BGU BBS 500 B User manual

page 1 / 51

Insructions manual CTR 520 GX 2014-05-05

INSTRUCTIONS FOR USE

THE LOG BAND SAW

BBS 500 B

Südharzer Maschinenbau GmbH Helmestraße 94 ∙ 99734

Nordhausen/Harz Zentrale: 03631/6297-0 ∙ 7-111 Internet:

www.bgu-maschinen.de e-mail: [email protected]

page 2 / 51

Insructions manual CTR 520 GX 2014-05-05

page 3 / 49

Insructions manual BBS 500 B 2014-05-05

0. Generally ............................................................4

0.1.Safety regulations.................................................. 4

0.2.Scope of use / Designated use.............................. 6

0.3. Unacceptable ways of using.................................. 6

0.4.Requirements for operational staff ........................ 6

0.5. Requirements for machine - security devices........ 7

0.6.Safety guards ........................................................ 7

1. Shipping, handling and storage.......................8

1.1.Surface protection ................................................. 9

1.2.Packing.................................................................. 9

1.3.Dismantling/ repacking .......................................... 9

1.4.Disposal................................................................. 9

2. Installation........................................................10

2.1.Required surface ................................................. 10

2.1.1. Danger zone, operator´s station....................... 11

2.2. Location of machine ............................................ 11

2.3.Fuel...................................................................... 11

3. The machine data ............................................12

3.1. Description of the machinery............................... 13

3.3. Technical data...................................................... 13

4. Putting into operation .....................................16

4.1. Safety check........................................................ 16

4.2. Parking zone........................................................ 16

4.3. The rst cut.......................................................... 16

4.4. Setting up and the clamping of material .............. 17

4.4.1.Angular rests .................................................... 17

4.4.2.Material clamps ................................................ 17

4.5.Residual risks and risk situations ........................ 18

5. Description of the machine and its adjustment........ 20

5.1.Arm................................................................................... 20

5.1.1. Adjustment of a saw band ............................................ 20

5.1.2. Replacing of the saw band ............................................ 22

5.1.3. Cooling, cleaning of the saw band................................. 22

5.1.4. The sliding guide bar of the saw band........................... 22

5.1.5. Replacing of the tensioning wheel V-belt ...................... 23

5.1.6. Tensioning of the drive wheel V-belt ............................. 23

5.1.7 Adjustment of the clutch and brake, belt replacement.... 23

5.2. The drive........................................................................... 24

5.2.1.Engine ........................................................................... 24

5.3. Setting the cut thickness .................................................. 25

5.3.1. Measurement of the cut height ..................................... 25

5.3.2. Thickness setting using the dial..................................... 25

6. Preventive maintenance of machine ........................ 26

6.1.Maintenance and inspection............................................. 26

6.2. Lubricating plan ................................................................ 27

7. Saw bands.................................................................... 27

7.1.Safety regulations............................................................. 27

7.2.Instructions for tool operation ........................................... 27

7.3. Troubleshooting when using the saw bands .................... 28

8. Faults - causes and remedies .................................... 29

9. Circuit diagram ............................................................ 30

9.1. Circuit diagram for BBS 500 B ...................................... 30

9.2.List of electrical components of BBS 500 B .................. 30

10. Machine accessories ................................................ 31

11. ............. 32

12. Assembly instructions.............................................. 33

13. Spare parts................................................................. 38

Dear Customer,

we thank you that you have decided to purchase our product, and we wish you much success with it. To get the

machine without problems served, please pay careful attention to the following instructions.

Manufacturer: Südharzer Maschinenbau GmbH

Helmestraße 94

99734 Nordhausen

Germany

© Copyright 2013 All rights, especially the right for copying, distribution and translation reserved. No part of

this manual must not , without the written permission of Südharzer Maschinenbau GmbH in any form (print,

photocopy, scanning, microfilm or any other method), be reproduced or with use of electronic systems recorded,

processed, copied or distributed.

These instructions correspond to the current technical specifications. Any technical changes, misprints and differences

in pictures are subject to change without notice. In case the machine will be sold to a third party, provide it with

this guide..

Content

ORIGINAL INSTRUCTIONS FOR USE ver. 05/05/2014

page 4 / 49

Insructions manual BBS 500 B 2014-05-05

0. Generally

This manual is intended to provide you information and help you to become familiar with the log band saw of the

BGU maschine company and utilizing its potential use by its determination. The operating instructions contain

important instructions how to operate the machine safely, professionally and economically. Its observance will avoid

risks, reduce repair costs and downtime and increase reliability and service life. Instruction manual provides

guidance based on the current national regulations for accident prevention and environmental protection. The

operating instructions must be in place to use the machine still available. Operating instructions must be read

and applied by anyone who is responsible for the installation, transport and storage, use, operation,

maintenance and disposal of equipment. In addition to the manual and binding rules applicable in the user

country and the place of use for the prevention of accidents must be observed and approved rules for safe and

professional work.

putting the machine into operation. The manufacturer is not liable for damages resulting from

disregard of operating instructions and safety instructions. At the same time the buyer loses

Warranty Card - service

The Warranty Card is a separate attachment of the operating instructions

The warranty period : see warranty card

Conditions for maintaining liability claims

• Transporting and storing the machine according to the manual

• Use and maintenance of equipment according to the manual

• The use of prescribed operational llings

The warranty does not apply to:

• Violent and mechanical damage to the machine by an intervention of consumers or other persons

• Unavoidable event (natural disaster)

• Damage to the machine during transport

• Storage or placement the machine in a humid, chemical, or otherwise unsuitable environment

• Wear parts - band saw guides, V-Belts of impellers, band saw blade

or by post to the address: see warranty card.

Notications to consumers:

The seller is obliged immediately to issue to the consumer when purchasing, the product warranty card which must

be completed correctly and legibly and stamped by the dealer signature and date of purchase. The seller must inform

the buyer informatively to be familiar with the product, its use and handling.

The data required for the application of the warranty (post warranty) repairs:

• Type of machine

• The warranty card number (the same as the serial number of the machine)

• Date of issue of the warranty certicate

0.1. Safety regulations

The machine is designed using state of the art and the approved safety rules. However, it may occur when using a

serious threat to the health of users or third parties or to adverse effects on the machine or other property values. In

order to avoid these threats as much as possible, it is essential to ensure the safety notes in the operating instructions.

These safety instructions the person has to read and understood before starting up the machine. Failure to follow

these instructions can result in serious injury and property damage!

page 5 / 49

Insructions manual BBS 500 B 2014-05-05

Particularly important points in this manual that relate to safety are highlighted with

Warning label - danger of compression, shear, impact

Warning label - danger of cuts or cut off, snatching, draw in

Warning label - Danger caused by a sawdust scattering

Warning label - Danger caused by falling objects or their ejection

Warning label - Danger - hot surface

Label TOTAL STOP - Use when necessary equipment emergency stop

Label of the need to use protective equipment - Eye and Ear Protectors

Label of the need to use protective equipment - Protective gloves, boots

Label of the machine safe handling - Place of suspension

understand its contents

page 6 / 49

Insructions manual BBS 500 B 2014-05-05

0.2. Scope of use / Designated use

Log Band Saw is designed primarily for the logs initial processing. It is intended solely for cutting wood materials,

whether soft, hard, dry, raw or frozen in length according to the machine design. The use according to specications

includes compliance with the operating instructions and compliance with inspection and maintenance conditions.

0.3. Unacceptable ways of using

Any other use dened in Chapter. 0.2. is understood as the use of inappropriate determination. For damages caused

by this way the manufacturer is not liable. Risk is borne by the user.

0.4. Requirements for operational staff

The machine operator is responsible for the overall safe operation of the machine and

compliance with safety and technical instructions given in this manual.

The machine may only be operated if it is in the perfect technical safety

User is obliged to at least once per shift to check the machine outside recognizable damages or defects (see Chapter

6). The resulting defects and damage to the protective devices, and machines behavioral changes that threaten the

safety, report immediately to the supervisor. Switch off the machine and secure against restarting. Wait for decision

on the repair and reinstatement of your machine.

When operating the machine, not remove, relocate, shut it down or modify any safety devices. Warranty claims are

otherwise ineffective! If during the repair or maintenance must be some safety devices removed, turn the ignition

switch, activate TOTAL STOP button and close the fuel supply.

• Remove when working loose clothing and cover long hair

• Ensure that other persons were away from the belt at least 5 m, protect them against ying sawdust and dangers

in the event that the saw band should have broken

• All the people that help you must be familiar with all safety rules

• Safety rules must be placed at the workplace on a clearly visible place

• Keep your hands away from the saw band, never adjust any saw band when the engine is running. Before you

manipulate with the saw band, turn off the motor and secure it against restarting!

appropriate protective equipment (eyewear, hearing, gloves, safety shoes

with steel toe).

page 7 / 49

Insructions manual BBS 500 B 2014-05-05

0.5. Requirements for machine - security devices

Before opening the protective device, wait until the saw band is at rest.

Shutting down the machine in case of an emergency with the button STOP TOTAL.

New start-up is possible only after the removal of the emergency and manual

override of the button by its pulling or turning.

machine and tool operation and deceleration, prohibited.

In the danger zone shall be any unauthorized person. The danger zone must also be free of foreign objects and the

ground must be at to prevent tripping.

Parking zone (see the chapter 4.2)

The parking zone is used to a safe shut down of the traversing bridge with a band saw arm.

• You provide the handling of the cut material (niggering of log, alignment, clamping, rotating, removing of timber)

• You provide the setting of the movable bar of the saw band (if the machine is not equipped with a motorized bar*)

• You provide the setting of the saw band cooling

• You provide the cleaning or maintaining the machine

• You provide the cleaning around the machine

• The machine operator leaving the workplace

0.6. Safety guards

The log band saw is the cutting machine equipped with a cutting saw band. To perform this process, the teeth of the

saw band must penetrate into the work piece in the machining area. Safety guards against the contact with the saw

band can therefore be installed only outside the machining area. Other safety guards protect against a contact with

dangerous parts of the drive or hot engine parts..

page 8 / 49

Insructions manual BBS 500 B 2014-05-05

• The safety arm cover (impellers of the saw band

with belt) is secured by two screws in captive design. If

the safety cover is not closed and both screws are not

tightened, it is not permitted to run the engine. Safety

covers are tted with hinges, in service operations is

not necessary to disassemble.

• Safety guards of the saw band drive (pulleys and

belts) . Guards must be removed during tensioning,

exchange and check of V-belts and the brake

adjusting.

• The safety guard of the band outside the machining

area on the moving guide bar. During service

operations is not necessary to remove the guard.

Safety guards are allowed to dismount only when the engine is not running and the

guards and after testing their safety functions.

1. Shipping, handling and storage

The machine is dispatched dismantled and packed on a wooden pallet. If, with the machine whose the basic length is

4500 mm, more than one extension section of length 2225 mm is supplied, these extension sections are stored on other

pallet. The machine is supplied with one saw band mounted on the machine, the oil lling of the engine and without

fuel. During transport must be taken appropriate measures to prevent damage from moisture, vibrations and shocks.

After installing the basic and extension section(-s) at the site of use, the bridge with the arm is lifted by crane and

placed gently on the basic section.

Traversing bridge can only be lifted by crane.

When the traversing bridge is attached to the original manufacturer pallet, it can be transported on

a pallet trolley.

SAFETY GUARD

OF ARM

SAFETY GUARD GRIP

BOLTS

BELTS GUARDS

BOLTS

THE BAND GUARD

page 9 / 49

Insructions manual BBS 500 B 2014-05-05

Scope of delivery:

• The basic machine (see chapter 3.2)

• Optional equipment according to the order (extension

section)

• 1 saw band (installed)

• Instructions for use

1.1. Surface protection

Machine components are protected against corrosion

with powder coat or base colour and two-component

polyurethane varnish. Sliding surfaces are coated with

anti-rust oil. Other components and machine parts are

nished with zinc.

Against weather influences during the transport, the

machine parts are packed in a stretch foil. Upon customer

request according the type of expedition, the machine

can be in casing or overseas box.

1. Set all machine parts to the basic position, the arm must be

2. Empty and clean the container of coolant

3. Clean machine

4. Drain the gasoline and treat the engine according to the user manual of the engine - page 13:

Engine laying

5. Coat the sliding surfaces of machine with anti-rust oil

6. Secure the bridge travel of the arm for transport

8. Enclose accessories

1.4. Disposal

After the nal removal from service, the machine is disposed according to the provisions in force in the respective

country. We recommend contacting a company specialized in disposal.

BRIDGE SUSPENSION

THROUGH THE HOLES

IN STIFFENERS

BRIDGE

FRAME

LONGERONS

BOARDING

OF LONGERONS

PALLET

BOXES

OF SMALL PARTS

FRAME

CROSSMEMBERS

page 10 / 49

Insructions manual BBS 500 B 2014-05-05

2. Installation

Installation of the machine is done by customer itself according to the „Mounting instructions“, see Annex 1. Installation

can be performed also by professional service - contact your dealer or manufacturer.

2.1. Required surface

The machine can be installed on any convenient at oor. For optimum machine performance and achievement of

maximum accuracy in cutting, it is recommended to install the machine on a at concrete surface or on concrete slabs

under shelter. Any other basis is necessary to consult the manufacturer. Due to the drive by gasoline engine is not

permitted to operate with in conned spaces.

Recommendations / preconditions:

• Plan to have enough space for the ow of material, material removal and machine maintenance, see Danger zone

• Post of the saw and staff must be at, clean and shall not impair the operation and activities of the operator

• Install lifting equipment for heavy materials

• Provide good lighting in the workplace

For the spatial arrangement of the machine, observe all applicable standards and sanitary regulations of the airspace

in the workplace. The deployment of machines must eliminate threats to other employees from the operation in the

event of the tool accident, by thrown material to be cut due to the insufcient clamping, breakage of the saw band

and the like.

BBS 500

The dimensions marked for K are the anchor holes dimensions of the machine basic section, holes ø11 mm.

BBS 50

The dimensions marked for K are the anchor holes dimensions of the machine basic section, holes ø 11 mm.

800 K800 K650 K800 K800 K396

698 K

275

4875

1650

565

254 800 K800 K396

225

698 K

page 11 / 49

Insructions manual BBS 500 B 2014-05-05

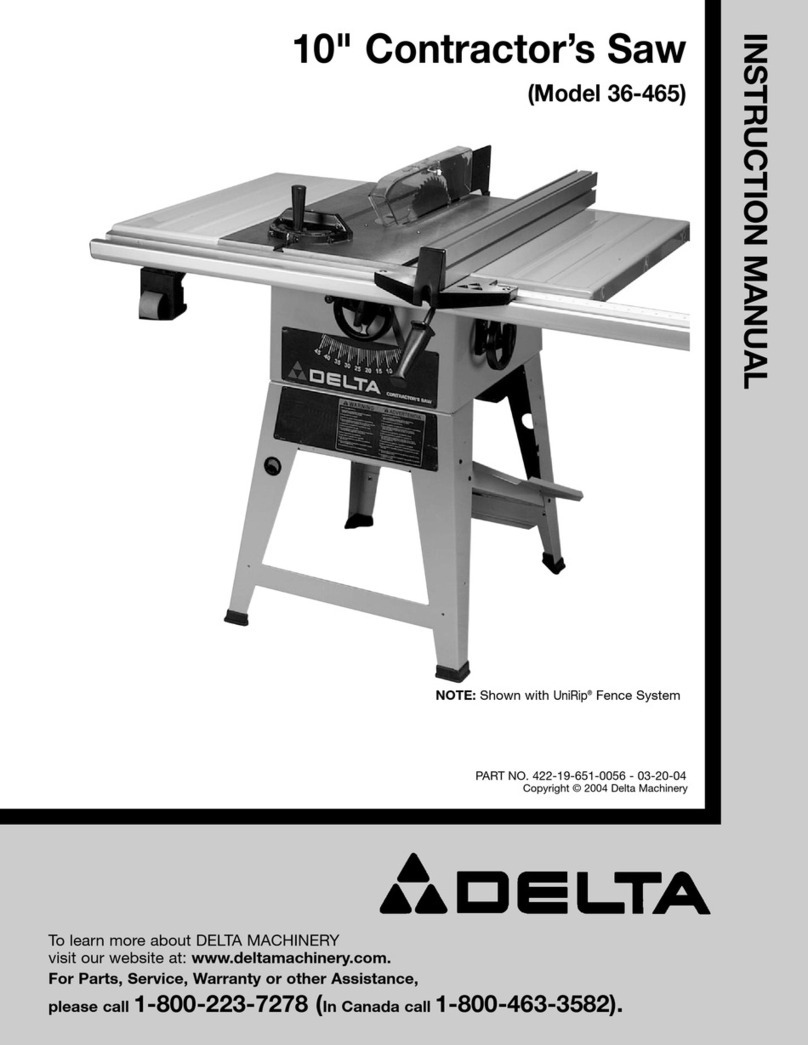

Danger zone is within 2.5 of each side of the machine. In the danger zone must not be any unauthorized person. The

danger zone must also be free of foreign objects and the ground must be at to prevent tripping.

the following features::

The machine operator must, when running the saw band, be located at the control

panel only.

2.2. Location of machine

The machine can be operated at ambient air temperature of + 5 ° C to + 40 ° C. The average air temperature must

never exceed 24 hours + 35 ° C. Relative humidity from 30% to 95%, to an altitude of 1000 m. In the case of higher

altitudes consult the use with the machine manufacturer. At temperatures lower than +5 ° C, replace conventional

refrigerants for the media which operate at the appropriate temperatures.

2.3. Fuel

Used engine is approved to operate on unleaded gasoline with an octane rating of 86 or higher.

burns or seriously injure. Turn off the engine, near must not be resources

Gasoline can damage varnishes and some plastics. Be careful not to spill gasoline. Damage caused by spilled gasoline

is not covered under warranty.

250

250 250

250

OPERATOR´S

PLACE

page 12 / 49

Insructions manual BBS 500 B 2014-05-05

3. The machine data

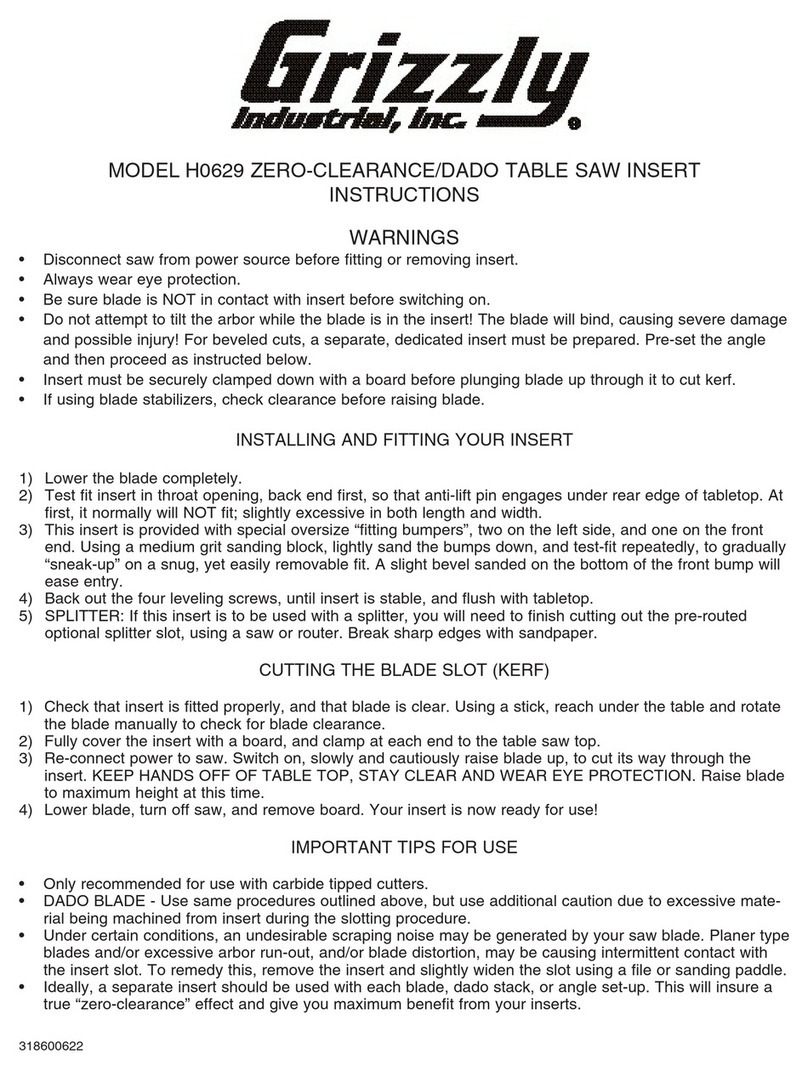

THICKNESS

GAUGE

LIFT HANDLE

ENGINE

HEIGHT INDICATOR

CLUTCH AND

BRAKE LEVER

COOLING

BASIC SECTION

ANGULAR REST

CLAMP

ADJUSTABLE LEG

FRAME CLUTCH

ARM

TENSIONER

SLIDE BAR

THROTTLE

LEVER

HANDLE

TOTAL STOP

TRAVERSING BRIDGE

page 13 / 49

Insructions manual BBS 500 B 2014-05-05

3.1. Description of the machinery

The machine is designed in a modular way which allows easy replacement or adjustment of all major technology units

and their individual parts. The machine consists of three basic parts:

The basis of each machine is a basic section to which you can connect, according the required cut length, the

extension sections. Basic and extension sections are tted with xed log loading surfaces, clamps of material and

angular adjustable rests.

On traversing sections moves the bridge of the band saw arm. The movement of the bridge on sections is manual -

pushing. On the bridge is placed the arm of the saw band which is placed on pulleys in order to move up and down.

The vertical movement of the arm is secured by a chain drive and worm gear. The movement of the arm is manually

operated by handle with arrestment. Precise adjustment of the arm height allows a circular scale indicator.

On the right side of the arm is a drive wheel of the saw band, driven by a spark ignition engine through a two-stage

belt gear. The clutch function represents the belt tension by the move of the entire motor, and a quick stop of the saw

band is secured by the brake shoe acting on the pulley. Position of the drive wheel pin is adjustable. On the left side

is located a tension wheel system. The movable body of the tensioning system moves in the cast iron guiding. Both

wheels are made of light alloy. In the circumference of the wheel is a machine cut groove for V-belt which forms the

interface between the wheel and the saw band. When cutting, the saw band is guided on both sides with guides of

hard metal.

3.2. Machine design

The basic design of the machine is possible, for an extra fee, to supply with special accessories.

The basic version:

Traversing frame, with length of 4.5 meters can cut logs of a maximum 3.45 m, is equipped with three sets of angular

rests and clamps. Material handling and clamping is manual.

Special accessories:

Extending sections: the total length of 2.25 m, it extends the cutting length of the basic section by 2.25 m, contains

1x angular rest and 1x clamp. The number of extending sections is not limited.

Angular rest with clamp: The basic version can be tted with a maximum of 6 angular rests with the clamp. Each

extension section can be equipped with a maximum of 3 angular rests with clamp.

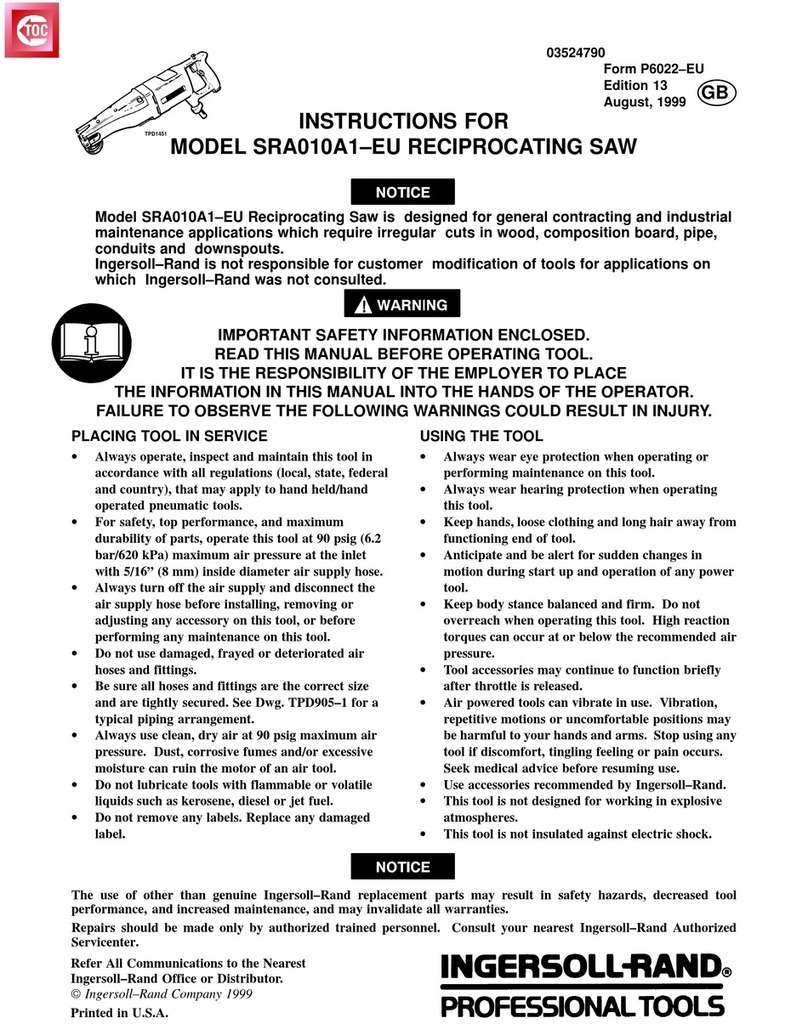

3.3. Technical data BBS 500 B

1 Max. diameter of the log 550 mm

2 Max. width of the beam (board) 530 mm

3 Max. stroke of the saw band 480 mm

4 Min. height of the saw band above the table 25 mm

5 Max. passage of the arm 200 mm

6 The cutting length of the basic section 3,45 m

7 The length of the extending section 2,25 m

8 Max. cutting length unlimited

9 Min. cutting length 0,75 m

10 The engine of the saw band 8,7 kW

11 Diameter of impellers 400 mm

12 Width of impellers 25 mm

13 Dimensions of the saw band 3340 × 27 × 0,9 mm

14 Cutting loss 1,5 - 2,2 mm

15 Saw band speed 15 m/s

16 Machine width - max. 1660 mm

17 Machine height min. - max. 1500 - 1600 mm

18 The length of the basic version incl. control panel 4,9 m

19 Weight of the basic version incl. accessories 370 kg

20 The length of the extending section 2.25 m

21 Weight of extension 73 kg

22 Working table height from oor 235 - 260 mm

page 14 / 49

Insructions manual BBS 500 B 2014-05-05

17

(MAX)

16

22 3

5

1

2

4

17

(MIN)

11

page 15 / 49

Insructions manual BBS 500 B 2014-05-05

The cutting lengths of the machine

To use the minimum length of the cut is necessary to place the clamp so that it is possible to clamp a log by two

clamps. Each extending section increases cutting length by 2.25 m

The noise measurements were made at machine steady state . During the operating state of a load, the most

commonly used technology process was measured. During operating statuses with the technology, the noise levels

were measured at a work station.

Measured according to EN ISO 3746:2011

The measured value exceeds the value specied in Decree 176/2008, Article 1.7.4.2. point, therefore it is necessary

during operation to use hearing protection devices and monitor the noise characteristics of the device.

The values of the measured noise level of the machine may vary according to the type of material and technology

used. These values are emission levels and may not represent the safe working level. Although the correlation

between emission levels and exposure levels, these values can not be used to reliably determine whether or not

further action is required. Factors that affect the actual level of exposure include the characteristics of the work area,

other sources of noise, etc., such as the number of machines and other adjacent processes. Maximum permissible

levels of exposure may also be different in different countries. This information is intended to serve users as better

tools for hazards and risk assessment.

Electromagnetic radiation

With regard to the electromagnetic field, the device meets all requirements of the standard EN 12198-1 + A1: 2008.

750

345

The measured values

Machine sound power LWA 109,8 dB (A)

Sound pressure LPA 92,3±3 dB (A)

page 16 / 49

Insructions manual BBS 500 B 2014-05-05

4. Putting into operation

It‘s all as for the technical safety in perfect condition?

Are all protective devices correctly installed?

• Check the position of the clamps and angular rests to be out of the cutting path of the saw band

• Check the positions of the cut material to prevent its release during the cutting or its thrust to the traversing bridge

• The machine is now ready for operation

The parking zone is used to a safe shut down of the traversing bridge with a band saw arm.

• You provide the handling of the cut material (niggering of log, alignment, clamping, rotating, removing of timber)

• You set the sliding guide rail of the saw band

• You set the cooling of the saw band

• You provide cleaning or maintaining the machine

• You clean around the machine.

• The machine operator leaves the workplace

1. Make sure that the TOTAL STOP button is released, the band covers are closed and the band is properly tensioned.

2. Make sure that traversing bridge is in the parking zone at the beginning of the machine track

3. Set up the angular rests to the vertical position

4. Load up the log on a saw table

a) using suitable machinery - such as a forklift truck

b) using the track for rolling up the log * and levers for rolling up the log *

- place the two parts for rolling up the log in suitable position with regard to the length of the log

- roll up the log, using a lever for turning the log, so that it has always been secured with the track latch

before changing the position of the lever

5. According to the diameter of the log, set the angular rests to the appropriate position

6. Clamp the log by the material clamps

7. Visually inspect if the position of the log, angular rests and clamps allows you to make the cut

8. Adjust the height of the saw band

9. Adjust the sliding guide bar to the suitable position according to the diameter of the log

10. Make sure that the clutch lever and the brake is in the position „braked

11. Open the fuel supply, turn the engine switch to position 1, and when the engine is cold turn the choke.

12. Pull the starter handle cable to start the motor. If necessary starting again, wait until the motor stops.

13. Adjust coolant ow

PARKING

ZONE

OPERATOR´S

PLACE

page 17 / 49

Insructions manual BBS 500 B 2014-05-05

14. If the choke was turned on, you can, after stabilization of the engine, turn it off.

15.With a throttle lever slightly increase the engine speed and smoothly move the clutch and brake lever to the position

„connected“.

16. Pull the throttle lever to the handle to set the maximum engine speed and smoothly move the band into the material.

17. During the cutting operation observe the machine, possibly the sound changes. If necessary (large knots, larger

width change of the cut), you can adjust the traverse speed - change the speed as smooth as possible, and in the

smallest necessary extent - a sharp change in traverse speed can affect the cut atness,).

18. Once the belt at the end of the log comes out of the wood, release the throttle and clutch lever and brake lever to

the position „stopped“.

19. Lift the saw band above the material being cut off

20. Move the travel bridge cross to the parking zone at the start of the track

21. Remove the cut material from the saw

22. Adjust the height of the band for the next cut

4.4. Setting up and the clamping of material

Any material handling perform only when traversing bridge with a band saw arm is

Before loading a log (logs) on the table, it is necessary the angular rests tilted so that the logs does not fall from the

table. This device is also used for slabing when producing the squared timber. Log clamping is carried out by material

clamps. Clamps can be moved on the machine frame according the length the cut log. The actual log clamping is

performed using the spikes of the clamp that can be adjusted in height by folding clamp arms according to shape

and size of timber.

4.4.1. Angular rests

Serve:

• To prevent rollover of the log via the machine table when loading

• As the rest when clamping

• To create a right angle

Before cutting or traversing a saw bridge, the angular rests must be set in such a position (height)

4.4.2. Material clamps

They are collapsible, allowing their height adjustment. They can be used in two ways:

1. Clamping against angular rests

The wood is pushed by spikes set to the appropriate height to angular rests

2. Clamping against the stop on the frame cross member

Applicable only for prisms

Angular rests are folded and the clamps are adjusted as low as possible

saw band and the guide rollers.

The sliding guide roller of the saw band must be as close as possible to the material being cut. Material must not with

its length exceed the length of the cutting machine.

When loading material on the machine frame store it gently and avoid greater impact - it could cause deformation of

the machine or its displacement.

Check logs before their cutting (stones in the bark, mud, sand, tie pins, etc.). Very dirty logs is necessary, especially

from the side where the saw band get into the log, to get rid of bark or clean (e.g. with a wire brush).

ANGULAR

REST

HANDLE

CLAMP

SPIKE

page 18 / 49

Insructions manual BBS 500 B 2014-05-05

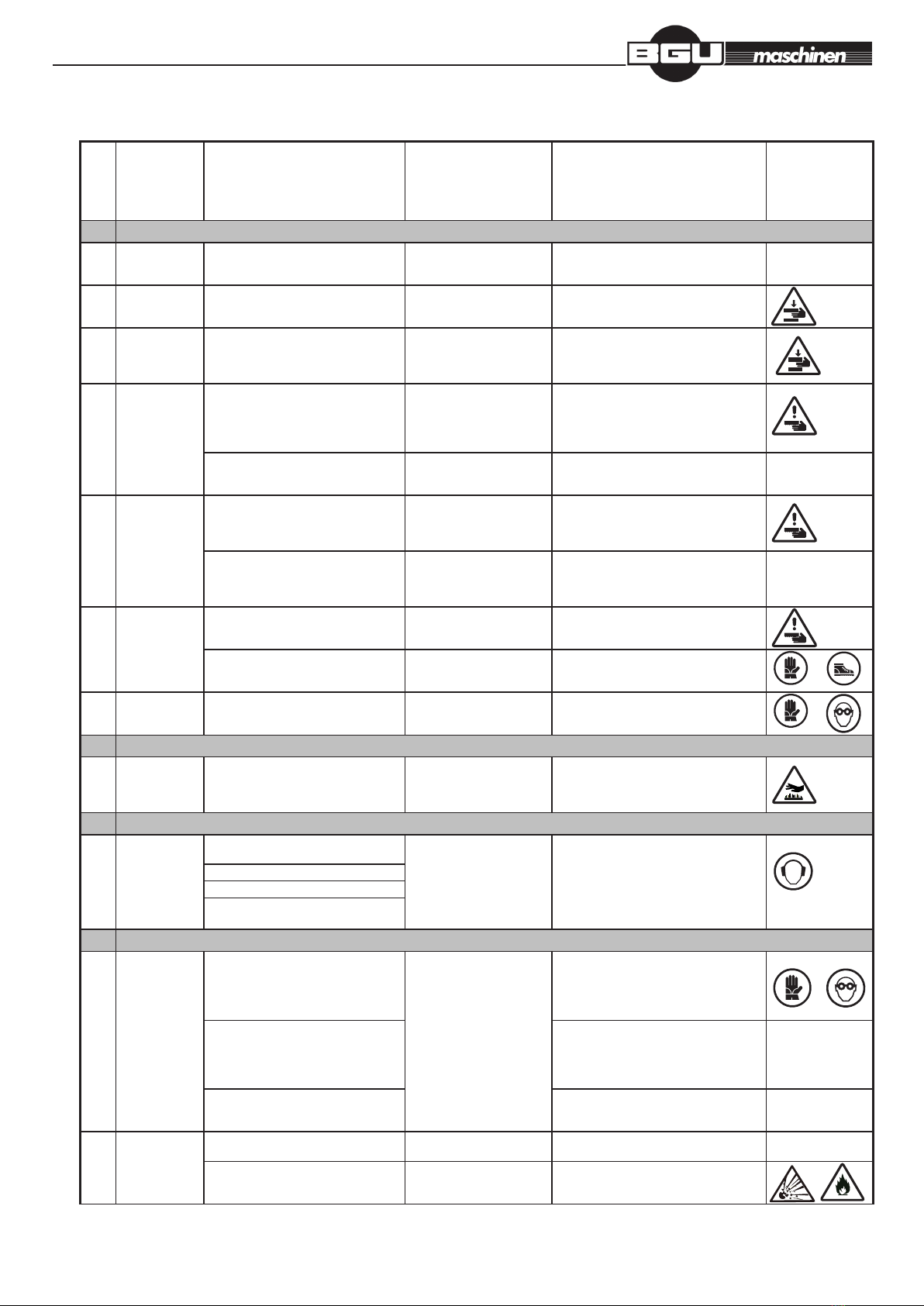

Processed according to standards: Directive 2006/42/EC, NV 176/2008 Coll., EN 1807+ A1: 2010, EN ISO 14121-1:2008

Accor

ding

to

EN

1050

Danger

situations / activities

Dangerous space

(spaces))

Protective measures

(implemented by the designer

/ user)

Safety sign at

machine

1 Mechanical danger

1.1 Compression

danger

Clamping of the cut material during

insertion / modication of the position /

removing material

Between the jaws and

material to be sawn

Warning instructions - use gloves It is not

1.2 Danger of cut Clamping of the cut material during

insertion / modication of the position /

removing material

Between the jaws and

material to be sawn

Warning sign on both ends of the arm

(covering) warnings in the instructions for

use

1.3 Danger of cutting

yourself or

cutting off

The moving of the cutting tool in the

work, machine adjusting, changing

cutting tools, maintenance, repair

For the cutting tool IInstallation of guards outside the cutting

area, warning signs at both ends of the

arm (covering) warnings in the instructions

for use

1.4 Danger of

capturing

Manually operated a cutting tool traverse

during an activity

For the the cutting tool and

the adjacent stationary parts

of the machine. Between the

facilities for cleaning tool and

the cutting tool for cutting

Installation of guards outside the cutting

area, warning signs at both ends of the

arm (covering) warnings in the instructions

for use

Parts of the machine during the

mechanically controlled movement (for

example, parts of the transmission)

For the moving part of the

machine

Safe covering of the belt drive, warnings in

the instructions for use

It is not

1.5 Danger of

drawing in or

capturing

The moving of the cutting tool in the work In the vicinity of the cut

material and adjacent parts of

the machine

IInstallation of guards outside the cutting

area, warning signs at both ends of the

arm (covering) warnings in the instructions

for use

Parts of the machine during the

mechanically controlled movement (for

example, parts of the transmission)

At places for insertion and

removal, and service areas

and in the vicinity of the

cutting process

Safe covering of the belt drive, warnings in

the instructions for use

It is not

1.6 Danger of impact Material handling during the activity,

adjustment of machine, assembly of tool

for cutting

Parts of the machine with

mechanical movement (such

as frame saw band in action)

Warning sign on both ends of the arm

(covering) warnings in the instructions for

use

The fall due to gravity U řezaného materiálu, u

mechanismů pro manipulaci s

obrobkem

Warnings in this manual, to observe the

conditions of occupational safety

1.7 Danger of stab or

puncturing

Handling the instrument (s) for cutting For cutting tool (especially

when replacing)

The sign to use protective equipment on the

control panel, warning in the instructions for

use - replacement of the saw band

3

3.2 Touching a

person of

parts with high

temperature

During repairs Hot engine parts, exhaust Partial covers, warnings in the instructions

for use

4

4.1 Loss of hearing

(deafness), other

physiological

disorders (loss

of balance,

consciousness)

●Vibration of the cutting tool and the cut

material

At the machine and / or in its

vicinity

The sign to use protective equipment on

the control panel, warning in the manual -

optimal work piece clamping and the choice

of cutting conditions

● Aerodynamic noise of the cutting tool

● Handling of the cut material

● Parts generating and transmitting

power

7

7.1 Hazards caused

by contact

with harmful

substances or

their inhalation

or swallowing

(liquids, mists,

gases, fumes,

dust)

Skin contact with harmful materials At the machine and / or in its

vicinity

Signs to use protective equipment on

the machine, instructions in the manual,

to observe the conditions and safety

instructions of the manufacturer of cooling

liquid

Inhalation or ingestion of substances

(e.g. coolant) used or generated during

cutting

To observe the safety conditions of work

and the manufacturer‘s instructions of

cooling liquid warning in the manual - when

spraying to reduce the amount of cooling

liquid

NIt is not

Leakage of dust, mists and fumes while

cutting

To observe the the safety conditions of

work, cautions in the manual - in the event

of change of cutting conditions

It is not

7.2 Risk of re or

explosion

Flammable material being cut and waste

(sawdust, shavings, bark)

At the machine and / or in its

vicinity

Caution in the manual - maintaining order at

the machine, cleaning of machine

It is not

Relling of gasoline At the machine and / or in its

vicinity

Caution in the manual, signs of explosion

and re

page 19 / 49

Insructions manual BBS 500 B 2014-05-05

8 Danger from neglecting of ergonomic principles

8.1 Unhealthy

position or

excessive

exertion

(repeated

overload)

Inappropriate body position and

excessive exertion

For the saw control The ergonomic design of the machine,

lifting of the cutting head is controlled by an

electric drive

It is not

Excessive

exertion and

/ or repeated

overloading

Manual control of the machine At the track of machine When manual handling of log use the track

for rolling up the log as well as the lever,

warnings in the manual

It is not

8.2 Inadequate

demands on the

anatomy of the

arm - hand

Manual control of the machine In places of the operator

when working

Ergonomic positioning of the control panel

and other controls, observe the conditions

of work safety, warnings in the manual

It is not

8.4 Inadequate local

lighting

Weakened balance and accuracy in

handling activities / setting the cut

material and cutting tools

In places of the insertion and

removal of cut material, in

places of tool assembly for

cutting

Observe the safety conditions of work,

cautions in the manual - recommended

lighting of machine

It is not

When inserting or removing material,

while adjusting, changing of cutting tool,

maintenance

Observe the safety conditions of work,

cautions in the manual - recommended

lighting of machine

It is not

8.6 Human errors,

human behaviour

Logically implied improper use For the machine Caution in the manual - forbidden use of the

machine

It is not

Careless operation of controls Warning in the manual - requirements for

operational staff

It is not

Improper handling of the material being

cut and the cutting tool, their incorrect

adjustment

Warning in the manual - safe handling and

clamping of material, machine adjustment

Není

When inserting or removing material,

while adjusting, changing of cutting tool,

maintenance

When replacing the saw blade, the machine

can not start (cover is open, service mode),

warning in the manual - a safe handling and

clamping of material, machine adjustment

It is not

8.7 Danger

caused by an

inappropriate

design,placement

or wrong

identication

of controls

Improper placement and choice of

manual controls (such as control device

to start, stop and for coolant) during the

operation, while adjusting, changing tools

for cutting and maintenance

For the machine Ergonomic positioning of the control panel

and other controls.

It is not

11

by the inability

to stop the

machine in most

appropriate

conditions

Malfunction or failure of the control

system during the working cycle of the

machine

At the machine and / or in its

vicinity

Installation of the emergency button

TOTAL-STOP on the control panel,

warnings in the manual

14 Failure

of control

circuit

When adjusting, cleaning For the machine Without deliberate mechanical action on

the starter cord, the engine can not start,

warnings in the manual - the correct and

safe maintenance and adjustment

It is not

15 Danger caused

by incorrect

connection

Tool for cutting, or its part ejected during

machine operation

At the machine and / or in its

vicinity

Covering of the most part of the saw band

on the arm, warnings in the manual -

replacement, tensioning and adjustment of

the saw band

It is not

17 Danger

caused by

falling down or

ejection

of objects

of liquid

Ejection or falling parts of the cut

material and debris, during the machine

operation, cutting, adjusting, changing

cutting tools, maintenance

At the space and / or in the

vicinity of the cutting area and

cut material

Signs to use protective equipment, warning

in the manual - the optimum cutting

conditions, setting the sliding guides,

maintenance instructions

Cutting tool or tooth breakage and

ejection

At the machine and / or in its

vicinity

Covering most of the saw band, warnings

in the manual - the optimum cutting

conditions, setting the sliding guide bar, the

control panel in a safe position

It is not

Ejection of broken machine parts Caution in the manual - in the danger zone

only machine operator

It is not

18

by loss of

stability

Dropping or tipping over an unsecured

machine or its parts

For the machine The machine has a robust design to

prevent overturning during normal

operation. When handling - warnings on

machinery packaging, warnings in the

manual - instructions for safe handling

and installation of equipment, anchoring of

equipment

page 20 / 49

Insructions manual BBS 500 B 2014-05-05

5. Description of the machine and its adjustment

Any material handling perform only when the traversing bridge with a band saw arm

5.1. Arm

5.1.1. Adjustment of a saw band

The arm is a sturdy steel weldment. The saw band is guided on the drive and tensioning wheel, front of and behind

the cut in two guides with hard metals. Fixed guide is placed on the saw arm. The movable guide is movable on the

guide bar and in feeds always as close to the material being cut. A sliding guide bar is provided with a saw band guard

out of the cut area.

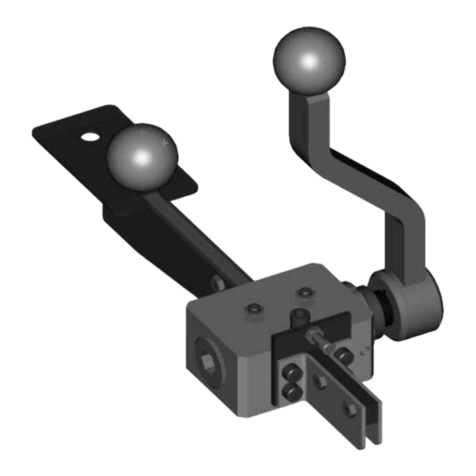

ARRESTING BOLT

OF THE GUIDE BAR

TILTING

BOLT

BOLTS OF

THE VERTICAL

ADJUSTMENT

BOLTS OF

THE HORIZONTAL

ADJUSTMENT

BOLTS FOR THE

SAW BAND

CLEARANCE

ADJUSTMENT

GUIDE PLATE GUIDE PLATE

BOLTS FOR THE

SAW BAND

CLEARANCE

ADJUSTMENT

COVER OF

BAND SAW

FIXED GUIDE MOVING GUIDE

Table of contents

Other BGU Saw manuals