3

BIJUR DELIMON INTERNATIONAL

(919) 465 4448 LOCAL

(800) 631 0168 TOLL-FREE

(919) 465 0516 FAX

WWW.BIJURDELIMON.COM/MOBILE

1 Copley Parkway, Suite 104

Morrisville, NC 27560

35993 • R6 04/19

Maintenance

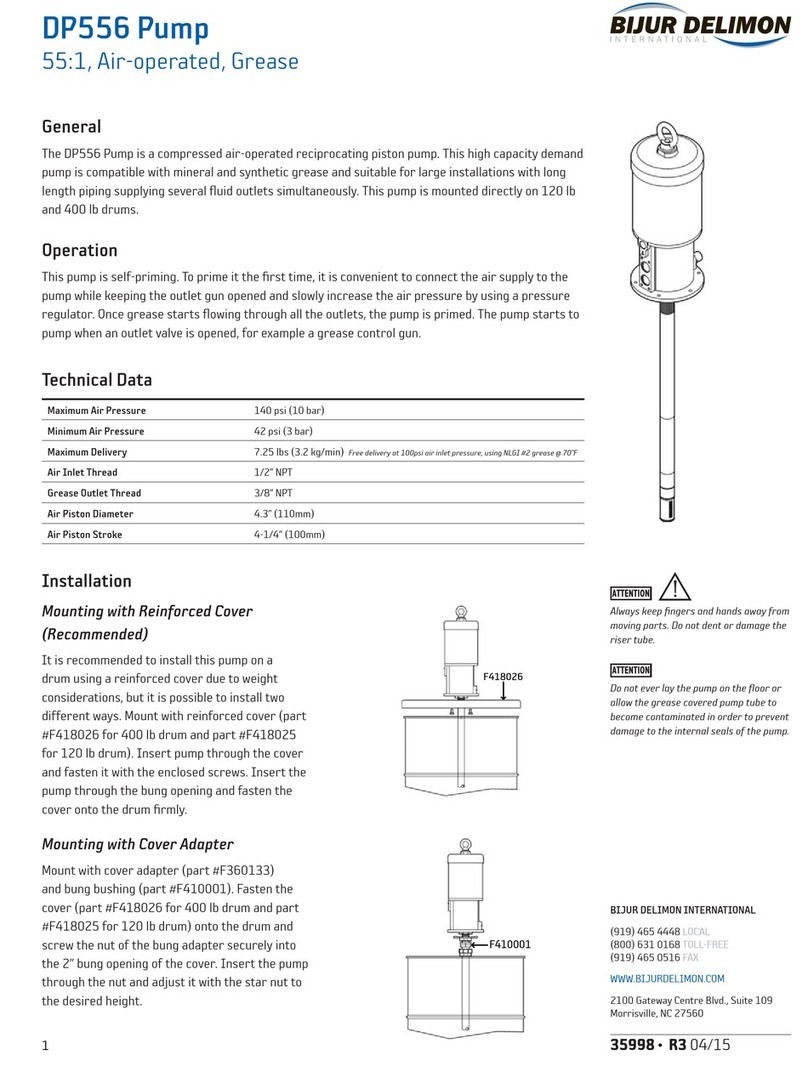

Separate the Air Motor from the Pump

1. Unscrew and remove the grease outlet adapter and the air inlet adapter. Remove the air

motor cover.

2. Mount the pump to a vise in horizontal position, securing it on the suction tube (47).

3. Unscrew the priming cylinder (60) from the priming filter head (57).

4. Unscrew the air motor body (15) from the suction tube (47) using a threaded rod or a pipe

wrench, and pull it out until it stops. The union nut (37) will be visible after cleaning the grease

from the rod.

5. Slide an open end wrench over the flats of the lower part of the air piston (36) and unscrew the

nut (59) and remove the washer (58).

6. Remove the large roll pin (38) located in the upper part of the union nut (37) and unscrew the air

motor body (15) from the suction tube assembly. (See drawing on right.)

Foot Valve

1. Unscrew the foot tube (53) with the priming filter (57) from the high pressure cylinder (51).

Attach the foot tube to the vise, unscrew the priming filter (57), remove the foot valve seat (56),

the foot valve assembly (55) and the valve washer (54).

2. Clean these parts, replace if damaged. Assemble the pump following the previous instructions,

reversing each step. (Note the position of (55 and 56) on page 5 – the mating surfaces are

ground flat and the conical surfaces are opposed.)

Pressure Check Valve

1. Insert a steel rod (ø4mm recommended) through the lower grease by-pass hole in the high-

pressure piston (44) and unscrew it from the grease valve body (40).

2. Clean the check ball (43) and its seat in the high pressure piston (44). If damaged, replace all the

affected parts.

3. If the high pressure piston (44) is scored, unscrew the high pressure cylinder (51) from the

suction tube (47) and from the foot tube (53) and replace it. Assemble the pump following the

previous instructions, reversing each step.

Inverting Set and Air Motor

1. Secure the air motor body (15) and loosen the five 4mm screws (29) to remove the air

motor dolly (1).

2. Slide an open-end wrench over the flats of the lower part of the air piston (36). With second

wrench unscrew the air piston nut (2) and remove the parts (2-5).

3. Pull the air piston rod (36) down and out of the air motor body (15).

4. Unscrew the toggle nut (27) from the air motor body (15) and remove the parts (23-27).

5. Unscrew the 3mm allen screws (22) and remove the parts (16-21).

Packing Set and O-ring

1. Follow the procedure for the air motor until the air piston rod (36) has been removed from the

air motor body.

2. Remove the packing set (32-35) and the seal O-ring (31). Replace these parts and clean the seat

of the seal O-ring (31).

Refer to page 5 for parts reference.

Before starting any kind of maintenance

or repair, disconnect the compressed air

supply and open a downstream valve to

relieve the grease pressure.

The high-pressure piston and cylinder

must always be replaced at the same

time; they are a matched set.

It is important that the packing set and

O-ring are mounted in the correct order:

First locate the O-ring in the correct

position inside the motor body and use a

dab of grease to hold it in position. Then

install the large and small packing set.

Unscrew intake filter tube from intake

filter head

Unscrew air motor body from suction tube

Unscrew nut, remove washer

Remove pin, unscrew air motor body

PM3 Pump

55:1, Air-operated, Grease