SAFETY__________________________

Improper operation can cause serious

injury or death.

Pre-operation

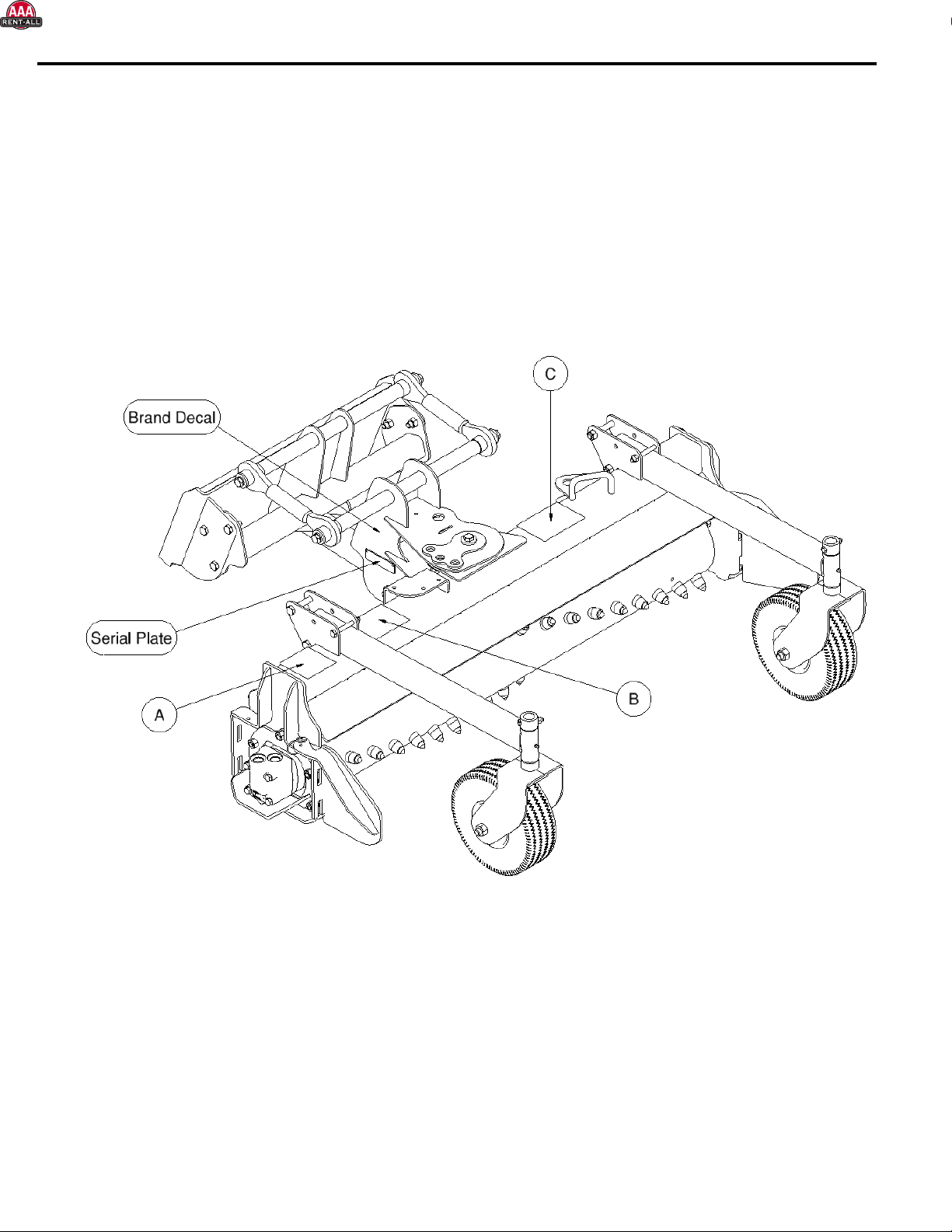

This attachment is designed to be used for

seedbed preparation by leveling and

pulverizing the top layer of soil. It is not

designed to be used as a deep soil tiller.

NEVER use this machine for any other

purpose.

Read the operator’s manual for the “Skid Steer

Loader.” NEVER allow untrained people to

operate.

Operating instructions must be given to everyone

before operating this attachment and at least

once a year thereafter in accordance with OSHA

regulations.

NEVER exceed the maximum recommended

input power or speed specifications for the

attachment. Over-powering or over-speeding the

attachment may cause personal injury and/or

machine damage.

Keep all shields, guards, and covers in place.

Do not modify equipment or add attachments that

are not approved by Quick Attach Attachments

LLC.

Use adequate safety warning lights and devices

as required by local regulations.Obey all local

laws and regulations regarding machine

operation on public property. Always call before

you dig (1-888-258-0808). When you call, you

will be directed to a location in your state/city for

information about buried lines (electric,

telephone, cable TV, water, sewer, gas, etc.).

Operation

Always wear eye protection that meets z87.1 or

use with a loader enclosure that provides similar

protection.

Hydraulic connections may be hot after use. Use

gloves if connecting or disconnecting after use.

Check and be sure all operating controls are in

neutral before starting the engine.

Operation (continued)

Keep people away from loader, attachment and

discharge when in use. This attachment sends

objects flying and has rotating parts. NEVER

direct discharge toward people –rocks and debris

can be thrown.

NEVER operate near embankments or terrain

that is so steep that rollover could occur.

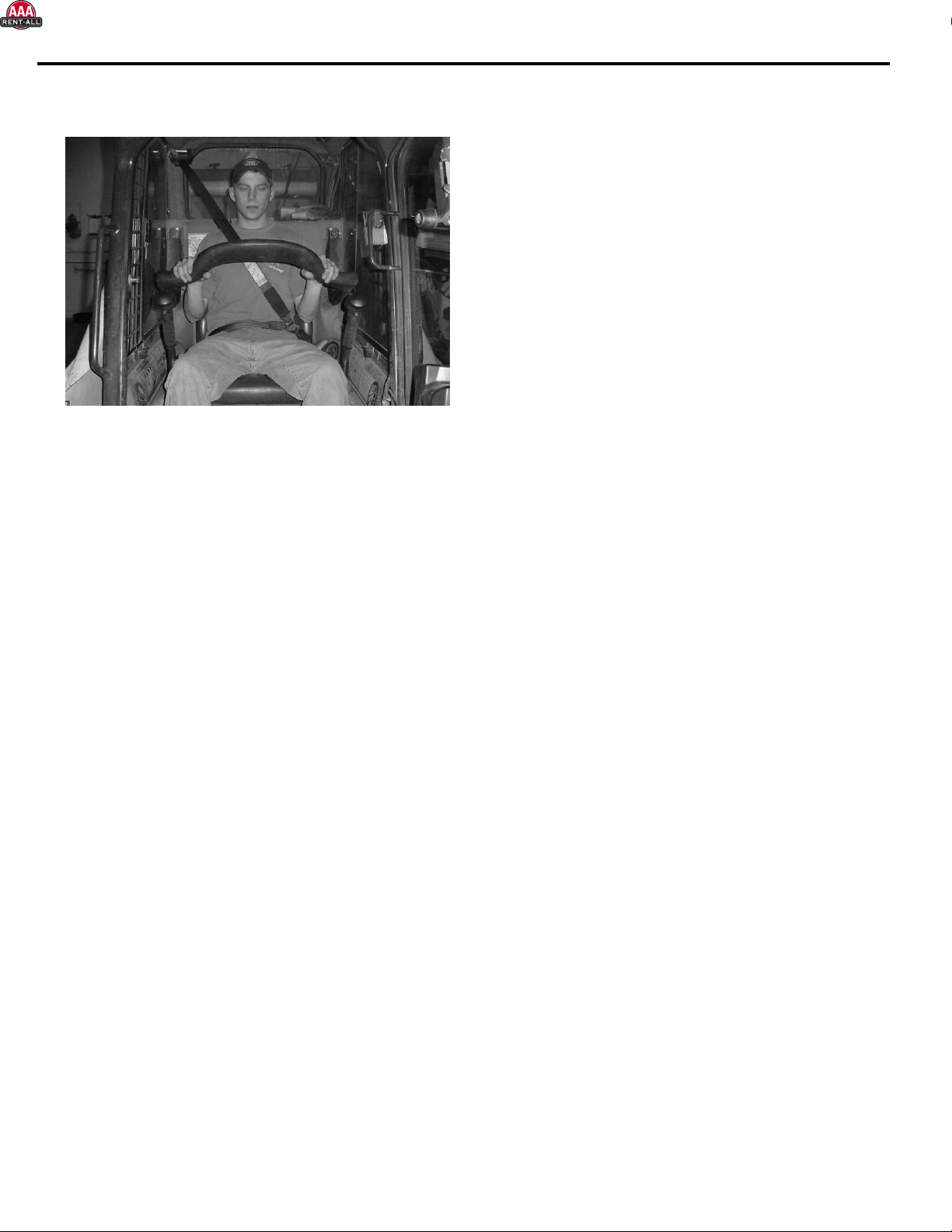

Always stay in the operator position when using

the attachment. If you are using a walk-behind

loader, stay behind the loader at the controls

while operating.

Before leaving the operators position, disengage

hydraulic drive, lower the attachment to rest flat

on the ground, stop engine, set park brake, and

wait for all motion to stop.

NEVER place hands in the discharge area or

clear debris while the engine is running.

Avoid High Pressure Fluids Hazard

Escaping fluid under pressure can

penetrate the skin causing serious

injury.

Avoid the hazard by relieving the

pressure before disconnecting

hydraulic lines.

Use a piece of paper or cardboard, NOT BODY

PARTS, to check for suspected leaks. Wear

protective gloves and safety glasses or goggles

when servicing or performing maintenance on

hydraulic systems.

If an accident occurs, see a doctor immediately.

Any fluid injected into the skin must be

surgically removed within a few hours or

gangrene may result.

Maintenance

NEVER make adjustments, lubricate, clean, or

perform any service on the machine while it is in

operation.

Make sure the attachment is serviced on a daily

basis. Improper maintenance can cause

serious injury or death in addition to damage to

the attachment and/or your equipment.

*Always follow manufacturer instructions*

*AAA Rent-All 225-291-1356*