BE USED WHEN OPERATING THIS

EQUIPMENT AND DURING THE HANDLING OF BLADES.

Check that all inner surfaces of the holder are free of dirt and dust.

Place blade in blade holder (#14) with gear teeth facing down.

Using a standard flat blade screwdriver, rotate blade hold down pins (#15)

to ride onto the blade.

COMPANY CONFIDENTIAL

Operating BETTCHER Whizard®Universal Blade Sharpener Model 210, 115V

Instructions INDUSTRIES, INC. Rev. 05/17/2019

Page 8

8.3 Installing Blade Into Blade Holder (Continued)

Check that blade is secure in the blade holder.

Note:

If blade turns freely in blade holder with hold down pins

in place, it is worn excessively and will not operate

at maximum efficiency in your Whizard® knife.

This blade can not be sharpened and should be discarded.

8.4 Grinder Feed Control

Turning the pedestal knob (#8) clockwise feeds the grinder wheel (#13) into

the blade and counterclockwise moves the grinder wheel away from the blade.

8.5 Positioning Grinder To Sharpen Blade

Loosen nut on positioner plate (#9) and align mark on positioner arm (#9A)

with mark on positioner plate (refer to "Position-Model" label on positioner

plate), then retighten nut. Holding the grinder pivot (#11) with your left hand,

press in the knob of the positioner shaft (#10) and lift the grinder (#12)

upward, allowing the positioner shaft to enter the slot of positioner arm (#9A).

Release positioner shaft into hole of the positioner arm.

Note:

Back away grinder as needed when raising

into position to avoid hitting the blade.

DO NOT lift grinder into position with the motor turned on.

8.6 Grinder Wheel

This grinder wheel is a CBN (Borazon) plated wheel-form and does not

require dressing of its grinding surfaces. See Section 9.0 for cleaning.

COMPANY CONFIDENTIAL

Operating BETTCHER Whizard®Universal Blade Sharpener Model 210, 115V

Instructions INDUSTRIES, INC. Rev. 05/17/2019

Page 9

8.6 Grinder Wheel (Continued)

Use the correct grinding wheel and grinding wheel surface to sharpen the

blades as shown below :

350, 520, 620,

500 564, 750,

754

1850, 900-

1500

360, 625,

505, 850

350 Cone

TRIMVAC®

TRIMVAC®

14/18 AMX

8.7 Sharpening The Blade

WARNING

EYE INJURY MAY OCCUR!

NEVER OPERATE THIS MACHINE WITHOUT THE EYE SHIELD IN PLACE.

Be sure grinder wheel (#13) is not touching blade. Turn on blade holder motor

switch (#2) and grinder motor switch (#3).

With both grinder wheel and blade holder rotating, slowly feed the grinder

wheel at a constant rate into the blade until a continuous 360 degree spark is

achieved.

CAUTION

PREMATURE FAILURE OF THE GRINDER WHEEL COULD RESULT IF EXCESSIVE PRESSURE

IS APPLIED. ALTHOUGH THE WHEEL SHOULD BE LOWERED AT A CONSTANT RATE,

IT MUST NOT BE JAMMED OR RAPIDLY FORCED INTO THE BLADE.

FATS AND OILS WILL PREMATURELY LOAD THE GRINDING WHEEL.

CLEAN BLADES BEFORE AND AFTER SHARPENING.

COMPANY CONFIDENTIAL

Operating BETTCHER Whizard®Universal Blade Sharpener Model 210, 115V

Instructions INDUSTRIES, INC. Rev. 05/17/2019

Page 10

8.7 Sharpening The Blade (Continued)

With a continuous spark appearing for complete revolutions

of the blade, proceed to steel the blade edges as described below.

For Model 360/505/625/850/880/350 Cone/TRIMVAC®/TRIMVAC®18AMX Blades:

With your right hand, grasp the knob of the steeling device (#6) between your

middle and index fingers.

Swing steeling device toward the center of the blade.

Slide the steeling device to the right until the steeling shaft contacts the inside

blade edge.

Hold the steeling device lightly against the blade for a few complete blade

revolutions.

Simultaneously release the steeling device from the blade edge and back off the

grinder with your left hand.

Swing steeling device out away from the blade.

Turn off blade motor switch (#2) and grinder motor switch (#3).

For Model 350/500/520/564/620/750/754/900/1040/1200/1000/1300/1400

and 1500 Blades:

With your right hand, grasp the knob of the steeling device (#6) between your

middle and index fingers.

Swing the steeling device toward the center of the blade.

Press down on steeling shaft knob (#7) with your thumb and slide the steeling

device to the right until the steeling shaft contacts the inside blade edge.

COMPANY CONFIDENTIAL

Operating BETTCHER Whizard®Universal Blade Sharpener Model 210, 115V

Instructions INDUSTRIES, INC. Rev. 05/17/2019

Page 11

8.7 Sharpening The Blade (Continued)

For Model 350/500/520/564/620/750/754/900/1040/1200/1000/1300/1400

and 1500 Blades: (Continued)

While holding the steeling shaft lightly against the blade edge, move the

steeling shaft in and out across the blade edge for a few complete blade

revolutions.

Simultaneously release the steeling device from the blade edge and back off the

grinder with your left hand.

Swing steeling device out away from the blade.

Turn off blade motor switch (#2) and grinder motor switch (#3)

8.8 To Lower Grinder After Sharpening And Steeling Blade

Holding the grinder pivot (#11) with your left hand, press in the knob of

positioner shaft (#10) and slowly swing grinder down until it comes to a stop.

Do not let the grinder drop freely.

8.9 Removing The Blade

WARNING

SHARP BLADE MAY CAUSE CUT INJURY!

FOR PROPER PROTECTION OF HANDS, A PROTECTIVE

GLOVE SHOULD BE USED WHEN OPERATING THIS

EQUIPMENT AND DURING THE HANDLING OF BLADES.

Rotate the blade hold down pins (#15) off the blade. Carefully lift the blade

from the blade holder.

CAUTION

AFTER SHARPENING, CAREFULLY WASH BLADE

WITH HOT, SOAPY WATER AND A SMALL BRUSH.

COMPANY CONFIDENTIAL

Operating BETTCHER Whizard®Universal Blade Sharpener Model 210, 115V

Instructions INDUSTRIES, INC. Rev. 05/17/2019

Page 12

8.10 Check Blade Wear

Blades should be checked after sharpening for their wear height to determine

if they should be discarded. Proper blade height effects trimmer operation,

steeling device function and performance on its trimming application. Blades

that pass through the gauge are worn to the point that they should be discarded.

Refer to the accessory listings in the service parts section of the manual to find

the blade wear gauges available.

Blades that pass through the gauge should be discarded.

COMPANY CONFIDENTIAL

Operating BETTCHER Whizard®Universal Blade Sharpener Model 210, 115V

Instructions INDUSTRIES, INC. Rev. 05/17/2019

Page 13

8.11 Fault Detection And Correction

PROBLEM PROBABLE CAUSE REMEDY

Excessive Sharpener

Vibration

Uneven bench top Level surface

Loose components Tighten fasteners

Excessive Grinder

Vibration

Wheel not properly

mounted

Check shaft fit and set

screw tightness

Damaged wheel

Loaded (dirty) grinder

wheel

Replace. Clean wheel

See Section 9.0

Blade Holder

Does Not Run

Gearmotor/capacitor

failure Replace

Broken drive belt Replace

Blade Holder Slows

Downs/Stops During

Sharpening

Loose drive belt Tighten belt

Grease on drive belt Clean belt

Blade Loose in Holder

Worn blade Discard

Loose hold down pin Check for missing snap

ring

Damaged hold down pin Replace

Blade Not Steeling

Properly Worn steeling device Replace

Excessive Sharpening

Time

Worn grinder wheel.

Loaded (dirty) grinder

wheel

Replace. Clean wheel.

See Section 9.0

COMPANY CONFIDENTIAL

Operating BETTCHER Whizard®Universal Blade Sharpener Model 210, 115V

Instructions INDUSTRIES, INC. Rev. 05/17/2019

Page 14

SECTION 9.0 Maintenance/Cleaning

General:

The Whizard® Universal Blade Sharpener has been designed to be practically

maintenance free. It is suggested that the sharpener be completely cleaned

periodically with the use of a small brush and vacuum cleaner. (Do Not use

pressure air hose to blow off grinding dust).

Procedure For Adjustments When Replacing The Grinder Motor, Grinder

Wheel And Pedestal Parts

WARNING

DISCONNECT POWER SOURCE BEFORE

MAKING ANY ADJUSTMENTS.

To Position The Grinder Motor:

• Loosen the two motor mounting screws under the motor pivot.

• Facing the top of the motor, rotate the motor counterclockwise until all

clearance in the mounting holes are taken up. Then tighten the mounting

screws. This ensures the wheel will only grind in the downward direction.

To Position The Grinder Wheel On The Motor Shaft:

• Place the grinding wheel on the motor shaft with 1/64 inch (4mm) space

between the end of the wheel hub and the front of the motor housing. Then

tighten the set screw on the wheel hub.

To Set The Pedestal Knob For Feed Control:

• Install a blade holder and place the grinder motor in its respective position

as indicated on the “positioner” plate.

• Loosen the pedestal knob set screw. Turn the pedestal knob clockwise

running the grinder in toward the blade holder to within 1/64 inch (.4mm)

from the top of the hold down pins.

• Tighten the pedestal knob set screw. Turn the pedestal knob

counterclockwise to return the grinder assembly to it’s full back position.

COMPANY CONFIDENTIAL

Operating BETTCHER Whizard®Universal Blade Sharpener Model 210, 115V

Instructions INDUSTRIES, INC. Rev. 05/17/2019

Page 15

SECTION 9.0 Maintenance/Cleaning (Continued)

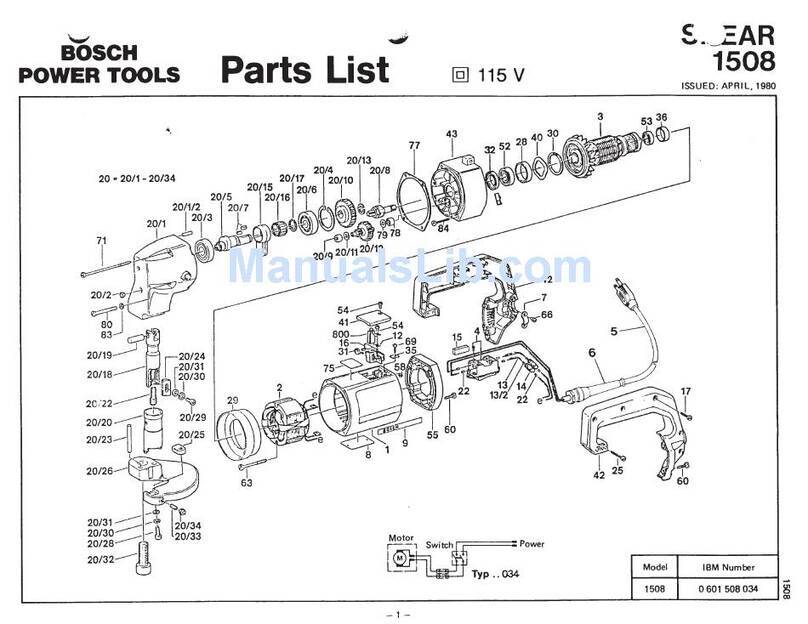

Check Grinder Wheel Position:

• Place a Model 620 blade (or similar angular type model blade) into the

blade holder and place the grinder in it’s respective position.

• Turn the grinder so the angled surface of the wheel contacts the blade. Contact

should be as shown.

If the blade and wheel do not make contact, loosen the two screws under

the pedestal knob and rotate the grinder, motor pivot and positioner plate

as a unit until the blade to wheel contact is as shown. Should more

adjustment be needed, loosen the pedestal mounting screws on the rear side

of the base plate. Then rotate the pedestal assembly as a unit until the blade

and grinder wheel make contact and tighten all screws.

Grinder Wheel:

Clean after approximately every 50 blade sharpenings with an all purpose

penetrant or cleaning solvent.

Check for smooth bare metal areas where the borazon crystals have been worn

or chipped off.

The sharpener requires no lubrication.

Blade

Grinder Wheel

COMPANY CONFIDENTIAL

Operating BETTCHER Whizard

®

Universal Blade Sharpener Model 210, 115V

Instructions INDUSTRIES, INC. Rev. 05/17/2019

Page 16

SECTION 10.0 Service Parts

10.1 Cabinet Assembly

COMPANY CONFIDENTIAL

Table of contents

Other Bettcher Power Tools manuals