Specifications ..........................................................................................1

Installation ..............................................................................................1

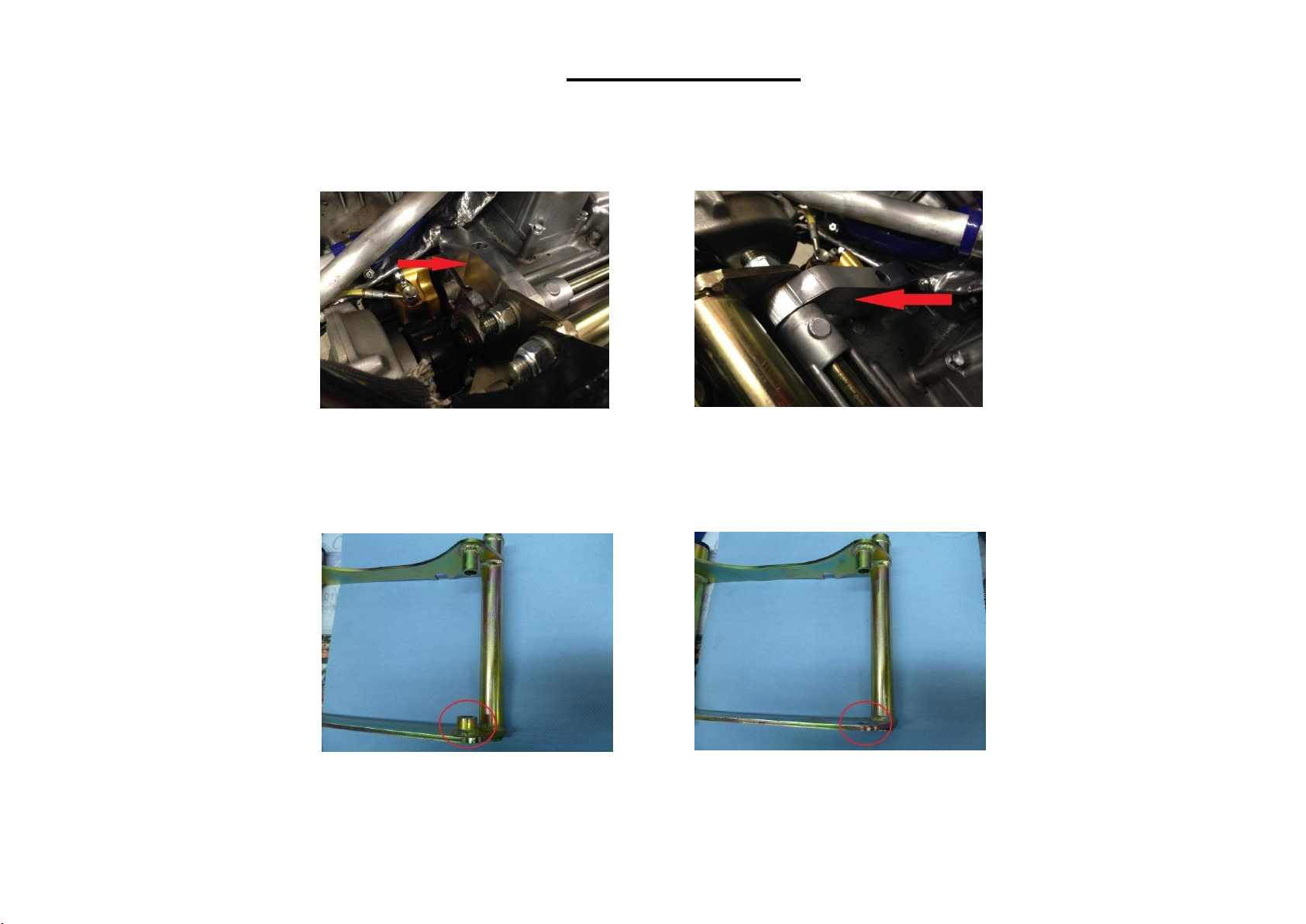

Rear Engine Brace ...............................................................................1

Oil System................................................................................................1

Coolant System ...................................................................................1

Fuel......................................................................................................1

Octane Boosters..................................................................................1

RPE –Quaife Gear Drive System.........................................................1

Types of Oil Systems ...............................................................................1

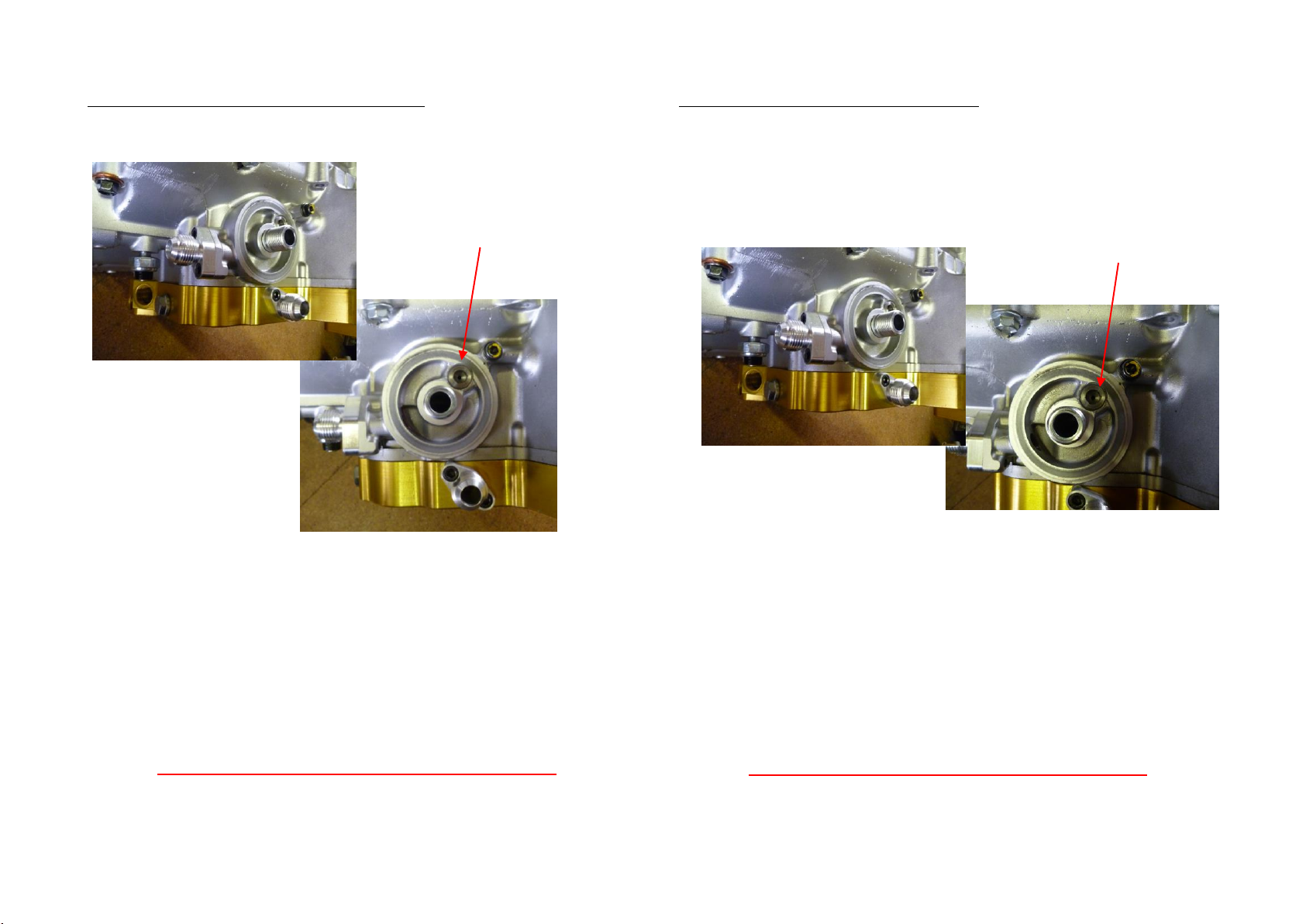

Oil Type Number 1 - Blanking Plates, No Jet.......................................2

Oil System Number 2 - Oil cooler fittings and jet ...............................2

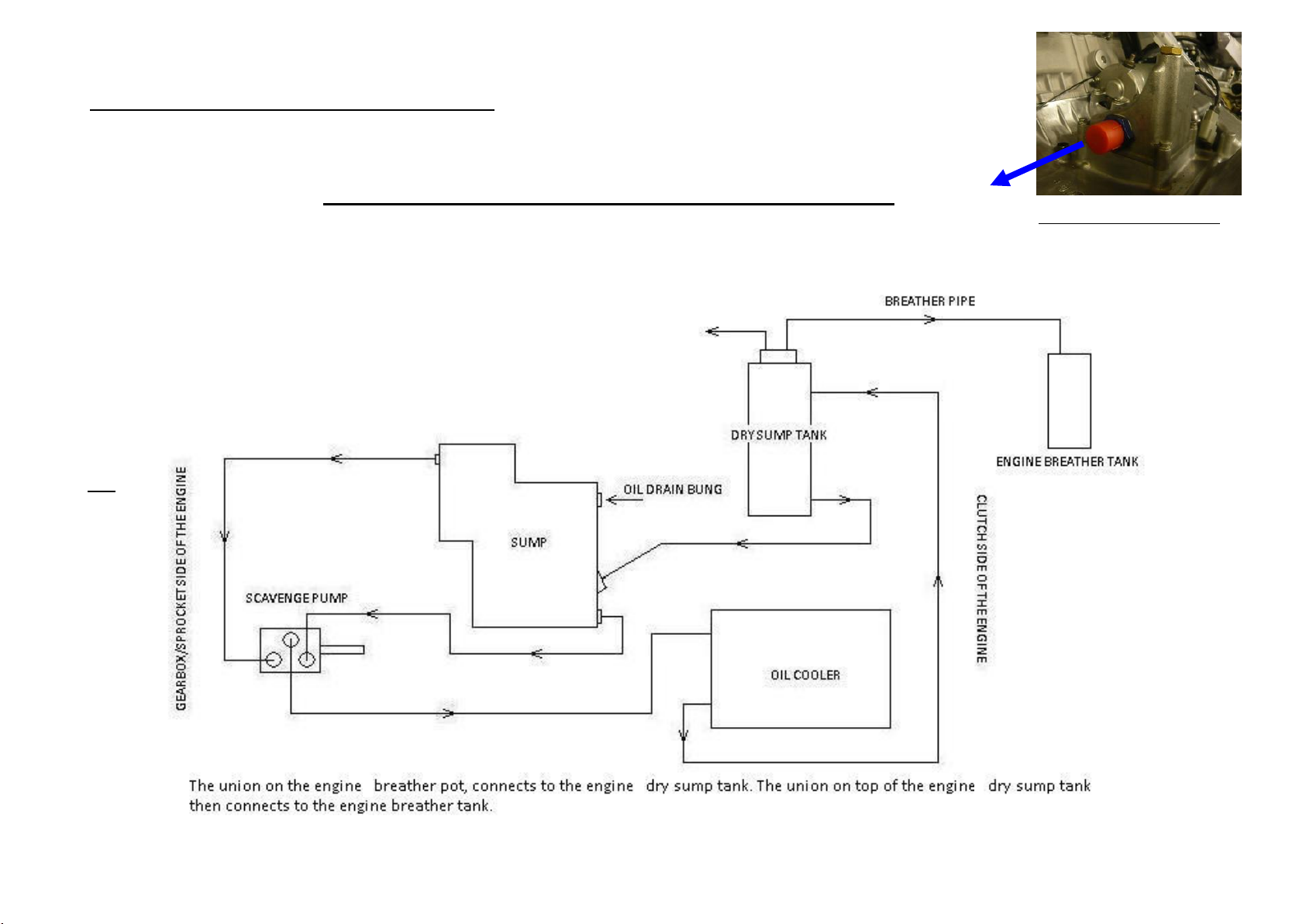

Oil System 3 –Oil Cooler Fittings and Bung........................................3

Oil System 1 Diagram - Cast Sump Pan……………………………………………5

Oil System 1 Diagram - Billet Sump Pan…………………………………..………6

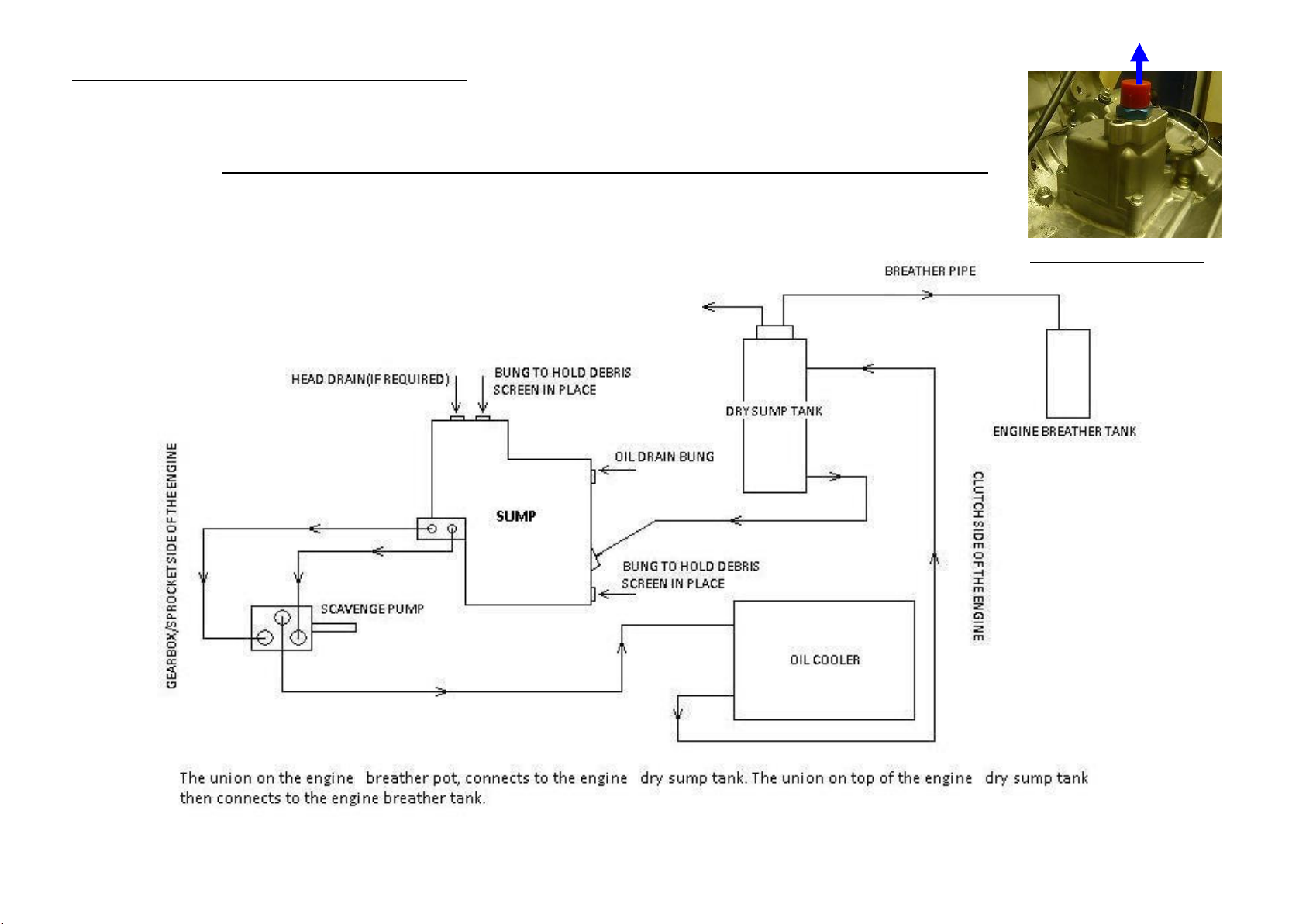

Oil System 2 & 3 Diagram…………………………………..…………………………..7

Engine Management...............................................................................7

MBE - Radical Easimap Setup Screen..................................................7

Life Racing - PTMon.............................................................................7

Throttle and Airbox installation..............................................................8

Airbox..................................................................................................8

Fluid Levels and Temperatures...............................................................8

Coolant Temperature..........................................................................8

Coolant Level.......................................................................................8

Oil Temperature –both Wet and Dry Sump Systems.........................8

Wet Sump Oil Level.............................................................................8

Dry Sump Oil Level ..............................................................................8

Starting Procedure……………………………………………………………………………10

Re-Starting ..........................................................................................9

Service Intervals......................................................................................9

Engine Oil and Oil Filter ...................................................................... 9

Oil Filter Fitting Procedure .............................................................9

Fuel Filter............................................................................................ 9

Air Filter ..............................................................................................9

Engine Returns...................................................................................... 10

Balancing Throttle Bodies on a 4 cylinder ............................................11

Life Racing ECU .................................................................................11

MBE ECU...........................................................................................12

Instructions For Retrieving Data from Life ECU and Data logger.........13

Driving Techniques for Cars with an RPE Engine..................................14

Contact Details...................................................................................... 15