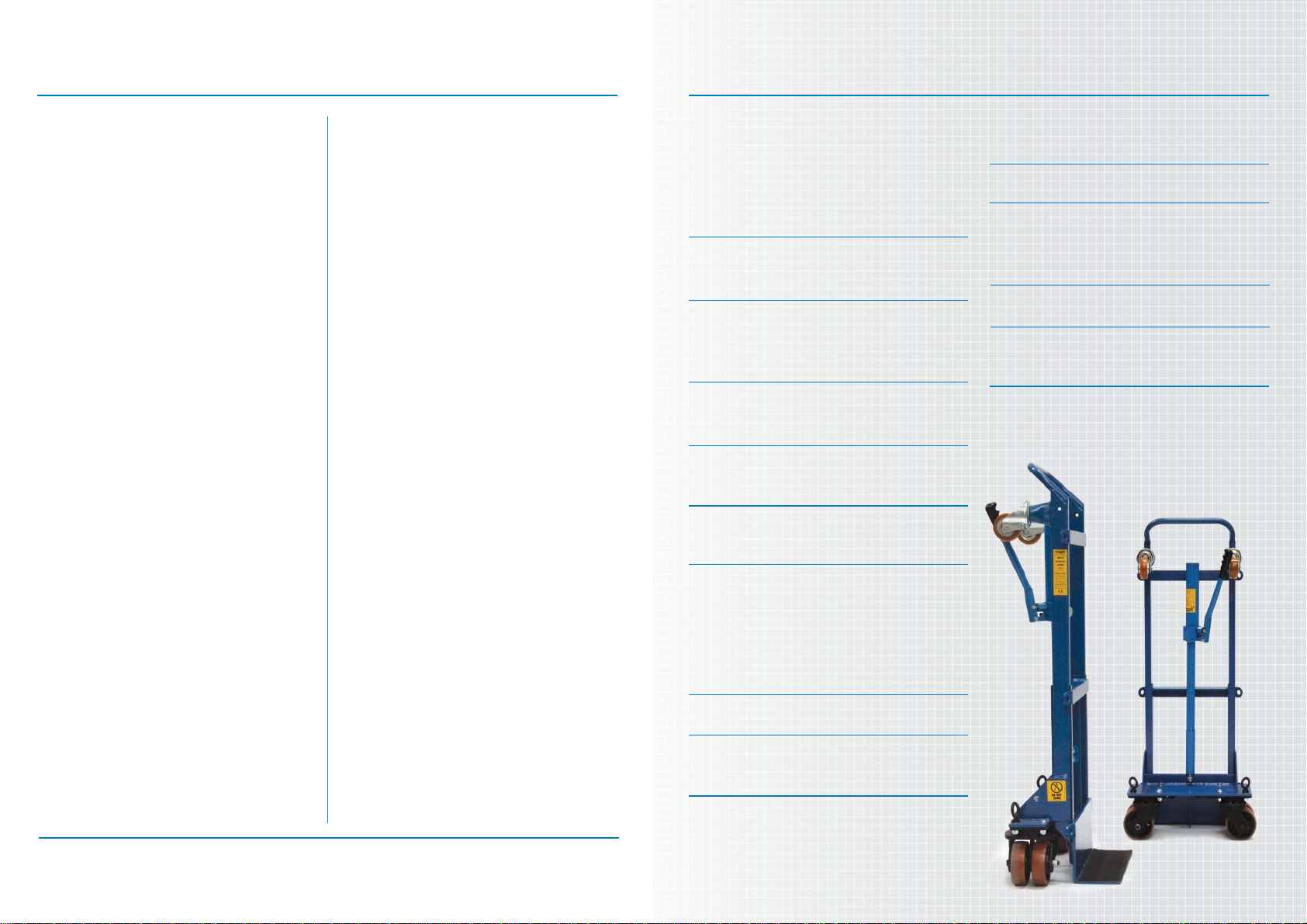

Skoots operating instructions Remember

1. Ensuretheloadiswithinthesafe

workingcapacityoftheskoots,all

floorareasaresuitableforthetotal

loadandtherouteisclearofall

hazards.

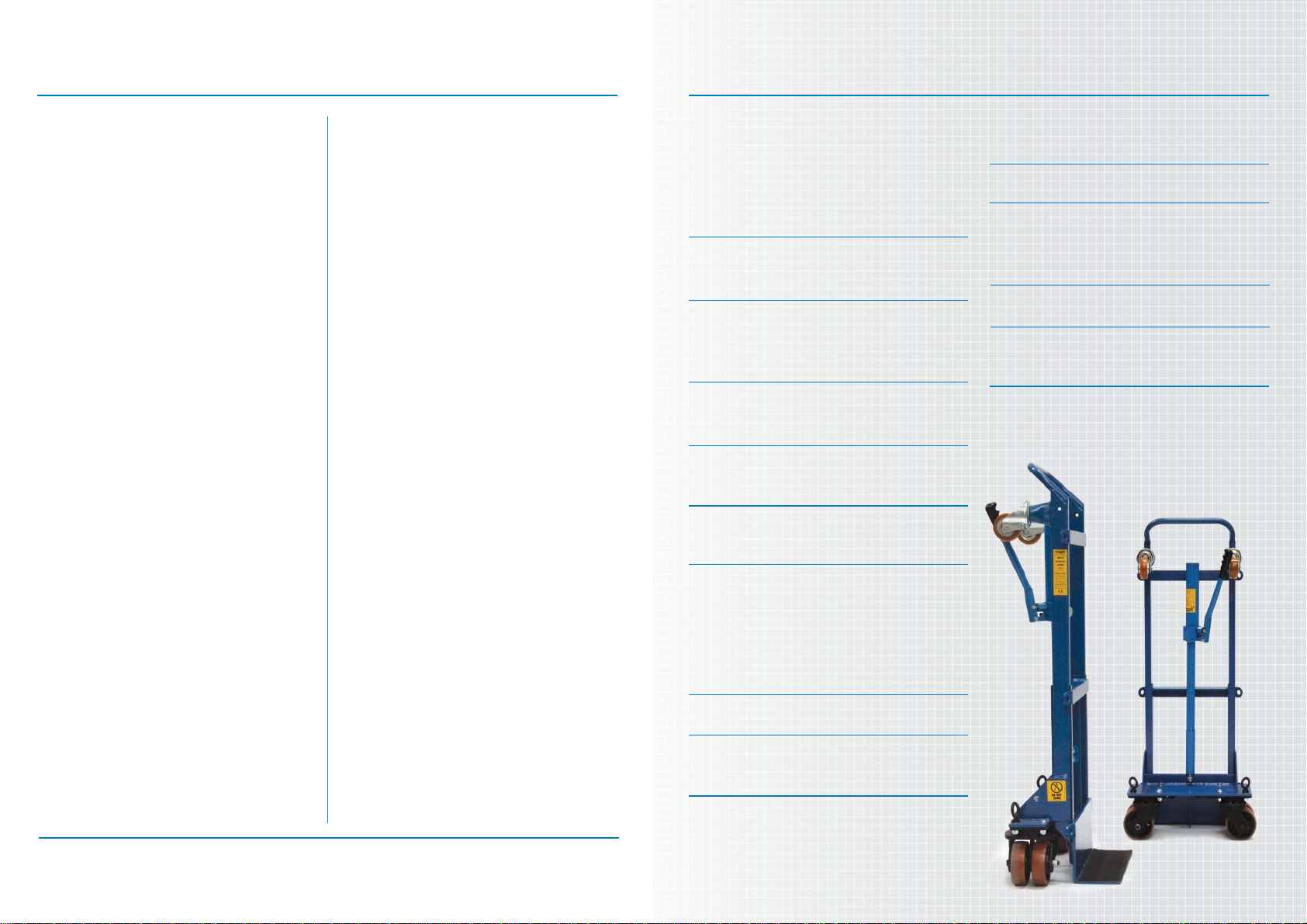

2. PlaceSkootsunitscentrallyunder

eachendoftheloadensuringthatthe

loadislocatedfirmlyintheheelof

thetoeplate.

3. Secureloadusingbothstraps,

ensuringtheyarehookedintothe

eyeboltsateachendandcrossatthe

backoftheSkootsunits.

4. PullstraptightsothattheSkoots

unitsarehardagainsttheload,and

closetheover-cambuckletolock.

Theloadisnowreadyforlifting.

5. Tightenthevalvewheel(clockwise)on

thesideofthejackunitsatbothends

toclosethevalve.

6. Usethepumphandlesonthejacksto

lifttheloadtoobtainminimumground

clearance.Liftevenly,alternating

eachend,tokeeploadhorizontal.

7. Youmaynowmovetheload,pushing

ratherthanpulling.

8. Makesurethatcontrolandstability

oftheloadismaintainedatalltimes.

Oncambersandslopesusethe

directionallocks*fittedtothecastors.

9. Oncetheloadisinposition,release

thevalvewheelsapproximatelyone

quarterturnanti-clockwise,

rememberingthatthelessopenthe

releasevalvestheslowertheloadis

lowered.

10. Releaseandremovethestrapsfrom

theSkoots,andthentheSkoots

fromtheload.

11. Skootsshouldbestoredinanupright

position.

12. WhenusingaSkootasasackbarrow

engagedirectionallockswithwheels

facingtowardstherearoftheunit.

Donotexceedloadcapacityshown

onwarninglabel.

13. IfusingaSkootasatrolley**

engagedirectionallockswithwheels

facingtowardstherearoftheunit.

Pullsprung-loadedringattopof

framestoremovedrawhandle.Lay

unitonitsbackandrefitdrawhandle

fromtopofframe.

•Donotexceedloadcapacityshownonwarninglabel.

Always...

Beforeuseregularlycheckskootsfor

looseormissingnutsandbolts,stress

cracks,brokenwelds,worntyresand

bearingsandgeneralwearandtear.

Keepwithinthesafeworkingloadas

designatedonthesideoftheskootsunits.

Keeptheworkingareafreefromhazards,

suchasdebris,electricalcables,potholes,

deepgullies,etc.

Lifttheloadevenlyanduseminimum

groundclearance.

Ensureyoucanseewhereyouaregoing

orgetacolleaguetohelpandguideyou.

Usearampwhennegotiatingakerbor

steps.

StoreSkootsinanuprightposition.

Never...

Underestimateweightandoverloadthe

Skootsunits.

Usewornordefectivestraps.

Raisetheloadwithoutitbeingsecurely

strapped.

Raisetheloadhigherthannecessary.

Placeyourhandsorfeetundertheloador

movingpartswhentheloadisraised.

UseSkootsonasteephillorincline.

Movetheloadfasterthanitissafe,to

ensureyoucankeepitundercontroland

upright.

Leavearaisedloadunattended.

Attachcranesorotherliftingtackleto

Skootsunits.

Interferewiththesealsorhydraulics.

* Not applicable on SK300N

** Only applicable on SK600

–

SK2000 models