bierkuhl BOS Cleantec IR duct inspection robot User manual

Bierkühl Oy +358 440 178 111

Pellonlaita 1, 506

00 Mikkeli Finland

www.boscleantec

.com

BOS® Cleantec

BOS®IR duct inspection robot

Operation and maintenance manual

Operating instructions must be read carefully before using the device. This is

important for correct and safe operation of the device!

Bierkühl Oy +358 440 178 111

Pellonlaita 1, 50600 Mikkeli Finland www.boscleantec.com

Operation and maintenancemanual

BOS® Cleantecventilation duct inspection

SIVU

2

i

ØREAD ALL SAFETY ANDOPERATING INSTRUCTIONS!

ØKEEP THE MANUAL FOR FUTURE USE!

Failure to follow the warnings andinstructions could result in electric

shock, fire and / orseriousinjury!

This manual only applies to BOS IR duct inspection robot. Device may only be used

in dry conditions without any danger of explosion.

Devices are not intended for use by persons (including children) with physical,

sensory or mental limitations, or lack of experience or knowledge as to how to use

the machine. Children must be kept at a distance from the devices.

Disclaimer: This manual has been reviewed, but 100% accuracy is not guaranteed.

As part of our policy of continuous product development we reserve the right to

revise features and specifications of the product. Therefore, any claims based on the

data, pictures, drawings or text in this manual cannot be accepted. We cannot

guarantee that there are no errors.

Bierkühl Oy +358 440 178 111

Pellonlaita 1, 50600 Mikkeli Finland www.boscleantec.com

Operation and maintenancemanual

BOS® Cleantecventilation duct inspection

SIVU

3

GENERAL REGULATIONS

Products covered by this manual have been manufactured in Finland to existing laws, decrees and

regulations as stated in the Declaration ofConformity below.

·The person who is in charge of machine operation must be acquainted with the construction

and operation of the machine and must ensure safe operation.

·The machine may only be used by people who are familiar with it.

·Safety devices must not be removed orchanged originalinstallations.

·If the device has to be installed in such a way that the operation of the safety devices is

prevented, the person responsible for use must be notified.

ØThe devices in this manual are only intended for the work for which they were

designed and are mentioned in the manual

ØUse of the device for other purposes is prohibited!

ØThe manufacturer is not liable for penalties if the device has been used in

violation of the instructions!

·Keep instructions available for the user.

·Read the operating instructions carefully before installing and using the device.

·Follow the operating and maintenance instructions to ensure trouble-free operation of the

device.

·Follow safety instructions.

·Only spare parts and components approved by the manufacturer must be used for

maintenance.

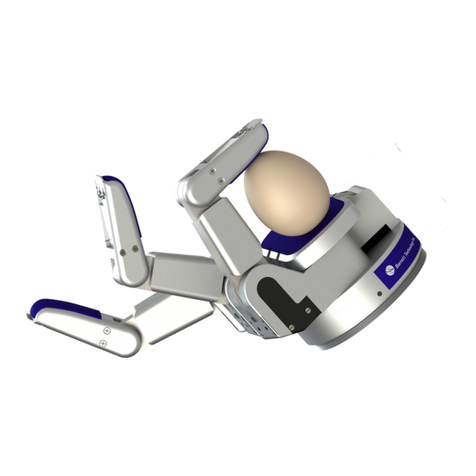

The BOS® IR inspection robot is designed and built in accordance with general safety and electrical

safety regulations. The inspection robots are intended for video recording and inspection of

ventilation ducts, as well as for storing data for later use.

Bierkühl Oy +358 440 178 111

Pellonlaita 1, 50600 Mikkeli Finland www.boscleantec.com

Operation and maintenancemanual

BOS® Cleantecventilation duct inspection

SIVU

4

TECHNICAL SPECIFICATIONS

Case,Polypropylene

- Dimensions, mm 480*440*20

Camera cable reel Marine aluminium

-Control cable LIYY 12x0,25 25m

Screen 7”inch LCD color screen, 12V DC

SD Recorder 1 CH mini dvr

- Memory card SD cardmax. 32 GB

Connection cable 2M

Charger 110-240 VAC, 50 – 60Hz

Control Unit / Control Panel Stainless Steel

- Dimension, mm 230*220*55

- Batteries 3 pcs

- Battery type Z LI 18650N

- Battery capacity 2600mAh

- Battery capacity Indicator LCD Battery LI ion Capacity Indicator

- Microfon Electrical microfon

Remote Control Joystick, one-handed

- Connectiong Cables LIYY8 x 0,25

Inspection Robot Stainless Steel

- Dimension , mm 190*150*90

- Motors, 4 pcs DC motor

- Cameras (Front and Back) FPV colour camera

- Lights Led5 pcs (4+1)

- Rims POM

- Tyres Rubber tyres, 10X86/55

Bierkühl Oy +358 440 178 111

Pellonlaita 1, 50600 Mikkeli Finland www.boscleantec.com

Operation and maintenancemanual

BOS® Cleantecventilation duct inspection

SIVU

5

PROPERLY USE

BOS® IR Inspection robots are designed for professional use. The following safety instructions

must be taken into account when working:

ØONLY USE THE DEVICES IN DRY CONDITIONS WITHOUT ANY DANGER OF

EXPLOSION!

ØProtect device from moisture and shaking.

ØThe device must not get wet during use!

ØDo not cover the device during use.

ØDo not make any changes to the BOS® IR robot. If changes are made, the

manufacturer is not liable for damage!

ØTake care of the equipment and all separate parts.

ØCheck the moving parts are working properly and that there are no broken or

damaged parts in the device that could interfere with operation.

ØMake sure that the electrical cable of the charger is correct!

ØClean thedevice and cables afteruse, ifnecessaryclean thecamera lenses with

a microfiber cloth or a cloth specially designed for cleaning the camera lenses!

ØThe user of the device is responsible for damage caused by wrong use!

ØThe type plate is located on the robot and case!

ØThe information on the nameplate must be noticed when ordering service or

spare parts!

ØWhen shooting with a robot, local regulations of the work site must be

followed!

ØFollow local country regulations.

ØPerson who using the device must read and understand the instructions.

Bierkühl Oy +358 440 178 111

Pellonlaita 1, 50600 Mikkeli Finland www.boscleantec.com

Operation and maintenancemanual

BOS® Cleantecventilation duct inspection

SIVU

6

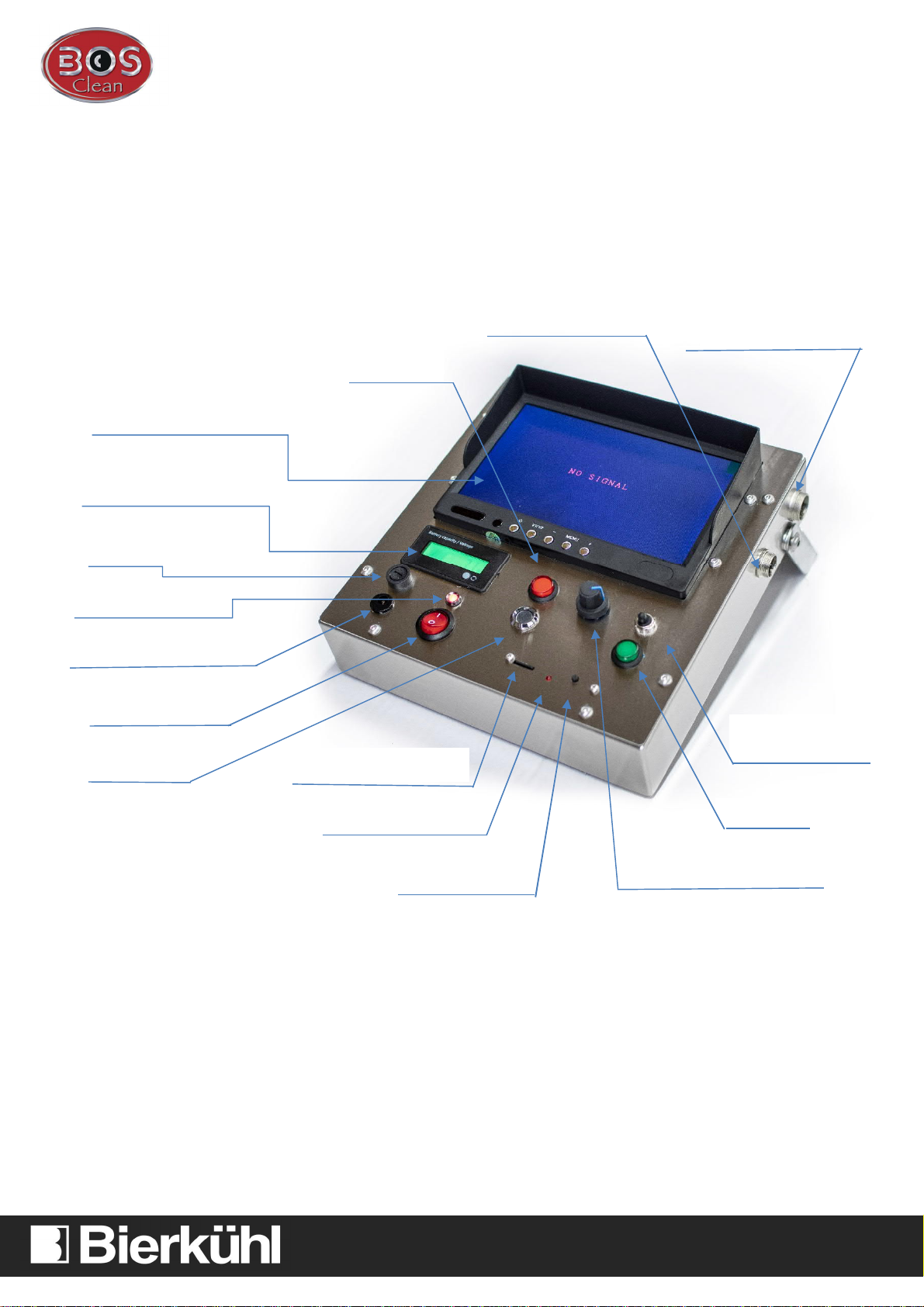

CONSTRUCTION AND CONTROLS

Recording to the SD card (max 32 Gb) :

Recording video file to the memory card:

·Push video reg switch àGreen indicator light turns on. Recording starts and Indicator LED-light flash.

Recording audio file to the memory card :

·Push audio reg switch à Red indicator lught turns on. At the end of the recording, push audio reg. switch

again.

Finishing recording

·Push recording ON / OFF switch, recording indicator light stays on red colour..

Continue recording:

· Push again recording ON / OFF switch à recording start and indicator light starts flashing . Audio files

can be added to the recorder as previously described.

ØIf recording is not performed, keep the recording switches OFF to save battery !

BOS®

IR Control Panel

Fuse

Charger Plug in

Power on/off I/O

Remote contor plug in

Battery charging indicator

7” TFT Colour Screen

Camera Switch

(Front/Back)

Microphone

Indicator Light

Robot plug in

Recorder, Micro SD card

Recording

ON / OFF

Audio reg.

Recording Indicator Video Reg.

Light brightness adjustment

Bierkühl Oy +358 440 178 111

Pellonlaita 1, 50600 Mikkeli Finland www.boscleantec.com

Operation and maintenancemanual

BOS® Cleantecventilation duct inspection

SIVU

7

OPERATING AND SAFETY INSTRUCTIONS

PLEASE CAREFULLY OBSERVETHE FOLLOWING BEFORE AND DURING OPERATION:

·The machine user must ensure that the machine is fit for the intended purpose.

·Theuser of the machine must ensure thatthe voltage andcurrent correspond to the ratings

on the CE plate.

·Occupational safety regulations must be observed.

·Before shooting, make sure that there is no risk of explosion in the operating environment.

·Flammable or explosive materials must not be stored or used in the place where the device

is used.

·The machine must be protected from moisture, vibration and getting wet.

·Only use spare parts that are suitable for the machine (approved by the manufacturer).

·Do not cover the robot during operation.

·The machine must keep as clean as possible.

·The operating temperature must not exceed + 35ºC or fall below -0ºC

·No changes may be made to the device.

·Donotusedamagedbatteries.Damagedormodifiedbatteriescanbehaveunexpectedlyand

cause a fire or explosion.

·Do not expose the battery to fire or excessive temperatures.

·Follow the download instructions.

·Never make anyservice fordamaged batteries. All battery maintenance must be performed

by the manufacturer or an authorized service center.

Person(s) working on site should wear a helmet, hearing and respiratory protection, goggles,

clothing and footwear,andotherpersonal protectiveequipment dependingon thework performed.

Bierkühl Oy +358 440 178 111

Pellonlaita 1, 50600 Mikkeli Finland www.boscleantec.com

Operation and maintenancemanual

BOS® Cleantecventilation duct inspection

SIVU

8

INSTRUCTIONS

1. Transport

Themachinemust be protected againstdirt andmoisture during transport. The machinemust not bestored

outdoorsunprotected.Exerciseextremecareandcautionwhen movingorliftingthemachine.Avoidimpacts

and knocks during transport and handling. Before commissioning, inspect the machine to make sure it is

exactly as it should be (and without any transport damage).

(Note the capacity of the batteries in air transport).

2. Storage

Store the machine in a dry place, protected from the weather. Avoid extreme temperatures (high and low)

during storage.

Batteries should becharged, the recommended charge level is 70-90%.

Never store the device below 0 ° or above + 30 °.

3. Comissioning

Install the case on a flat surface and check that it is protected from the weather. Make sure the equipment

is in good condition, fasten thecables as instructed before starting work. Protectthe case andits parts from

vibrationandpossibledamages.Checkthatallcomponentsareinplaceandtheequipmentisfullyfunctional.

Check the connections are correct and the battery is fully charged. (The maximum operating temperatureis

35° C.

4. Use of the machine

·Before starting work, make sure that the work area is free and there are no obstacles that restrict

work.

·Check all accessories

·Take careof personal protective equipment.

·Putthe robotin the duct and startrecording.Use thecameraselectorswitch on thecontrol panel to

select the front camera whendriving forward, use the rear camera whendriving back.

·Save audio and/ or video files on amemory card in the recorder for later use.

·When work is complete, clean the equipmentand place itin the casein its designated locations.

·Note thebattery charge afteruse.

5. Charging voltage

The battery can be charged in the mains 100- 240 VAC, and 50-60 Hz.

ØMake sure the battery is charged!

ØMake sure that the connecting cables are correct!

ØClean the equipment after use!

ØOnly a suitably qualified person can use the equipment!

Bierkühl Oy +358 440 178 111

Pellonlaita 1, 50600 Mikkeli Finland www.boscleantec.com

Operation and maintenancemanual

BOS® Cleantecventilation duct inspection

SIVU

9

MAINTENANCE

ØThe equipment and cables must be cleaned of dirt and dust after each use!

ØRunning water for cleaning is prohibited!

ØBefore carrying out maintenance and cleaning work on the device

, operating switch must be set to the off position!

All maintenance and repair work that requires the protection of the robot, control unit or

remote control to be opened must be carried out by an authorized customer service

workshop. Only original spare parts must be used formaintenance.

Equipment in continuous professional use should be serviced every year.

If the device malfunctions, it must be returned for service immediately.

During transport, care must be taken to protect the product and prevent furtherdamage.

Maintenance work includes cleaning the device and checking the condition of the cables, also

cleaning the tires if necessary. Maintenance and repair work on the control unit and

batteries may only be carried out by a specialist, authorized by themanufacturer.

ØAny repairs must be carried out by a specialist, approved by the manufacturer.

ØThe cables and the robot should always be cleaned of dirt and grease with a mild

detergent after use and the batteries must be charged for the next use.

ØClean the camera lenses with a microfiber cloth or a cloth specially designed for

cleaning lenses!

ØExpired batteries can be replaced with new ones from the service door below the

control panel.

ØThe manufacturer accepts no liability for maintenance performed by a third party.

Bierkühl Oy +358 440 178 111

Pellonlaita 1, 50600 Mikkeli Finland www.boscleantec.com

Operation and maintenancemanual

BOS® Cleantecventilation duct inspection

SIVU

10

WARRANTY

Provided that the operating and maintenance instructions are strictly adhered to, the product is

covered by a 12-month factory warranty starting from the date of purchase.

Any defects discovered during this warranty period are rectified free of charge, provided that

·The defect is in materials or components

·The defect has occurred during normal use

·Allmaintenanceandrepairworksonthemachinehavebeenperformedbythemanufacturer

oran authorizedrepresentative –the manufactureraccepts noliabilityforany maintenance

works performed by a third party

·Products repaired or replaced by the manufacturer are warranted as of the original date of

purchase.

·A warranty claim has been submitted in writing.

Thewarrantydoesnotcoverdefectsresultingfromnormalwearandtear,negligence,improperuse

or maintenance/repair works not performed by the manufacturer.

The product has been manufactured to existing international regulations. In case of any questions

regarding commissioning or malfunctions, please contact the manufacturer.

For maintenance or warranty repair, the machine should be sent to the following address:

Bierkühl Oy

Pellonlaita 1, 50600 Mikkeli

Puh. +358 440 178 111

Bierkuhl reserves the right to make changes.

Bierkühl Oy +358 440 178 111

Pellonlaita 1, 50600 Mikkeli Finland www.boscleantec.com

Operation and maintenancemanual

BOS® Cleantecventilation duct inspection

SIVU

11

ENVIRONMENT / RECYCLING

ØWaste materials must be disposed of in compliance with the relevant legislative

requirements and without harming the environment.

ØA discarded machine or any part of it must not be disposed of together with household

waste!

ØDiscarded machine parts and accessories must be taken to an environmentally compatible

recycling point.

ØThe product uses valuablematerials and components that are recommended for recycling

and reuse.

If an appropriate recycling point cannot be found, the product can also be returned to the seller or

manufacturer to be recycled.

Metal parts (housing and motor) can be recycled as scrap metal.

Electronic parts should be taken to an authorised recycling facility.

Batteries must be taken to appropriate recycling points.

Other parts can be recycled as mixed waste.

In observance of the European Directive on waste electrical and electronic equipment and its

implementation in accordance with national law, discarded electric tools must be collected

separately and returned to an approved recycling facility.

Bierkühl Oy +358 440 178 111

Pellonlaita 1, 50600 Mikkeli Finland www.boscleantec.com

Operation and maintenancemanual

BOS® Cleantecventilation duct inspection

SIVU

12

DECLARATION OF CONFORMITY

Manufacturer: Bierkühl Oy, Pellonlaita 150600MIKKELI FINLAND

Tel.: +358 440 178 111

Website: www.boscleantec.com

Product designation: Electric duct cleaning machine

Product name: BOS® Clean

Intended use: Duct description, inspection and recording

Serial number:

Year of manufacture::

We hereby declare that the product named above has been designed to comply with the Finnish

Government Decree on the safety of machinery (400/2008) and meets the requirements of the

Machinery Directive( 2006/42/EY). We also declare that the following Directives and

harmonised standards have been applied:

Essential characteristics and performance Harmonised technical specification

Safety of machinery SFS – EN ISO 12100:2010

Electrical equipment of machinery – Part 1:

General requirements SFS _ EN 60204-1:2007

Decree on the safety of machinery Finnish Government Decree No. 400/2008

Machine Directive (MD ) MD 2006 / 42 / EY

Low Voltage Directive (LVD) 2014/35/EU

Electromagnetic Compatibility (EMC)

Directive EMC 2004/108/EY

2014/30/EU

Restriction of Hazardous Substances

(RoHS) Directive 2011/65/EU

Waste Electrical and Electronic Equipment

Directive (WEEE) WEEE 2012/19/EU

This product conforms with the requirements to achieve CE marking.

Bierkühl Oy 26.04.2021

Pentti Hiltunen

Managing Director

Table of contents