BGU WK 600 B CLASSIC User manual

Südharzer Maschinenbau GmbH

Helmestraße 94 ∙ 99734 Nordhausen/Harz

Zentrale: 03631/6297-0 6297-111

Internet: www.bgu-maschinen.de

e-mail: [email protected]

LOG SAW

WK 600 B CLASSIC

Carefully read these instructions

before starting and using your saw!

OPERATION MANUAL

Set-up & instal-

lation

Use

Maintenance

Accessories

Made in Ger-

many

2

TABLE OF CONTENTS

1. GENERAL INFORMATION 3

1.1 About the manual 3

1.2 Delivery and transport claims 3

2. PRODUCT OVERVIEW 5

2.1 Log-saw with gasoline engine 5

3. DECAL LISTINGS 6

4. SAFETY RULES 8

4.1 Safety rules about saw blade 9

4.2 Mandatory application field 9

5. OPERATION 10

6. REPAIRS AND MAINTENANCE 11

6.1 First maintenance after initial start-up 11

6.2 Ordinary maintenance 12

6.3 Cleaning after use 12

6.4 Replacing the saw blade 12

6.5 Tensioning and replacing the V-belt 13

6.6 Consumables 13

7. HANDLING AND Transport 14

8. DISPOSAL 14

9. Technical Data 15

9.1 Noise emissions 15

10. TROUBLE-SHOOTING CHART 16

11. OTHER AREAS OF POSSIBLE HAZARD 16

11.1 Mechanical dangers 16

11.2 Environmental dangers 16

12. WARRANTY 17

13. SPARE PARTS for WK 600 B classic 18

14. CE – STATEMENT OF COMPLIANCE 23

3

Dear customer,thank you very much for your trust and preference in

choosing our equipment and joining the number of our best custo-

mers in the world. We are confident that our equipment will be up to

all your expectations and assure you a long lasting quality and perfor-

mance.

1.1 About the manual

Please take time to read this manual and learn to how operate and

maintain the saw safely.

For your easier reading this manual is laid out in several sections pro-

gressively numbered 1 through 14 and listed on the “content” page.

The information, pictures and technical data in this document reflect

current or planned product features, functions, and characteristics as

of the publication date. Because of on-going product improvements

and feature additions, information in this document is subject to

change without notice.

If you are experiencing a problem or functional trouble on your machi-

ne, please read the “trouble-shooting” section to identify possible cau-

ses and remedies. If the problem or functional trouble is not listed in

the troubleshooting chart contained in this manual, ask your Authori-

zed Service Centre for service. When you have checked all the possib-

le causes listed and you are still experiencing the problem, ask your

Authorized Service Centre for help.

When you order parts maintenance or repair services, your Authorized

Service Centre, your dealer or eventually the manufacturer need your

machine serial number and engine serial number. These are the num-

bers that you have recorded on the product identification label of the

manufacturer on the machine.

1.2 Delivery and transport claims

Upon delivery of the machine please check for visual machine dama-

ges such as damaged packing or scratched buckled parts. If so, make

a remark on all copies of the delivery bill before signing for accep-

tance.

Also have the truck driver sign al copies of the delivery bill.

Should your shipper or the truck driver refuse to accept your claim,

fully reject delivery and make sure to inform us (the manufacturer)

immediately. No claims shall be taken into account by the shipper or

by the insurance company, if a reservation note is not made on the

delivery bill.

1. GENERAL INFORMATION

4

All transport damages including hidden ones must be notified within

latest 2 days from delivery. Therefore delivery must be collected and

inspected within this term. Later claims shall be disregarded.

In case of assumed but not visually clear transport damages make su-

re to mark the following sentence on the delivery bill: „Reserved de-

livery due to assumed transportation damages.“

Insurance and shipping companies act with extreme caution in case of

transport damages and sometimes refuse to accept responsibility.

Please make sure to provide clear and exhaustive evidence (photos)

of the claimed damages.

Thank you in advance for your help and understanding in this matter.

5

Rear grip-handle

2.1 Log-saw with gasoline engine

2. PRODUCT OVERVIEW

Upper hood

Gasoline engine

Stand Wheels

Log carriage

Saw blade

6

1. Warning label „Do not operate the machine in-

doors!“

Never run the machine inside a closed area.

Exhaust fumes are toxic!

2. Aufkleber

Safety pictogram

„Wear ear plugs and goggles!“

Loud noise can cause impairment or loss of hearing, wear a suitable

protective device such as ear plugs and safety goggles.

3. Personal protection sign

Mind these instructions for safe operation!

4. Machine safety label

„Before operating the machine read this manual

and mind all safety instructions“

To avoid personal injury or death, carefully read and understand all

instructions pertaining to the saw including the engine manufacturer’s

operating and maintenace instruction manual.

5. Safety-alert symbol

Read and recognize safety information. Be alert to the potential

for personal injury when you see this safety-alert symbol.

6. Personal protection sign “Wear suitable protec-

tive boots!”

7. Personal protecion sign “Wear suitable protect

ve gloves!”

This label shows that you must wear safety gloves when working with-

the saw.

3. DECAL LISTINGS

7

8. Machine safety label

„Before setting-up, servicing, maintaining and clea -

ning the machine, disengage power and stop the en-

gine. Lock the tool and secure it against acciden-tal

start.“

This safety label reminds users of a pinched hands danger.

9. “BGU-maschinen” Manufacturer’s logo

10. Identification label „Product identification“

This label shows the company details of the manufacturer and the

main machine technical data.

11. Machine safety label Keep your hands off all machine

parts identified by this

label! Burning danger.

BEWARE!

hot parts

8

Strictly perform installation, set-up, maintenance, cleaning

and transportation with the motor switched off and the blade

firmly secured against accidental operation.

Immediately disconnect power off the machine in case of any

eventual fault or trouble.

Before operating the saw for the first time read and familiarize

with the instructions of the engine manufacturer!

The user shall strictly comply with these operation, set-up, mainte-

nance, repair and trouble-shooting instructions in order to assure safe

operation and no damages to the equipment. Moreover we recommend

to let the machine be run and maintained only and strictly by trained

and skilled staff who must be familiar with the applicable occupational

safety and health administration rules as well as applicable transportati-

on rules. Incorrect use of the saw can cause serious injury or death.

No person under school leaving age should operate a circular saw.

Those who have reached school leaving age but are below the age of

18 may operate a circular saw, if supervised by a competent person of

18 years or over. The machine shall be installed and kept in a suitable

location selected by the customer for safest operation.

The working area around the machine must be kept as clear as pos-

sible from surrounding obstacles and slippery foundation floors should

be duly treated (do not use saw dust or wood ash for this purpose).

Make sure that the equipment stands on a safe stable foundation.

Do not allow within the hazardous zone any unauthorized third or persons

who are not familiar with the dangers related to use and operation of the ma-

chine. Allow no bystanders, especially children and pets in the working area.

● Due and proper illumination of the working site must be provided at all times.

● The saw blade must be duly sharpened for maximum performance

and no recoil danger. Flash and chips must be removed off the

crown wheel.

● Damaged or buckled blades (very likely to break during operation)

should not be used.

● Always wear suitable hearing (ear plugs or muffs) and eye

protection(goggles or safety glasses) while operating the machine.

● Set up the machine on a firm surface which is free from stumps,

boulders and other obstructions and ensure that a wide but confined

area is available around the machine.

● Operators must wear steel toe safety shoes and snug-fitting tear-re-

sistant work cloths.

● No additional customised protections or tools should be provided on

board of the machine, other than the ones designed and supplied by

the manufacturer.

4. SAFETY RULES

9

● Do not apply pressure (for instance by means of the wood stock)

against the blade to make it come to a quicker stop.

●

The machine is not designed for indoor use (dust release).

● NEVER leave the machine unattended with the running motor.

● Before leaving the operator‘s station for any reason, stop the engi-

ne, disconnect power and secure the machine against accidental

operation.

4.1 Safety rules about saw blade

The unit is strictly designed for use with a 600mm (outer diameter)

blade. The blade (Cr) is capable to withstand a maximum number of

revolutions of 3000 rev. per minute.

Strictly use blades as per EN Standard 847-1.

Do not ever use worn out blades in need of sharpening.

Make sure that the blade shows good conditions, no damages, no

cracks, no buckling and no missing/broken teeth/bits.

Hard metal blades require special care and handling. Make sure that

the blade bits do not ever hit against hard surfaces (for example conc-

rete floors), which might cause invisible bits damage.

Hard metal blades must be suitable to operate at 3250 revolutions per

minute.

4.2 Mandatory application field

These log-cutting saws are strictly designed for preparation of fire-

wood. Sawing to be strictly performed with wood stock on the log car-

riage. All other applications are forbidden and considered as “misuse”.

The manufacturer is not liable for any damage or injury resulting from

misuse!

The machine is capable to handle wood stocks in diameter of 8-19.5

cm. Shrubs and tiny branches bundles must be loaded on the trough

and securely hold on both sides of the blade.

The machine is strictly conceived for ONE-MAN OPERATION

ONLY.

Check the tension of the V-belt before first use!

Misuse will completely void your warranty. The manufacturer

accepts no liability for personal injuries and damages to other

equipment caused by misusing the machine.

10

5. OPERATION

This log-cutting saw model WK 600 B Classic is ideally recommended

for stationary use in your yard.

A rugged all-steel construction assures longest machine life at any

operative condition.

This machine is equipped with inbuilt gasoline engine for independent

power provision. Please read the instructions of the engine ma-

nufacturer before use.

When you switch the machine on make sure to check that the blade is

mounted to rotate in the proper direction before cutting any materi-

al. The tool must rotate against the operator that is upward toward the

operator. Load the log in the carriage and smoothly push to the blade.

Make sure to avoid inhaling gasoline vapors during use.

If you working with twisted or crooked logs make sure to load the

log on the carriage, so that the bolged side of the log is turned to the

blade in order to avoid the log from tipping over or jamming during

cutting and consequent possible even major damages to the blade.

Now fasten the grip on the log carriage and push to smoothly tilt it

over towards and through the blade.

NOTE: avoid excessive pressure on the carriage through the

blade with cutting. Excessive hold-down pressure may slow the

blade down and cause dangerous jamming!

When pushing the log through the blade doing so avoid all jerky, bum-

py movements that could lead to risky and dangerous situations. Tim-

ber in maximum diameter of 200mm and length of 1.1 m must lay on

the carriage by the entire length with no projecting end.

After the first log is cut off the timber, let the carraige swing down to

start-position (wide opened) before advancing the remaining timber to

the blade and starting a new sawing cycle.

If you try to feed the stock forward and cut before the carriage rea-

ches back to start position, you may run the risk of hitting the stock

against the blade guard consequently causing severe personal injuries

and machine damages for which the manufacturer carries no liability.

If the maximum 16 mm spacing between clearance inserts (wood

strips) is reduced because of excessive wear, provide for immediate

replacement of the wooden inserts! (see Figure 1)

Fig. 1

wood strips

Saw blade

11

6. REPAIRS AND MAINTENANCE

Make sure that the machine is fully disconnected and all mo-

ving parts are secured before performing any maintenance/re-

pair work on the machine. In the event of any malfunctioning,

switch the machine off before trouble-shooting.

6.1 First maintenance after initial start-up

Check and tighten all fixation elements after 1 operation hour, in or-

der to avoid damages to the motor.

Make sure to check the torque of all fixation hardware used for the

driving pulley of the motor. Adjust torque, as necessary.

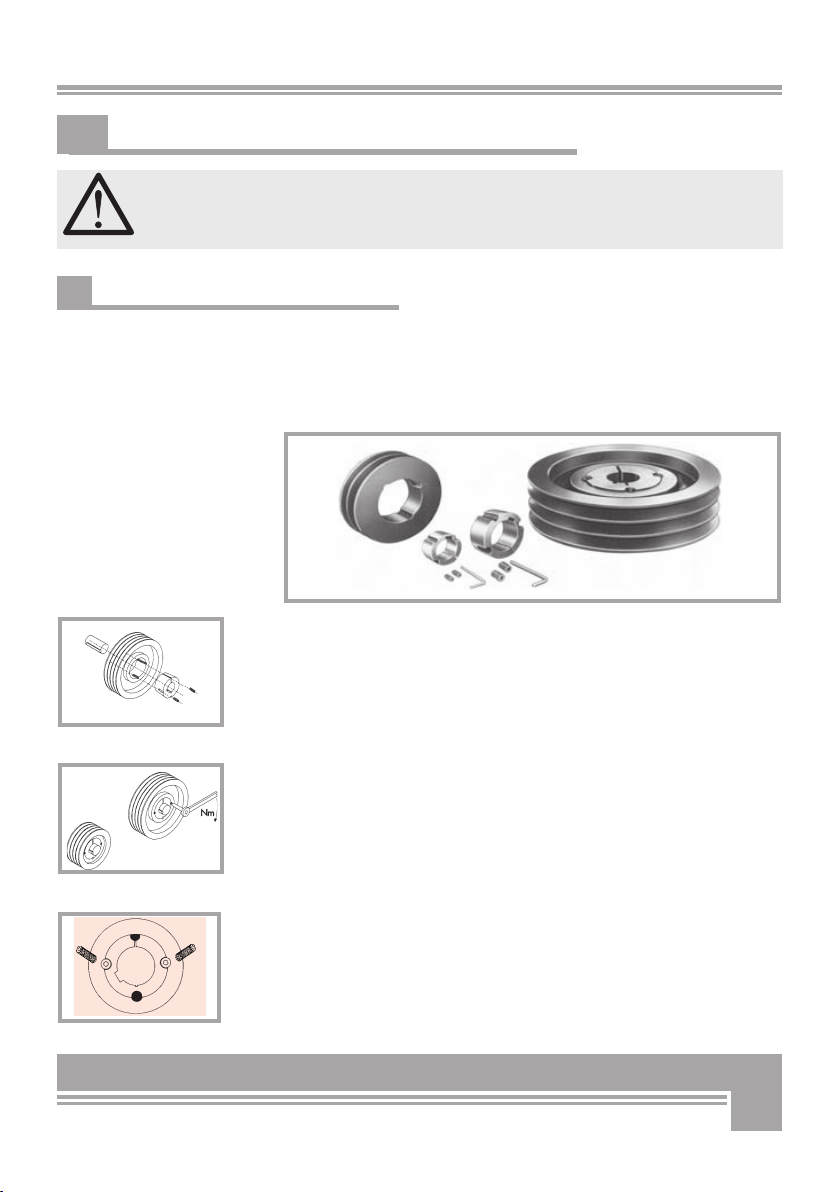

Procedure:

• Unscrew and remove the cover 2 (pos. 8 of the spare part list) over

the pulley by removing the 4 hex screws M6x16 and relative was-

hers (pos. 31, 23 see spare part list)

• Remove screw M8x25 (Pos. 41) with its spring lock (Pos. 40, of the

spare part list) and washer (Pos. 38, of the spare part list)

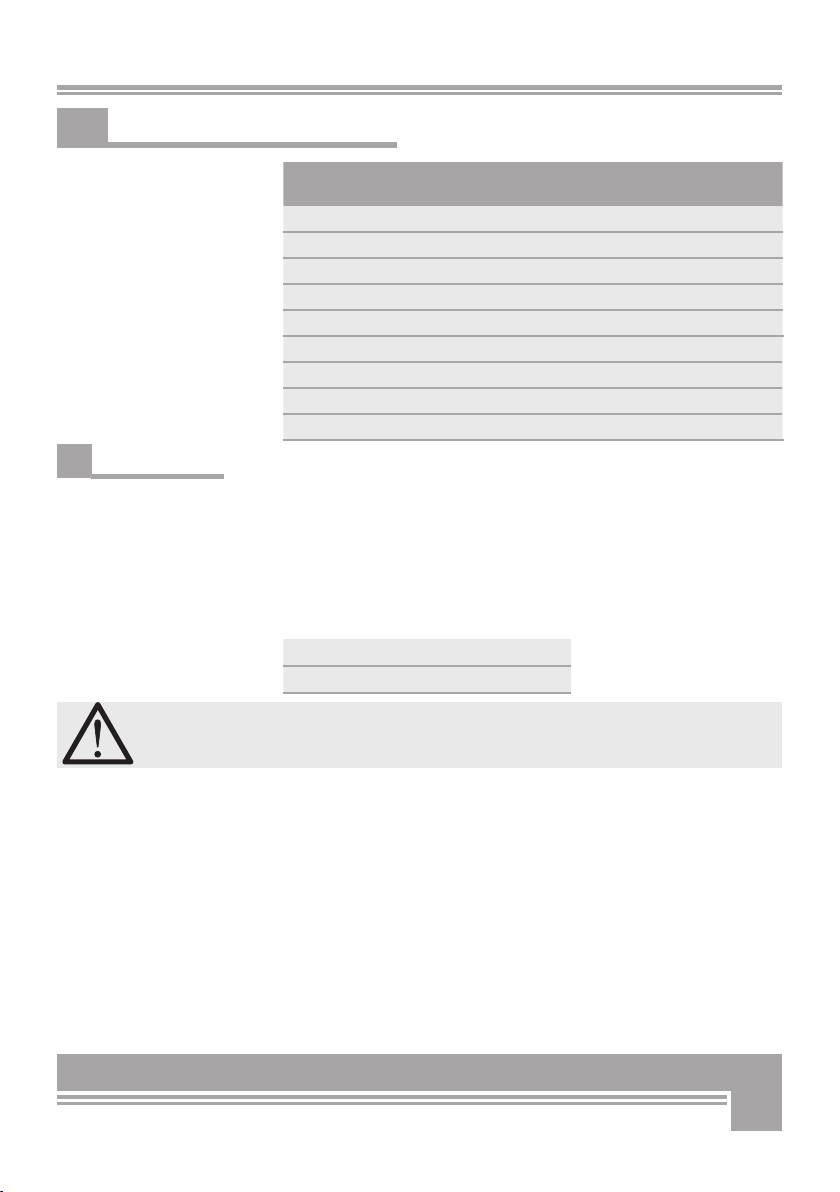

• Check the torque of both threaded pins and adjust them, if necessa-

ry, using a wrench 3 with 5.7 Nm torque (fig. 5)

Fig. 2

optibelt

Die Keilrillenscheiben sind vor der Neumontage auf Beschädigungen und korrekte

Ausführung zu überprüfen.

Taper-Buchsen, Schrauben-Anzugsmomente

Abmessung Schlüssel- Schrauben- Anzugs-

TB 1008, 1108 3 2 5,7

TB 1210, 1215, 1310, 1610, 1615 5 2 20,0

TB 2012

TB 2517

TB 3020, 3030 8 2 92,0

TB 3525, 3535 10 3 115,0

TB 4040

TB 4545

TB 5050

Fig. 3

Fig. 4

Fig. 5

3. Welle säubern und entfetten. Scheibe mit Taper-Buchse bis zur

5. Mittels Inbusschlüssel nach DIN 911 Stiftschrauben bzw.

Zylinderschrauben gleichmäßig mit den in der Tabelle ange-

12

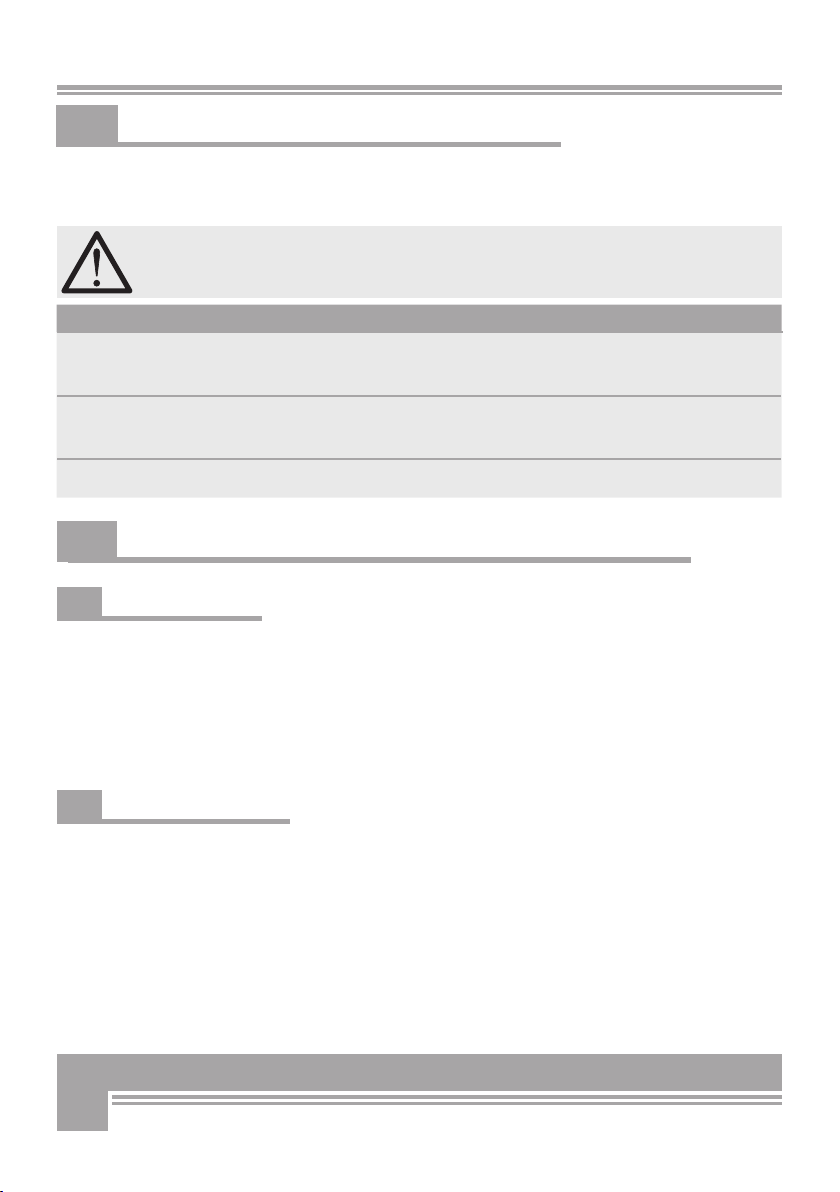

Fig. 6

saw blade

Log carriage

6.2 Ordinary maintenance

The following tasks belong to ordinary maintenance works:

● Clean the machine from eventual residual wood, chips or dirt.

● Lubricate all moving parts.

● Grease all pivoting parts of the log carriage

6.3 Cleaning after use

Remove wood chips and saw dust produced and left on the machine

during work.

Clean the log carriage assembly removing all wood rests.

6.4 Replacing the saw blade

Safety note ! Wear safety gloves - pinched hands danger!

Before replacing the blade make sure to disconnect the machine

from power (unplug the electric motor or turn the tractor off).

Following instructions apply for safe and proper blade replacement:

● Disconnect power off the machine (unplug power cord or stop the

motor of the tractor) and wait for the blade to come to a complete stop.

● Tipp the upper blade hood over by releasing the 4 screws

● Release and undo the fixation bolt on the blade clamping flange

using a spanner to secure the blade flange on the motor side as you

undo the nut (spanner SW 41).

● Remove the clamping flange.

● Pull the old blade off the shaft (make sure to wear tear-resistant

gloves. DANGER!)

● Fit the new blade on the shaft. Note direction of rotation. All tools must

always work against the feed direction that is revolutions must occur

towards the operator’s station. (see Figure 6)

● Mount the locking flange back on the blade shaft minding the right

position of the feather-key in the flange.

● Tighten fixation bolt on the flange. BEWARE: when assembling the

new blade make sure to follow the dismounting procedure: saw

blade, external saw blade clamping flange, washer, fixation screw.

● Refit the blade hood in the original position duly set and clamped.

Saw blades, where tips do not any longer show through the

slot in the log carriage with the saw in its start/posions, will

have reached the end of their regrind life and shall be taken

out of service.

13

6.5 Tensioning and replacing the V-belt

If you are operating a WK 600 B model, proper maintenance requires

re-tensioning of the belt after a certain number of operation

hours. To perform stretching of the V-belt, you need adjusting the

special regulation screw located underneath the gearbox cover.

Release the engine mount fixation and adjust the V-belt so that you

can still provoke an approx. 10 mm of deflection by applying one fin-

ger tip pressure (see figure 7 - Stretching of the V-belt).

Fit the gearbox cover and the engine mount back into place before

operating the machine again.

Running the saw with a loose V-belt will cause increased wear and

shorten you belt life.

To replace the belt, release the clamp-screws and remove the

safety guard from the V-belt drive area. Remove the old belts from

the sheaves and fit the new ones on.

Make sure to refit the V-belt casing back in place before operating the

machine again.

BEWARE: failure to provide due re-tensioning will result into a less ef-

ficient V-belt drive that slips and may be wear out faster

6.6 Consumables

Consumable parts that are subject to normal wear are not covered by

the manufacturer‘s warranty. These are:

Saw blade (Code 95004 for HM versions)

Wood strips (Code 54383)

V-belt (Code 56187)

Figure 7

Stretching of the V-belt

14

These log & timber cutting saws are light equipment that can be

easily moved on short-distance by means of two caster wheels and

an ergonomic, comfortable grip handle located on the chassis on the

opposite side as the log carriage. In order to avoid infringement of the

clearance area around the machine, the grip handle can be swivelled

up and down on the model WK 600B.

Simply fasten the grip and lift the saw for safe and rapid hauling of

the machine.

For safety reasons the grip handle should remain retracted (or lifted

up) during work to avoid risk of tripping or entanglement.

7. HANDLING AND TRANSPORT

8. DISPOSAL

When the machine is fully obsolete and cannot be of any longer use,

it should be duly dismounted ahead of discarding. Certain components

need deactivation and dismantling in order to assure that no further

use is made by other parties and that no worn out parts are recycled

for other applications.

During dismantle be alert for possible recyclable materials and compo-

nents that belong to differentiated waste collection procedures applica-

ble in your country.

The manufacturer is not liable and undertakes no responsibility for per-

sonal injuries or damages that may result from the recycling of worn

out machine parts and eventual re-use in other applications different

than originally stated in this manual.

Dismantling procedure:

Take good note please: each and every dismantling task must be per-

formed by authorized service centres or trained skilled staff only!

● Lock and secure all moving parts of the machine and pull the ma-

chine down into single components

● Deliver each single component only to authorized waste manage-

ment facilities

● Remove rubber and plastic parts from the machine that must be-

separately disposed

Deactivated, clamped moving/driving parts and components are of no

further risk and danger.

15

9.1 Noise emissions

The noise level was measured in compliance with the general rules for

establishment of noise and acoustic pollution of garden and agricultu-

ral equipment on work sites as well as with other national standards

for noise measurement. The applicable measuring parameters were:

Measurement on the machine front edge at 1600 mm height and

400mm away from the blade on the right hand side, while processing

beech wood in the size of 80+/-5% of the admissible timber diameter

as per this instruction. Detected noise levels:

Without load 92 db(A)

With max load 110 db(A)

Hearing protection is mandatory!!

The above mentioned values are emission measurements and may not

be therefore assumed as for a safe work environment. Although there is

a relationship between noise emission and immission levels, this is not a

sufficient basis to determine the extent of on-site required protection.

There are a lot of other factors that can influence site work and risk of

injuries and namely: the actual site/buildings configuration,

the concomitant presence of other noise sources (for instance other ma-

chines performing other works in the neighbourhood) etc... The factors

applied for determining safety of a workplace may also very

from one country to the other. We are reporting here the noise values

detected in the facility of the manufacturer on order to allow the user

performing a better evaluation of the possible risk/disturbance.

Technical data Unit/Mea-

sure

WK 600 B Classic

Max. timber diameter mm 195 (7.6 in)

Saw blade diameter mm 600/30

Power of gasoline engine PS 5

Engine speed RPM 3600

Saw blade speed RPM 1780

Length mm 900 (35.4 in)

Width mm 680 (26.7 in)

Height mm 1030 (40.5 in)

Weight kg 95 (209 lbs)

9. TECHNICAL DATA

16

11.1 Mechanical dangers

Possible dangers related to machine moving parts (saw blade) are

minimized by means of suitable safeties and protections that cannot

be dismounted unless special tools and equipment is used. Do not

attempt to remove or by-pass any of the machine inbuilt safeties.

DANGER: removing or by-passing inbuilt machine safeties may result

into serious operator’s personal injuries.

11.2 Environmental dangers

The machine is strictly designed for outdoor applications.

DANGER: do not operate the machine indoors to avoid risk of inha-

ling wood dust.

The following section will detail procedures for checking your saw,

should you encounter a malfunction.

Before setting, operating, cleaning, maintaining or repairing

the processor, read the manufacturer’s operating and mainte-

nance instruction manual.

10. TROUBLE-SHOOTING CHART

Type of trouble Possible causes Remedies

The machine does not

start

- Faulty engine

- No gas in tank

- Oil level in the engine too low

- Check/replace the engine

- Fill new gas

- Touch up the oil

The machine starts but

the blade is not blade is not

running

- Locking flange of the blade

shaft or engine side is not tight

- Tighten both the screw and its

nut

Blade chops - Stump blade - Sharpen or replace the blade

11. OTHER AREAS OF POSSIBLE HAZARD

17

12. WARRANTY

All BGU machines are covered with warranty terms in accordance with

the law. Customers should promptly notify the manufacturer eventual

material or production claims on their detection. While asking for war-

ranty service, customer should show copy of their purchase invoice or

receipt. The warranty does not cover for faults due to natural wear,

temperature or weather agents as well as misuse, faulty installation

or set-up, improper operation and lubrication or acts of vandalism.

No warranty will be given on parts damaged by improper handling,

use and application. The manufacturer is further not responsible for

warranty service on machines used for other applications than men-

tioned in this manual, altered or modified by the customer or other

thirds, or overloaded. Never attempt to use an incomplete machine or

one fitted with unauthorized modification. Any modifications to your

machine can cause personal injuries, and will void your Warranty.

Consumable parts with a prescribed life (i.e. pulleys, tools, blades and

various auxiliary materials) are excluded from the warranty as well as

adjustment, optimization and fine-setting or retrofitting works.

18

WK 600 B Classic

1

2

3

4

5

6

7

8

9

11,38,40,41

12

13

14

15

16

16

31

22

18

36

22

29

18,23,31

32

23

23

27

24,29

37

22

31

20

20

27

34

28

28

21,33

39

44

45

13. SPARE PARTS FOR WK 600 B CLASSIC

19

Pos.

Description

Code

DIN

Dimensions

1Steel stand assembly

24661

2Log carriage assembly

20531

3Upper saw hood, assembly

20977

4Saw arbor, complete assembly

24678

5Cover for saw arbor assembly

24685

6Grip handle, assembly

24688

7V-belt casing 1

24681

8V-belt casing 2

24682

9Angle plate for V-belt casing

24683

11 Drivingpulley of the engine

24684

12 Engine mount

24690

13 Locking lever

20907

14 Honda gasoline engine

53897

15 Circular saw blade

95004

600x2,8x30(d=30H8)

16 Caster wheels

52565

200x50x16

17 Raw-edge V belt

56187

AX 40 1046 LP

18 Multi-range blind rivet (multigrip)

51847

d=4,8 l=11 (1,5-6,5mm)

19 Spring washer

51705

127 B6

20 Washer

51647

125 6,4

21 Washer

51648

125 8,4

22 Washer

51650

125 13

23 Washer

51969

9021 6,4

24 Washer

51698

9021 10,5

25 Washer

51651

125 10,5

26 Washer

51699

9021 13

27 Self-locking hex nut

51606

985 M6

28 Self-locking hex nut

51607

985 M8

29 Self-locking hex nut

51609

985 M12

30 Hex nut

51594

934 M10

31 Hex screw

51429

933 M6x16

32 Hex screw

51431

933 M6x20

33 Hex screw

51443

933 M8x16

34 Hex screw

51454

933 M8x50

20

Pos.

Description

Code

DIN

Dimensions

35 Hex screw

54467

933 M10x80

36 Hex screw

51478

933 M12x30

37 Hex screw

51481

933 M12x45

38 End plate

10612

39 Blind rivet nut

51987

M6 L=19 (3-5,5) D=9

40 Spring washer

51706

127 B8

41

Hexagon socket button head screws

51552

7380 M8x25

42

Hex screw

52134

933 M8x45

43

Washer

51697

9021 8,4

44

Side stop

21642

45

Star grip screw

51006

D=40 M8x20

Table of contents

Other BGU Saw manuals

Popular Saw manuals by other brands

Hitachi Koki

Hitachi Koki C 7SB2 Handling instructions

GMC

GMC LS1620 instruction manual

Hilti

Hilti SC 60W-A36 manual

Jet

Jet J-3410 Operating instructions and parts manual

MK Diamond Products

MK Diamond Products MK-APC Owner's manual & operating instructions

Fieldmann

Fieldmann FDK 200802-E instruction manual