1Standard equipment

Abrasive cut-off wheel 355

Socket wrench 17 (for LW1401 only)

Note: The standard equipment may vary by country or model variation.

2Optional accessory

Abrasive cut-off wheel 355

3Index

1Standard equipment.............................................................................................................................................................2

2Optional accessory ..............................................................................................................................................................2

3Index....................................................................................................................................................................................2

4Caution ................................................................................................................................................................................2

5Repair ..................................................................................................................................................................................3

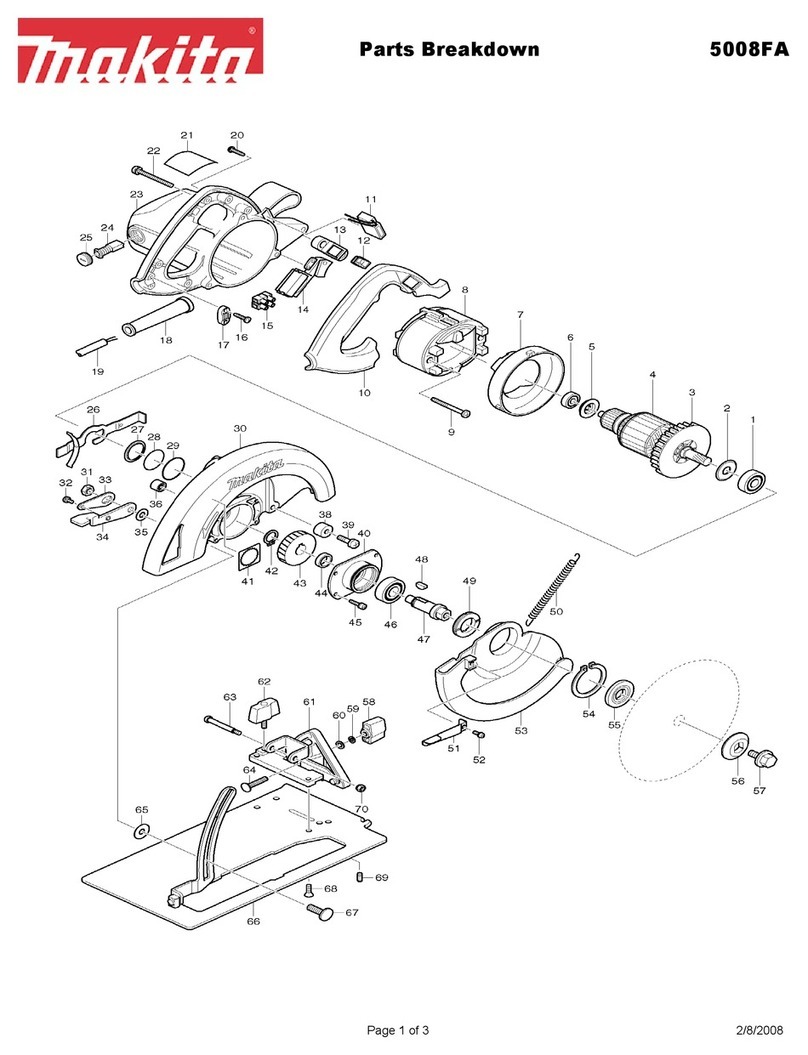

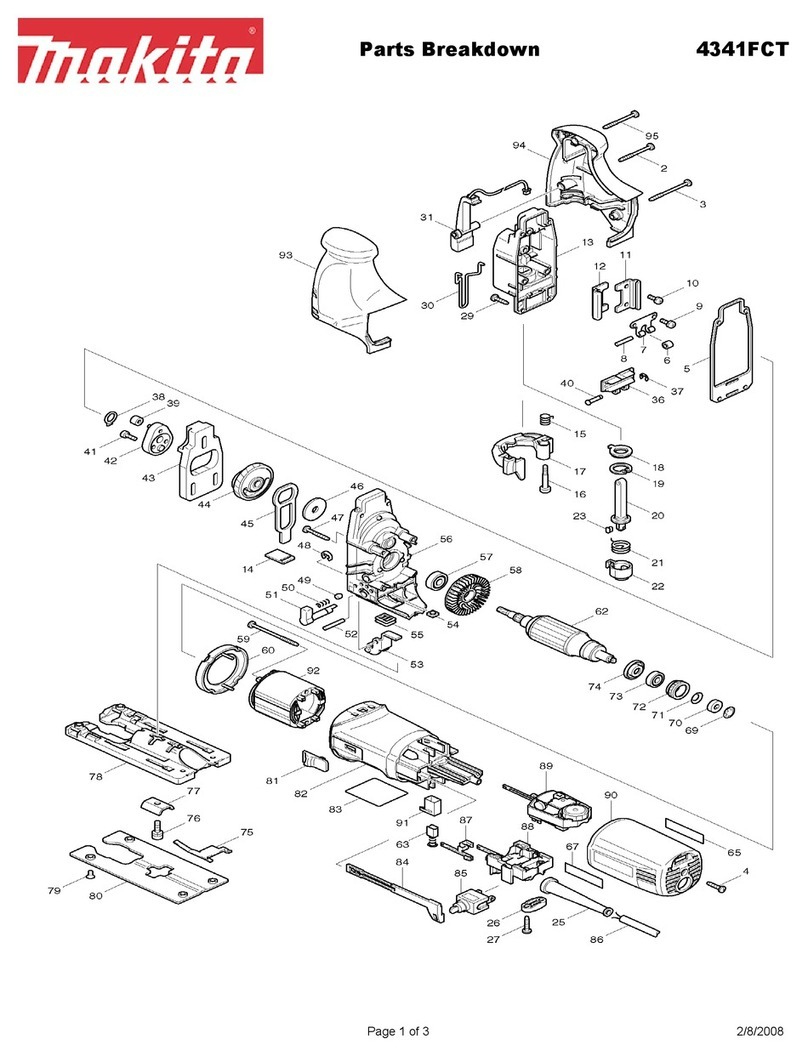

5-1 NECESSARY REPAIRING TOOLS .........................................................................................................................3

5-2 LUBRICANT AND ADHESIVE APPLICATION ....................................................................................................4

5-3 DISASSEMBLY/ASSEMBLY...................................................................................................................................5

5-3-1 Armature.............................................................................................................................................................5

5-3-2 Handle section ....................................................................................................................................................5

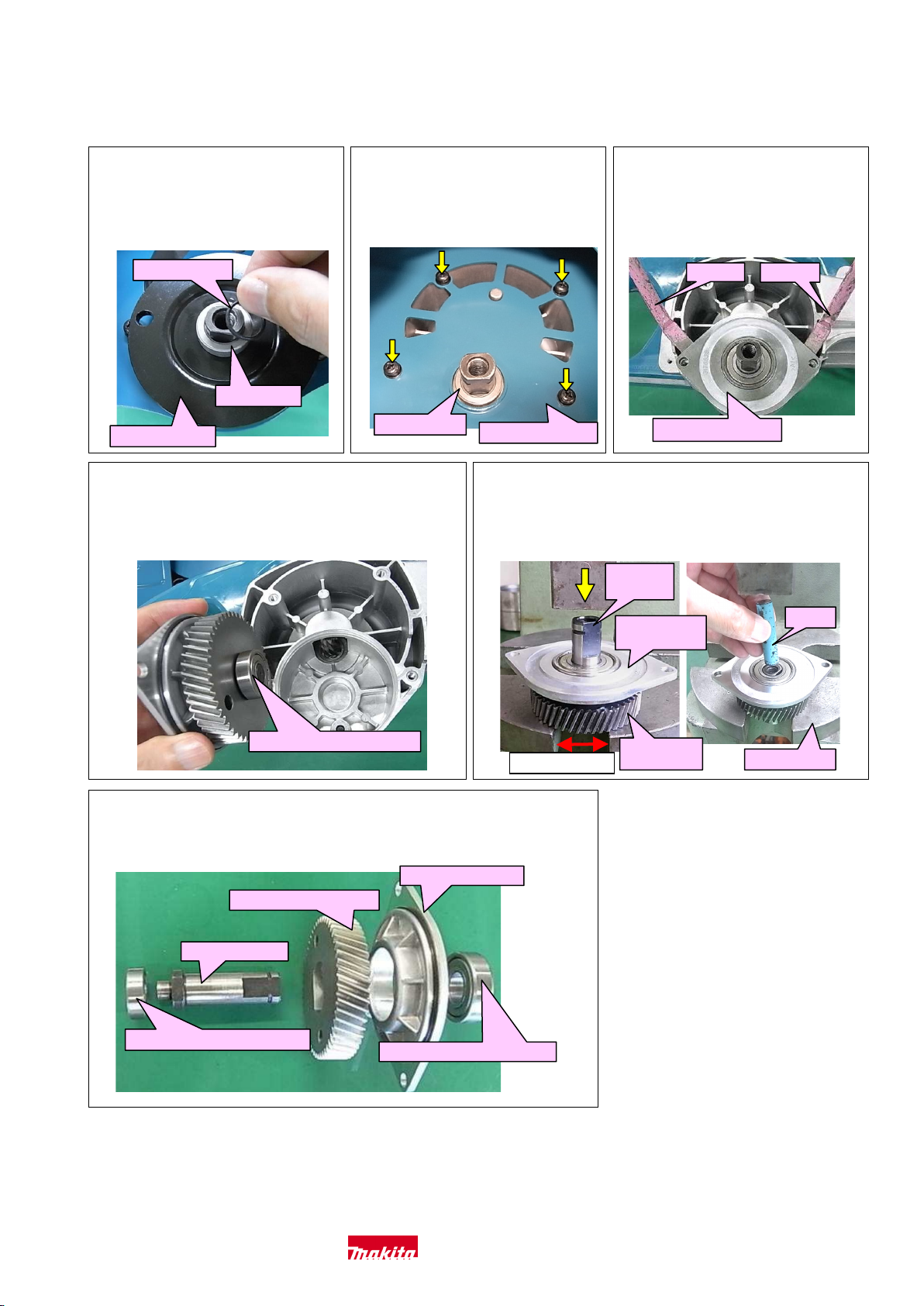

5-3-3 Helical gear 50....................................................................................................................................................6

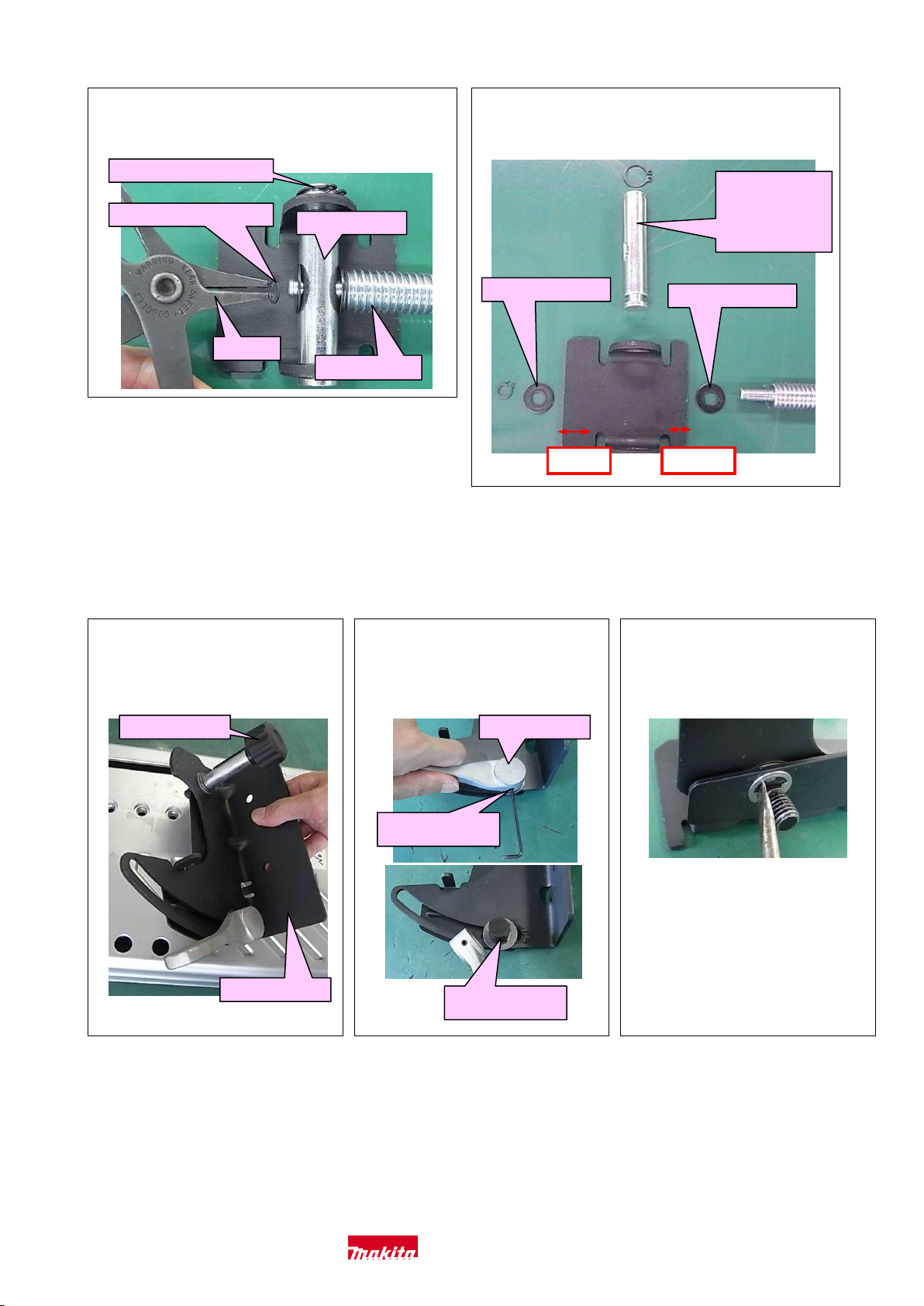

5-3-4 Vise Section ........................................................................................................................................................8

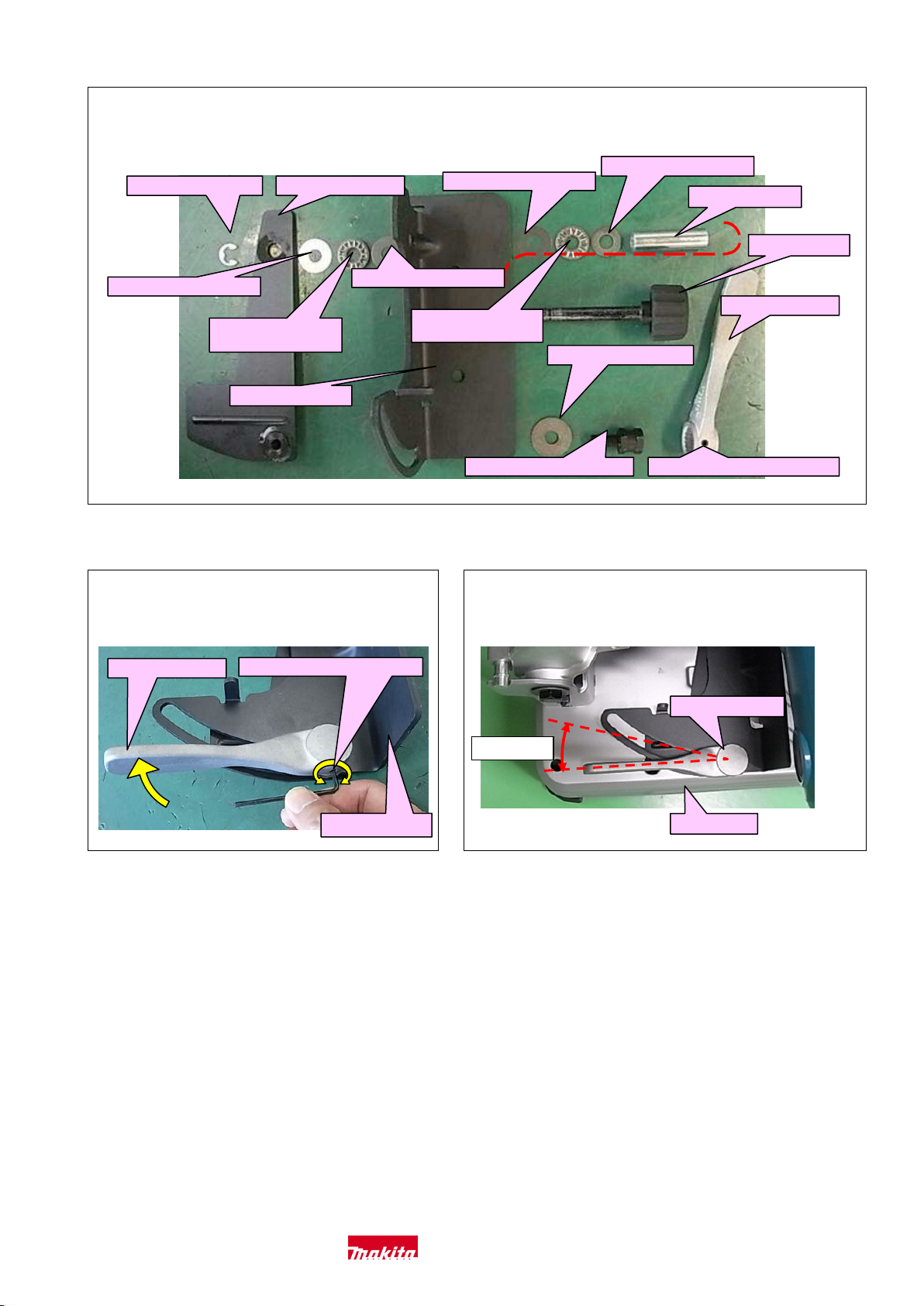

5-3-5 Guide plate..........................................................................................................................................................9

5-3-6 Main frame, Base and others ............................................................................................................................ 11

6Circuit diagram..................................................................................................................................................................13

7Wiring diagram..................................................................................................................................................................14

4Caution

Repair the machine in accordance with “Instruction manual” or “Safety instructions

Follow the instructions described below in advance before repairing:

· Wear gloves.

· Remove Abrasive cut-off wheel.

· When the engine is hot from use, cool down the engine enough or you can get burned.

· In order to avoid wrong reassembly, draw or write down where and how the parts are assembled, and what are the parts.

· It is also recommended to have boxes ready to keep disassembled parts by group.

· Handle the disassembled parts carefully.

· If some bolts and screws are too tight, use an impact driver.

· Tighten the bolts and the screws to the specified torque.

Makita Corporation 2/ 15