8

Peristaltic pumps Series M300 / T300

1.0 General

The following instructions refer only to the

peristaltic pump M300 and T300.

Since the pumps will be used in combination

with other assemblies, such as combustion

engines and electric motors, you must strictly

observe and comply with the operating and

maintenance instructions for these

components as well as the corresponding

notes on safe and reliable operation.

These on-hand instructions contain

information for installation, operation and

maintenance of ELRO pumps.

You should thoroughly read these

instructions before use and always follow the

information contained therein.

All personnel involved in activities on pump

or equipment must have read this manual,

especially the chapter ”Safety” before

starting work. This applies especially for

persons who work on the pump only

occasionally, e.g. for maintenance and

cleaning work.

Each pump is subjected to stringent

inspections and function tests before

leaving the factory.

You should always bear in mind that the

correct function, long lifetime and optimal

operational reliability of the pump mainly

depend on

correct installation

correct commissioning

and proper maintenance.

Enquiries concerning service, spare parts

or repairs should be addressed to the

manufacturer or an authorized dealer.

Always provide the following information:

Pump type

Serial number of pump

This information is stamped on the

identification plate on the base of the pump.

When returning pumps or pump parts to the

manufacturer or an authorized dealer for

repair or overhaul, the delivery must be

accompanied by a certificate stating that

the pump is free of product or other aggres-

sive or hazardous substances.

1.1 Warranty

Each ELRO peristaltic pump is checked in

the factory before shipment. The

manufacturer assumes warranty for his

product as specified in the effective terms

of sales and delivery. Faults resulting from

the non-compliance with the afore

mentioned regulations and notes can only

be rectified at the cost of the customer.

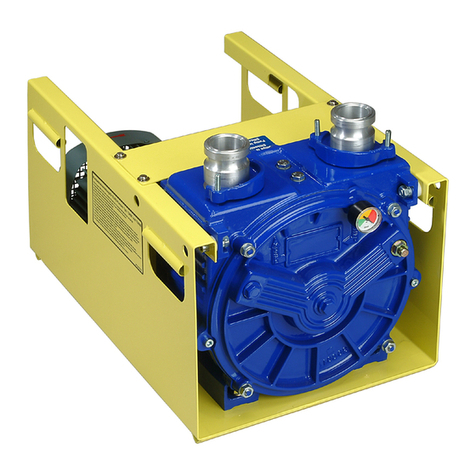

Fig. 1: Exemplary installation for peristaltic