BGD WOW User manual

1

Version 1.0 November 2020Version 1.0 November 2020

2

Version 1.0 November 2020

CONTENTS

Contents

Welcome

Introduction / Overview of Parts

Installation

Deploying

Repacking

Maintenance and Repairs

Guarantee

Specications

Closing

Repacking record

3

I5

7

8

9

14

16

17

18

19

3

Version 1.0 November 2020

WOW Owner’s Manual

Reserve parachute for paragliding

Welcome

Welcome to Bruce Goldsmith Design

BGD is a specialist manufacturer of high quality paragliding equipment. We y, research and develop in the south

of France, where Gourdon produces active-air test conditions year round. Bruce Goldsmith has been designing

paragliders and equipment since 1991, and has produced some of the world’s most loved and successful wings,

including two World Championship winning designs. We apply our competitive knowledge to design top quality

products that combine the highest performance with the safe handling our customers value and respect. BGD

pilots appreciate our quality and reliability. BGD´s World Class status is based on the skills and expertise we have

developed in combining aerodynamic design with cloth and materials technology. All BGD products are developed

and made with the same skill and attention to good design that are synonymous with the ultimate performance and

precision required by paragliders.

Congratulations on your purchase of a BGD WOW

The Wow is a modern square reserve parachute with a fast opening time, low sink rate and high pendulum stability.

The corner cut-outs make it very stable in descent immediately after deployment, and the symmetrical design

prevents system-related forward movement, resulting n a stable descent with easy landing.

The materials and technologies used in its construction ensure its reliability and robustness so it will have a long

service life. It is made from lightweight materials and packs down small. The panels are CNC precicion cut, and the

polyamide lines attach to the canopy with traditional loops, so they are quick and easy to replace if necessary. The

lines have some stretch, so they absorb some of the impact of a deployment.

The reserve is packed in a lightweight inner container linked to a deployment handle. The inner container is designed

4

Version 1.0 November 2020

Welcome

to open in any direction. The handle is reinforced for an easy grip, even when wearing gloves.

Before each ight, check all straps securing the outer container to the harness (where applicable). Ensure that the

container is closed properly, and visually inspect the pins for damage and make sure that they are secure.

5

Version 1.0 November 2020

Introduction

Operating limits / precautions

The WOW has been specially developed for use as a reserve parachute for paragliding. It is not intended to be used

for other ying sports including BASE-jumping and skydiving. It is suitable for integrated reserve containers.

• According to EN 12491, the reserve should only be used up to maximum speeds of 32m/s or 115km/h.

• The reserve should be aired out and repacked every 6 months.

• After a deployment, the reserve should be inspected by a qualied person.

• The reserve parachute must be replaced after 10 years, even if it has never been used.

• A compatibility test should be carried out to ensure harness and rescue are compatible.

• This parachute system has been tested and found compliant using the original manufacturer’s inner container.

Use of any other inner container may produce different results, including failures

Pre-ight check

Before each ight, check all straps securing the outer container to the harness (where applicable). Ensure that the

container is closed properly, and visually inspect the pins for damage and make sure that they are secure.

Introduction

6

Version 1.0 November 2020

Overview of parts

Introduction

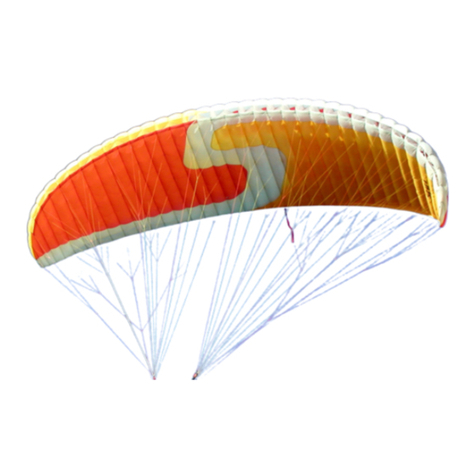

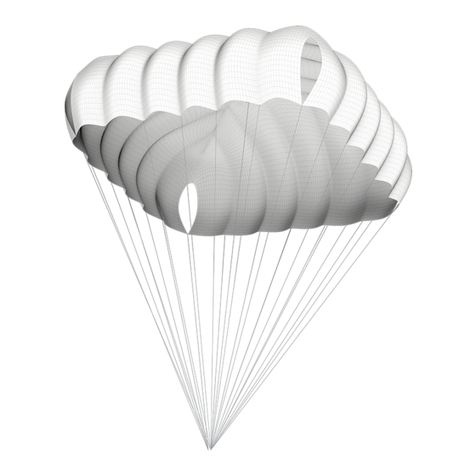

Canopy

Lines

Corner openings

Bridle

Centre or apex lines

Packing loops (on top surface)

1

2

3

4

5

6

3

6

1

2

3

4

5

7

Version 1.0 November 2020

Installation

Compatibility Check

The WOW rescue system is suitable for integrated reserve containers in a wide range of harnesses. The rst-time

installation of the reserve chute into a harness should be carried out only by an expert, to ensure the harness is

compatible with the reserve.

To connect the reserve chute to the V-bridle, use an oval screw shackle with at least 2200 daN ultimate strength. The

lines should be secured on both sides of the screw shackle with rubber bands by means of a Larks Head knot; xing

tape or a neoprene cover can be used to protect against fraying and abrasion.

Directly connecting the bridle to the harness attachment webbing is not recommended, as if knotted incorrectly it

could signicantly weaken the system.

It is important to ensure that the connection is centred, that is, the two connecting lines leading to the shoulder straps

are of the same length. If the harness does not have an integrated attachment for the reserve chute on the shoulder

straps, then the reserve chute connecting lines can also be attached to the main karabiners.

Practice throw

After the initial installation, and if the back protection has been moved or changed, it is essential to do a simulated

reserve deployment under a static swing to ensure the parachute release system operates correctly and the

parachute comes out easily.

Installation

8

Version 1.0 November 2020

Deploying

To deploy the WOW in an emergency:

1. Visually locate the deployment handle.

2. Grasp the deployment handle and pull it to release the parachute in its inner container, from the external

outer container or harness.

3. Using the deployment handle, throw the inner container forcefully into open air (AWAY from the paraglider

canopy). If in a strong rotation, throw downwards towards your feet. The canopy will separate from the inner

container and inate quickly and easily thanks to the central line.

4. Stop your paraglider from ying to ensure a stable parachute descent. This can be achieved by pulling the

B-risers.

As with all paraglider reserve systems, the deployment throw must be forceful enough to separate the inner container

from the canopy. The special coating of the WOW makes this easier, and reduces failed deployments.

However, if the initial throw was not powerful enough for the system to deploy immediately, grasp the parachute

bridle attached to the harness, and pull it back for another, more forceful, throw.

Poorly maintained reserve chutes may open more slowly. If the container does not separate from the chute after

throwing, pull rmly and sharply on the lines to assist separation.

This guide conforms to requirements specied by Regulation EN 12491.

Deploying

9

Version 1.0 November 2020

Repacking

Repacking

Your parachute should be repacked every 6 months, preferably by a qualied professional. When removing the

parachute from the harness take the opportunity to complete a practice deployment. Check that you can reach your

handle easily and that the parachute exits the harness smoothly and easily.

Proper packing of the canopy is essential for the reliability and safety of the system. Therefore it is strongly

recommended to have the system re-packed by an authorised and trained specialist.

These instructions are aimed at pilots who are competent in folding a modern square reserve. They do not serve as a

substitute for proper training in folding a parachute.

The manufacturer can ensure the safety and reliability of the system only when it has been packed by a trained

professional who followed a proper packing procedure.

Before repacking

Airing

Before repacking, the reserve chute must be aired out, ideally for 12 hours in a cool, dry room.

Inspection

A thorough inspection is necessary. Visually inspect the reserve chute, checking for damage to the canopy, the lines,

the suspension points, the main riser and the screw shackle.

LINES: carefully inspect all the lines on both sides to ensure that they are undamaged, from the riser all the way to the

canopy. Make sure that the parachute is completely disentangled and that both the lower line and the upper of the

reef knot run freely from the risers to the canopy.

10

Version 1.0 November 2020

CLOTH: Ensure that it is not damaged or contaminated.

OUTER AND INNER CONTAINERS: Ensure that the handle is properly and securely attached to the inner container

and the riser is securely (tightly) attached to the harness.

If you nd any damage or contamination that may lead to system failure, the system must be checked by the

manufacturer. If you are not certain about the reliability of the system, send it to a professional for inspection.

Packing Area

Ensure the packing area is large enough, clean, level and dry. You will need the following to help you repack:

• A 30cm length of line

• Silicon-based rubber rings to organise the lines

• A line separator

• Weights or clips to hold the sections together as you fold

Repacking

11

Version 1.0 November 2020

Use the length of line to thread the packing loops together. Don’t forget the four corner

loops mounted slightly further back on the panels.

Secure the packing loops to something rigid, and pull on the bridle and the attached

loops until the apex line is tensioned.

Ensure that the lines are free of twists and tangles – start at the bridle and work

towards the parachute keeping the apex lines central and the suspension lines on either

side separated. Make sure none of the lines are twisted around the apex lines or each

other.

Lay out the canopy with one of the four corner points at the bottom, one on the left,

one on the right and one on top. Start with the rst corner at the bottom and smooth

the material by running your hand along it on the table.

Pull the base from each line attachment point to the next along the seam to the side

you are sorting and smooth out the crossed panel. A line separator and a weight will

help to secure the already sorted lines.

1

2

3

4

Repacking

12

Version 1.0 November 2020

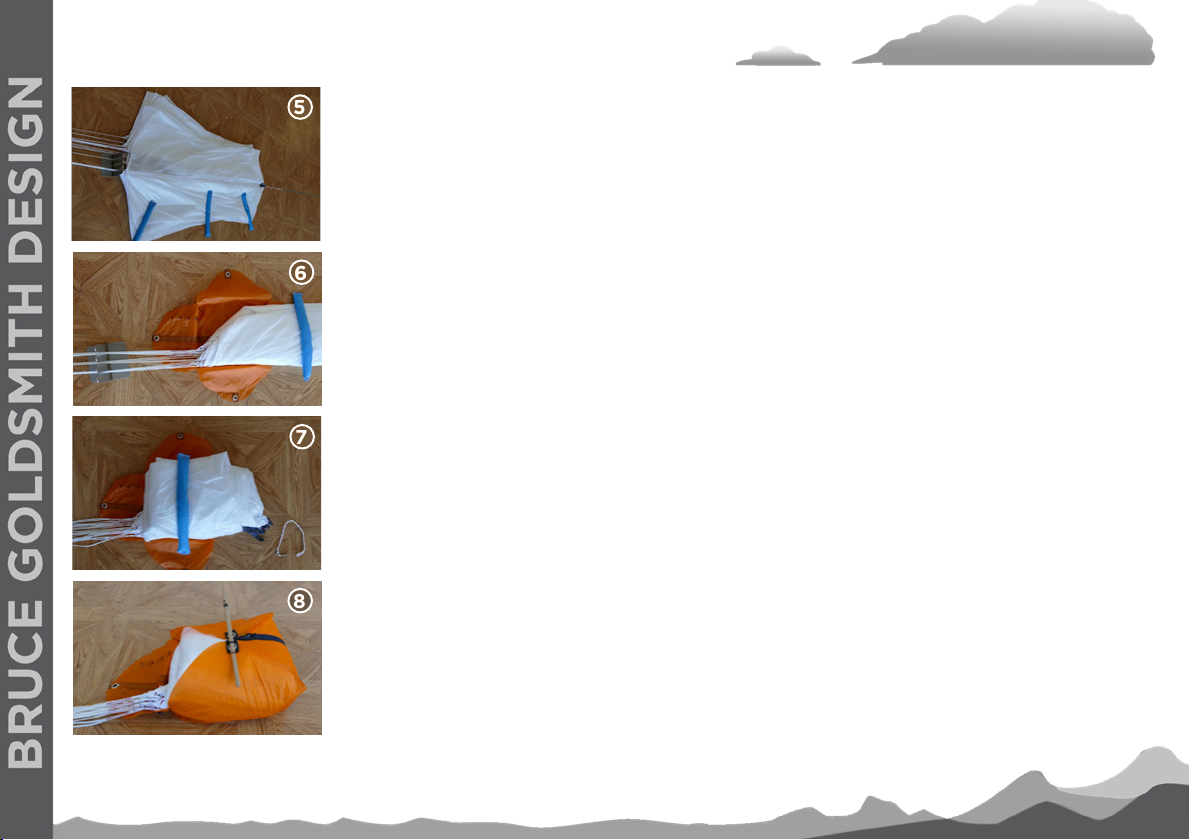

Lay out the next panels in a rectangular fashion. Identify the corner that points to one

of the sides. This is also to be laid out in a crossed fashion, as shown.

Continue with rectangular panels until the next corner is reached, which is now

the uppermost one and last on this side. Leave a channel through so that the table

underneath is visible. Use weights to secure the rst side, then repeat for the second.

Return to the channel and run hands along the connecting points of the middle lines

until they are free of material. Extra material can simply be pushed up inside the

channel, to prevent the material from burning during a deployment.

Panel sorting is now complete.

Inspect the middle line towards the bridle to check that it is free.

Fold the reserve chute with a “double-S fold“ as shown and place in the reserve

container with the line pocket in the direction of the base/bridle, using the full length

and width.

Close the rst three rescue aps and secure them with a small line loop. This method

will avoid burns from a deployment since the bundle of lines will be released rst and

will not come in contact with the material.

5

6

7

8

Repacking

13

Version 1.0 November 2020

Starting at the main riser, loop the line bundles in the shape of a gure-eight. Use

silicone-based rubber rings to x the line bundles. The gure-eights should be made to

the same width as the deployment bag. Leave approximately 30cm free for the nal

line loop.

Place the line bundles in the designated line pocket inside the reserve container. Secure

the fourth and nal rescue ap with the remaining line length.

Make sure that none of the items that you used to help with the packing, have accidentally been packed with the

parachute.

9

Repacking

14

Version 1.0 November 2020

Maintenance and Repairs

Maintenance

The canopy must be stored in a clean and dry place. Avoid extensive exposure to direct sunlight. If it gets wet,

immediately dry the canopy and the lines to prevent damage caused by mould. Contamination by oils or other chemicals

could signicantly reduce the load stability of the life saving system. A contaminated canopy must be inspected by a

professional. The outer container can be cleaned (without the canopy inside!) using water and a mild detergent followed

by a thorough rinse and drying. Use only clean water without soap to clean the canopy and lines.

The parachute must be checked and repacked before the rst installation by an authorised packer. We recommend it

is checked and repacked every 6 months, to ensure it remains clean and dry and does not become compressed. The

repacking should be recorded in the Maintenance and Packing log book.

When repacking, we recommend the parachute is aired, ideally between 1 and 3 days (to discharge static electricity).

Take care to keep out any insects or moisture.

If you have own in damp conditions or landed in a wet or snowy place, it is recommanded to check within 24 hours

whether the rescue was affected by humidity. If it has been, you should unfold it, dry it and repack it.

The parachute should be replaced after ten years from the date of purchase. The purchase date must be written on

the certication label by the dealer when the parachute is sold.

Repairs

All repairs must be carried out by the manufacturer. Any unqualied repair might lead to the system failure.

Maintenance and repairs

15

Version 1.0 November 2020

Recycling

We all have a responsibility to look after the environment and protect the places in which we y. Even the best

products have a limited service life, and once your reserve chute reaches this point it should be disposed of in an

appropriate recycling facility.

Maintenance and repairs

16

Version 1.0 November 2020

Guarantee

Our reserves are guaranteed against any production fault for two years from the date of purchase.

The guarantee does not cover damage caused by misuse, by neglecting the regular maintenance, by poor storage

conditions, or overloading.

Guarantee

17

Version 1.0 November 2020

Specications

90 110

Area (m2)22.5 27.5

Weight (kg) 1.2 1.4

Length of centre lines (mm) 4448 4915

Max. payload* (kg) 90 110

Min. payload* (kg) 60 73

Sink rate at max. payload* (m/s) 4.9 5.25

Volume (l) 4.1 5.2

Certication EN / LTF

*Payload = Weight of fully equipped pilot without paraglider

Specications

Materials

Canopy:

Lines:

Riser:

Nylon 6.6, 33dTEX

Edelrid A-6798-150

Dyneema/polyester 13 mm

18

Version 1.0 November 2020

Closing

If you are ever unsure about the information contained in the manual, contact your BGD dealer.

This document is not a contract.

BGD reserves the right to alter or modify its products without notice.

Closing

BGD GmbH, Am Gewerbepark 11, 9413 St. Gertraud, Austria. Tel: +43 (0) 4352 20477

sales@ybgd.com www.ybgd.com

19

Version 1.0 November 2020

Repacking Record

Date of Packing: By: Signature:

Repacking Record

Table of contents

Other BGD Aircraft manuals

Popular Aircraft manuals by other brands

Daher-Socata

Daher-Socata TBM 900 Pilot's information manual

czech sport aircraft

czech sport aircraft SportCruiser Pilot operating handbook

PAPILLON

PAPILLON BODYGUARD 7 manual

Direct Fly

Direct Fly ALTO 912 TG Aircraft Maintenance Manual

AIR TRACTOR

AIR TRACTOR AT-502A Maintenance section

Nova

Nova MENTOR 3 manual