FK-Lightplanes FK 9 Mk IV User manual

AIRCRAFT MAINTENANCE

MANUAL

FK 9 Mk IV / Mk V ELA

Certified as Ultralight Aircraft according to

BFU 95 / LTF-UL 2003

Kennblatt Nr. 61102.1 and Nr. 61102.2

(Germany)

Type Certificate: US-SLSA

Model: FK9 Mk IV FK9 Mk V ELA

Serial Number:

Registration :

Date of manufacture:

Manufacturer and exclusive Distributor:

FK-Lightplanes Krosno - Poland

Design Organisation and Owner of IP Rights:

B & F Technik Vertriebs GmbH Speyer –Germany

document code: des.003

revision date: 01.of november 2013

document code: des.003

Design organization, owner of IP rights and customer support:

B & F Technik Vertriebs GmbH Speyer - Germany

Anton-Dengler-Str. 8

D-67346 Speyer

Phone:+49(0)6232 / 720 76

Fax:+49(0)6232/720 78

E-mail:info@fk-lightplanes.com

Service / parts only via service@fk-lightplanes.com

www.fk-servicecenter.com

This manual is issued by B&F Technik Vertriebs GmbH and no part of this manual may be reproduced or changed in any

manner without written consent.

Important service information/bulletins can be obtained from our service website. Check our website regularly as

automatic update by mail is not assured.

▲WARNING

Before starting any maintenance activities, read the entire Maintenance Manual carefully, as it contains

important safety-relevant information. Failure to do so may void warranty or cause serious personal injury or

death!

Please pay attention to the following reoccurring symbols, warning, caution and note, which you will find throughout the

maintenance manual. These symbols/signs indicate special safety guidelines and therefore are of high importance.

▲WARNING: Instructions, which if not followed, may cause serious injury or death.

█CAUTION: This section describes an instructions which if not followed, may result in

damage to the aircraft or could void warranty.

Note: Proposal for better handling, useful recommendations or durability

We appreciate critical observations, suggestions, ideas and other feedback concerning the maintenance manual.

We would like to thank our customers and users, who have sent suggestions and requirements for further development.

Maintenance Manual FK 9

B&F Technik Vertriebs GmbH

Revision 2

Section 0 Introduction

page 1

document code: des.003

TABLE OF CONTENTS

0. INTRODUCTION....................................................................................................................................... 0-6

0.1. Revisions..................................................................................................................................... 0-6

0.2. Record of Revisions................................................................................................................... 0-6

0.3. List of effective Pages................................................................................................................ 0-7

1. GENERAL................................................................................................................................................. 1-1

1.1. Equipment List............................................................................................................................ 1-1

1.1.1. Placards.................................................................................................................................... 1-2

1.1.2. Instrument Markings ................................................................................................................. 1-2

1.2. Sources to purchase Parts........................................................................................................ 1-2

1.3. List of disposable replacement parts....................................................................................... 1-3

1.4. Engine specifications................................................................................................................. 1-3

1.4.1. Power Plant Limitations ............................................................................................................ 1-3

1.5. Weight and Balance ................................................................................................................... 1-4

1.5.1.Abbreviations and Terminology ................................................................................................ 1-4

1.5.2. Basic Empty Weight.................................................................................................................. 1-4

1.5.3. Weighing................................................................................................................................... 1-5

1.5.4. Required Tools.......................................................................................................................... 1-5

1.5.5. Parts/materials required............................................................................................................ 1-5

1.5.6. Level of maintenance................................................................................................................ 1-5

1.5.7. Certification required................................................................................................................. 1-5

1.6. Tire Inflation Pressure................................................................................................................ 1-6

1.7. Approved Oils and Capacities................................................................................................... 1-6

1.7.1. Oil.............................................................................................................................................. 1-6

1.7.2. Fuel........................................................................................................................................... 1-6

1.7.3. Coolant...................................................................................................................................... 1-6

1.7.4. Brake Fluid................................................................................................................................ 1-6

1.8. Recommended Fastener Torque Values.................................................................................. 1-7

1.9. General Safety Information........................................................................................................ 1-7

1.10. Instructions for Reporting ......................................................................................................... 1-7

2. INSPECTIONS .......................................................................................................................................... 2-1

2.1. Inspections.................................................................................................................................. 2-1

2.1.1. Required Tools.......................................................................................................................... 2-1

2.1.2. Parts/materials required............................................................................................................ 2-1

2.1.3. Level of maintenance................................................................................................................ 2-1

2.1.4. Certification required................................................................................................................. 2-1

2.2. General Advice ........................................................................................................................... 2-1

2.3. Regular Maintenance and Lubrication Schedule.................................................................... 2-2

Maintenance Manual FK 9

B&F Technik Vertriebs GmbH

Revision 2

Section 0 Introduction

page 2

document code: des.003

2.4. Hard Landing Inspection ........................................................................................................... 2-3

2.4.1. Required Tools.......................................................................................................................... 2-3

2.4.2. Parts/materials required............................................................................................................ 2-3

2.4.3. Level of maintenance................................................................................................................ 2-3

2.4.4. Certification required................................................................................................................. 2-3

2.4.5. Nose landing gear..................................................................................................................... 2-3

2.5. Time between Overhaul (TBO) .................................................................................................. 2-4

3. STRUCTURES.......................................................................................................................................... 3-1

3.1. Ground Handling ........................................................................................................................ 3-1

3.2. Cleaning....................................................................................................................................... 3-1

3.2.1. Required Tools.......................................................................................................................... 3-1

3.2.2. Parts/materials required............................................................................................................ 3-1

3.2.3. Level of maintenance................................................................................................................ 3-1

3.2.4. Certification required................................................................................................................. 3-1

3.2.5. Painted Surfaces....................................................................................................................... 3-1

3.2.6. Windshield and Windows.......................................................................................................... 3-2

3.2.7. Engine and Engine Cowling...................................................................................................... 3-2

3.2.8. Upholstery and Interior.............................................................................................................. 3-2

3.2.9. Propeller.................................................................................................................................... 3-2

3.2.10. Wheels................................................................................................................................... 3-2

3.3. Wing & Struts Removal / Installation........................................................................................ 3-3

3.3.1. Required Tools.......................................................................................................................... 3-3

3.3.2. Parts required............................................................................................................................ 3-3

3.3.3. Level of maintenance................................................................................................................ 3-3

3.3.4. Certification required................................................................................................................. 3-3

3.3.5. Instructions................................................................................................................................ 3-3

3.4. Fuselage Interiors............................................................................................................................. 3-4

3.4.1. Required Tools.......................................................................................................................... 3-4

3.4.2. Parts required............................................................................................................................ 3-4

3.4.3. Level of maintenance................................................................................................................ 3-4

3.4.4. Certification required................................................................................................................. 3-4

3.4.5. Dismantling interiors and seats................................................................................................. 3-4

3.5. Landing Gear .................................................................................................................................... 3-5

3.5.1. Landing Gear Description......................................................................................................... 3-5

3.5.2. Required Tools.......................................................................................................................... 3-5

3.5.3. Parts/materials required............................................................................................................ 3-5

3.5.4. Level of maintenance................................................................................................................ 3-5

3.5.5. Certification required................................................................................................................. 3-5

3.6. Flight Controls.................................................................................................................................. 3-6

3.6.1. General ..................................................................................................................................... 3-6

3.6.2. Required Tools.......................................................................................................................... 3-6

3.6.3. Parts required............................................................................................................................ 3-6

3.6.4. Level of maintenance................................................................................................................ 3-6

3.6.5. Certification required................................................................................................................. 3-6

3.6.6. Rudder ...................................................................................................................................... 3-7

3.6.7. Flaps and ailerons..................................................................................................................... 3-8

3.6.8. Elevator..................................................................................................................................... 3-9

3.6.9. Trim System............................................................................................................................ 3-10

Maintenance Manual FK 9

B&F Technik Vertriebs GmbH

Revision 2

Section 0 Introduction

page 3

document code: des.003

3.7. Control Surface Deflection ...................................................................................................... 3-10

3.8. Jacking / Towing / Storage ...................................................................................................... 3-10

3.8.1. Jacking.................................................................................................................................... 3-10

3.8.2. Towing..................................................................................................................................... 3-11

3.8.3. Flyable Storage....................................................................................................................... 3-12

3.8.4. Temporary Storage................................................................................................................. 3-12

3.8.5. Indefinite Storage.................................................................................................................... 3-13

4. ENGINE..................................................................................................................................................... 4-1

4.1. Inspections.................................................................................................................................. 4-1

4.1.1. Required Tools.......................................................................................................................... 4-1

4.1.2. Parts required............................................................................................................................ 4-1

4.1.3. Level of maintenance................................................................................................................ 4-1

4.1.4. Certification required................................................................................................................. 4-1

4.2. General ........................................................................................................................................ 4-1

5. FUEL SYSTEM.......................................................................................................................................... 5-1

5.1. Inspections.................................................................................................................................. 5-1

5.1.1. Required Tools.......................................................................................................................... 5-1

5.1.2. Parts required............................................................................................................................ 5-1

5.1.3. Level of maintenance................................................................................................................ 5-1

5.1.4. Certification required................................................................................................................. 5-1

5.1.5. Option 1: Fuselage Tanks......................................................................................................... 5-2

5.1.6. Additional flexible Wing tanks................................................................................................... 5-3

5.1.7. Option 2: Wing Tanks: .............................................................................................................. 5-4

5.1.8. Fuel Low Pressure Warning...................................................................................................... 5-6

5.1.9. Fuel Quantity Indication ............................................................................................................ 5-6

5.1.10. Maintenance.......................................................................................................................... 5-6

5.1.11. Fuel Filter Removal and Installation...................................................................................... 5-6

5.1.12. Electrical Fuel Pump Removal and Installation..................................................................... 5-7

6. PROPELLER............................................................................................................................................. 6-1

6.1. Inspections.................................................................................................................................. 6-1

6.1.1. Adjusting of angle of attack....................................................................................................... 6-1

6.1.2. Required Tools.......................................................................................................................... 6-2

6.1.3. Parts required............................................................................................................................ 6-2

6.1.4. Level of maintenance................................................................................................................ 6-2

6.1.5. Certification required................................................................................................................. 6-2

7. FUSELAGE, INTERIOR AND UTILITY SYSTEMS.................................................................................. 7-1

7.1. Rescue system ........................................................................................................................... 7-1

7.2. Baggage....................................................................................................................................... 7-1

7.3. Doors ........................................................................................................................................... 7-1

7.3.1. Removal and Installation........................................................................................................... 7-1

7.3.2. Required Tools.......................................................................................................................... 7-2

7.3.3. Parts/materials required............................................................................................................ 7-2

7.3.4. Level of maintenance................................................................................................................ 7-2

7.3.5. Certification required................................................................................................................. 7-2

Maintenance Manual FK 9

B&F Technik Vertriebs GmbH

Revision 2

Section 0 Introduction

page 4

document code: des.003

7.4. Windscreen and Windows......................................................................................................... 7-2

7.5. Hydraulic brake system ............................................................................................................. 7-3

7.5.1. Brake bleeding.......................................................................................................................... 7-4

7.5.2. Required Tools.......................................................................................................................... 7-4

7.5.3. Parts required............................................................................................................................ 7-4

7.5.4. Level of maintenance................................................................................................................ 7-4

7.6. Heating and Ventilation.............................................................................................................. 7-5

7.6.1. Inspections................................................................................................................................ 7-5

7.6.2. Required Tools.......................................................................................................................... 7-5

7.6.3. Parts required............................................................................................................................ 7-5

7.6.4. Level of maintenance................................................................................................................ 7-5

7.7. Parking......................................................................................................................................... 7-5

7.8. Tie-Down...................................................................................................................................... 7-6

8. INSTRUMENTS AND AVIONICS ............................................................................................................. 8-1

8.1. Instrument Panel ........................................................................................................................ 8-1

8.2. Antennas ..................................................................................................................................... 8-5

8.2.1. COM Antenna ........................................................................................................................... 8-5

8.2.2. Transponder Antenna............................................................................................................... 8-5

8.2.3. GPS Antenna............................................................................................................................ 8-5

8.3. Static and Dynamic Pressure System...................................................................................... 8-5

9. ELECTRIC................................................................................................................................................. 9-1

9.1. Description.................................................................................................................................. 9-1

9.1.1. Required Tools.......................................................................................................................... 9-1

9.1.2. Parts required............................................................................................................................ 9-1

9.1.3. Level of maintenance................................................................................................................ 9-1

9.1.4. Certification required................................................................................................................. 9-1

10.STRUCTURAL REPAIR ......................................................................................................................... 10-1

10.1. Main Structure........................................................................................................................... 10-1

10.1.1. Required Tools.................................................................................................................... 10-1

10.1.2. Parts required...................................................................................................................... 10-1

10.1.3. Level of maintenance .......................................................................................................... 10-1

10.1.4. Certification required ........................................................................................................... 10-1

10.2. Subsidiary Structure ................................................................................................................ 10-1

10.2.1. Required Tools.................................................................................................................... 10-1

10.2.2. Parts required...................................................................................................................... 10-1

10.2.3. Level of maintenance .......................................................................................................... 10-1

10.2.4. Certification required ........................................................................................................... 10-1

Maintenance Manual FK 9

B&F Technik Vertriebs GmbH

Revision 2

Section 0 Introduction

page 5

document code: des.003

11.PAINTING AND COATINGS................................................................................................................... 11-1

11.0.1. Required Tools.................................................................................................................... 11-1

11.0.2. Parts required...................................................................................................................... 11-1

11.0.3. Level of maintenance .......................................................................................................... 11-1

11.0.4. Certification required ........................................................................................................... 11-1

11.1. Preparation Procedures........................................................................................................... 11-1

11.1.1. Preparation of Metal............................................................................................................ 11-1

11.1.2. Preparation of Composites.................................................................................................. 11-1

11.1.3. Preparation of Fabric........................................................................................................... 11-1

11.2. Painting...................................................................................................................................... 11-2

11.2.1. Primer.................................................................................................................................. 11-2

11.2.2. Final Coat............................................................................................................................ 11-2

12.ANNEX .................................................................................................................................................... 12-1

12.1. Airplane Registration Card...................................................................................................... 12-1

12.2. Warranty claim report .............................................................................................................. 12-2

13.FEEDBACK FORM................................................................................................................................. 13-1

Maintenance Manual FK 9

B&F Technik Vertriebs GmbH

Revision 2

Section 0 Introduction

page 6

document code: des.003

0. Introduction

0.1.

Revisions

The owner/operator is responsible for keeping all pages of this manual to the revision status indicated in the table, by

exchanging the relevant pages as and when a new revision is published.

For updates regularly check the technical service site of B & F Technik Vertriebs GmbH.

This revision information page shall be filed behind the checklist for amendments for about 6 month in order to get at a

glance all the changes that became effective during this time.

Index/Page

remove REV

insert REV

Remark / Reason for REV

all

all

REV 2

several editorial changes due to authorities request

0.2.

Record of Revisions

The fact of having inserted revised pages shall be confirmed in the list below.

Revision

inserted

Revision

inserted

No.

of

by --- on

No.

of

by --- on

FE

--

--

REV 1

1.Dec.2012

KR 1.Dec.2012

REV 2

1.Nov.2013

Maintenance Manual FK 9

B&F Technik Vertriebs GmbH

Revision 2

Section 0

page 7

document code: des.003

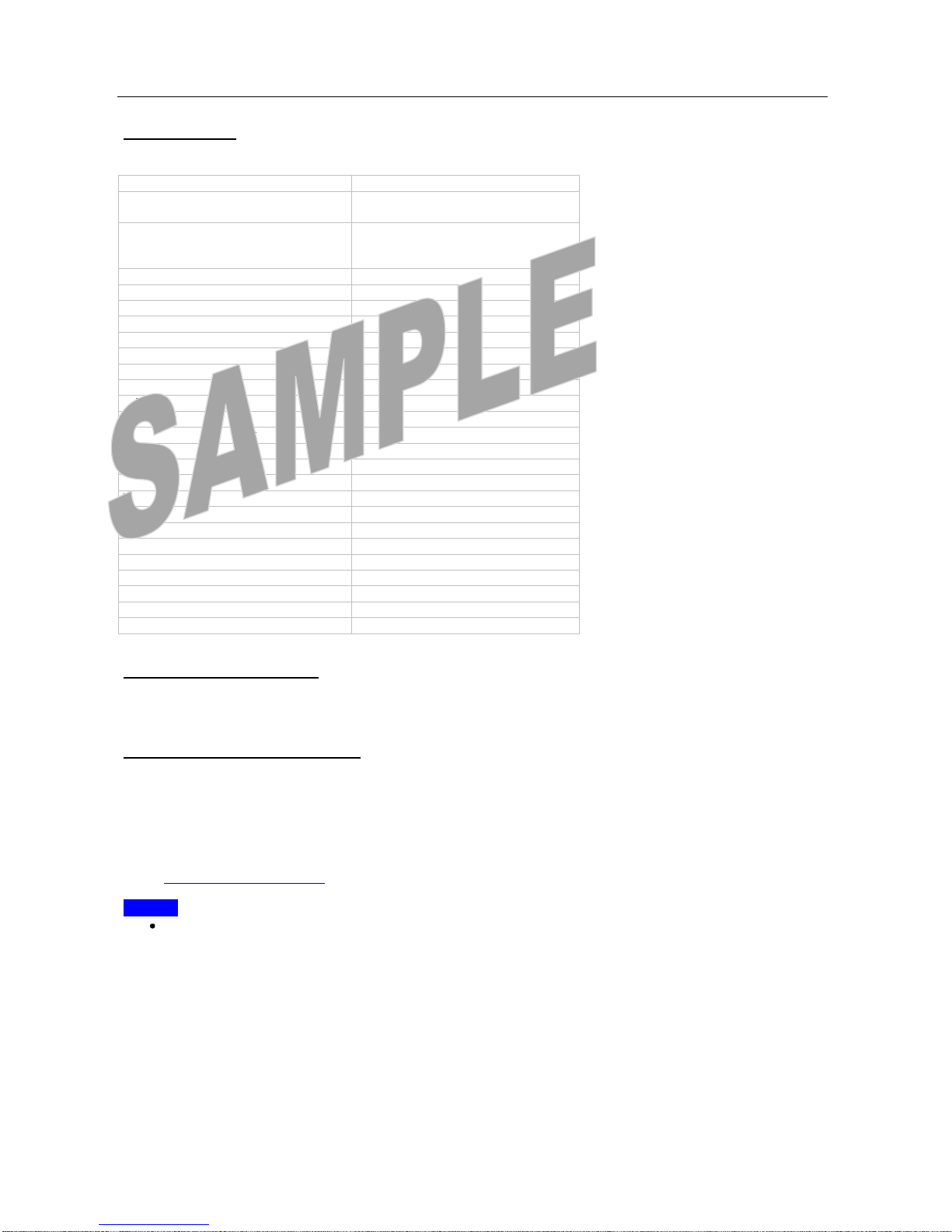

0.3.

List of effective Pages

Date: 1. of November 2013

Page

Revision

Date

Page

Revision

Date

Page

Revision

Date

0-1

Rev 2

01.11.13

0-2

Rev 2

01.11.13

0-3

Rev 2

01.11.13

0-4

Rev 2

01.11.13

0-5

Rev 2

01.11.13

0-6

Rev 2

01.11.13

0-7

Rev 2

01.11.13

1-1

Rev 2

01.11.13

1-2

Rev 2

01.11.13

1-3

Rev 2

01.11.13

1-4

Rev 2

01.11.13

1-5

Rev 2

01.11.13

1-6

Rev 2

01.11.13

1-7

Rev 2

01.11.13

2-1

Rev 2

01.11.13

2-2

Rev 2

01.11.13

2-3

Rev 2

01.11.13

2-4

Rev 2

01.11.13

3-1

Rev 2

01.11.13

3-2

Rev 2

01.11.13

3-3

Rev 2

01.11.13

3-4

Rev 2

01.11.13

3-5

Rev 2

01.11.13

3-6

Rev 2

01.11.13

3-7

Rev 2

01.11.13

3-8

Rev 2

01.11.13

3-9

Rev 2

01.11.13

3-10

Rev 2

01.11.13

3-11

Rev 2

01.11.13

3-12

Rev 2

01.11.13

3-13

Rev 2

01.11.13

4-1

Rev 2

01.11.13

4-2

Rev 2

01.11.13

4-3

Rev 2

01.11.13

5-1

Rev 2

01.11.13

5-2

Rev 2

01.11.13

5-3

Rev 2

01.11.13

5-4

Rev 2

01.11.13

5-5

Rev 2

01.11.13

5-6

Rev 2

01.11.13

5-7

Rev 2

01.11.13

6-1

Rev 2

01.11.13

6-2

Rev 2

01.11.13

7-1

Rev 2

01.11.13

7-2

Rev 2

01.11.13

7-3

Rev 2

01.11.13

7-4

Rev 2

01.11.13

7-5

Rev 2

01.11.13

7-6

Rev 2

01.11.13

8-1

Rev 2

01.11.13

8-2

Rev 2

01.11.13

8-3

Rev 2

01.11.13

8-4

Rev 2

01.11.13

8-5

Rev 2

01.11.13

9-1

Rev 2

01.11.13

10-1

Rev 2

01.11.13

11-1

Rev 2

01.11.13

11-2

Rev 2

01.11.13

12-1

Rev 2

01.11.13

12-2

Rev 2

01.11.13

13-1

Rev 2

01.11.13

Maintenance Manual FK 9

B&F Technik Vertriebs GmbH

Revision 2

Section 1 General

page 1

document code: des.003

1.

General

This manual must be read carefully by the owner and operator in order to become familiar with the maintenance of the

FK 9 Mk IV and Mk V (ELA). The manual presents suggestions and recommendations to help obtain safe and maximum

performance without sacrificing economy. It does not replace procedures or limitations mentioned in the Pilot’s Operating

Handbook (POH)!

The owner and operator should also be familiar with the applicable aviation regulations concerning operation and

maintenance of his airplane.

All limits, procedures, safety practices, servicing, and maintenance requirements contained in this manual are considered

mandatory to keep the airplane airworthy.

All values in this manual are based on ICAO Standard Atmosphere conditions and maximum take-off weight (MTOW).

The pilot in command shall make sure that the airplane is airworthy and operated according to this manual.

1.1.

Equipment List

The following shows a list of the standard equipment for the FK9 Mk IV and FK9 Mk V (ELA). A current list with optional

equipment can be found on the FK-Lightplanes webpage. The ballistic recovery system (BRS) is not required by law in

every country and is therefore not part of the standard equipment.

Note:

For weight and balance it is mandatory to list all installed equipment.

Standard FK9 MK IV equipment:

basic instruments: speed indicator, altimeter (5000ft), compass,

slip indicator, oil pressure and oil temperature, cylinder head temperature (CHT), rpm indicator, Junkers 3-blade

propeller.

hydraulic disc brake 6" main wheel system with park lock

fiberglass seats with two color upholstery

oil-inspection cap integrated in engine cowl

side air vents in both cockpit doors

mechanical elevator trim, electrical flap position indicator

60l fuselage fuel tank with electric level indicator and drain vent

electric fuel booster pump and fuel pressure warning

single color white with standard decoration

Standard FK9 ELA equipment:

basic instruments: speed indicator, altimeter (5000ft), compass,

slip indicator, oil pressure and oil temperature, CHT, rpm indicator, Junkers 3-blade prop.

hydraulic disc brake 6" main wheel system with park lock

fiberglass seats with two color upholstery

seatrests adjustable in position and angle

oil-inspection cap integrated in engine cowl

side air vents in both cockpit doors

mechanical elevator trim, electrical flap position indicator

60l fuselage fuel tank with electric level indicator and drain vent

electric fuel booster pump and fuel pressure warning

additional pockets on both cockpit sidewalls

electrically operated flaps

luggage compartment with external access door

additional aerodynamic fairing set for wing strut nose and intersections

electric multi-information display (MID)

Maintenance Manual FK 9

B&F Technik Vertriebs GmbH

Revision 2

Section 1 General

page 2

document code: des.003

1.1.1.

Placards

Refer to the respective POH

Location:

Placard:

In the Cockpit

max. TOW ............. kg

spins and acrobatics prohibited

Cockpit

Weighing date:

Empty weight:

Poss. load including fuel:

Cockpit rear section

Type placard (metal)

Door handles (inside + outside)

OPEN / CLOSE

Fuel selector in flow direction

Fuel

Fuel selector closed position

Close

Aft baggage compartment

max. load 15 kg with 60L fuel

Choke (ROTAX only)

Choke

Carburetor heat

carb. (option)

Cabin heat

cabin heat (option)

Trim handle

Trim

Trim markings

Neutral; nose up; nose down

Oil temperature indication VDO

OIL

CHT indication VDO

CHT

Fuel cap (for Rotax Version)

FUEL AVGAS / MOGAS

Fuel indication

Markings every 10l

Vicinity of rescue system

placard Rescue system

Rocket Exit Area

Danger: Rocket Exit Area

safety pin rescue system

Remove before flight

Wheel fairings main wheels

2.0 bar

Wheel fairing nose wheel

1.5 bar

Towing version only:

Vicinity of airspeed indicator

Care for tow speed !

Handle for cowl flap

Cowl flap

Handle for towing clutch

TOW

1.1.2.

Instrument Markings

Airspeed Indicator: refer to respective POH

Engine Instruments: refer to respective engine manual

1.2.

Sources to purchase Parts

Spare parts and service/support for all FK planes can be ordered from your local dealer or directly from:

B & F Technik Vertriebs GmbH Speyer

Anton-Dengler-Str. 8

D-67346 Speyer, Germany

Tel.:+49(0)6232/72076

Fax:+49(0)6232/72078

Email: [email protected]

Note:

Please use the relevant form to order spare parts.

All spare part orders are processed and delivered in the quickest possible time.

Ask your local dealer to maintain a spare parts inventory, it might be better and faster (especially outside Europe) to

purchase orders from the local FK dealer.

Maintenance Manual FK 9

B&F Technik Vertriebs GmbH

Revision 2

Section 1 General

page 3

document code: des.003

1.3.

List of disposable replacement parts

Description

Type

Engine:

ROTAX 912

oil

Shell Advance VSX 4

oil filter

Rotax 825706, gasket oil filter, gasket for oil drain

Air filter

Rotax 825551

spark plugs

Rotax NGK DCPR7E (80hp)

NGK DCPR8E (100hp)

engine shock mount

Megi Konus

exhaust-muffler support spring

Rotax

coolant

Glysantin @ 50% mixing ratio

fuel filter

MANN WK 42/2

Electric:

battery

Motorcycle battery 12V / 14Ah

12V / 16Ah, Hawker gel battery

fuses

Micro fuse 0,5- 8 A (delay action)

generator blade type fuses 20 A

Landing light bulb

12V 50W

Tail light bulb

12V 5W

Strobe light bulb

12 V 30W (Xenon) not for LED

Position light bulb

12 V 5W

Landing gear:

Nose wheel

Duro 4.00x4 4-ply

Main wheel

Sava 4.00 x 6 ply

Tundra 8.00 x 6 ply4

Tube nose wheel

4.00 x 4 with 90° valve

Tube main wheel

4.00 x 6 with 90° valve

Tundra8.00 x 6 with 90° valve

Disk brake

M.I. 42354-6

Brake pads

M.I 42176

Fuselage:

Seat cover

FK-Lightplanes

1.4.

Engine specifications

refer to the respective engine manual

Exhaust system (ROTAX):

The engine is delivered optionally with a Rotax steel or with a stainless steel exhaust system.

Note:

Based on past experience, it is recommended to install the stainless steel system because of the durability of

the product, especially in regions with high humidity.

█CAUTION:

A complete description of engines, parts, their maintenance requirements, performance and service bulletins

can be found in the manufacturer’s manuals or on the manufacturer’s webpage.

1.4.1.

Power Plant Limitations

refer to the respective engine manual

Note:

The following SB-912-036R1 has been issued for all ROTAX 912A / 912F / 912S / 914F engines:

Subject: Oil system, Engine lubrication system

Engines which have had the propeller spun for more than 1 turn in reverse direction allow air to be ingested into the

valve train.

Action:

1. It is forbidden to turn the propeller in reverse direction for more than 1 turn.

2. Inspection for correct venting of the oil system has to be performed in cases when the propeller has been spun

in reverse direction for more than 1 turn.

Maintenance Manual FK 9

B&F Technik Vertriebs GmbH

Revision 2

Section 1 General

page 4

document code: des.003

1.5.

Weight and Balance

1.5.1. Abbreviations and Terminology

Reference Datum

An imaginary vertical plane from which all horizontal distances are measured

for balance purposes

Arm

The horizontal distance from the reference datum to the center of gravity of an

item

Moment

The product of the weight of an item multiplied by its arm

Airplane center of gravity (C.G.)

The point at which an airplane would balance if suspended. Its distance from

the reference datum is found by dividing the total moment by the total weight of

the airplane

C.G. arm

The arm obtained by adding the airplane’s individual moments and dividing the

sum by the total weight

C.G. limits

The extreme center of gravity locations within which the airplane must be

operated at a given weight

Empty weight

Weight of the airplane including unusable fuel, full operating fluids and full oil;

equipment as indicated

1.5.2. Basic Empty Weight

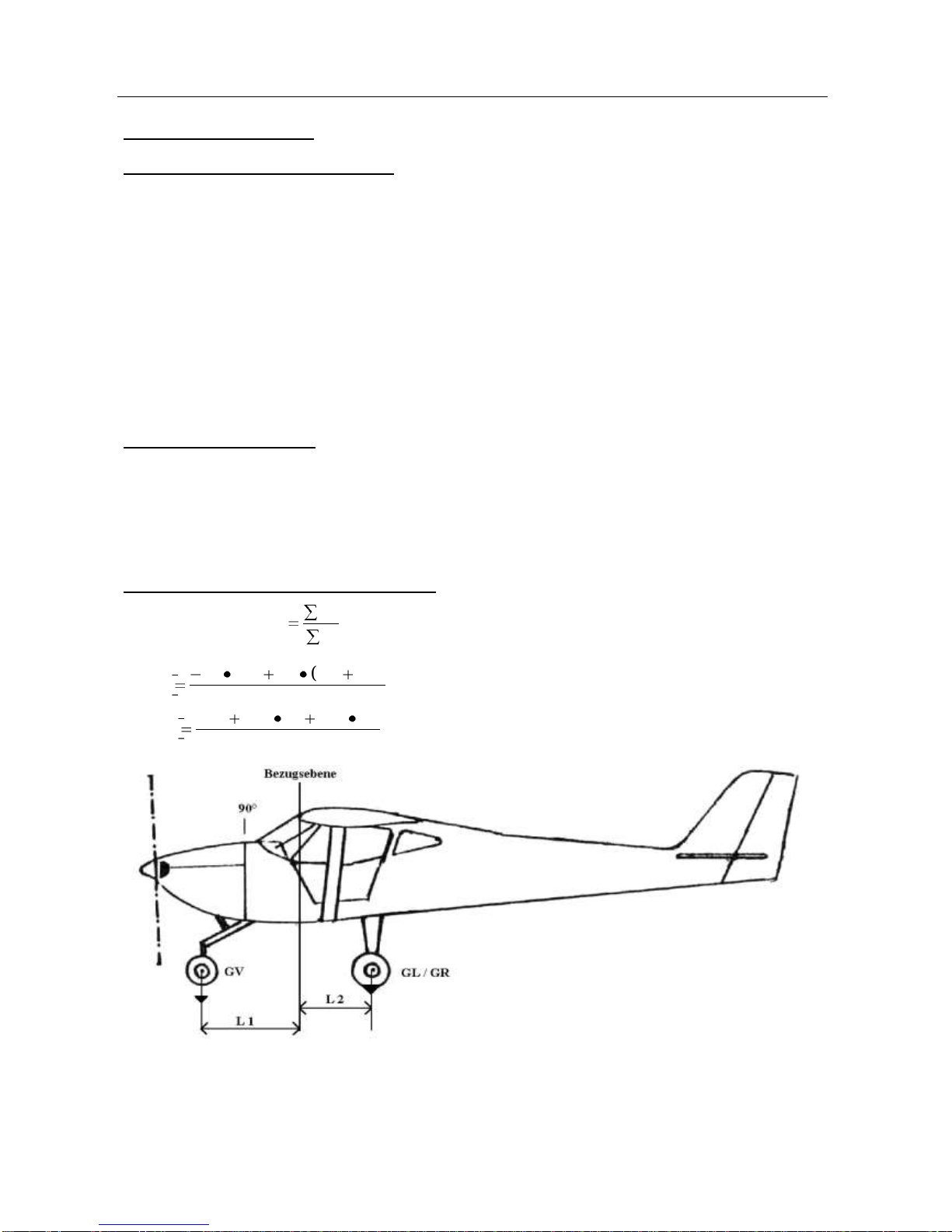

By using the following formula, the C.G. is computed. Reference line (datum) for all arms is the leading edge of the wing.

Prior to delivery, each aircraft has been weighed with the fuselage level, (reference line see drawing below), including oil

and coolant, as well as equipment as indicated but no fuel (except un-drainable fuel). During this procedure the

respective arms are determined as well.

All these data are transferred to the Basic Empty Weight and Balance Form (German: Wägebericht). This “Wägebericht”

contains a list of equipment installed and is part of the POH.

All changes to the airplane affecting weight and balance (installation of new equipment etc.) require a new weighing.

Formula to compute the center of gravity (X):

Center of Gravity in [m]

CG M

G

GG = total weight

GV = weight front

GR = weight right

GL = weight left

GG GLGRLGVL

mX )(21

Tricycle

GG LGHLGLGR

mX 21)(

Tail wheel

GH = weight aft

Maintenance Manual FK 9

B&F Technik Vertriebs GmbH

Revision 2

Section 1 General

page 5

document code: des.003

Arms (Datum: wing leading edge):

See actual Form “Wägebericht”

For the tail wheel version, following applies:

L 1 = from datum to the axle of the main wheels

L 2 = from datum to the axle of the tail wheel

1.5.3. Weighing

The best place for the weighing is inside a hangar with a flat surface and no air current. The weighing should be

performed as shown. For a correct result the plane should be rolled, if necessary over ramps onto the three weighing

scales. It is very important that the plane is not lifted on the scales. By lifting the plane on the scales the lateral forces of

the main gear spring can falsify the result. Once the plane stands on the scales, it must be checked if the firewall is

perpendicular to the floor. By inserting a plate under the front or main wheels, the plane can be aligned correctly.

█CAUTION:

The plane must be secured with the park brake to prevent rolling.

1.5.4. Required Tools

3 x weighing scales (min. measuring range for each scales 200Kg / 441 lbs.)

if necessary ramps for the scales

spirit level

plummet

tape measure

1.5.5. Parts/materials required

None

1.5.6. Level of maintenance

Line

1.5.7. Certification required

A&P Mechanic or LSA Repairman Maintenance

Maintenance Manual FK 9

B&F Technik Vertriebs GmbH

Revision 2

Section 1 General

page 6

document code: des.003

1.6.

Tire Inflation Pressure

Wheel

Size

Pressure

Main

6.00 x 6, 4.00 x 6

8.00 x 6

1.8 to 2 bar

17 –29 psi

Front

4.00 x 4

1.5 - 2 bar

21 - 29 psi

Tail

120 / 150mm

Note:

To improve the durability of the tires, you should avoid excessive solar radiation (UV radiation) as it causes

premature ageing. It is recommended to examine the tires for wear marks during pressure checking.

1.7.

Approved Oils and Capacities

1.7.1. Oil

refer to the respective engine manual

1.7.2. Fuel

Fuel capacity Option 1 Fuselage tank:

2 x fuselage fuel tank 30l (7.92 US gal.) each, 60l (15.85 US gal.) total.

Optional flexible Wing tanks (in addition to fuselage tank):

2 x wing tanks 20l (5.28 US gal.) each, 76l (10.57 US gal.) total.

Fuel capacity Option 2 Wing tank:

2 x wing tanks 38l (10 US gal.) each, 76l (20 US gal.) total

LSA optional: Long range wing tanks 2 x 55l (14.5 US gal.) each, 110l (29 US gal.) total

▲WARNING:

The values include unusable fuel!

Fuel specification:

Refer to the original corresponding chapter in the engine operator's manual.

Rotax:

AVGAS should only be used if MOGAS is not available or in case of problems caused by vapor locks.

AVGAS 100 LL

MOGAS

premium unleaded automobile fuel without bioethanol (ASTM D4814)

Smart:

Unleaded fuel, mandatory for M160 (smart)

Min. ROZ/ RON 95-Octane rating without bioethanol (unleaded fuel)

▲WARNING:

Restrictions apply for use of fuels containing methanol –see related service bulletin!

1.7.3. Coolant

approx. (ROTAX) 1.5l (0.4 US gal.)

delivered ex-factory with Glysantin Protect Plus/G48 from BASF® mixture with water 1:1

1.7.4. Brake Fluid

FMVSS 116-DOT4 - SAE J 1073

▲WARNING:

Never mix brake fluids with different DOT ratings.

Using DOT ratings not listed above can damage seals.

Maintenance Manual FK 9

B&F Technik Vertriebs GmbH

Revision 2

Section 1 General

page 7

document code: des.003

1.8.

Recommended Fastener Torque Values

The torque values set out in the table are ISO standards and should only be used as reference. All values should be

used for any installation described in the maintenance manual, unless other values are specified.

Note:

All bolts must be mounted up to down, inside to outside or front to back, unless design does not permit.

Metric Bolt Assembly Torque, Grade 8.8

Size

Wrench size mm

tightening torque in Nm

tightening torque in lbf ft.

M4

7

4

2.9

M5

8

6

4.4

M6

10

10

7.3

M8

13

24

16.9

M10

16

35

25.8

█CAUTION:

Never exceed the values set out in the tables as this will result in mechanical damage. Once you have re-

opened any lock nut, it must be replaced with new nut. Never re-use lock nuts. Bolts or nuts without any self-

locking property must be marked with thread locker.

1.9.

General Safety Information

This chapter deals with the normal procedures recommended for the safe operation of the FK 9.

▲WARNING:

Ensure that the parachute system is always secured with the safety pin.

Never leave the plane unattended with unauthorized persons especially when the engine is running.

Use caution during taxi and engine run up. Note that a foreign object can come into the danger zone of the

propeller at any time.

Never perform engine run up with full throttle on smooth surfaces without wheel chocks.

Ensure that the keys are removed and main switches and ignition switch are turned OFF during any work on the

engine and propeller.

Note:

The illustrations of this Manual show the typical construction. They may not represent in full detail or the exact

shape of the parts, which have the same or similar function.

1.10.

Instructions for Reporting

Aircraft Make, Model, Serial Number

Engine Make, Model, Serial Number

Date of Inspection

Total Time

Airframe

Engine

Color

Description of the un-airworthy items found

Owner of Aircraft

Maintenance Manual FK 9

B&F Technik Vertriebs GmbH

Revision 2

Section 2 Inspections

page 1

document code: des.003

2.

Inspections

2.1.

Inspections

Light Sport Aircraft (LSA) aircraft are designed to be lighter than normal aircraft but must withstand similar loads. The

structure and the engine must be inspected regularly to maintain airworthiness.

If there is any damage it is recommended to consult a certified maintenance facility or contact the manufacturer. This

applies especially to composite and aluminum structures.

Note:

Weather or environmental influences may negatively influence the recommended intervals. The result is a

reduction of the intervals.

2.1.1.

Required Tools

Set hexagon Allen wrench

Set screwdriver

Set metric ratchet wrench or set of metric combination wrench

Torque wrench

Oil filter wrench

Side cutters

Pliers

Safety wire twisters

2.1.2.

Parts/materials required

Metric screws and nuts

Loctite 243

Safety wire

Oil filter

Gaskets

Spark plugs

2.1.3.

Level of maintenance

Line

2.1.4.

Certification required

Owner, LSA Repairman Inspection, LSA Repairman Maintenance, A&P

2.2.

General Advice

The vibration dampers at the engine mount should be treated regularly with Vaseline to prevent aging.

Fuel lines, cables and Bowden cables must not be damaged.

█CAUTION:

For any maintenance or repair works first secure rescue system with safety pin and disconnect aircraft battery

completely from electric system.

Never turn the propeller for more than 1 turn in opposite direction (ROTAX engine)

Maintenance Manual FK 9

B&F Technik Vertriebs GmbH

Revision 2

Section 2 Inspections

page 2

document code: des.003

2.3.

Regular Maintenance and Lubrication Schedule

The following actions must be performed after certain flight hours or time intervals as applicable.

There are some actions which must be done for the first time after the very first 2 / 10 / 25 flight hours. The regular

maintenance intervals are 100 / 200 / 500 flight hours or every year / every 2 / every 4 years.

Engine maintenance is not part of this manual, it must be performed additionally according to the respective engine

manual.

Download the latest, valid updated version of the maintenance plan from the FK-Service site!

Item

Interval

Check and tighten all engine connections (oil, coolant and fuel lines)

after the first 2

hours

Check oil level

Check cooling and brake system for leaks

after the first 10

hours

Check all screws

Check the screws (tight and secured) of the main gear beam to the fuselage

Check the propeller for blade synchronization and wear at the spinner

Item

100

200

500

Check engine vibration damper for cracks and wear

X

X

X

Treat the Bowden cables with Teflon spray

X

X

X

Check the screw connection of the main gear beam to the fuselage and gear-beam for no play

Change screws every 1000 landings

X

X

X

Check the propeller for synchronization, proper connection and wear

X

X

X

Check flight controls for wear, lubrication and bearings are secured

X

X

X

Check the trim for proper operation; the friction must be high enough to assure the trim does not move

without pilots action

X

X

X

Check fuel system for leaks, contamination, dirt. Change the fuel filter

X

X

X

Check nose wheel damper for cracks and wear

X

X

X

Check tail wheel for cracks and wear. Check nose / tail wheel steering for wear, corrosion, lubrication

X

X

X

Item

100

200

500

Check flaps for no play when retracted

X

X

X

Check flap handle for correct position

X

X

X

Check tires for wear and tire pressure

X

X

X

Check brake system for wear; hydraulic disc brake only: check for leaks, change fluid every 2 years

X

X

X

Check elevator bearing bolts secured

X

X

X

ROTAX only: change carburetor flange

(with air box change required every 200 hours)

X

X

X

After 500 hours total:

check the rivets at the elevator

X

X

X

Air box: check all screws and mechanical parts tight

X

X

X

Change or clean air filter

X

Check Bowden cables of carburetors for lubrication and wear; replace every 400 hours

X

Or every 2 years: replace engine vibration damper

X

Check rudder cables for wear

X

Check bearings of flight controls and flaps for wear / play

X

Check bolts for wear and corrosion

X

Check Ceconite covered parts for condition of the skin

X

Or every 4 years: replace all rubber tubes for fuel, oil and cooling liquid

X

Lubrication Schedule

Or every year: Bearings nose-/tail wheel steering

X

X

X

Flight control linkage

X

X

X

Flight control bearings

X

X

X

Or every year: Bolts

X

X

X

Engine control cables

X

X

X

This manual suits for next models

1

Table of contents

Other FK-Lightplanes Aircraft manuals

Popular Aircraft manuals by other brands

Horejsi

Horejsi Q12 X manual

Air Creation

Air Creation FUN 450 Instruction and maintenance handbook

Carl Goldberg Models

Carl Goldberg Models Tiger 2 ARF manual

ROBBE

ROBBE SAPPHIRE 2678 Instruction and user's manual

Piel

Piel EMERAUDE CP301 VH-SJH Aircraft flight manual

Piper

Piper CHEROKEE WARRIOR PA-28-151 1995 Maintenance manual