Bevent Rasch RCMU8-MOD User manual

20/11/2018

www.bevent-rasch.com

RCMU8/-MOD

Control unit

Monitoring system MRB

FIRE SAFETY

2BORÅS Tel +46 (0)33 - 23 67 80 STOCKHOLM Tel +46 (0)8 - 54 55 12 70

Monitoring system MRB – Control unit RCMU8

• Groups A and B work together as a single group and

close the corresponding damper groups, regardless of

which detector in groups A and B was triggered, while

the detectors in group C and group D only affect their

corresponding damper group respectively.

• Groups C and D work together as a single group and

close the corresponding damper groups, regardless of

which detector in groups C and D was triggered, while

the detectors in group A and group B only affect their

corresponding damper group respectively.

• All groups work together and all dampers close, regard-

less of the triggered detector.

The detector outputs feature an electronic short circuit

fuse. All connected dampers enter the alarm position in

the event of a short circuit or a break in one of the detec-

tor loops. The RCMU can even be made to enter alarm

operation mode for the A+B group and the C+D group via

an external incoming alarm.

Alarm functions

Operating parameters are easy to change as they are pro-

grammed in a so-called EEPROM. Control unit RCMU has

an output relay main alarm (A alarm) and a service alarm (B

alarm).

The main alarm is triggered in case of:

• Fault in detector loop

• Triggered detector

• Damper fault

• External incoming alarm

• Power failure

• System fault or communication fault

The service alarm is triggered in case of a dirty detector.

Each alarm relay has an alternating potential free contact,

24 V AC, 3 A.

Quick facts

• Up to 8 dampers and 8 smoke detectors

split into four groups

• Indicators for each individual damper

• Optional external incoming alarm

• Night operation function

• Alternating relay contacts for both main alarm

and dirty detector

• Alternating relay to, for example, turn off unit

during function test

• Integrated transformer from 230 V to 24 V

for powering actuators

Function description

The RCMU is an encapsulated microprocessor-based,

intelligent, self-monitoring control unit split into four groups,

A to D, for connecting up to 2 dampers and 2 detectors in

each group.

The RCMU8 can either act as an independent control unit

and perform automatic function tests every 48 hours after

power up/resetting or it can be connected in a network

to a minimaster RCMM for centralised registration, con-

trol and monitoring. RCMU8-MOD is used to connect to

Modbus. Function tests can also be initiated by an external

switch. During the test, damper groups A+B are tested first

then C+D. The RCMU has electronic circuits that automati-

cally connect outputs with connected damper actuators.

By setting a microswitch, a so-called DIP switch, you can

determine the effect of the smoke detectors as follows:

• The four detector groups A-D only affect their corre-

sponding damper group.

3BORÅS Tel +46 (0)33 - 23 67 80 STOCKHOLM Tel +46 (0)8 - 54 55 12 70

Monitoring system MRB – Control unit RCMU8

Operating indicators

34 LEDs are used to present the control unit’s operating

status with, among other features, individual indicators for

each damper and function as follows:

OPERATION is indicated by a green LED as follows:

- Lit during normal operation when the RCMU is

functioning independently and is not connected to

a network

- Lit 2 s/off 0.5 s during normal operation when the RCMU

is connected to a network

- Lit 0.1 s/off 0.1 s in case of network fault

- Off in case of power failure

OPERATION VENT. - Green LED lit when output relay for

vent. unit is activated.

NIGHT OPERATION - green LED lit in case of activated

input.

FUNC. TEST - yellow LED lit during internal function test.

- Lit 2 s/off 0.5 s during external function test

EXT. ALARM - red LED lit in case of activated alarm input.

DAMPER POSITION - indicated by green LED as follows:

- Lit in open position

- Lit 2 s/off 0.5 s in closed position

- Lit 0.1 s/off 0.1 s in middle position

- Off when damper motor is not connected/overloaded

DAMPER FAULT - indicated by red LED.

Function when LED for DAMPER POSITION is lit with

indicator as above:

- Lit when damper will not open

- Lit 2 s/off 0.5 s when damper will not close

- Lit 0.1 s/off 0.1 s when damper will neither open nor

close

- Lit 0.5 s/off 2 s when damper indicates open and

closed simultaneously

Function when the LED for DAMPER POSITION is off:

- Lit 0.1 s/off 0.1 s in case of overload on one of outputs

(both damper fault LEDs flash).

- Lit 2 s/off 0.5 s in case of motor failure

DETECTORS FAULT - red LED lit for each detector loop

in case of break in detector loop.

- Lit 0.1 s/off 0.1 s for each detector loop in case of

short circuit in detector loop.

DETECTORS ALARM - red LED lit for each detector loop

in case of triggered detector.

DETECTORS SERVICE - yellow LED lit for each detector

loop in case of dirty detector.

Resetting

The RESET button resets all alarms. After activation the

microprocessor performs a self-test, a memory test and an

EEPROM test, all LEDs are lit for a visual test, output relays

are activated and then dampers connected to groups A+B

and then groups C+D are function tested. After the test the

RCMU8 enters normal operation mode.

External incoming alarms can be reset remotely by activat-

ing the “External Function Test” input. Other alarms cannot

be reset remotely. Not used with network connection.

Night operation

Via an external switch the panel enters NIGHT OPERA-

TION mode, at which time the dampers close without the

control unit triggering an alarm.

The external switch must be controlled by a time channel

from DUC, a timer or similar device and not from the venti-

lation unit to avoid “self-locking”. Used, for example, during

intermittent operation. Not used with network connection.

Controlling the ventilation unit

If you want to stop the ventilation unit in conjunction with

a function test or in case of alarm operation, there is an

integrated closing relay switch, 24 V AC, 3 A.

A microswitch marked “Delay” can be used to activate

a 5-minute delay on the dampers’ function test if using

an electrically-heated thermobattery. The relay remains

activated throughout night operation. Damper faults do not

affect the above functions.

Network connection

When the RCMU is connected in a network to a minimas-

ter RCMM, the RCMM determines which functions the

RCMU is to perform. In the case of a network fault during

operation the RCMU will enter alarm mode and the main

alarm will be triggered.

Use RCMU8-MOD to connect to a Modbus network. The

network can have free topology and the following informa-

tion can be transferred:

• Status of RCMU8-MOD

• Which outputs have connected dampers

• Damper faults with detailed causes

• Detector faults and detector alarms

• Service alarms

Furthermore, the following options are available for con-

trolling RCMU8-MOD Modbus-based equipment:

Remote reset | Function test | External alarm | Night

operation

4

Brand-/Brandgasspjäll BSKC6 EI60

BORÅS Tel +46 (0)33 - 23 67 80 STOCKHOLM Tel +46 (0)8 - 54 55 12 70

Monitoring system MRB – Control unit RCMU8

External alarm

There are two inputs for external alarms: one for alarm op-

eration of group A+B and one for group C+D. If connected

to a network the minimaster is used to control this.

External alarm

The microswitch marked “Delay func. test 12h” can be

used to delay the function test. In the ON position and

after power up/resetting a function test is performed, with

the next test 12 hours later, followed by a return to every

48 hours. This enables the automatic test to be performed

during the night.

Control unit RCMU8

-”- RCMU8-MOD - for connection to Modbus network

ACCESSORIES:

RCKD/-RD - Smoke detectors

Specification

Technical data RCMU8-MOD

Supply voltage: 230 V AC +10% -15%, 50 Hz

Power rating: 75 VA

Encapsulation class: IP 65

Ambient temp.: 0° – +50°C

Output relays: Potential free, 24 V AC, 3 A,

resistive load

Max. load per

damper output: 10 VA, 24 V AC

Max. detectors

per output: 2 units

Internal fuse: 500 mA tube fuse, delay

EMC: EN 50081-1 (1992)

EN 50082-2 (1995)

Technical data RCMU8-MOD

Interface: RS485 (MODBUS-RTU)

Communication

speeds: 9600/19200 baud, 8 bit, even parity

with termination function

All addresses from 0 to 247.

5

EI60 Brand-/Brandgasspjäll BSKC6

BORÅS Tel +46 (0)33 - 23 67 80 STOCKHOLM Tel +46 (0)8 - 54 55 12 70

Monitoring system MRB – Control unit RCMU8

Block diagram RCMU8, RCMU8-MOD

Detector group

Main

alarm A

Damper fault

Detector alarm

Detector fault

External alarm

System fault

Communication fault

Power failure

Dirty detector

Opt. comm. bus

230V AC

Air handling unit

External alarm A+B *)

External alarm C+D *)

External func. test/Reset ext. alarm *)

Night operation *)

*) Not with network connection

Main

alarm B

Damper group

Detector group Damper group

Detector group Damper group

Detector group Damper group

Weight 2,2 kg

Dimensions and weight

250

175

1 cpl M20 (6-12 mm)

TEST

ÅTERSTÄLL

75

16 cpl M12 (3-6,5 mm)

RCMU 8

DRIFT

DRIFT VENT

NATTDRIFT

FUNK.TEST

EXT. LARM A+B

EXT. LARM C+D

GRUPP A

GRUPP B

GRUPP C

GRUPP D

SPJÄLL 1 LÄGE

SPJÄLL 1 FEL

SPJÄLL 2 LÄGE

SPJÄLL 2 FEL

DETEKTORER FEL

DETAKTORER LARM

DETEKTORER SERVICE

6

Brand-/Brandgasspjäll BSKC6 EI60

BORÅS Tel +46 (0)33 - 23 67 80 STOCKHOLM Tel +46 (0)8 - 54 55 12 70

12-0540_ENG / Nov. 2018 teamfront.se

Wiring diagram RCMU8, RCMU8-MOD

Thermal

sensor

dF2

dF1

1

2

Actuator

64112

*) 24V AC max. 10VA

When separate

thermal sensor is

used, connect in

series with motor.

3

6

1

3

6

1

3

6

1

3

6

1

36 1

36 1

***) With duct-

detector RCKD

**) With room-

detector RCRD

Detector 1)

group A

Damper group A 2)

damper 1

Damper group A 2)

damper 2

Actuator *) Actuator *)

**) With room detector

RCRD connected in series

***) With duct detector

RCKD connected in series

Detector 1)

group B

Damper group B 2)

damper 1

Damper group B 2)

damper 2

Actuator *) Actuator *)

***) With duct-

detector RCKD

**) With room-

detector RCRD

Conn.

box

Conn.

box

Conn.

box

Conn.

box

***) With duct-

detector RCKD

**) With room-

detector RCRD

***) With duct-

detector RCKD

**) With room-

detector RCRD

Detector 1)

group C

Damper group C 2)

damper 1

Damper group C 2)

damper 2

Group AGroup BGroup C

Group D

Actuator *) Actuator *)

Actuator *) Actuator *)

Detector 1)

group D

Damper group D 2)

damper 1

Damper group D 2)

damper 2

DIP switch

X-conn. A+B

X-conn. C+D

X-conn. A+B+C+D

Delay air handling unit.

Delay function test 12 h

ON

12

0

34 5

Max. 2 detectors per group (tot. 8

detectors per RCMU). See product

sheet for series connection. A 2.2 kΩ

terminating resistor is connected to

the last detector in each loop.

If no detector group is connected,

short the terminals with a 2.2 kΩ resistor.

1)

50

49

Network

connection

(BUS)

3)

52 5351

Main alarm:

Fault in detector loop

Triggered detector

Damper fault

External alarm

Power failure

System fault

Communication fault BUS

55 5654

6)

Detector

Service alarm

58

57

Operation

air handling

unit

3)

42

41

External

func. test/

Reset

ext. alarm

5)

44

43

External

inc. alarm

A + B

4)

46

45

External

inc. alarm

C + D

4)

48

47

Night

operation

7)

The damper output is 24 V AC, max.

10 VA per actuator. Low current contacts

are used for position indication.

Break between terminals triggers alarm.

Jumpered at factory. Not used with

network connection.

2)

4)

Potential free contact max. 24 V AC, 3 A.

Shows potential free/alarm mode.

3)

Function test/Reset ext. alarm in

case of short circuit. Not used

with network connection.

5)

Potential free contact 24 V AC, 3 A.

Shows potential free/normal mode.

6)

Night operation in case of short circuit.

Not used with network connection.

7)

Monitoring system MRB – Control unit RCMU8

Table of contents

Other Bevent Rasch Control Unit manuals

Popular Control Unit manuals by other brands

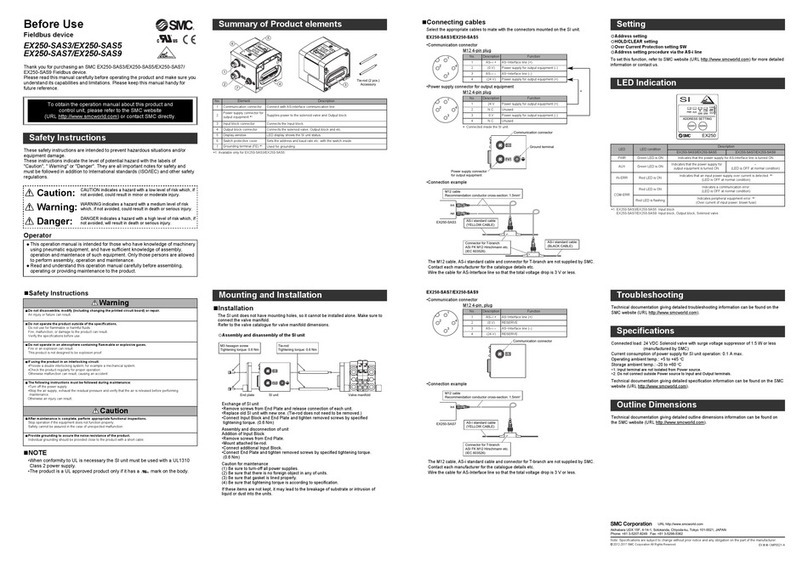

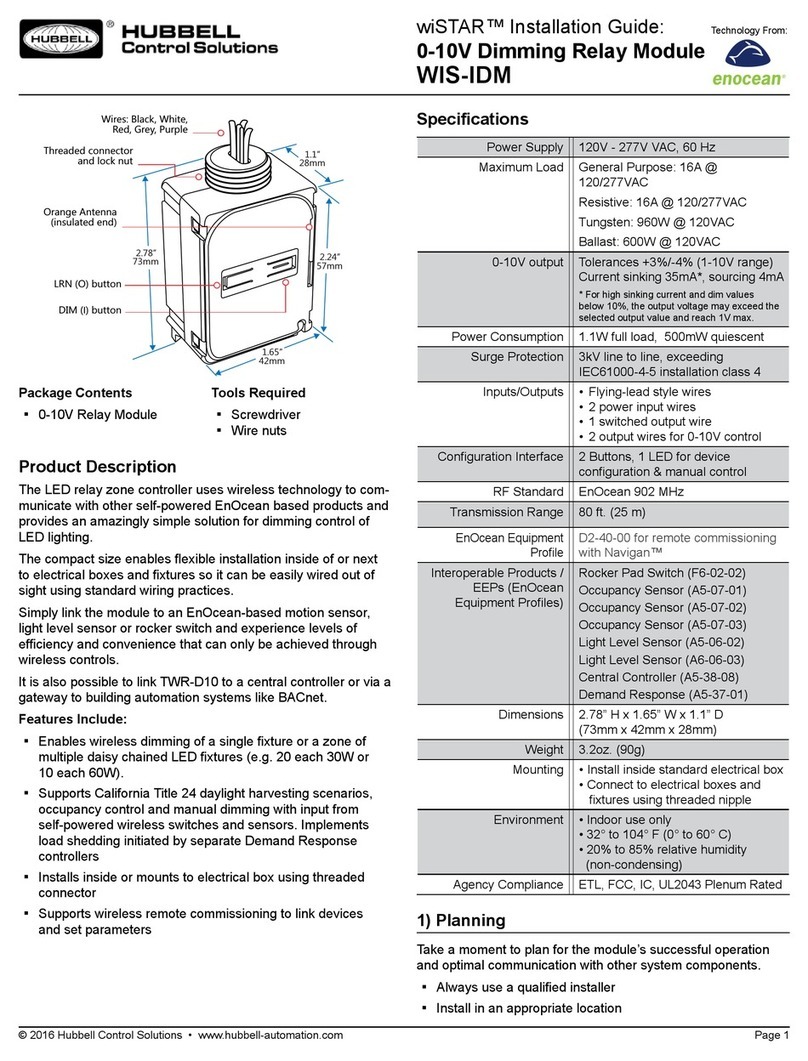

Hubbell

Hubbell wiSTAR WIS-IDM installation guide

Viessmann

Viessmann EM-EA1 extension Installation and service instructions for contractors

Keysight Technologies

Keysight Technologies M9195A PXIe Startup guide

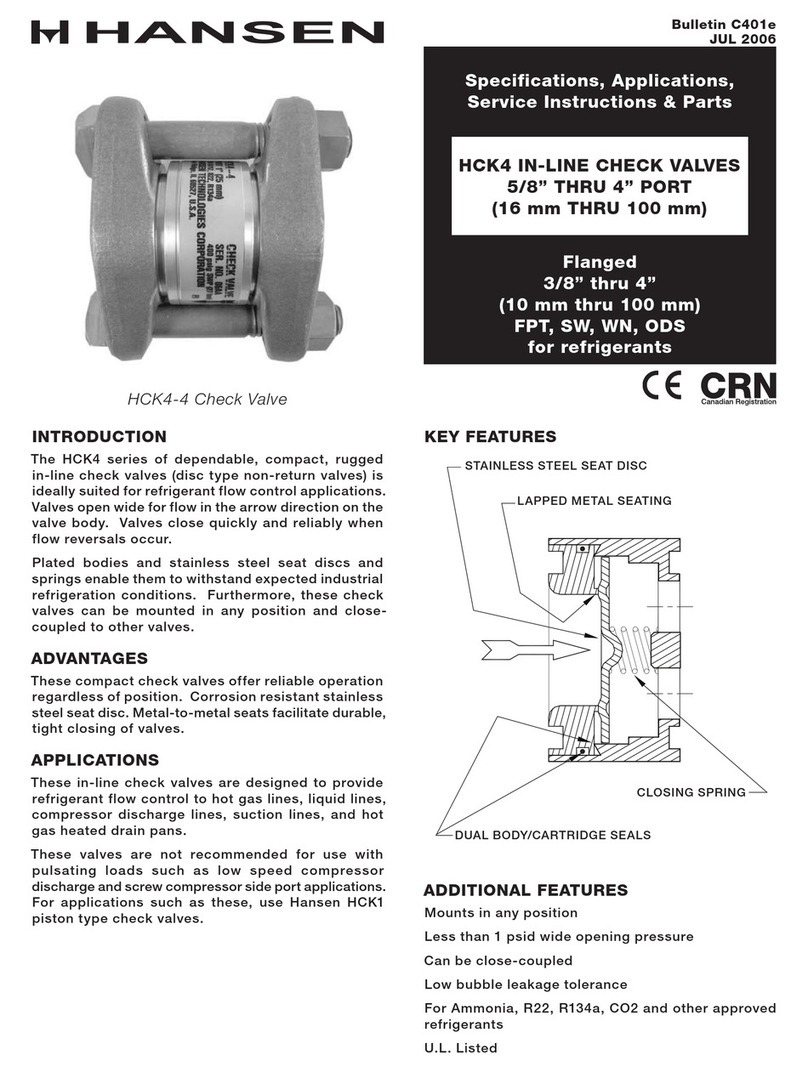

Hansen

Hansen HCK4-2 Specifications, Applications, Service Instructions & Parts

Parker

Parker Racor 200 Series installation instructions

GEM

GEM 550 Installation, operating, & maintenance instructions