Big Daishowa LEVEL MASTER WIRELESS User manual

Precision Electronic Level

LVM-18052101

C

E

R

T

I

F

I

E

D

M

A

N

A

G

E

M

E

N

T

S

Y

S

T

E

M

QUAL I T Y SYST EM

JQA-QM3913

FADept.

■EXPORT DEPT.

Takaramachi5-2,HigasiosakasiOsaka579-8025JAPAN

Phone:072-982-8277Fax:072-982-8370

Operation manual

Thank you for using Level Master Wireless(LVM-WL).

Please handle it as a measuring instrument and utilize it for long time.

Please be sure to read this manual before using the device and also keep it in a

location where all the operators may consult it in case of necessity.

INDEX

1. SPECIFICATIONS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ P 1

2. NAMES OF PARTS AND FUNCTIONS ・・・・・・・・・・・・・・・・・・・・・・ P 1~P 2

3. HOW TO INSTALL THE BATTERIES ・・・・・・・・・・・・・・・・・・・・・・・・・・・・ P 2

4. BEFORE USING THE DEVICE

P 3

P 3~P 6

5. OPERATIONS

P 8

P 7~P 8

5-1. Levelling operation

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

4-1. Environmental settings

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

4-2. How to execute the zero adjustment

・・・・・・・・・・・・・・・・・・・

5-2. How to turn on/off the buzzer

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

5-3. How to reset the device to its default values

・・・・・・・・・・・・・・・・・・ P 8

6. SAFETY NOTES ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ P 9

7. WARRANTY ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ P10

8. EMC INFORMATION ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ P10

110

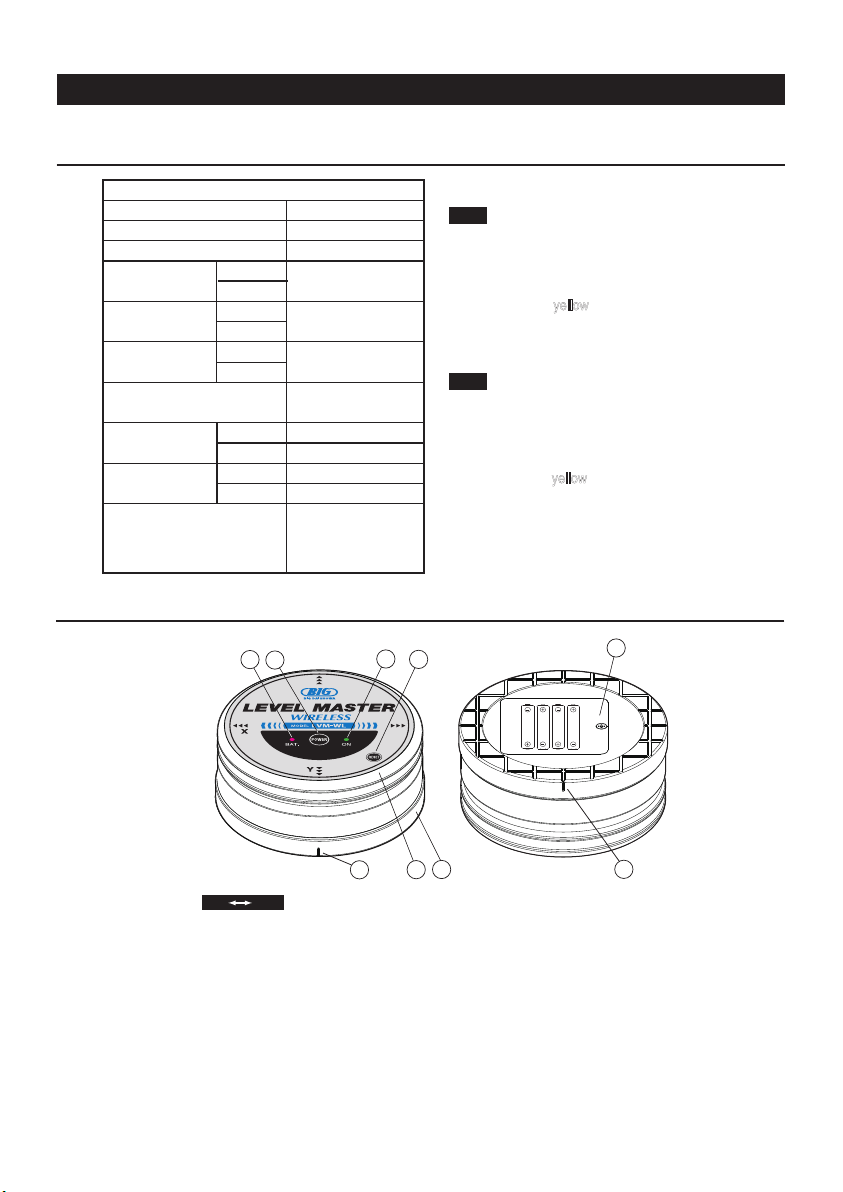

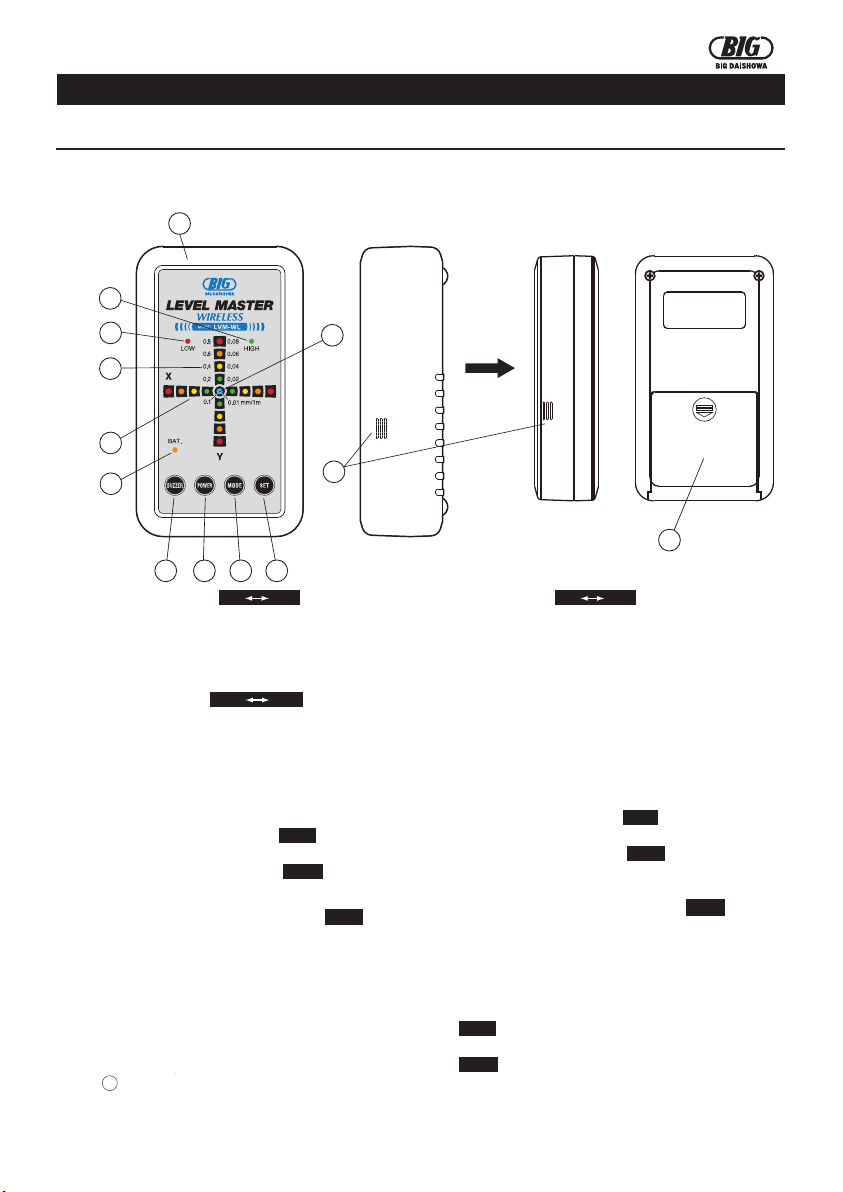

●Body

1.SPECIFICATIONS

●LED indicators

Blinking LED (red):Inclination exceeding 0.08mm/1m

Continuous LED (red):Inclination of 0.08mm/1m or less

Continuous LED (orange):

Inclination of 0.06mm/1m or less

Continuous LED(yellow):Inclination of 0.04mm or less

Continuous LED(green):Inclination of 0.02mm/1m or less

Continuous LED(blue):Inclination of 0.01mm/1m or less

mode

HIGH

mode

Blinking LED (red):Inclination exceeding 0.8mm/1m

Continuous LED (red): Inclination of 0.8mm/1m or less

Continuous LED (orange): Inclination of 0.6mm/1m or less

Continuous LED(yellow):Inclination of 0.4mm/1m or less

Continuous LED(green):Inclination of 0.2mm/1m or less

Continuous LED(blue):Inclination of 0.1mm/1m or less

LOW

SPECIFICATIONS - NAMES OF PARTS AND FUNCTIONS

Wireless system

0.01mm/1m

2.4GHz

φ109mm×H143mm

H143×W81×D43mm

0.99kg

0.28kg

LVM-WL

Body

Receiver

Body

Receiver

Body

Receiver

Body

Receiver

Body

Receiver

Specifications

Auto-power OFF

Operating temperature

Dimentions

Weight

Battery life

Power supply

Minimum readable value

Model

0℃~ 40℃

(

Recommended 20℃±5℃)

30 minutes after power

is turned on

30 hours

Alkaline dry battery

LR03 (AAA) x4

Included items

Operation manual

Aluminumstoragebox

2.NAMES OF PARTS AND FUNCTIONS

77

56

8

12

34

①POWER switch O

Push the POWER swtich to turn ON the power.

Push it again to turn OFF the power.

②Power LED

LED (green) is lighted during the power is ON.

⑦Line markers

They are used for determining the direction of the

X and Y axes.

⑧Batteries box

It is the location where the batteries are installed (LR03: AAA x4).

⑤Body base ⑥Body case

③Battery alarm LED

LED (orange) flickers to inform battery exchange time

when voltage falls below the prescribed value.

④RESET switch

ush to reset the measurement in case abnormality

occurs.

ON OFF

7.WARRANTY

Warranty period: 1 year from the delivery

However, the below situations are excluded from the warranty.

・If the device is subject to shocks or vibrations of 3G or more.

・If the device is intentionally disassembled.

・If damages and breakdowns are caused by unreasonable repairs or modifications

or in case of utilization errors.

・If after the purchase, damages and breakdowns are caused by moving, transporting or

dropping the product.

・In case of damages and breakdowns caused by fires, earthquakes, storms, floods,

lightning, seawater or other natural disasters.

WARRANTY,EMCINFORMATION

8.EMC INFORMATION

Class and Group Description of EN 55011

This is a group 1, class B product according to EN 55011. This means that this product does not

generate and/or use intentionally radio-frequency energy, in the form of electromagnetic

radiation, inductive and/or capacitive coupling, for the treatment of material or inspection /

analysis purpose and that it is suitable for use in domestic establishments and in establishments

directly connected to a low voltage power supply network which supplies buildings used for

domestic purposes.

Note: Since this product is battery operated, this product is not connected to this low voltage

power supply network.

Manufacturer Name : BIG DAISHOWA SEIKI CO LTD

Address : Nishiishikiricho 3-3-39, Higashiosakashi, Osaka, JAPAN

EU Name : BIG KAISER PRECISION TOOLING LTD.

Address : Glattalstrasse 516, 8153 Rümlang, Switzerland

Alkaline dry battery

: LR03 (AAA) x4

92

●Receiver

21

19

20

⑳

Protective

cover removed

15

911 12

13

10

16

17

14

18

⑨POWER switch

Push the POWER swtich to turn ON the

receiver, and the LED level indicator is lighted

and measurement becomes ready.

Push it again to turn OFF the power.

⑪MODE switch

Push the MODE switch to change the precision

level. The "HIGH" mode is selected when turning

ON the device.

⑫SET switch

This switch is used to execute the zeroadjustment.

⑮Mode LED

The LED (red) turns on when the LOW mode

is selected.

⑯Mode LED

The LED (green) turns on when the

HIGH

mode

is selected.

⑰Battery alarm LED

LED (orange) flickers to inform battery xchange

time when voltage falls below the prescribed

value.

⑩Buzzer sound ON OFF switch

Push it to turn ON the buzzer. Buzzer sounds

when leveled within 0.1 (LOW mode) or 0.01

(HIGH mode).

Push it again to turn OFF the buzzer.

ON OFF ON OFF

HIGH LOW

⑬

LED level indicators (X-axis)

They indicate the level status.

The inclination is between 0.8mm/1m and

0.1mm/1m in case of the LOW mode.

The inclination is between 0.08mm/1m and

0.01mm/1m in case of the HIGH mode.

⑭

LED level indicators (Y-axis)

They indicate the level status.

The inclination is between 0.8mm/1m and

0.1mm/1m in case of the LOW mode.

The inclination is between 0.08mm/1m and

0.01mm/1m in case of the HIGH mode.

⑳Buzzer sound

Outlet of buzzer sound.

⑱LED level indicator (Central position)

The LED (blue) turns on when the level status

reaches the central position.

The inclination is 0.1mm/1m or less in case of the

LOW mode.

The inclination is 0.01mm/1m or less in case of the

HIGH mode.

⑲Receiver case

21

Batteries box

It is the location where the batteries are installed

(LR03: AAA x4).

・Use a plate with good surface flatness to be sure to obtain a level within 0.01.

・Since the diameter of the LEVEL MASTER WIRELESS is φ109mm, if only 2μof dirt get caught by the

device, a distortion of 0.018mm for 1m will be generated.

・This device (Body/Receiver)is a precision instrument. Do not drop it or cause shocks to it. Also, after the

use, always apply antirust oil to its base and store it using the exclusive storage case.

・When storing the device(Body/Receiver), store it in an environment with a temperature between 0℃and

40℃.

・Since the device is a precision instrument, do not apply coolant to it. Also, after the use, do not leave it on

the machine table, plate or installation jig.

・Since the device(Body/Receiver)is a precision instrument, do not disassemble or modify the device.

Otherwise, its efficiency or lifespan may worsen and the warranty annulled.

・Remove the batteries if the device is not used for a long period.

・If accuracy problems or malfunctions occur, stop using the device and send it to using our

distributors for inspections and repairs.

SAFETY NOTES

6.SAFETY NOTES

SPECIFICATIONS - NAMES OF PARTS AND FUNCTIONS

3 8

③Insert 4 batteries (LR03: AAA) as indicated in the battery box.

④Slide and fit the cover.

②Slide to remove the cover of the battery box.

①Remove the protective cover.

[BUZZER]

[SET]

[POWER]

INSTALL THE BATTERIES

3.HOW TO INSTALL THE BATTERIES

●Body

②Insert the 4 batteries included (LR03: AAA) in the base of the

batteries box as indicated on the figure on the right.

③After have installed the batteries, insert the projecting part of the

cover into the recess of the batteries box. Then, secure the cover

by tightening the screw.

①Loose the screw of the cover of the batteries box.

Batteries box

Batteries box

Batteries

LR03 (AAA) x4

Cover

Projecting part

of the cover

Screw

Always check the polarity of the batteries. If the batteries

are inserted with the polarity inverted, the device may not

work and the internal electric circuit may get damaged

making the device not utilizable.

Always check the polarity of the batteries. If the batteries

are inserted with the polarity inverted, the device may not

work and the internal electric circuit may get damaged

making the device not utilizable.

Caution

Caution

●Receiver

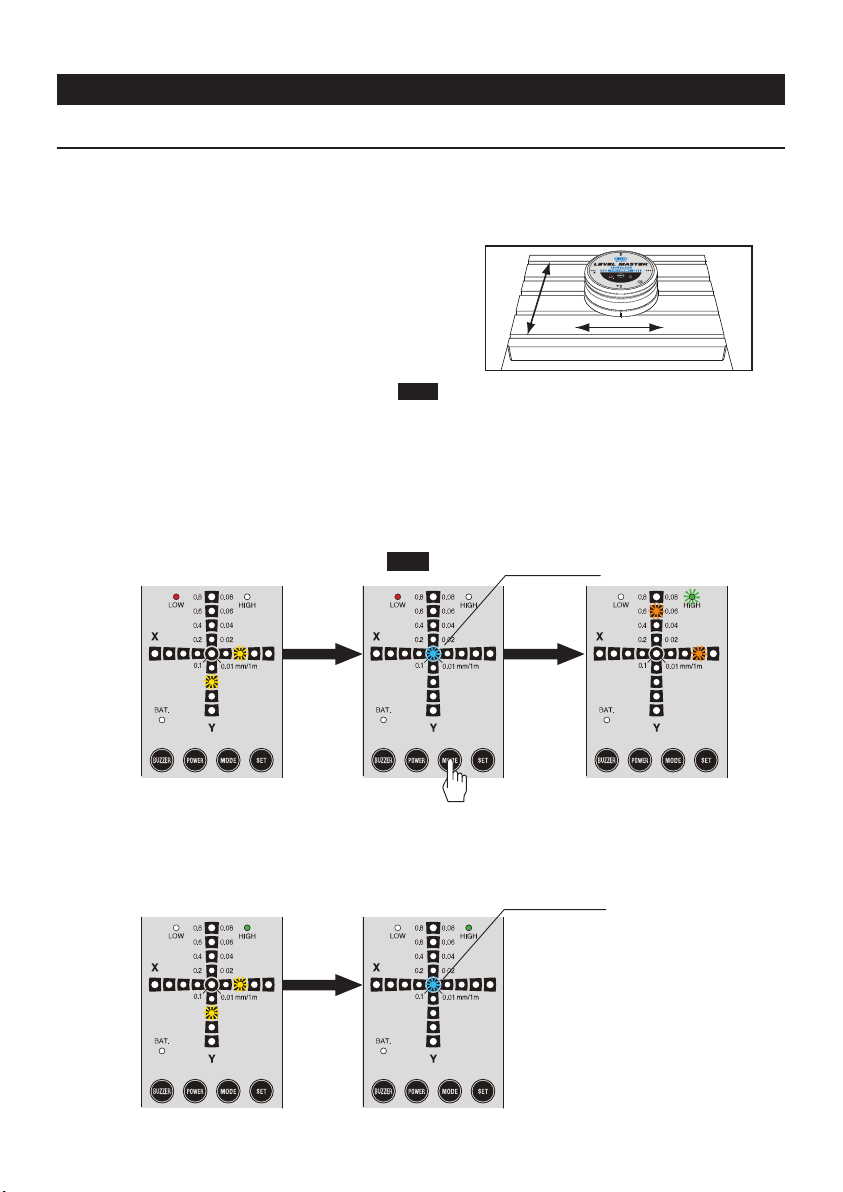

When the inclination is within 0.01( HIGH mode)

or within 0.1 (LOW mode), the LED (blue) turns

on and the buzzer emits a sound. It is possible to

turn on/off the buzzer's sound by using the

switch of the device.

5-2.How to turn on/off the buzzer《Receiver》

5-3.How to reset the device to its default values《Receiver》

To reset the device to its default values (delivery

condition), push the "SET" switch while turning ON the

power. The internal data are cleared.

OPERATIONS

74

T

u

r

n

b

y

1

8

0

°

T

u

r

n

b

y

1

8

0

°

④When power of the receiver is turned ON, LOW mode (inclination: 0.1mm - 0.8mm) is selected.

If the LED (red) in the 0.08. position blinks, inclination exceeds 0.8.

Levelling at

LOW mode

Change to

HIGH mode

Levelling at

HIGH mode

OPERATIONS

5.OPERATIONS

5-1.Levelling operation

①Remove oil, dirt, notches and marks from the machine table's surface and from the base of the device.

②Place the device carefully on the reference surface

parallel to the X and Y axes.

X-axis

Y-axis

③Push the POWER switch to turn ON the power of

Body/Receiver.

⑤Adjust the level in order to turn on the LED (blue) of the central position. When the LED (blue) turns

on, the inclination is within 0.1.

When the inclination of one of the axes is adjusted within 0.1, the LED (blue) turns on and the buzzer

emits a sound [Beep, beep].

When the inclination of both axes is within 0.1, the LED (blue) turns on and the buzzer emits a

sound [Beep-beep-beep].

HIGH

⑥Push the MODE switch to change to the mode.

⑦Adjust the level in order to turn on the LED (blue) of the central position.

When the inclination of one of the axes is adjusted within 0.01, the LED (blue) turns on and the

buzzer emits a sound [Beep, beep]. When the inclination of both axes is within 0.01, the LED

(blue) turns on and the buzzer emits a sound [Beep-beep-beep].

ContinuousLED(blue)

ContinuousLED(blue)

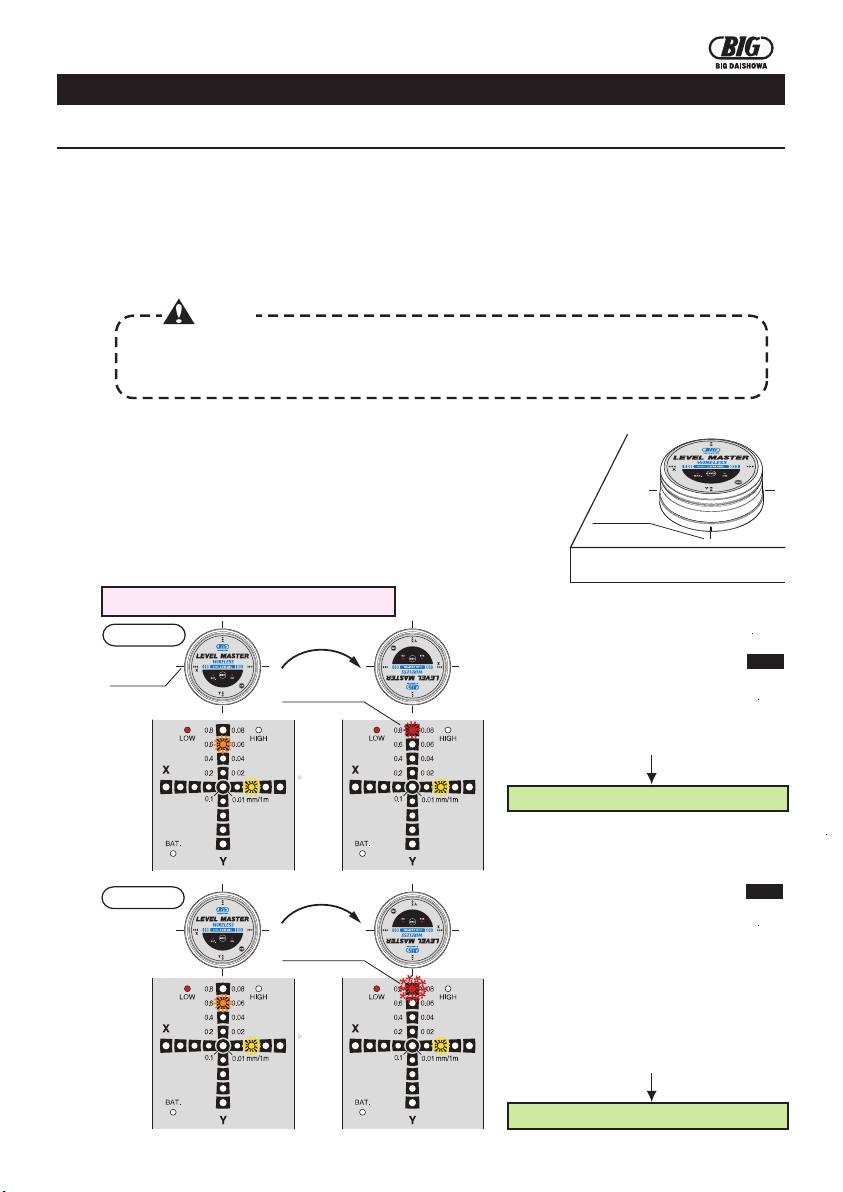

4.BEFORE USING THE DEVICE

BEFOREUSING THE DEVICE

4-1.Environmental settings

4-2.How to execute the zero adjustment

If there is a difference in the temperature between the storage location and the utilization location,

leave the device for a certain amount of time in the utilization location to perform the average

environmental settings (temperature, humidity).

When the Level MasterWireless(Body/Receiver) is turned on, depending on the utilization

environment and on the status of the reference surface measured, the level position may not be

always the "0" position (continuous blue LED). Execute every time the reference settings by

means of zero adjustment in accord with the utilization environment.

③Push the POWER switch to turn ON the power.(Body/Receiver)

④Execute the zero adjustment and the levelling checks following

the procedures below.

②Use as reference the line markers on the base of the Body and

mark 4 points in the X and Y directions on the reference surface.

4 markings

①Position the Body on the reference surface. When placing the

device, remove oil and dirt from its base and also remove notches,

oil and dirt from the reference surface of the precision plate.

(Example: If the difference in the temperature is 10℃, leave the device for 15~20 minutes.)

Caution

How to check the levelling value in LOW mode

Case 2

Case 1

marking

Blinking LED (red)

Continuous LED (red)

②The levelling value of both axes is

within 0.8 after turning the device by

180°.

①The levelling value of the X and Y axes

is within 0.8 after switching to the LOW

mode.

Go to P5 →How to execute the zero adjustment in LOW mode

Go to P5 →How to execute the zero adjustment in LOW mode

②The levelling value of one of the axes

exceeds 0.8 after turning the device by

180°.

①The levelling value of the X and Y axes

is within 0.8 after switching to the LOW

mode.

③Adjust the level of the reference

surface in order to obtain a levelling

value within 0.8 for both axes.

65

④

Rotate the Body by 180°using .

BEFORE USING THE DEVICE BEFORE USING THE DEVICE

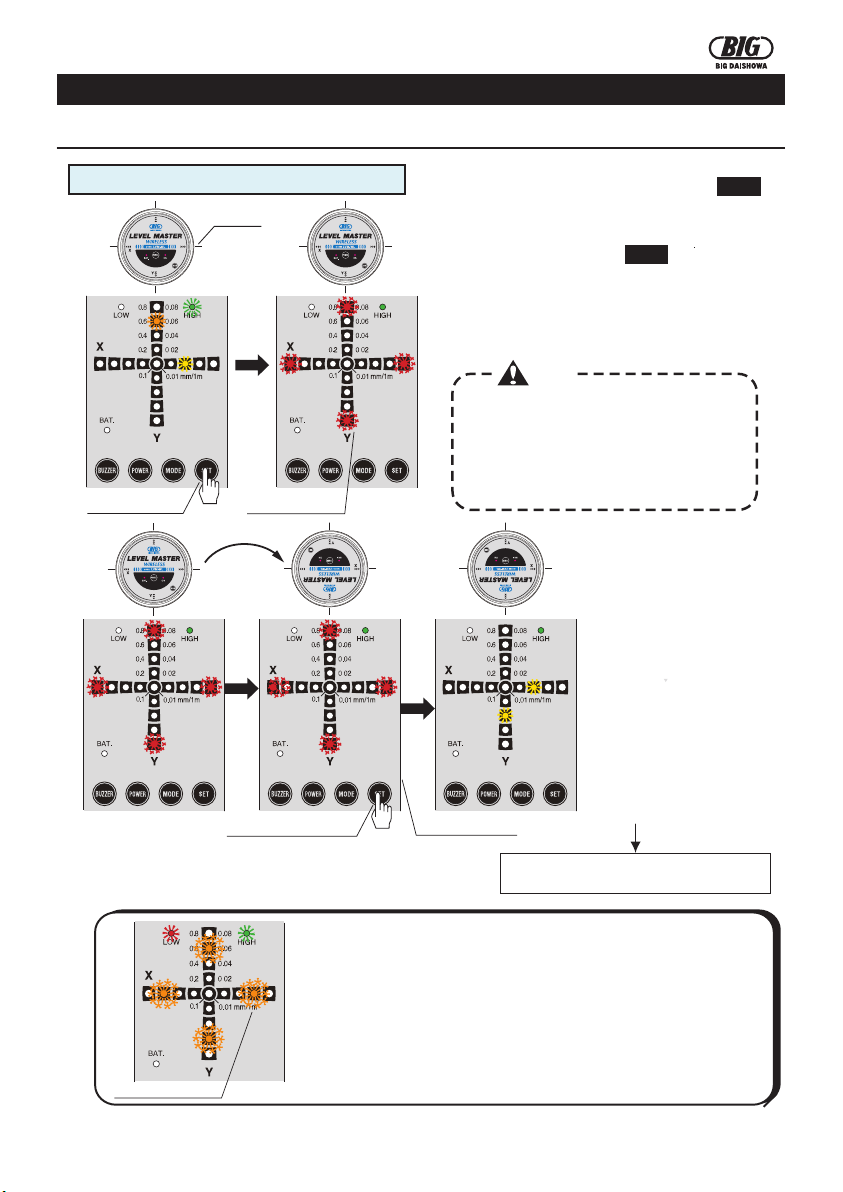

How to execute the zero adjustment in LOW mode

①Push the "SET" switch after 10 seconds.

The 4 external LEDs (red) start blinking.

When executing the "zero adjustment" in the

LOW mode, adjust the level in order to obtain

an inclination of the reference surface within

0.8 and then execute the "zero adjustment".

It is not possible to execute the "zero

adjustment" if the inclination exceeds 0.8.

Caution

marking marking

The 4 LEDs (red) start blinking The 4 LEDs (red) start blinking

Push the SET switch Push the SET switch

②Rotate the Body by 180°using

as reference the markings on the

reference surface.

Errors in the "zero adjustment"

may occur if the device is not

rotated correctly by 180°or if it is

not aligned with the markings.

③Push again the "SET" switch

after 10 seconds. The buzzer

will emit a "Beep" to notify

the completion of the

"zero adjustment".

Buzzer's sound "Beep" Buzzer's sound "Beep"

Push the SET switch Push the SET switch

Buzzer's sound

"Beep-beep-beep"

When the inclination of one of the axes is

adjusted within 0.1, the LED (blue) turns on

and the buzzer emits a sound [Beep, beep].

When the inclination of both axes is within

0.1, the LED (blue) turns on and the buzzer

emits a sound [Beep-beep-beep].

⑤Adjust the level of the reference surface in

order to obtain an inclination within 0.1 for

both axes.

Go to P6 →How to execute the zero adjustment in HIGH mode

Level adjustment of

the reference surface Continuous LED (blue)

How to execute the zero adjustment in HIGH mode

③Push the "SET" switch after 10 seconds.

The 4 external LEDs (red) start blinking.

Execute the levelling operation.

③Push again the "SET"

switch after 10 seconds.

The buzzer will emit a

"Beep" to notify the

completion of the

"zero adjustment".

④Rotate the device by180°

using asreference the

markings on the reference

surface.

Errors in the "zero

adjustment" may occur if

the device is not rotated

correctly by 180°

or if it is not aligned with the

markings.

The 4 LEDs (orange) start blinking

When executing the "zero adjustment" in

the HIGH mode, adjust the level in order to

obtain an inclination of the reference

surface within 0.08 and then execute the

"zero adjustment".

It is not possible to execute the "zero

adjustment" if the inclination exceeds 0.08.

Caution

In case of executing the "zero adjustment" in the LOW mode:

◆When the level exceeds 0.8

In case of executing the "zero adjustment" in the HIGH mode:

◆ When the level exceeds 0.08

In case of pushing the "SET" switch, turning the device by 180°

and pushing again the "SET" switch in the above situations, the 4

orange LEDs of 0.6 (for the LOW mode) / 0.06 (for the HIGH

mode) blink 4 times and at the same time the buzzer emit a

"be-be-be-be" sound to notify that it is not possible to execute the

setting operation.

①Push the MODE switch to change to the HIGH

mode.

②The levelling value of the X and Y axes is within

0.08 after switching to the HIGH mode.

T

u

r

n

b

y

1

8

0

°

T

u

r

n

b

y

1

8

0

°

T

u

r

n

b

y

1

8

0

°

65

④

Rotate the Body by 180°using .

BEFORE USING THE DEVICE BEFORE USING THE DEVICE

How to execute the zero adjustment in LOW mode

①Push the "SET" switch after 10 seconds.

The 4 external LEDs (red) start blinking.

When executing the "zero adjustment" in the

LOW mode, adjust the level in order to obtain

an inclination of the reference surface within

0.8 and then execute the "zero adjustment".

It is not possible to execute the "zero

adjustment" if the inclination exceeds 0.8.

Caution

marking marking

The 4 LEDs (red) start blinking The 4 LEDs (red) start blinking

Push the SET switch Push the SET switch

②Rotate the Body by 180°using

as reference the markings on the

reference surface.

Errors in the "zero adjustment"

may occur if the device is not

rotated correctly by 180°or if it is

not aligned with the markings.

③Push again the "SET" switch

after 10 seconds. The buzzer

will emit a "Beep" to notify

the completion of the

"zero adjustment".

Buzzer's sound "Beep" Buzzer's sound "Beep"

Push the SET switch Push the SET switch

Buzzer's sound

"Beep-beep-beep"

When the inclination of one of the axes is

adjusted within 0.1, the LED (blue) turns on

and the buzzer emits a sound [Beep, beep].

When the inclination of both axes is within

0.1, the LED (blue) turns on and the buzzer

emits a sound [Beep-beep-beep].

⑤Adjust the level of the reference surface in

order to obtain an inclination within 0.1 for

both axes.

Go to P6 →How to execute the zero adjustment in HIGH mode

Level adjustment of

the reference surface Continuous LED (blue)

How to execute the zero adjustment in HIGH mode

③Push the "SET" switch after 10 seconds.

The 4 external LEDs (red) start blinking.

Execute the levelling operation.

③Push again the "SET"

switch after 10 seconds.

The buzzer will emit a

"Beep" to notify the

completion of the

"zero adjustment".

④Rotate the device by180°

using asreference the

markings on the reference

surface.

Errors in the "zero

adjustment" may occur if

the device is not rotated

correctly by 180°

or if it is not aligned with the

markings.

The 4 LEDs (orange) start blinking

When executing the "zero adjustment" in

the HIGH mode, adjust the level in order to

obtain an inclination of the reference

surface within 0.08 and then execute the

"zero adjustment".

It is not possible to execute the "zero

adjustment" if the inclination exceeds 0.08.

Caution

In case of executing the "zero adjustment" in the LOW mode:

◆When the level exceeds 0.8

In case of executing the "zero adjustment" in the HIGH mode:

◆ When the level exceeds 0.08

In case of pushing the "SET" switch, turning the device by 180°

and pushing again the "SET" switch in the above situations, the 4

orange LEDs of 0.6 (for the LOW mode) / 0.06 (for the HIGH

mode) blink 4 times and at the same time the buzzer emit a

"be-be-be-be" sound to notify that it is not possible to execute the

setting operation.

①Push the MODE switch to change to the HIGH

mode.

②The levelling value of the X and Y axes is within

0.08 after switching to the HIGH mode.

T

u

r

n

b

y

1

8

0

°

T

u

r

n

b

y

1

8

0

°

T

u

r

n

b

y

1

8

0

°

74

T

u

r

n

b

y

1

8

0

°

T

u

r

n

b

y

1

8

0

°

④When power of the receiver is turned ON, LOW mode (inclination: 0.1mm - 0.8mm) is selected.

If the LED (red) in the 0.08. position blinks, inclination exceeds 0.8.

Levelling at

LOW mode

Change to

HIGH mode

Levelling at

HIGH mode

OPERATIONS

5.OPERATIONS

5-1.Levelling operation

①Remove oil, dirt, notches and marks from the machine table's surface and from the base of the device.

②Place the device carefully on the reference surface

parallel to the X and Y axes.

X-axis

Y-axis

③Push the POWER switch to turn ON the power of

Body/Receiver.

⑤Adjust the level in order to turn on the LED (blue) of the central position. When the LED (blue) turns

on, the inclination is within 0.1.

When the inclination of one of the axes is adjusted within 0.1, the LED (blue) turns on and the buzzer

emits a sound [Beep, beep].

When the inclination of both axes is within 0.1, the LED (blue) turns on and the buzzer emits a

sound [Beep-beep-beep].

HIGH

⑥Push the MODE switch to change to the mode.

⑦Adjust the level in order to turn on the LED (blue) of the central position.

When the inclination of one of the axes is adjusted within 0.01, the LED (blue) turns on and the

buzzer emits a sound [Beep, beep]. When the inclination of both axes is within 0.01, the LED

(blue) turns on and the buzzer emits a sound [Beep-beep-beep].

ContinuousLED(blue)

ContinuousLED(blue)

4.BEFORE USING THE DEVICE

BEFOREUSING THE DEVICE

4-1.Environmental settings

4-2.How to execute the zero adjustment

If there is a difference in the temperature between the storage location and the utilization location,

leave the device for a certain amount of time in the utilization location to perform the average

environmental settings (temperature, humidity).

When the Level MasterWireless(Body/Receiver) is turned on, depending on the utilization

environment and on the status of the reference surface measured, the level position may not be

always the "0" position (continuous blue LED). Execute every time the reference settings by

means of zero adjustment in accord with the utilization environment.

③Push the POWER switch to turn ON the power.(Body/Receiver)

④Execute the zero adjustment and the levelling checks following

the procedures below.

②Use as reference the line markers on the base of the Body and

mark 4 points in the X and Y directions on the reference surface.

4 markings

①Position the Body on the reference surface. When placing the

device, remove oil and dirt from its base and also remove notches,

oil and dirt from the reference surface of the precision plate.

(Example: If the difference in the temperature is 10℃, leave the device for 15~20 minutes.)

Caution

How to check the levelling value in LOW mode

Case 2

Case 1

marking

Blinking LED (red)

Continuous LED (red)

②The levelling value of both axes is

within 0.8 after turning the device by

180°.

①The levelling value of the X and Y axes

is within 0.8 after switching to the LOW

mode.

Go to P5 →How to execute the zero adjustment in LOW mode

Go to P5 →How to execute the zero adjustment in LOW mode

②The levelling value of one of the axes

exceeds 0.8 after turning the device by

180°.

①The levelling value of the X and Y axes

is within 0.8 after switching to the LOW

mode.

③Adjust the level of the reference

surface in order to obtain a levelling

value within 0.8 for both axes.

3 8

③Insert 4 batteries (LR03: AAA) as indicated in the battery box.

④Slide and fit the cover.

②Slide to remove the cover of the battery box.

①Remove the protective cover.

[BUZZER]

[SET]

[POWER]

INSTALL THE BATTERIES

3.HOW TO INSTALL THE BATTERIES

●Body

②Insert the 4 batteries included (LR03: AAA) in the base of the

batteries box as indicated on the figure on the right.

③After have installed the batteries, insert the projecting part of the

cover into the recess of the batteries box. Then, secure the cover

by tightening the screw.

①Loose the screw of the cover of the batteries box.

Batteries box

Batteries box

Batteries

LR03 (AAA) x4

Cover

Projecting part

of the cover

Screw

Always check the polarity of the batteries. If the batteries

are inserted with the polarity inverted, the device may not

work and the internal electric circuit may get damaged

making the device not utilizable.

Always check the polarity of the batteries. If the batteries

are inserted with the polarity inverted, the device may not

work and the internal electric circuit may get damaged

making the device not utilizable.

Caution

Caution

●Receiver

When the inclination is within 0.01( HIGH mode)

or within 0.1 (LOW mode), the LED (blue) turns

on and the buzzer emits a sound. It is possible to

turn on/off the buzzer's sound by using the

switch of the device.

5-2.How to turn on/off the buzzer《Receiver》

5-3.How to reset the device to its default values《Receiver》

To reset the device to its default values (delivery

condition), push the "SET" switch while turning ON the

power. The internal data are cleared.

OPERATIONS

92

●Receiver

21

19

20

⑳

Protective

cover removed

15

911 12

13

10

16

17

14

18

⑨POWER switch

Push the POWER swtich to turn ON the

receiver, and the LED level indicator is lighted

and measurement becomes ready.

Push it again to turn OFF the power.

⑪MODE switch

Push the MODE switch to change the precision

level. The "HIGH" mode is selected when turning

ON the device.

⑫SET switch

This switch is used to execute the zeroadjustment.

⑮Mode LED

The LED (red) turns on when the LOW mode

is selected.

⑯Mode LED

The LED (green) turns on when the

HIGH

mode

is selected.

⑰Battery alarm LED

LED (orange) flickers to inform battery xchange

time when voltage falls below the prescribed

value.

⑩Buzzer sound ON OFF switch

Push it to turn ON the buzzer. Buzzer sounds

when leveled within 0.1 (LOW mode) or 0.01

(HIGH mode).

Push it again to turn OFF the buzzer.

ON OFF ON OFF

HIGH LOW

⑬

LED level indicators (X-axis)

They indicate the level status.

The inclination is between 0.8mm/1m and

0.1mm/1m in case of the LOW mode.

The inclination is between 0.08mm/1m and

0.01mm/1m in case of the HIGH mode.

⑭

LED level indicators (Y-axis)

They indicate the level status.

The inclination is between 0.8mm/1m and

0.1mm/1m in case of the LOW mode.

The inclination is between 0.08mm/1m and

0.01mm/1m in case of the HIGH mode.

⑳Buzzer sound

Outlet of buzzer sound.

⑱LED level indicator (Central position)

The LED (blue) turns on when the level status

reaches the central position.

The inclination is 0.1mm/1m or less in case of the

LOW mode.

The inclination is 0.01mm/1m or less in case of the

HIGH mode.

⑲Receiver case

21

Batteries box

It is the location where the batteries are installed

(LR03: AAA x4).

・Use a plate with good surface flatness to be sure to obtain a level within 0.01.

・Since the diameter of the LEVEL MASTER WIRELESS is φ109mm, if only 2μof dirt get caught by the

device, a distortion of 0.018mm for 1m will be generated.

・This device (Body/Receiver)is a precision instrument. Do not drop it or cause shocks to it. Also, after the

use, always apply antirust oil to its base and store it using the exclusive storage case.

・When storing the device(Body/Receiver), store it in an environment with a temperature between 0℃and

40℃.

・Since the device is a precision instrument, do not apply coolant to it. Also, after the use, do not leave it on

the machine table, plate or installation jig.

・Since the device(Body/Receiver)is a precision instrument, do not disassemble or modify the device.

Otherwise, its efficiency or lifespan may worsen and the warranty annulled.

・Remove the batteries if the device is not used for a long period.

・If accuracy problems or malfunctions occur, stop using the device and send it to using our

distributors for inspections and repairs.

SAFETY NOTES

6.SAFETY NOTES

SPECIFICATIONS - NAMES OF PARTS AND FUNCTIONS

110

●Body

1.SPECIFICATIONS

●LED indicators

Blinking LED (red):Inclination exceeding 0.08mm/1m

Continuous LED (red):Inclination of 0.08mm/1m or less

Continuous LED (orange):

Inclination of 0.06mm/1m or less

Continuous LED(yellow):Inclination of 0.04mm or less

Continuous LED(green):Inclination of 0.02mm/1m or less

Continuous LED(blue):Inclination of 0.01mm/1m or less

mode

HIGH

mode

Blinking LED (red):Inclination exceeding 0.8mm/1m

Continuous LED (red): Inclination of 0.8mm/1m or less

Continuous LED (orange): Inclination of 0.6mm/1m or less

Continuous LED(yellow):Inclination of 0.4mm/1m or less

Continuous LED(green):Inclination of 0.2mm/1m or less

Continuous LED(blue):Inclination of 0.1mm/1m or less

LOW

SPECIFICATIONS - NAMES OF PARTS AND FUNCTIONS

Wireless system

0.01mm/1m

2.4GHz

φ109mm×H143mm

H143×W81×D43mm

0.99kg

0.28kg

LVM-WL

Body

Receiver

Body

Receiver

Body

Receiver

Body

Receiver

Body

Receiver

Specifications

Auto-power OFF

Operating temperature

Dimentions

Weight

Battery life

Power supply

Minimum readable value

Model

0℃~ 40℃

(

Recommended 20℃±5℃)

30 minutes after power

is turned on

30 hours

Alkaline dry battery

LR03 (AAA) x4

Included items

Operation manual

Aluminumstoragebox

2.NAMES OF PARTS AND FUNCTIONS

77

56

8

12

34

①POWER switch O

Push the POWER swtich to turn ON the power.

Push it again to turn OFF the power.

②Power LED

LED (green) is lighted during the power is ON.

⑦Line markers

They are used for determining the direction of the

X and Y axes.

⑧Batteries box

It is the location where the batteries are installed (LR03: AAA x4).

⑤Body base ⑥Body case

③Battery alarm LED

LED (orange) flickers to inform battery exchange time

when voltage falls below the prescribed value.

④RESET switch

ush to reset the measurement in case abnormality

occurs.

ON OFF

7.WARRANTY

Warranty period: 1 year from the delivery

However, the below situations are excluded from the warranty.

・If the device is subject to shocks or vibrations of 3G or more.

・If the device is intentionally disassembled.

・If damages and breakdowns are caused by unreasonable repairs or modifications

or in case of utilization errors.

・If after the purchase, damages and breakdowns are caused by moving, transporting or

dropping the product.

・In case of damages and breakdowns caused by fires, earthquakes, storms, floods,

lightning, seawater or other natural disasters.

WARRANTY,EMCINFORMATION

8.EMC INFORMATION

Class and Group Description of EN 55011

This is a group 1, class B product according to EN 55011. This means that this product does not

generate and/or use intentionally radio-frequency energy, in the form of electromagnetic

radiation, inductive and/or capacitive coupling, for the treatment of material or inspection /

analysis purpose and that it is suitable for use in domestic establishments and in establishments

directly connected to a low voltage power supply network which supplies buildings used for

domestic purposes.

Note: Since this product is battery operated, this product is not connected to this low voltage

power supply network.

Manufacturer Name : BIG DAISHOWA SEIKI CO LTD

Address : Nishiishikiricho 3-3-39, Higashiosakashi, Osaka, JAPAN

EU Name : BIG KAISER PRECISION TOOLING LTD.

Address : Glattalstrasse 516, 8153 Rümlang, Switzerland

Alkaline dry battery

: LR03 (AAA) x4

Precision Electronic Level

LVM-18052101

C

E

R

T

I

F

I

E

D

M

A

N

A

G

E

M

E

N

T

S

Y

S

T

E

M

QUAL I T Y SYST EM

JQA-QM3913

FADept.

■EXPORT DEPT.

Takaramachi5-2,HigasiosakasiOsaka579-8025JAPAN

Phone:072-982-8277Fax:072-982-8370

Operation manual

Thank you for using Level Master Wireless(LVM-WL).

Please handle it as a measuring instrument and utilize it for long time.

Please be sure to read this manual before using the device and also keep it in a

location where all the operators may consult it in case of necessity.

INDEX

1. SPECIFICATIONS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ P 1

2. NAMES OF PARTS AND FUNCTIONS ・・・・・・・・・・・・・・・・・・・・・・ P 1~P 2

3. HOW TO INSTALL THE BATTERIES ・・・・・・・・・・・・・・・・・・・・・・・・・・・・ P 2

4. BEFORE USING THE DEVICE

P 3

P 3~P 6

5. OPERATIONS

P 8

P 7~P 8

5-1. Levelling operation

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

4-1. Environmental settings

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

4-2. How to execute the zero adjustment

・・・・・・・・・・・・・・・・・・・

5-2. How to turn on/off the buzzer

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

5-3. How to reset the device to its default values

・・・・・・・・・・・・・・・・・・ P 8

6. SAFETY NOTES ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ P 9

7. WARRANTY ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ P10

8. EMC INFORMATION ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ P10

This manual suits for next models

1

Table of contents

Other Big Daishowa Laser Level manuals

Popular Laser Level manuals by other brands

geo-FENNEL

geo-FENNEL MULTI-LINER FL 55 PLUS HP user manual

Endress+Hauser

Endress+Hauser Liquicap M FMI51 operating instructions

Leica

Leica Rugby 320 SG user manual

LaserLiner

LaserLiner AutoCross Laser ACL 2 operating instructions

Hilti

Hilti PR 35 operating instructions

GOBLIN TOOLS

GOBLIN TOOLS CLX-PG22 instruction manual