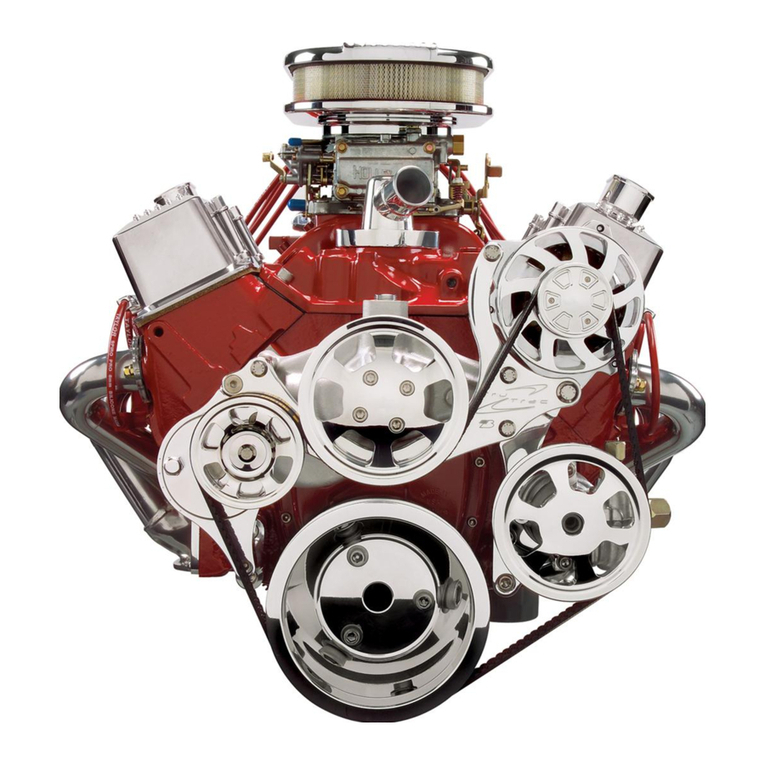

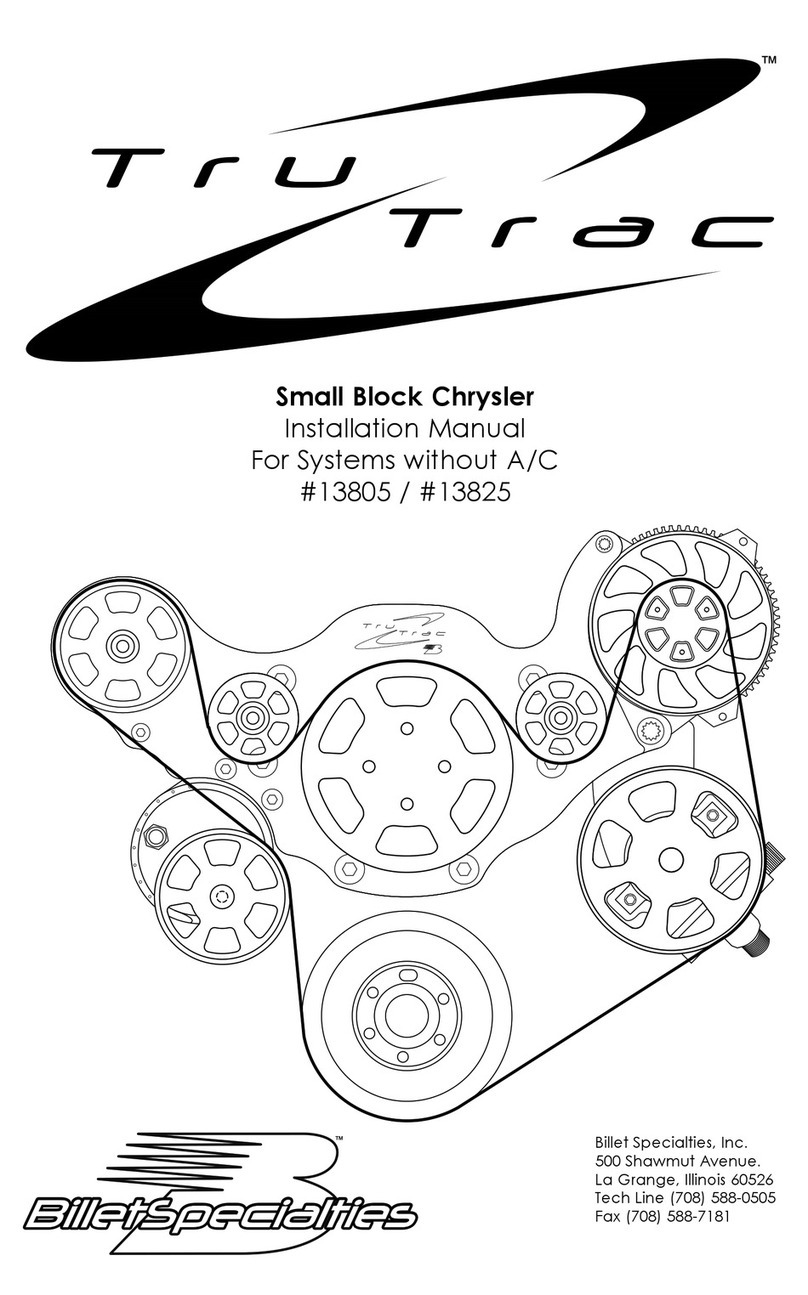

Billet Specialties TryTrac User manual

This manual suits for next models

2

Table of contents

Other Billet Specialties Engine manuals

Popular Engine manuals by other brands

Briggs & Stratton

Briggs & Stratton 252799 Series Operating and maintenance instruction

SOMFY

SOMFY Sonesse 30 RTS 24V DC Quick programming guide

ZIEHL-ABEGG

ZIEHL-ABEGG ECblue Assembly instructions

Briggs & Stratton

Briggs & Stratton 12X800 Series Operator owner's manual

Alcatel-Lucent

Alcatel-Lucent dunkermotoren BG 65 MI Series instruction manual

Yamaha

Yamaha MX800V Service manual

Continental Refrigerator

Continental Refrigerator CD-170 Operation & maintenance manual

Exergia

Exergia ecorun2.0 quick start guide

Belimo

Belimo KM24-SR Information

RADEMACHER

RADEMACHER RooloTube S Sun DuoFern Medium Series Operating and assembly manual

DERRICK

DERRICK EX Maintenance & Operation Manual

Texas A/S

Texas A/S TG 850ES instruction manual