Stober PK Series User manual

PK/PKX/PHK/PHKX/PHQK/KS/KL gear units, geared motors

Operating manual

en-US

10/2019

ID 443150_en.00

Table of contents

ii

10/2019 | ID 443150_en.00

Table of contents

1 User information ....................................................................................................................................................... 4

1.1 Storage and transfer ................................................................................................................................................ 4

1.2 Original language ..................................................................................................................................................... 4

1.3 Formatting conventions........................................................................................................................................... 4

1.4 Terms ....................................................................................................................................................................... 5

1.5 Supporting documents............................................................................................................................................. 5

1.6 Limitation of liability ................................................................................................................................................ 5

1.7 Product names and brands ...................................................................................................................................... 5

1.8 Copyright notice....................................................................................................................................................... 5

2 General safety instructions........................................................................................................................................ 6

2.1 Intended use ............................................................................................................................................................6

2.2 Requirements for personnel .................................................................................................................................... 6

2.3 Prevention of personal injury .................................................................................................................................. 6

2.3.1 Mechanical hazards ................................................................................................................................ 6

2.3.2 Thermal hazards ..................................................................................................................................... 7

2.4 Prevention of property damage............................................................................................................................... 7

3 Product description ................................................................................................................................................... 8

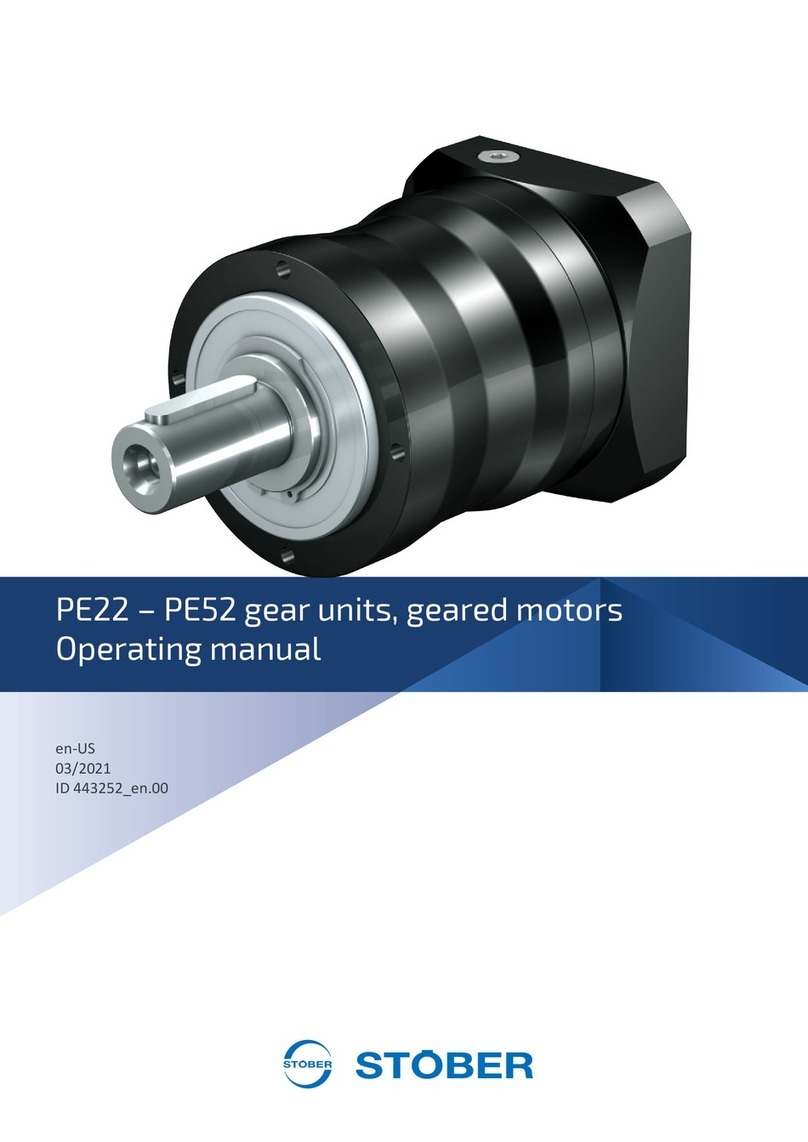

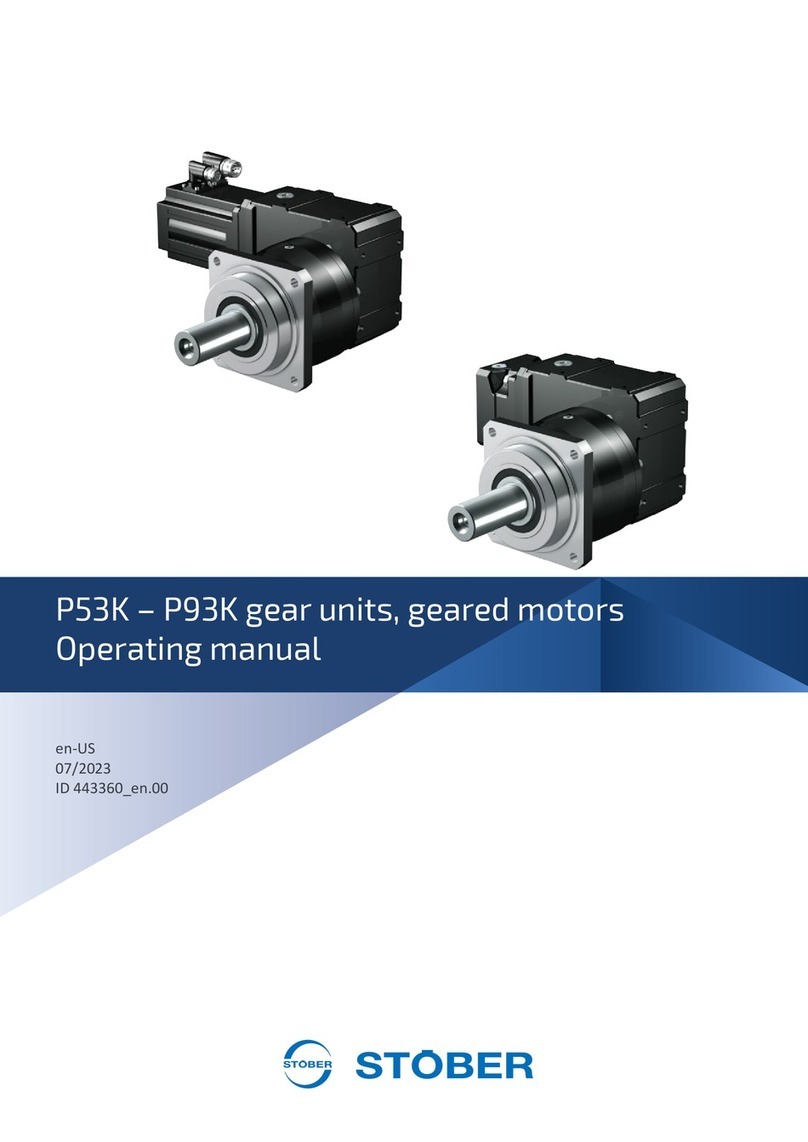

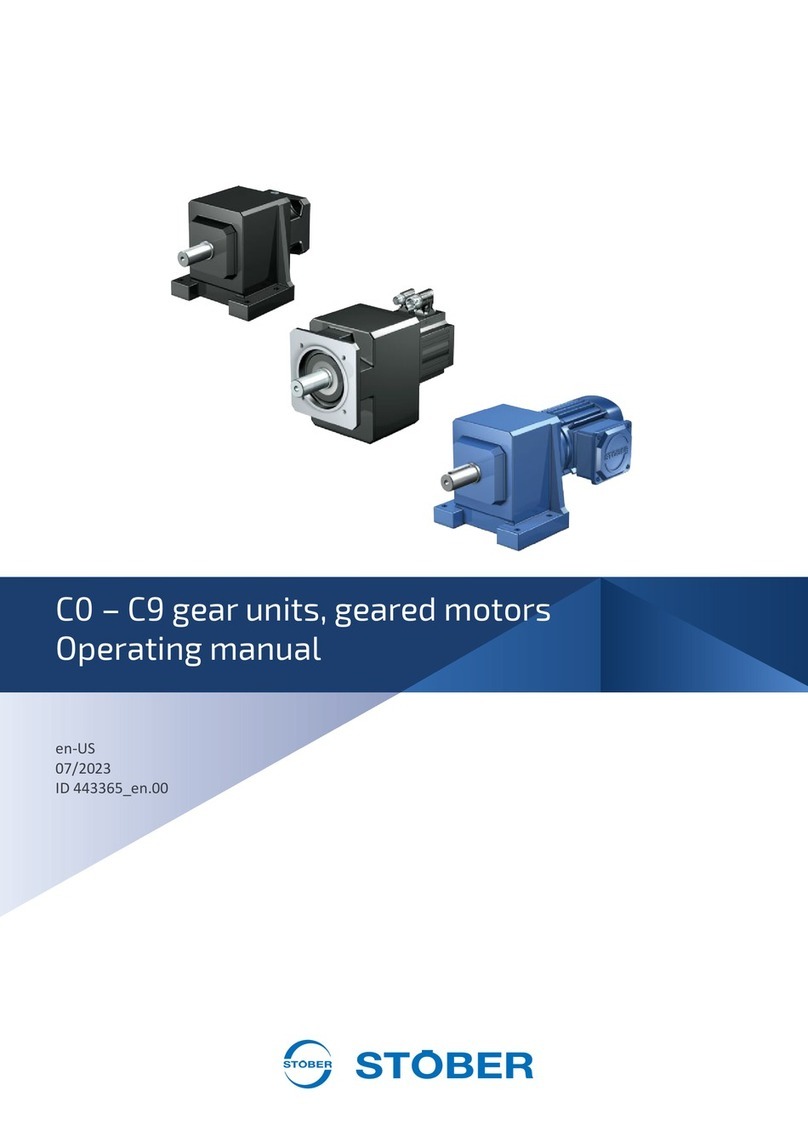

3.1 Basic structure ......................................................................................................................................................... 8

3.1.1 Basic structure of PK, PKX....................................................................................................................... 8

3.1.2 Basic structure of PHK, PHKX, PHQK....................................................................................................... 9

3.1.3 Basic structure of KS ............................................................................................................................... 9

3.1.4 Basic structure of KL ............................................................................................................................. 10

3.2 Type designation.................................................................................................................................................... 10

3.2.1 PK, PKX, PH5K – PH8K, PHKX, PHQ5K-PHQ8K type designation ........................................................... 10

3.2.2 PH9K – PH10K, PHQ9K – PHQ12K type designation ............................................................................. 11

3.2.3 KS type designation .............................................................................................................................. 12

3.2.4 KL type designation............................................................................................................................... 12

3.3 PK, PHK, KL nameplate........................................................................................................................................... 13

3.4 PKX, PHKX, KS nameplate....................................................................................................................................... 14

3.5 Mounting positions................................................................................................................................................ 14

3.5.1 PK, PHK, PHQK mounting positions ...................................................................................................... 14

3.5.2 PKX, PHKX, KS mounting positions........................................................................................................ 16

3.5.3 KL mounting positions .......................................................................................................................... 17

3.6 Direction of rotation .............................................................................................................................................. 17

3.7 Ambient conditions................................................................................................................................................ 19

3.8 Other product features..........................................................................................................................................20

3.9 Additional documentation ..................................................................................................................................... 20

Table of contents

10/2019 | ID 443150_en.00

iii

4 Transport and storage ............................................................................................................................................. 21

4.1 Transport ............................................................................................................................................................... 21

4.2 Storage................................................................................................................................................................... 21

4.2.1 Long-term storage ................................................................................................................................ 21

5 Installation .............................................................................................................................................................. 22

5.1 Cleaning agent and solvent.................................................................................................................................... 22

5.2 Mounting the motor on a gear unit ....................................................................................................................... 22

5.2.1 Permitted tilting torques at the gear unit input ................................................................................... 23

5.2.2 Tolerances for the add-on motor ......................................................................................................... 23

5.2.3 Mounting the motor on a gear unit with ME/MEL/MF/MFL adapter .................................................. 24

5.2.4 Mounting the motor on a gear unit with MB adapter.......................................................................... 28

5.2.5 Mounting the motor on a gear unit with MQ adapter ......................................................................... 28

5.3 Mounting the output shaft ....................................................................................................................................31

5.3.1 Mounting drive elements on a solid shaft ............................................................................................ 31

5.3.2 Mounting drive elements on a flange shaft.......................................................................................... 32

5.3.3 Mounting a hollow shaft with keyway.................................................................................................. 33

5.3.4 Mounting a hollow shaft with shrink ring............................................................................................. 34

5.4 Mounting the gear unit on the machine................................................................................................................36

5.4.1 Mounting PK, PKX, PHK, PHKX, PHQK gear units on the machine ........................................................ 36

5.4.2 Mounting the KS gear unit to the machine........................................................................................... 38

5.4.3 Mounting the KL gear unit on the machine .......................................................................................... 39

5.5 Tightening torques................................................................................................................................................. 41

6 Commissioning ........................................................................................................................................................ 42

6.1 Before commissioning............................................................................................................................................ 42

6.2 During commissioning............................................................................................................................................ 42

7 Servicing.................................................................................................................................................................. 43

7.1 Cleaning ................................................................................................................................................................. 43

7.2 Inspection .............................................................................................................................................................. 43

7.3 Remedying faults ................................................................................................................................................... 44

7.3.1 Troubleshooting faults.......................................................................................................................... 44

7.4 Servicing................................................................................................................................................................. 44

7.5 Service.................................................................................................................................................................... 45

8 Removal and disposal.............................................................................................................................................. 46

8.1 Removal ................................................................................................................................................................. 46

8.1.1 Removing PK, PKX, PHK, PHKX, PHQK, KS gear units ............................................................................ 46

8.1.2 Removing KL gear units......................................................................................................................... 46

8.2 Disposal.................................................................................................................................................................. 47

1 | User information

4

10/2019 | ID 443150_en.00

1 User information

This documentation is a part of the product. It applies to products in the standard design according to the corresponding

STOBER catalog.

1.1 Storage and transfer

As this documentation contains important information for handling the product safely and efficiently, it must be stored in

the immediate vicinity of the product until product disposal and be accessible to qualified personnel at all times.

Also pass on this documentation if the product is transferred or sold to a third party.

1.2 Original language

The original language of this documentation is German; all other language versions are derived from the original language.

1.3 Formatting conventions

Orientation guides in the form of signal words are used to emphasize specific information so that you are able identify it in

this documentation quickly.

Safety notes indicate special risks when handling the product and are accompanied by relevant signal words that express

the extent of the risk. In addition, warning notes for possible property damage and useful information are also indicated by

signal words.

DANGER!

Danger

This word with a warning triangle indicates that there is a considerable risk of fatal injury

▪ if the stated precautionary measures are not taken.

WARNING!

Warning

This word with a warning triangle means there may be a considerable risk of fatal injury

▪ if the stated precautionary measures are not taken.

CAUTION!

Caution

This word with a warning triangle indicates that minor personal injury may occur

▪ if the stated precautionary measures are not taken.

ATTENTION!

Notice

This indicates that damage to property may occur

▪ if the stated precautionary measures are not taken.

1 | User information

10/2019 | ID 443150_en.00

5

Information

Information indicates important information about the product or serves to emphasize a section in the documentation that

deserves special attention from the reader.

Embedded warning information

Embedded warning information is integrated directly into the instruction manual and is structured as follows:

SIGNAL WORD! Type of hazard, its cause and possible consequences of disregarding it! Measures for avoiding the hazard.

Signal words in embedded warning information have the same meaning as in the normal warning information described

previously.

1.4 Terms

This documentation describes both STOBER gear units and gear components of STOBER geared motors. For reasons of

clarity, the collective term drives is used for these.

1.5 Supporting documents

Separate documents apply to the drive components which can be attached to STOBER gear units, depending on the design.

These documents can be found by entering the serial number of the gear unit at https://id.stober.com or by scanning the

QR code on the nameplate of the gear unit.

Alternatively, you can find supporting documents at http://www.stoeber.de/en/downloads/. Enter the ID of the

documentation in the Search... field:

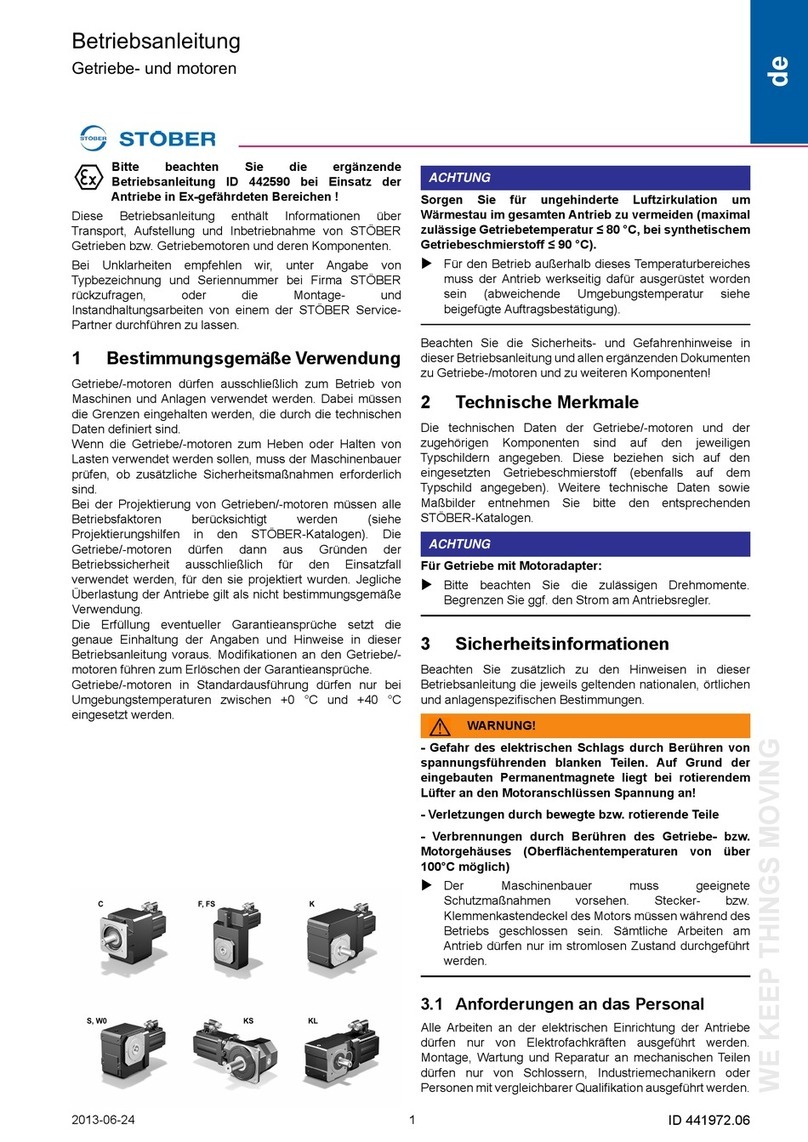

Drive components Operating manual ID

LM Lean motor 443048_en

EZ synchronous servo motor 443032_en

MB motor adapter with brake 441846_en

1.6 Limitation of liability

This documentation was created taking into account the applicable standards and regulations as well as the current state of

technology.

STOBER shall assume no responsibility for damage resulting from failure to comply with the documentation or from use

that deviates from the intended use of the product. This is especially true for damage caused by individual technical

modifications to the product or projecting and operation of the product by unqualified personnel.

1.7 Product names and brands

Product names that are registered as brands are not specifically identified in this documentation. Existing property rights

(patents, trademarks, protection of utility models) are to be observed.

1.8 Copyright notice

Copyright © STOBER. All rights reserved.

2 | General safety instructions

6

10/2019 | ID 443150_en.00

2 General safety instructions

There are risks associated with the product described in this documentation that can be prevented by complying with the

described warning and safety instructions as well as the included technical rules and regulations.

2.1 Intended use

The drives described in this documentation are intended for installation in industrial machines or systems.

The following are considered non-intended use:

§Any overloading of the drives

§Operation in ambient conditions that deviate from those described in the corresponding technical documentation

§Modifying or refitting the drives

§Using the drives for an application other than that defined during project configuration

Commissioning the machine in which the drives are installed is prohibited until it has been determined that the machine

corresponds to regional laws and guidelines. In particular, the (Machinery) Directive 2006/42/EC is to be observed in the

respective scope.

Operation of the drives in potentially explosive atmospheres is prohibited, unless they are expressly designed for this.

2.2 Requirements for personnel

All mechanical tasks that arise during the assembly, commissioning, maintenance and removal of the product may be

performed only by specialized personnel who hold a corresponding qualification in the field of metal technology.

All electrical tasks that arise during the assembly, commissioning, maintenance and removal of the product may be

performed only by electricians who hold a corresponding qualification in the field of electrical engineering.

Tasks that arise during transport, storage and disposal may be performed by personnel who have been instructed in the

suitable method for doing so.

Furthermore, personnel who handle the product must carefully read, understand and observe the valid regulations, legal

requirements and applicable basic rules as well as this documentation and the safety instructions it contains.

2.3 Prevention of personal injury

2.3.1 Mechanical hazards

WARNING!

Dangerous movements of machine parts!

Moving machine parts can cause serious injuries or even death!

üBefore starting the motor or drive:

▪ Install all protective devices necessary for operation.

▪ Make sure that no one is standing in the danger area or able to enter it unchecked.

▪ Leave the danger area.

2 | General safety instructions

10/2019 | ID 443150_en.00

7

WARNING!

Sinking or falling of gravity-loaded axes or vertical axes after switching off the motor due to gravity!

Falling gravity-loaded axes or vertical axes can cause serious injuries or even death!

▪ Be aware that the holding brake of the motor does not offer sufficient safety for persons that are in the hazard area

of gravity-loaded axes or vertical axes.

▪ Move gravity-loaded axes or vertical axes to their lowest position and lock or brace them mechanically before

allowing people to enter the danger area.

WARNING!

Unsecured feather keys or drive elements can be thrown due to the rotation of the input shaft!

Flying metal parts can cause serious injuries!

▪ Mount the provided drive elements properly or remove them before a test run.

2.3.2 Thermal hazards

CAUTION!

The surface of the drive can reach temperatures over 65°C during operation!

Touching the hot surface of the drive can cause severe skin burns!

▪ Do not touch the drive during operation or immediately afterward.

▪ Allow the drive to cool sufficiently before carrying out work on the drive.

▪ Wear protective gloves when working on the drive.

2.4 Prevention of property damage

ATTENTION!Damage to bearings and shafts due to improper assembly! Never use force when installing

machine elements with fittings, e.g. hitting power transmission elements, shafts or the motor or gear unit housing with a

hammer, but rather install them in accordance with the following instructions.

ATTENTION!Shaft seal rings can be damaged by solvents! Prevent shaft seal rings from coming into contact with

solvents when cleaning and degreasing unpainted surfaces.

3 | Product description

8

10/2019 | ID 443150_en.00

3 Product description

In this chapter, you can find product details that are relevant for assembly, commissioning and maintenance. Detailed

technical data on your gear unit/geared motor can be found in the order confirmation. You will find more product

information and dimensional drawings in the corresponding catalog (Additional documentation [}20]). The respective

separate technical documentation applies to the attached motors.

3.1 Basic structure

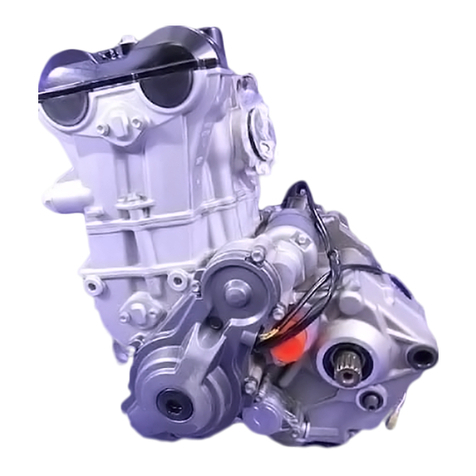

3.1.1 Basic structure of PK, PKX

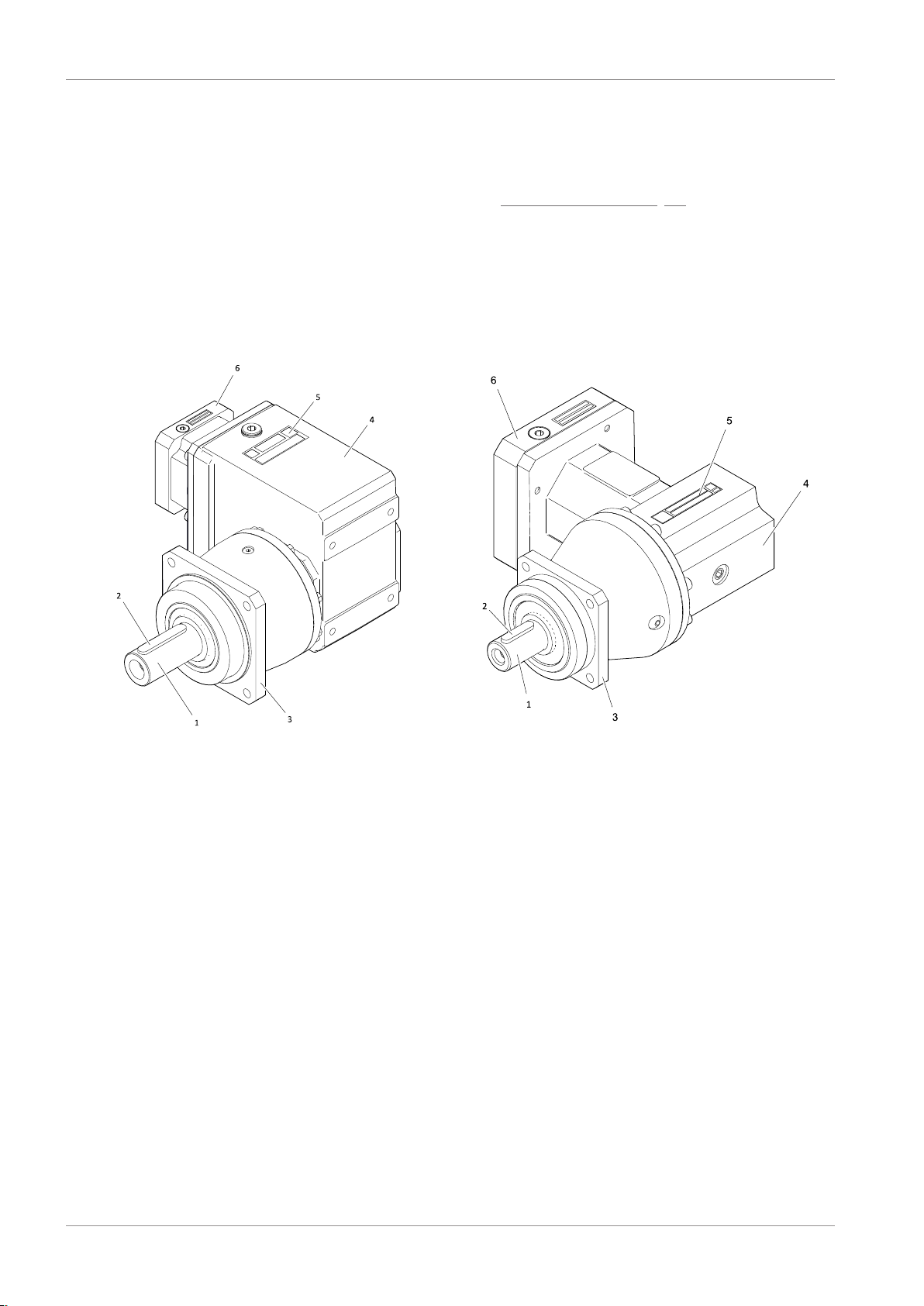

Tab. 1: Basic structure of a P431_K202 gear unit (left) and P431_KX4 gear unit (right)

1 Solid shaft 2 Feather key (if present)

3 Output flange 4 Gear unit housing

5 Nameplate 6 ME motor adapter

3 | Product description

10/2019 | ID 443150_en.00

9

3.1.2 Basic structure of PHK, PHKX, PHQK

Tab. 2: Basic structure of a PHQ831_K402 gear unit (left) and PH731_KX7 gear unit (right)

1 Flange shaft 2 Output flange

3 Gear unit housing 4 Nameplate

5 ME motor adapter

3.1.3 Basic structure of KS

Tab. 3: Basic structure of a KS502F gear unit (left) and KS502S gear unit (right)

1a Flange hollow shaft 1b Hollow shaft with shrink ring

2 Output flange 3 Gear unit housing

4 Nameplate 5 ME motor adapter

3 | Product description

10

10/2019 | ID 443150_en.00

3.1.4 Basic structure of KL

Tab. 4: Basic structure of a KL102ANG gear unit (left) and KL102PF gear unit (right)

1a Hollow shaft 1b Solid shaft with feather key

2a Foot plates (option) 2b Output flange (option)

3 Nameplate 4 Gear unit housing

5 MQ motor adapter

3.2 Type designation

3.2.1 PK, PKX, PH5K – PH8K, PHKX, PHQ5K-PHQ8K type designation

In this chapter, you can find an explanation of the type designation for the gear unit types mentioned in the title.

Sample code

P 5 3 1 S G S S 0050 K102VF 0060 ME20

Explanation

Code Designation Design

P

PH

PHQ

Type Planetary gear unit with solid shaft

Planetary gear unit with flange shaft

Planetary gear unit with flange shaft

5Size 5 (example)

3Generation Generation 3

1Stages Single-stage

SHousing Standard

F

G

P

Shaft Flange shaft (PH, PHQ gear unit)

Solid shaft without feather key (P gear unit)

Solid shaft with feather key (P gear unit)

3 | Product description

10/2019 | ID 443150_en.00

11

Code Designation Design

S

D

Z

V

Bearing Standard bearing

Axially reinforced bearing (P gear unit)

Radially reinforced bearing (P gear unit)

Reinforced bearing (PH/PHQ gear unit)

S

R

Backlash Standard

Reduced

0050 Transmission ratio of output

(i x 10)

i = 5 (example)

K102VF

KX701VF

Input K1 right-angle gear unit (example)

KX7 right-angle gear unit (example)

0060 Transmission ratio of input

(i x 10)

i = 6 (example)

ME20

MF

MB

Motor adapter ME20 motor adapter (example) with EasyAdapt coupling

MF motor adapter with FlexiAdapt coupling

ServoStop motor adapter with brake

EZ

LM

Motor EZ synchronous servo motor

LM Lean motor

3.2.2 PH9K – PH10K, PHQ9K – PHQ12K type designation

In this chapter, you can find an explanation of the type designation for the gear unit types mentioned in the title.

Sample code

PH 9 3 1 F 0040 K513VF 0100 ME30

Explanation

Code Designation Design

PH

PHQ

Type Planetary gear unit with flange shaft

9Size 9 (example)

3Generation Generation 3

1Stages Single-stage

FShaft Flange shaft

0040 Transmission ratio (i x 10) i = 4 (example)

K513VF Input K5 right-angle gear unit (example)

0100 Transmission ratio of input

(i x 10)

i = 10 (example)

ME30

MF

MB

Motor adapter ME30 motor adapter (example) with EasyAdapt coupling

MF motor adapter with FlexiAdapt coupling

ServoStop motor adapter with brake

EZ

LM

Motor EZ synchronous servo motor

LM Lean motor

3 | Product description

12

10/2019 | ID 443150_en.00

3.2.3 KS type designation

In this chapter, you can find an explanation of the type designation for the gear unit types mentioned in the title.

Sample code

KS 5 0 2 G F 0200 ME

Explanation

Code Designation Design

KS Type Right-angle servo gear unit

5Size 5 (example)

0Generation Generation 0

2

3

Stages Two-stage

Three-stage

F

S

G

P

Shaft Flange hollow shaft

Hollow shaft with shrink ring

Solid shaft without feather key

Solid shaft with feather key

FHousing Standard

0200 Transmission ratio (i x 10) i = 20 (example)

ME

MEL

Motor adapter Motor adapter with EasyAdapt coupling

Motor adapter with EasyAdapt coupling for large motors

EZ

LM

Motor EZ synchronous servo motor

LM Lean motor

3.2.4 KL type designation

In this chapter, you can find an explanation of the type designation for the gear unit types mentioned in the title.

Sample code

KL 2 0 2 P G 0080 MQ

Explanation

Code Designation Design

KL Type Helical bevel gear unit

2Size 2 (example)

0Generation Generation 0

2Stages Two-stage

A

S

G

P

Shaft Hollow shaft with keyway

Hollow shaft with shrink ring

Solid shaft without feather key

Solid shaft with feather key

3 | Product description

10/2019 | ID 443150_en.00

13

Code Designation Design

G

F

NG

Housing Pitch circle diameter

Flange

Foot + pitch circle diameter

0080 Transmission ratio (i x 10) i = 8 (example)

MQ Motor adapter Square motor adapter with backlash-free plug-in coupling

EZ

LM

Motor EZ synchronous servo motor

LM Lean motor

3.3 PK, PHK, KL nameplate

An example nameplate for the gear unit types listed above is explained in the figure below.

1

2

3

4

5

6

7

8

9

10

Code Designation

1 Name of manufacturer

2 Type designation

3 Gear ratio of the gear unit

4 Lubricant specification

5 Serial number of the gear unit

6 QR code (link to product information)

7 Dimensions of the motor adapter (pilot/bolt circle/motor shaft diameter)

8 Date of manufacture (year/calendar week)

9 Lubricant fill volume

10 Customer-specific data

3 | Product description

14

10/2019 | ID 443150_en.00

3.4 PKX, PHKX, KS nameplate

An example nameplate for the gear unit types listed above is explained in the figure below.

1

2

345678910

Code Designation

1 Name of manufacturer

2 Type designation

3 Gear ratio of the gear unit

4 Serial number of the gear unit

5 Dimensions of the motor adapter (diameter of pilot/bolt circle/motor shaft)

6 Customer-specific data

7 Lubricant specification

8 Lubricant fill volume

9 Date of manufacture (year/calendar week)

10 QR code (link to product information)

3.5 Mounting positions

3.5.1 PK, PHK, PHQK mounting positions

STOBER coordinates the lubricant fill volume and structure of the gear unit types listed above to the mounting position of

the gear unit in the machine. The mounting position of a gear unit is determined upon ordering and specified in the order

documents.

The standard mounting positions of the gear unit types listed above is depicted in the images below, using the PK gear unit

type with output on side 4 as an example. For PHK and PHQK gear unit types, the output shaft is designed as a flange shaft,

not a solid shaft.

The numbers identify the gear unit sides. The mounting position is defined by the gear side facing downwards.

3 | Product description

10/2019 | ID 443150_en.00

15

EL1 EL2 EL3

EL4 EL5 EL6

An adhesive label is applied to the gear unit that explains the designated mounting position. The arrow on the adhesive

label indicates the side with which the gear unit must be mounted facing down.

Fig.1: Adhesive label for the mounting position

3 | Product description

16

10/2019 | ID 443150_en.00

3.5.2 PKX, PHKX, KS mounting positions

STOBER coordinates the lubricant fill volume and structure of the gear unit types listed above to the mounting position of

the gear unit in the machine. The mounting position of a gear unit is determined upon ordering and specified in the order

documents.

The standard mounting positions of the gear unit types listed above are illustrated in the images below, using the PHKX

gear unit type as an example. For the PKX gear unit type, the output shaft is implemented as a solid shaft, not a flange

shaft. For the KS gear unit type, the output shaft is either implemented as a solid shaft, flange hollow shaft or hollow shaft

with shrink ring on side 3.

The numbers identify the gear unit sides. The mounting position is defined by the gear side facing downwards.

EL1 EL2 EL3

EL4 EL5 EL6

An adhesive label is applied to the gear unit that explains the designated mounting position. The arrow on the adhesive

label indicates the side with which the gear unit must be mounted facing down.

Fig.2: Adhesive label for the mounting position

3 | Product description

10/2019 | ID 443150_en.00

17

3.5.3 KL mounting positions

The KL gear unit can be installed in any mounting position. The figure below illustrates the gear sides referenced by the

shaft and housing designs.

3.6 Direction of rotation

The following figures illustrate the direction of rotation of the output in relation to the direction of rotation at the input of

the respective gear unit. All gear unit types are shown in mounting position EL1

Output on side 4 of K gear unit Output on side 3 of K gear unit

Tab. 5: Direction of rotation of the PK gear unit

PKX3 − PKX5 PKX7

Tab. 6: Direction of rotation of the PKX gear unit

3 | Product description

18

10/2019 | ID 443150_en.00

Output on side 4 of K gear unit Output on side 3 of K gear unit

Tab. 7: Direction of rotation of the PHK, PHQK gear unit

PH3KX − PH5KX PH7KX − PH8KX

Tab. 8: Direction of rotation of the PHKX gear unit

KS

Tab. 9: Direction of rotation of the KS gear unit

3 | Product description

10/2019 | ID 443150_en.00

19

Output on side 4 Output on side 3

Tab. 10: Direction of rotation of the KL gear unit

The specified direction of rotation also applies to other designs of the KL gear unit:

§Design with hollow shaft (A), for which the entry side of the machine shaft corresponds to the side of the solid shaft

that is shown

§Design with hollow shaft with shrink ring (S), for which the position of the shrink ring corresponds to the side of the

solid shaft that is shown.

3.7 Ambient conditions

Standard ambient conditions for transport, storage and operation of the gear unit are described in this chapter. Deviating

ambient conditions for special designs are specified in the order confirmation. Ambient conditions for motors attached to a

gear unit can be found in the technical documentation of the motor.

Feature Description

Transport/storage surrounding temperature −10 °C to +50 °C

Surrounding operating temperature 0 °C to +40 °C

Installation altitude ≤ 1000 m above sea level

Notes

In order to prevent corrosion damage and damage to the shaft seal rings, protect the drive from the following influences:

§Environments with harmful oils, acids, gases, vapors, dust or radiation

§Extreme temperature fluctuations with high humidity

§Thawing or icing

§Strong UV radiation (e.g. direct sunlight)

§Presence of salt spray

§Sparks

In potentially explosive atmospheres, only gear units in an explosion-proof design in accordance with (ATEX) Directive

2014/34/EU may be used. Separate documentation applies to the explosion-proof design.

3 | Product description

20

10/2019 | ID 443150_en.00

3.8 Other product features

Other features of gear units in the standard design can be found in the following table.

Feature Description

Maximum permitted gear unit temperature (on the surface

of the gear unit)

≤ 90°C

Paint Black RAL 9005

Lubricant Synthetic; for specification and quantity, see nameplate

Ventilation Gear unit housing closed on all sides, no ventilation

provided

Weight See order documents

Protection class IP65

With a geared motor, keep in mind that the motor protection class may be lower.

3.9 Additional documentation

You will find more information about the product at http://www.stoeber.de/en/downloads/. Enter the ID of the

documentation in the Search... field.

Product combination Catalog title ID

Gear unit + MB motor adapter with brake Motor adapters with brake 441904

Gear unit + ME/MEL/MF/MFL motor adapter Servo gear units 443054_en

Gear unit + MQ motor adapter Servo gear units 443054_en

Gear unit + EZ synchronous servo motor EZ synchronous servo geared motors 442437_en

Gear unit + LM Lean motor Lean motors 443016_en

If you have questions about your drive that are not answered by this documentation, please contact STOBER Service

(Service [}45]).

This manual suits for next models

22

Table of contents

Other Stober Engine manuals

Popular Engine manuals by other brands

Ametek

Ametek dunkermotoren BG dCore Series Translation of the original manual

Schachner Elektrofahrzeuge

Schachner Elektrofahrzeuge MM13 user manual

Vexta

Vexta CFK II Series operating manual

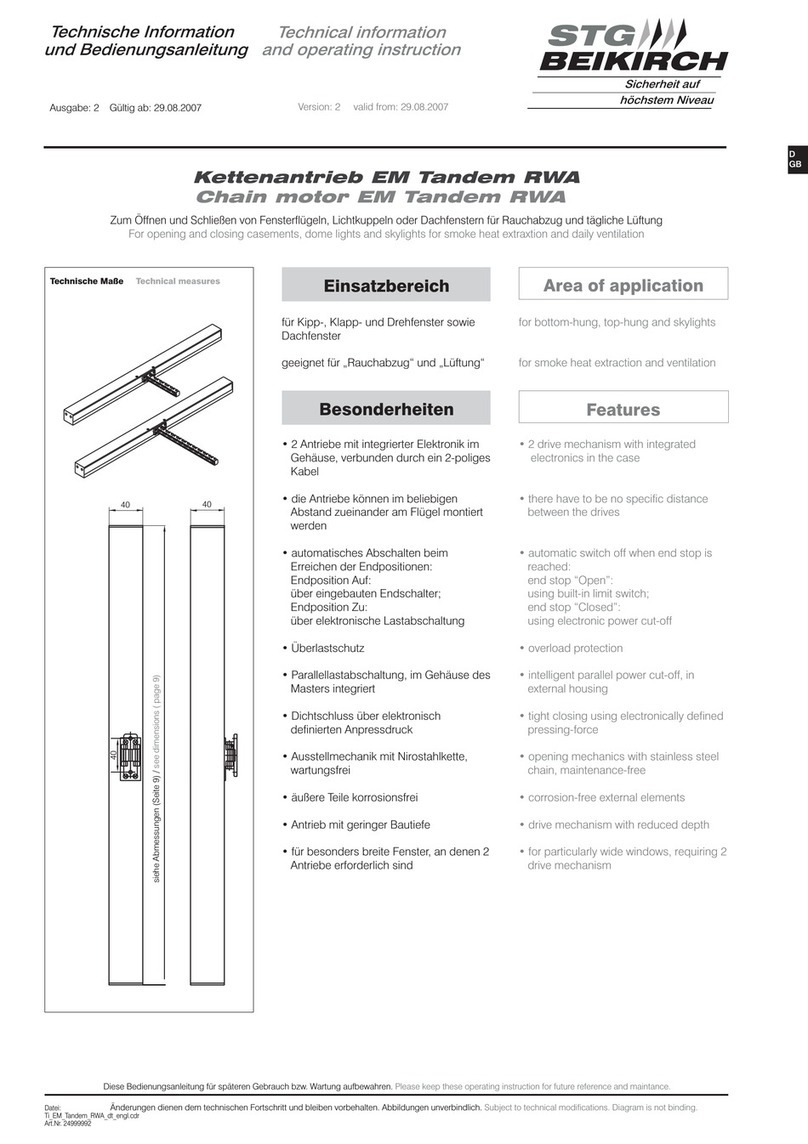

STG-BEIKIRCH

STG-BEIKIRCH EM Tandem RWA Technical information and operating instruction

phytron

phytron ZSH 57 Assembly instructions

Danfoss

Danfoss VLT OneGearDrive instruction manual