Instructions EH10000 - 06/10

10000 Series Double Ported Globe Valves 4

advantage in continuing, as too much lapping may result in

rough seats. The only remedy is replacement or re-machining of

one or both parts. When lapping new plug and seat ring, begin

with medium compound and finish with fine.

Before lapping plug and stem must be true (see pinning

operation, section 6.4).

Note: Seat repair in a double seated valve is critical. In a

new valve the distance between the upper and lower seat

ring seats is established in manufacturing and only lapping is

required to make both parts close simultaneously. In the field,

it is best to lap the seats first. If one of the seats is damaged

beyond what is repairable by lapping, care must be taken to

maintain the original distance between the seats on both the

plug and seat rings. Therefore, when machining one seat

of the plug or one seat ring the other must be machined in

exactly the same way.

A. Clean body gasket surface areas.

B. When the seats have been removed, ensure that the sealing

surfaces in the body bridge and the threads are thoroughly

cleaned.

Note: A lubricant such as Chesterton 725 or a sealant

compatible with the process should be applied sparingly, to

the seat ring threads and sealing shoulder.

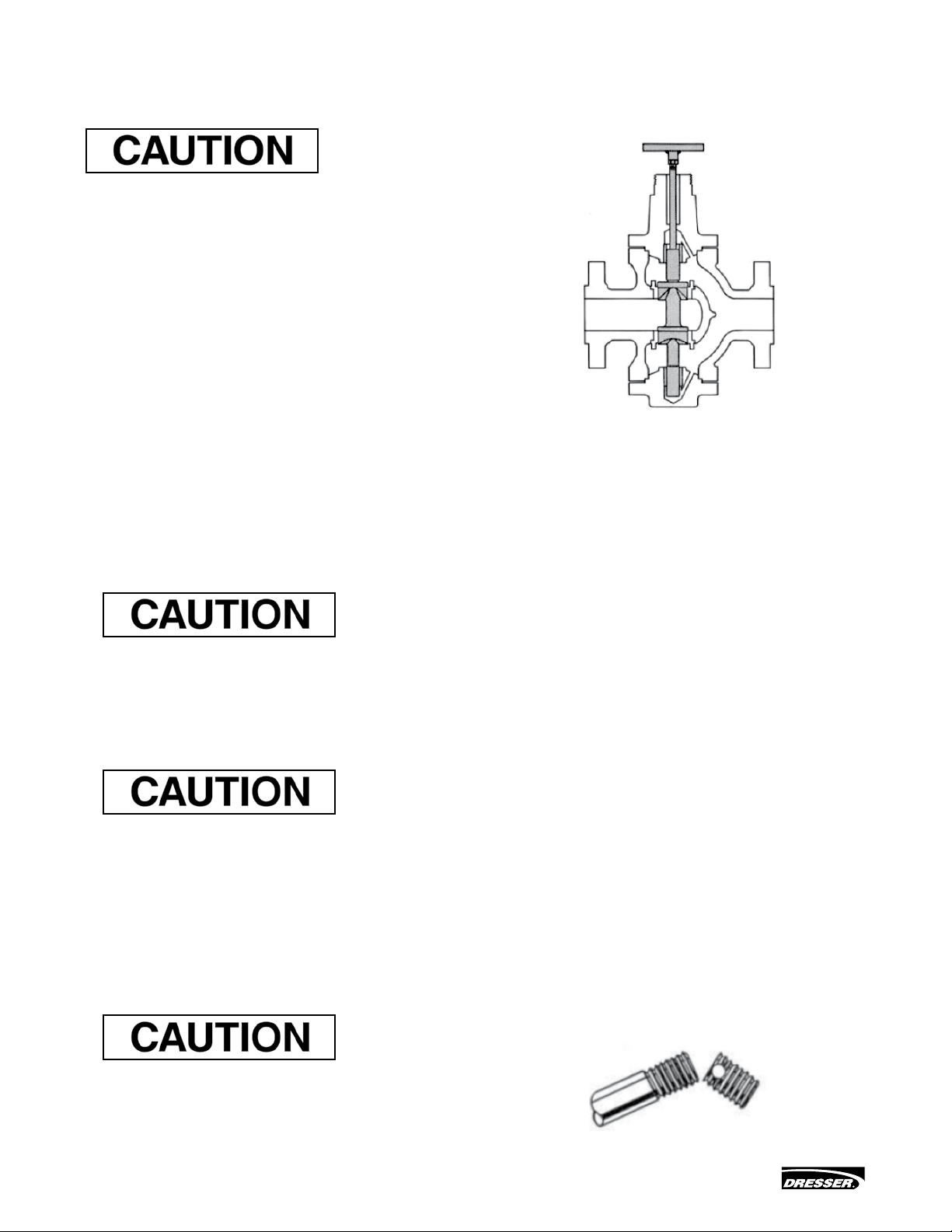

C. Install and tighten seat rings using fabricated wrench used for

removal. (See Figure 3).

Do not over tighten. Do not strike seat ring lugs, this could

distort the seat ring resulting in unwarranted seat leakage.

D. Install bottom flange (10), ensuring bottom bushing (14) is

in place and secure to the body using body stud nuts (12)

spaced equally apart. Fasten the bottom flange to the body

using only slight pressure and tighten evenly.

Do not tighten nuts to torque specifications at this time. The

bottom flange is used temporarily for guiding purposes.

E. Apply lapping compound at several spots equally spaced

around the seating areas of the plug.

F. Insert the stem and plug assembly carefully into the body

until it is seated.

G. Place bonnet (6) on the body and using body stud nuts (12),

spaced equally apart, fasten to the body using only slight

pressure and tighten evenly.

Do not tighten nuts to torque specifications at this time. The

bonnet is used temporarily for guiding purposes.

H. Insert two or three pieces of packing (17) into the packing

box to assist in guiding the stem and plug during lapping.

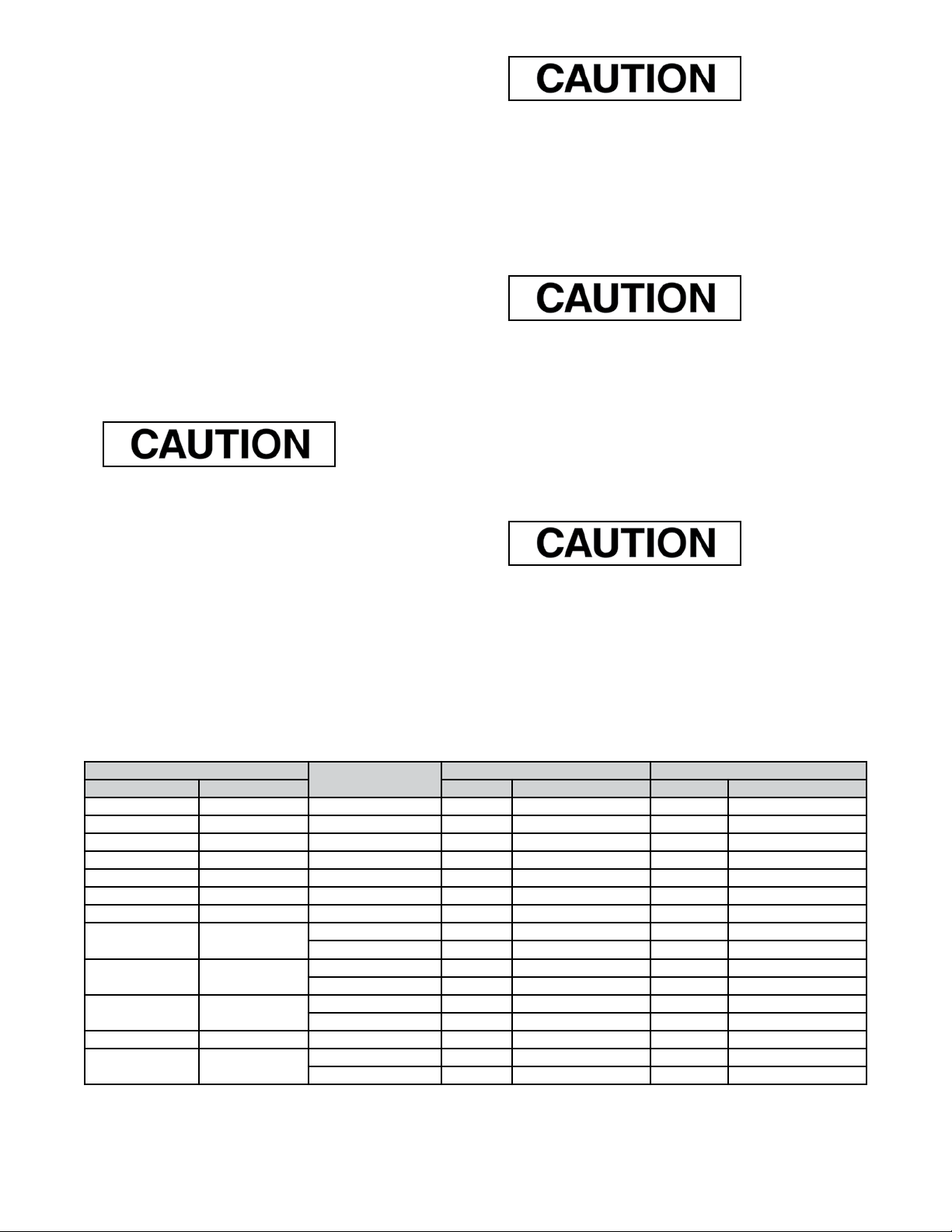

I. Screw a drilled and tapped rod with a tee handle onto the

plug stem and secure with a lock nut. (See Figure 5).

Note: As an alternative, drill a hole through a flat piece of

steel and fasten to the plug stem using two lock nuts.

Figure 5

J. Apply a slight pressure on the stem, rotating the stem in short

oscillating strokes eight to ten times.

Note: The plug should be lifted and turned 90˚ before

repeating step 10. This intermittent lifting is required to

keep the plug and seat ring concentric during lapping. After

completion of the lapping operation, remove body stud nuts

(12) from the bonnet (6) and bottom flange (10).

K. Remove bonnet (6) and bottom flange (10).

L. The seat rings, plug and internal components of the valve

must be cleaned of all lapping compound in preparation for

reassembly.

6.4 Plug Stem Pinning

Valve plug and stem assemblies are normally furnished as a

complete assembly in which case the installation involves no

problem. It is only necessary to lap the plug and seat ring and

assemble the valve. If it is necessary to replace the plug it is

recommended that a new stem be used. If the old stem must be

used, it is necessary to determine if the stem will be long enough

since the stem will require cutting. If the stem does not engage

the actuator stem by a minimum of one stem diameter, the old

stem should not be used. If it does not engage a minimum of

one stem diameter, proceed as follows.

Note: While pinning is being performed, care must be taken

not to damage the seating surface and plug guides.

A. Using a drift punch, drive out the old pin (8).

Note: If it is necessary to drill out the pin, a drill somewhat

smaller than the pin should be used and the remainder of

the pin driven out.

B. Unscrew the plug from the stem (counter clock-wise).

Figure 6