Bibo 2 TOUCH User manual

BIBO 2 TOUCH 3D PRINTER

---Operation Manual

SHAOXING BIBO AUTOMATIC EQUIPMENT CO., LTD.

V3.0a

Please operate the machine strictly according to this operation manual to

have a promised warranty from BIBO! As the warranty is based on the

correct operation according to the operation manual.

REVISION RIGHTS RESERVED

Shaoxing Bibo Automatic Equipment Co., Ltd.

Tel:+86 575 88918283 Mobile:+86 133 25759139

Url: www.ourbibo.com E-Mail: bibo@ourbibo.com

1

Content

1. Caution.......................................................................................... 2

2. What's in the box?.........................................................................3

3. Initial Hardware Installation.........................................................4

4. First Print.................................................................................... 10

5. Some Notices for Printing.......................................................... 29

6. Software Installation...................................................................32

7. Slicing for A Gcode File.............................................................35

8. Acrylic Cover Installation.......................................................... 51

9. Function Introduction(including copy printing).........................53

10. USB Driver Installation (not necessary).................................. 57

11. WIFI (optional function).......................................................... 60

12. Maintenance/Optimal Operational Tips................................... 83

Shaoxing Bibo Automatic Equipment Co., Ltd.

Tel:+86 575 88918283 Mobile:+86 133 25759139

Url: www.ourbibo.com E-Mail: bibo@ourbibo.com

2

1. Caution

Please be careful for human electrostatic especially in winter when touching the

motherboard or extruders. The easiest way to solve this problem is that we can

touch the metal part nearby by hand first before touching the motherboard or

extruders. So the electrostatic usually will be gone before touching the

motherboard or extruders.

SD card or USB drive for the printer should be smaller than 16GB. SD card should be class 4.

★★★If unloading the filament, please load it first, then unload it AT ONCE.

1. Do not leave the extruder heated for long time, just stay with the printer for heating.

The filament might decompose after leaving it at high temperatures, leaving a layer of

contaminants behind in the hot-end nozzle, and the extruder will be clogged.

2. Printing PLA not more than 200 degree, usually 180-190 degree is the best. Setting a

printing temperature above 230-245 degree for PLA is starting to get into bad territory as

the plastic will start to change properties if left in the nozzle for too long and can cause

clogs.

3. During heating or close heating or stop the printing on touch screen or inserting

SD card to the printer, the other operation on touch screen will be not responded as

the former action (heating or close heating or reading the sd card) should be finished first,

and temperature reading will not be correct. You can power off the printer and power

on again, everything will be ok too. Touch screen sometimes may have crash fault

like computer or phone. Restart the printer and it will be ok.

4. It is strongly not recommended to replace the parts, as replacing the parts usually

causes the damage or the new problem. Please kindly contact bibo@ourbibo.com first

before replacing, as there may be much easier way to solve your problem without

disassembling anything. For example, pushing down filament or the metal stick to the

heated extruder is much easier then replacing the hot ends for the extruder clog problem.

NOTE: Before power on the printer, please check printer input voltage showed on

nameplate whether fit for your local power supply. Nameplate is stick on the backside

or two sides of printer. If not fit for your local power supply or no power to the printer,

change the switch position on power source under the bottom plate of the printer to

avoid damage.

Before repairing or making any alterations to the BIBO 3D printer, it is essential that the machine is turned off

and the power cord is unplugged.

The BIBO 3D printer operates at very high temperature; allow the nozzle, the extruded plastic and heating.

Do not wear gloves when operating or repairing, as entanglement may occur and cause injury.

Do not leave the machine unattended when in operation.

Shaoxing Bibo Automatic Equipment Co., Ltd.

Tel:+86 575 88918283 Mobile:+86 133 25759139

Url: www.ourbibo.com E-Mail: bibo@ourbibo.com

3

2. What's in the box?

The printer may be re-taped during inspection at the customs.

There is troubleshooting files in the SD card which can also help you.

The frame of BIBO 3D printer is CNC machined, and we cleaned the printer

before delivery. But during violent transportation vibration, there maybe some

machining powder of the aluminum composite panel come out from the frame

junctions or some dust from the cartons. Sorry for this trouble. Please blow the

dust away.

Along with your BIBO 3D printer, this package contains the following which are

in the small carton above the build platform, there are(the words and pictures are

lined in the same order ):

1 roll PLA filament, 1 or 2 filament holders, some allen wrenches (packed with

black clamps), some bolts and nuts, 1 glue stick, 1 power cord, 1 USB A to B

cable, 1 or 2 filament guide tubes (may already fixed on the filament tube couplers

support), 1 filament tube couplers support, 2 extruder wire clamps, 1 spare

thermistor, acrylic cover bolts and nuts, 1 cross screwdriver, 1 SD card(not inside

this small box, but above it ).

Please remove all the files we sent to you in SD card to your computer, or

SD card printing may not run. When you want to print something, please

copy the gcode files to SD card.

Red acrylic cover panels and clear door may have paper or film protected.

If you need to transport the printer to other place, please

keep all the packing carton and material, and take the photos

step by step when you do unboxing. In this way, you can

pack the printer the same as us, and the transportation of

the printer will be safe.

The packing manual is here:

https://drive.google.com/file/d/1-CAvBgYopazYT4lmRduwQr

P8KD-b0Q7L/view?usp=sharing

Shaoxing Bibo Automatic Equipment Co., Ltd.

Tel:+86 575 88918283 Mobile:+86 133 25759139

Url: www.ourbibo.com E-Mail: bibo@ourbibo.com

4

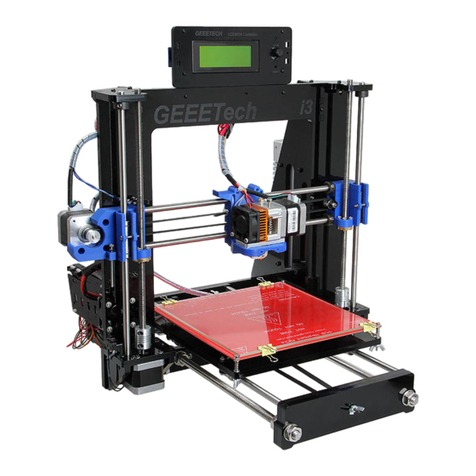

3. Initial Hardware Installation

BIBO 3d printer’s working principle is Fused Filament Fabrication(FFF). FFF is the

most common method of 3D printing. It works by melting plastic material called

filament onto a print surface in high temperature. The filament solidifies after it

cools down, which happens instantaneously after it is extruded from the nozzle.

3D objects are formed with the filament laying down multiple layers. 3d printing is

similar to building a house.

3D printing involves three steps:

1. Create or download a 3D model (usually in stl format).

2. Slice the 3D model in the slicing software (repetier host, cura or simplify 3d)

and export the 3D file in gcode format file.

3. The printer recognizes the gcode format file and builds the 3D model.

We have the BIBO parts assembly video and acrylic cover assembly video,

and you can copy it from the SD card which is sent with the printer to you or

download from this link:

https://drive.google.com/file/d/1e02U8qIDgyE1xym4yPbTf_fmFDw2x0-b/view?us

p=sharing

The file is ZIP format which was compressed, and you can use winrar or other

software to open these videos. There may be some difference, but the

operation principle is similar.

The printer is usually transported by courier. If the printer is all assembled, its

volume will be much bigger, and the courier freight will be much more as freight

depends on its volume, not actual weight. So we will let big volume part such as

acrylic cover (fragile for shipping), filament run-out detection part not be

assembled, to reduce the expensive transportation freight and let the

transportation be more safe. These parts are easy to assemble.

The first step is to take the machine from carton , also taking the parts out from

the small carton in the printer first , then take the small carton out from the

printer, and remove all the protection bubble wrap and zip ties.

Now raise the build platform by rotating clockwise the lead screw. Then take out

the packed acrylic cover. Please check the photo below:

Shaoxing Bibo Automatic Equipment Co., Ltd.

Tel:+86 575 88918283 Mobile:+86 133 25759139

Url: www.ourbibo.com E-Mail: bibo@ourbibo.com

5

Then install the extruders with two bolts in 10mm or 8mm length (in a bag marked

with 10 or 8), and connect two fans with black coupler. See the photo below:

Do not touch the red wires and

transparent wires

Shaoxing Bibo Automatic Equipment Co., Ltd.

Tel:+86 575 88918283 Mobile:+86 133 25759139

Url: www.ourbibo.com E-Mail: bibo@ourbibo.com

7

If you want to take the extruders down form the printer, just unlock two black

coupler, no need to remove the cooling fan support, the same as you assemble

the extruder. When you unlock two black coupler, please push the button first then

unlock the black coupler as the photo below:

The second step is to install the filament guide tube support on the back of the

printer with 16mm length bolts and nuts (bolts in a bag marked with 16 ), and do

not connect the black coupler first as the photo below.

These raised

edge sides

should be

connected in

the same

direction

Push this first when

unlock the black

coupler

Extruder1(right extruder)

Extruder2(left extruder)

Put this

connector down

to avoid

knocking the

front panel

Shaoxing Bibo Automatic Equipment Co., Ltd.

Tel:+86 575 88918283 Mobile:+86 133 25759139

Url: www.ourbibo.com E-Mail: bibo@ourbibo.com

8

The third step is to install filament holders on the back of printer with two big white

bolts.

Some printers’ filament holders are fixed in a different way, with 12mm length

bolts (in a bag marked with 12). Please kindly check the photo as below:

Pleas press two nuts by two fingers

during assembly to avoid nuts falling

down.

Please do not connect the

black coupler first

Shaoxing Bibo Automatic Equipment Co., Ltd.

Tel:+86 575 88918283 Mobile:+86 133 25759139

Url: www.ourbibo.com E-Mail: bibo@ourbibo.com

9

The fourth step is to assemble the extruder wire clamp with 16mm or 12mm

length bolt. We have sent you two clamps. One is to be assembled on the top side

of the printer’s back panel, and the other one is for spare. Please kindly check

the photoes as below. Let the black wire cable be straight (just only a little

tight) . If too loose, the black wire may be not long enough for extruders to travel

inside the printer.

Congratulations! You have completed the initial hardware installation!

For acrylic cover installation, it is in chapter 8. You can install it after first printing

test.

Black tube can be inserted

into black support

Bolt cap this

side

This two sides should be locked first

This two side should be locked later

If you want to unlock the clamp, you

can insert allen wrench or

screwdriver to the hole of the clamp

Shaoxing Bibo Automatic Equipment Co., Ltd.

Tel:+86 575 88918283 Mobile:+86 133 25759139

Url: www.ourbibo.com E-Mail: bibo@ourbibo.com

10

4. First Print

The first step is Leveling the heated bed(not necessary).

After transportation, only a few printers’s beds have to be leveled to ensure

your 3D prints stick well to the heated bed. How to check whether you have to

level your heated bed or not, please follow steps below.

1.Put the glass plate on the aluminum heated bed (two ways).

Some printers don’t have four clips sent with the printer, but with two

clamps fixed on the backside of the heated bed. If so, the fixed way is

below:

Glass plate

Aluminum

heated bed

Four clips to fix the glass bed in front

and back side. Please open the clip first

then fix it on or remove it, or the clip

may scratch the circuit in the bottom of

the heated bed .

Shaoxing Bibo Automatic Equipment Co., Ltd.

Tel:+86 575 88918283 Mobile:+86 133 25759139

Url: www.ourbibo.com E-Mail: bibo@ourbibo.com

11

Push the glass plate to the bolts on the two rear clamps in the back of aluminum

heated bed and press it down to install it . Let the glass plate be well contacted

with aluminum heated bed by pressing the sides of glass plate as the photo

below:

Please also check the glass bed whether can be easily moved in horizontal

direction.

2. Start the machine to see the main menu and touch the “Home” button

3. Now move the extruders to the right side first, and use your fingernail to

touch the “Z” button to run the Z axis homing. If touch “all”, the extruders will

be locked and you can’t move it, and the following leveling step can’t be done.

You can restart the printer and touch “Z” again to home Z axis.

Move extruders’ nozzles to be up on heated bed slowly. If nozzles can be

moved on heated bed (even the nozzles knock the bed and a little below the

Shaoxing Bibo Automatic Equipment Co., Ltd.

Tel:+86 575 88918283 Mobile:+86 133 25759139

Url: www.ourbibo.com E-Mail: bibo@ourbibo.com

12

bed but still can move on the bed), then you can go to the second step to

load the filament first.

If nozzles can’t be moved on heated bed as they are below heated bed glass a

lot, the video instruction is here:

https://drive.google.com/file/d/12BrsKYa6_Yj4E5fzE3rCPnxrbGgEIkqr/view?usp=

sharing

You should do the following steps to level the bed as below:

Put a paper such as a A4 paper on the glass plate,

Rotate three wing nuts Clock-wise to let the glass bed down and nozzles can

move on the paper. If the nozzles still can’t move above the glass bed, please

check the file named “leveling problem Bend and move the Z axis limit switch” in

the troubleshooting file in the SD card sent with the printer.

Shaoxing Bibo Automatic Equipment Co., Ltd.

Tel:+86 575 88918283 Mobile:+86 133 25759139

Url: www.ourbibo.com E-Mail: bibo@ourbibo.com

13

Now move the extruders between the printer nozzles and heated bed to let a A4

paper be a little hard to pull through nozzles and the bed. You can adjust three

wing nuts and bolts under the heated bed. first level the front side with two

screws and fix in place, then level the back side with one screw. Just level in

this order to level the bed again and again.Please note that the leveling

can’t be perfect, as the bed can’t be perfectly flat. After printing, when there

is some places not stick well for the print, we can apply more glue there. So

the lower place can be even too. After leveling, please make sure three

springs under the bed should be tight, or the leveling calibration can’t be

kept well for long time and you should level it again.

You can also use leveling menu on the touch screen (not recommended), just

click one by one with fingernail or a pen, checking the paper movement and adjust

the wing nuts. Without leveling the center point, the leveling can be easier.

This leveling menu has the bug now, sometimes it will be not responsive. We

recommend to move the extruder by hand which is faster and easier, and

can feel the obstruction between nozzles and the bed, also safer.

Level front side first

Level back

side after the

front side

Shaoxing Bibo Automatic Equipment Co., Ltd.

Tel:+86 575 88918283 Mobile:+86 133 25759139

Url: www.ourbibo.com E-Mail: bibo@ourbibo.com

14

The Second step is loading the filament for two extruders

BIBO touch 3D printer has the function of filament run-out detection.

Beeping problem:

We should load filament for both extruders. Or we can't print or engrave and

the printer will beep when you start the printing because of filament run out

detection. We send one spool of PLA filament, and you can cut some from

that spool to have a roll of filament. If the printer has the latest touch screen

firmware, the touch screen will show “filament detection switch not pressed” when

two filament detection switches are not both pressed because of filament run out

detection.

If you don’t want this function or you just want to load only one spool filament for

one extruder, you can unlock the black coupler. If you want to print flexible

filament (soft filament), you’d better tie the limit switch with tape or rope to

push the switch back for better printing quality

Limit switch

can be pushed

back

Black connector for filament run out detection.

Disconnect it if you only insert the filament in on

e limit switch as the photo here shows, or it will b

eep when printing is started.

If you insert the filament in two limit switches, yo

u can connect this black coupler.

If your coupler has the black cap (not blue cap),

another way to disable the filament run out

detection function is to push the white plastic tube

down to let the limit switch be pressed.

If you want to enable the filament detection

function again, please press the black cap first

then pull the white plastic tube up again.

Shaoxing Bibo Automatic Equipment Co., Ltd.

Tel:+86 575 88918283 Mobile:+86 133 25759139

Url: www.ourbibo.com E-Mail: bibo@ourbibo.com

15

1) Turn on the power switch on the back of the printer and you will see the main

menu:

If your touch screen’s main menu’s background is not in black as the photo

above,

You can update the latest firmware according to this link:

https://docs.google.com/document/d/1dpXsl0ZKrTG7c7OuIY9BxZCUDk8tSWcX/

edit?usp=sharing&ouid=103768291371300327502&rtpof=true&sd=true

2) Now use your fingernail to touch the “Preheat” button, and you will see

NOTE: Using fingernail or a pen, not finger bellies or soft part to touch the

touch screen, or will let some move button not be responsive. Please kindly

check our way to click the touch screen on this

link: https://drive.google.com/file/d/0B76TjeOkslHlNl9fZUI3U0xoMTg/view?usp=s

haring&resourcekey=0-TuvWre7IijIVJTd3nALrSQ

3)You can choose nozzle Extruder 1(right extruder) and nozzle2 Extruder 2(left

extruder), then set the temperature at 220℃by “add” button as usual (this

temperature is according to your material type and manufacture’s instruction. For

PLA usually 200℃, and for ABS usually 220-240℃. It also based on the former

existing filament in the nozzle). Now you will see two extruder’s temperature is

rising.

4) Now we will do the loading filament step for two extruders. Put two spools

of filament in the back of the printer (We send one spool of PLA filament, and you

Touch this to choose Extruder1

or Extruder 2 or Bed

Shaoxing Bibo Automatic Equipment Co., Ltd.

Tel:+86 575 88918283 Mobile:+86 133 25759139

Url: www.ourbibo.com E-Mail: bibo@ourbibo.com

16

can cut some from that spool to have a roll of filament ). One runs clockwise and

the other one runs counter – clockwise. For not rolled on spool test filament, is the

same operation.

Sharp the filament head with scissor and let the filament be as straight as you

can to ensure it come to the hole of extruder smoothly. If it is difficult to put the

filament to the hole of nozzle on the way, please rotate the filament in different

direction and try more times.

The loading filament video is here:

https://drive.google.com/file/d/18hwVbFtGzk53abkJP-N7KkdXEnYZVg6_/view?u

sp=sharing

Load the filament to the filament guide tube for two extruders (if only loading

for one extruder, the printing will be paused or beeping) as the photo below:

When the extruders reach 220℃, please push the filament down to the extruder

about 90mm (3.54 inches ) deep by hand. If the extruder has the lever, please

Shaoxing Bibo Automatic Equipment Co., Ltd.

Tel:+86 575 88918283 Mobile:+86 133 25759139

Url: www.ourbibo.com E-Mail: bibo@ourbibo.com

17

press the lever down a little before pushing the filament into the extruder.

If it is hard for you to push the filament down, please check the filament

whether is straight enough in 90 mm (3.54 inches), and the filament tip is

pointed in “V” shape. You can also rotate the filament inside the extruder and try

more times. Usually it will work. Another cause is that the extruder motor is

locked, you can restart the printer or click “Motor-off” button on the Home menu

in the touch screen.

This is for E2 (left extruder) in the photo above

The filament will come out from the extruder’s brass nozzle. Go back to the main

menu to touch “Preheat” to go to the “preheat” interface again

Shaoxing Bibo Automatic Equipment Co., Ltd.

Tel:+86 575 88918283 Mobile:+86 133 25759139

Url: www.ourbibo.com E-Mail: bibo@ourbibo.com

18

Touch “close” to let the extruder’s temperature come down (if the filament stays

in the hot nozzle for long time, the extruder will be clogged. We should cool

down the extruder after loading filament).

Now loading filament for one extruder is finished.

Another way of loading filament is below:

Touch the “Preheat” button, and you will see

You can choose nozzle Extruder 1(right extruder) and nozzle2 Extruder 2(left

extruder), then set the temperature at 220℃by “add” button as usual (this

temperature is according to your material type and manufacture’s instruction. For

PLA usually 200℃, and for ABS usually 220-240℃. It also based on the former

existing filament in the nozzle). Now you will see two extruder’s temperature is

rising.

When the extruders reach 220℃, please push the filament down to the extruder

about 40mm (1.57 inches ) deep by hand. If it is hard for you to push the filament

down, please check the filament whether is straight enough in 40 mm (1.57

inches), and the filament tip is pointed in “V” shape. You can also rotate the

filament inside the extruder and try more times. Usually it will work.

Touch this to choose Extruder1

or Extruder 2 or Bed

Table of contents