BILT HARD 10-INCH User manual

10-INCH DRILL PRESS

IMPORTANT:

Your new tool has been engineered and manufactured to highest standards for dependability,

ease of operation, and operator safety. When properly cared for, this product will supply you years of rugged,

trouble-free performance. Pay close attention to the rules for safe operation, warnings, and cautions. If you use

your tool properly and for its intended purpose, you will enjoy years of safe, reliable service.

INSTRUCTION MANUAL

Thank you for ordering our product. If you have any issue, please email with

2

CONTENTS

3EMOCLEW

Introduction ..................................................................................................... 3

Specifications................................................................................................... 3

4YTEFAS

General Safety Rules........................................................................................ 4

Drill Press Safety Warnings ............................................................................. 6

Electrical Information....................................................................................... 8

BEFORE OPERATING 9

Unpacking & Packing List................................................................................ 9

Know Your Drill Press .................................................................................... 10

Assembly & Adjustment................................................................................. 11

OPERATION & MAINTENANCE 61

Operation ....................................................................................................... 16

Maintenance................................................................................................... 17

Troubleshooting Guide................................................................................... 19

Exploded View & Parts List............................................................................ 21

3

SPECIFICATIONS

Motor 120V, 60 Hz, 6.2A

Speeds 350-3,000 r/min. (RPM)

Swing 10"

Table Size 7-5/8 in. x 6-1/2 in.

Total Height 29"

INTRODUCTION

Thanks for purchasing the Drill Press. We know you are excited to put your tool to work, but first, please take

a moment toread through the manual. Safe operation of this tool requires that you read and understand this

operator’s manual and all the labels affixed to the tool. This manual provides information regarding potential safety

concerns, as well as helpful assembly and operating instructions for your tool.

NOTE: The following safety information is not meant to cover all possible conditions and situations that may occur.

reserves the right to change this product and specifications at any time without prior notice.

Keep this manual available to all users during the entire life of the tool and review it frequently to maximize

safety for both yourself and others.

SAFETY ALERT SYMBOL: Indicates danger, warning, or caution. The safety symbols and the explanations

with them deserve your careful attention and understanding. Always follow the safety precautions to reduce the

risk of fire, electric shock or personal injury. However, please note that these instructions and warnings are not

substitutes for proper accident prevention measures.

4

GENERAL SAFETY RULES

WORK AREA SAFETY

1. Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

2. Do not operate power tools in explosive atmo-

spheres, such as in the presence of flammable liquids,

gases or dust. Power tools create sparks which may ig-

nite the dust or fumes.

3. Keep children and bystanders away while operating

a power tool. Distractions can cause you to lose control.

ELECTRICAL SAFETY

1. Power tool plugs must match the outlet. Never mod-

ify the plug in any way. Do not use any adapter plugs

with earthed (grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of electric shock.

2. Avoid body contact with earthed or grounded surfac-

es such as pipes, radiators, ranges and refrigerators.

There is an increased risk of electric shock if your body

is earthed or grounded.

3. Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of elec-

tric shock.

4. Do not abuse the cord. Never use the cord for car-

rying, pulling or unplugging the power tool. Keep cord

away from heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of electric

shock.

5. When operating a power tool outdoors, use an ex-

tension cord suitable for outdoor use. Use of a cord

suitable for outdoor use reduces the risk of electric

shock.

6. If operating a power tool in a damp location is un-

avoidable, use a ground fault circuit interrupter (GFCI)

protected supply. Use of a GFCI reduces the risk of elec-

tric shock.

PERSONAL SAFETY

1. Stay alert, watch what you are doing and use com-

mon sense when operating a power tool. Do not use a

power tool while you are tired or under the influence

of drugs, alcohol or medication. A moment of inatten-

tion while operating power tools may result in serious

personal injury.

2. Use personal protective equipment. Always wear

eye protection. Protective equipment such as a respira-

tory mask, non-skid safety shoes and hearing protection

used for appropriate conditions will reduce the risk of

personal injury.

3. Prevent unintentional starting. Ensure the switch is

in the off-position before connecting to power source

and/or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or

energizing power tools that have the switch on invites

accidents.

4. Remove any adjusting key or wrench before turning

the power tool on. A wrench or a key left attached to a

rotating part of the power tool may result in personal

injury.

5. Do not overreach. Keep proper footing and balance

at all times. This enables better control of the power

tool in unexpected situations.

6. Dress properly. Do not wear loose clothing or jew-

elry. Keep your hair and clothing away from moving

parts. Loose clothes, jewelry or long hair can be caught

in moving parts.

Safety is a combination of common sense, staying alert and knowing how your item works. The term “power tool”

in the warnings refers to your mains-operated (corded) power tool or battery-operated (cordless) power tool.

SAVE THESE SAFETY INSTRUCTIONS.

WARNING! Read all safety warnings and all instructions. Failure to follow the warnings and instructions may

result in electric shock, fire and/or serious injury.

5

GENERAL SAFETY RULES

7. If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection

can reduce dust-related hazards.

POWER TOOL USE AND CARE

1. Do not force the power tool. Use the correct power

tool for your application. The correct power tool will

do the job better and safer at the rate for which it was

designed.

2. Do not use the power tool if the switch does not turn

it on and off. Any power tool that cannot be controlled

with the switch is dangerous and must be repaired.

3. Disconnect the plug from the power source and/or

the battery pack from the power tool before making

any adjustments, changing accessories, or storing

power tools. Such preventive safety measures reduce

the risk of starting the power tool accidentally.

4. Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the power

tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained us-

ers.

5. Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and any

other condition that may affect the power tool’s opera-

tion. If damaged, have the power tool repaired before

use. Many accidents are caused by poorly maintained

power tools.

6. Keep cutting tools sharp and clean. Properly main-

tained cutting tools with sharp cutting edges are less

likely to bind and are easier to control.

7. Use the power tool, accessories and tool bits, etc.

in accordance with these instructions, taking into ac-

count the working conditions and the work to be per-

formed. Use of the power tool for operations different

from those intended could result in a hazardous situa-

tion.

8. Use clamps to secure your workpiece to a stable

surface. Holding a workpiece by hand or using your

body to support it may lead to loss of control.

9. KEEP GUARDS IN PLACE and in working order.

SERVICE

1. Have your power tool serviced by a qualified repair

person using only identical replacement parts. This

will ensure that the safety of the power tool is main-

tained.

CALIFORNIA PROPOSITION 65 WARNING

Some dust created by power sanding, sawing, grinding,

drilling, and other construction activities may contain

chemicals, including lead, known to the State of Califor-

nia to cause cancer, birth defects, or other reproductive

harm. Wash hands after handling. Some examples of

these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks, cement, and other

masonry products.

• Arsenic and chromium from chemically treated

lumber.

Your risk from these exposures varies depending on

how often you do this type of work. To reduce your ex-

posure to these chemicals, work in a well-ventilated area

with approved safety equipment such as dust masks

specially designed to filter out microscopic particles.

Safety is a combination of common sense, staying alert and knowing how your item works. The term “power tool”

in the warnings refers to your mains-operated (corded) power tool or battery-operated (cordless) power tool.

SAVE THESE SAFETY INSTRUCTIONS.

WARNING! Read all safety warnings and all instructions. Failure to follow the warnings and instructions may

result in electric shock, fire and/or serious injury.

6

DRILL PRESS SAFETY WARNINGS

1. TOOL PURPOSE. This drill press is designed to

drill through metal and wood. Drilling through other

materials could result in fire, injury, or damage to the

workpiece. Using the machine for any other purpose

for which it is not designed may result in serious in-

juries, machine damage and voiding of the warranty.

2. MACHINE MOUNTING. For operation safety, the

drill press must be securely mounted onto a flat and

stable surface or stand.

3. PERSONAL SAFETY.

• Always wear ANSI Z87.1-approved glasses with

side shields, hearing protection, and a dust mask.

• Do not wear loose clothing or jewelry, as they

might get drawn in by the tool. Tie back long hair.

• Do not wear gloves while operating this machine.

4. ELECTRIC CORDS. Keep cords away from heat,

oil, sharp edges, and moving parts of the tool. Have

an electrician replace or repair damaged or worn

cords immediately.

5. TOOL & ACCESSORIES INSPECTION. Before op-

eration, check the tool and accessories for any dam-

age or missing parts. Do not use the tool if any part

is missing or damaged. Make sure all adjustments

are correct and all connections are tight. Keep all

guards in place.

6. DRILLING ACCESSORIES.

• Make sure the drill bit is not damaged before

use, only use undamaged drill bits

• Make sure the drill bit is securely locked in the

chuck before turning ON.

• Make sure the chuck key is removed from the

chuck before turning ON.

• Use clamps or a vise to secure a workpiece to

the table. This will prevent the workpiece from

rotating with the drill bit.

7. Make sure the table lock is tightened before start-

ing the drill press.

8. WORKPIECE REQUIREMENTS.

• Only stand workpieces sturdy enough to with

stand the force of the drill bit.

• Inspect workpiece for imperfections, nails,

staples, etc. before drilling. Never drill stock that

has questionable imperfections or embedded

foreign objects.

• Do not drill materials without a flat surface un

less a suitable support is used (clamp or vise).

9. PREVENTING ACCIDENTAL STARTING. Make sure

the power switch is in the OFF position prior to plug-

ging in the machine. Always make sure the power

switch is in the OFF position and the machine is un-

plugged when doing any cleaning, assembly, setup

operations, or when not in use.

10. Do not operate this tool until it is completely as-

sembled and installed according to the instructions.

11. Remove scrap pieces and other objects from the

table before turning ON the drill press.

12. DRILLING THE WORKPIECE.

• Allow spindle to reach full speed before drilling

the workpiece.

• Never start the machine with the drill bit pressed

against the workpiece.

• Adjust the table or depth stop to avoid drilling

into the table.

• Set the drill press to the speed that is appropriate

for the material being drilled.

13. Do not touch moving pieces. Keep hands away

from the drill bit during operation. If cleaning is nec-

essary, turn off the machine and use a brush to re-

move sawdust and chips instead of your hands.

14. Never perform layout, assembly or set-up work

on the table while the machine is ON.

WARNING! Do not operate the power tool until you have read and understood the following instructions and

the warning labels.

7

DRILL PRESS SAFETY WARNINGS

15. After turning off the drill press, wait until the

spindle comes to a complete stop before touching

the workpiece. Always turn the drill OFF before re-

moving scrap from the table.

16. Before leaving the machine, always turn OFF and

unplug the machine, remove the drill bit, and clean

the table. Turn Off and unplug the machine before

cleaning, making adjustments or changing drill bits.

Accidental start-ups may occur if the tool is plugged

in during an accessory change or adjustment.

17. CLEANING. Never use solvents to clean plastic

parts. Solvents could dissolve or otherwise dam-

age the material. Use only a soft damp cloth to clean

plastic parts.

18. REPLACEMENTS. Should any component of

your drill press be missing/damaged or fail in any

way, shut OFF the switch and remove the plug

from power supply outlet. Replace the missing,

damaged, or failed parts using only identical re-

placement parts before resuming operation.

CALIFORNIA PROPOSITION 65 WARNING

Some dust created by power sanding, sawing, grind-

ing, drilling, and other construction activities may

contain chemicals, including lead, known to the

State of California to cause cancer, birth defects, or

other reproductive harm. Wash hands after handling.

Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks, cement, and other

masonry products.

• Arsenic and chromium from chemically treated

lumber.

Your risk from these exposures varies depending

on how often you do this type of work. To reduce

your exposure to these chemicals, work in a well-

ventilated area with approved safety equipment such

as dust masks specially designed to filter out micro-

scopic particles.

WARNING! Do not operate the power tool until you have read and understood the following instructions and

the warning labels.

8

ELECTRICAL INFORMATION

AMPERAGE REQUIRED GAUGE FOR EXTENSION CORDS

25 ft. 50 ft. 100 ft. 150 ft.

2.3A 18 gauge 16 gauge 16 gauge 14 gauge

3. Check

with a licensed electrician or service personnel if you do not completely

understand the grounding instructions or whether the tool is properly grounded.

4. Use only three-wire extension cords

that have three-pronged plugs and outlets

that accept the tool’s plug (INSERT CR). Repair or replace a damaged or worn cord

immediately.

CAUTION!

In all cases, make certain the outlet in question is properly grounded. If

you are not sure, have a licensed electrician check the outlet.

GUIDELINES AND RECOMMENDATIONS FOR EXTENSION CORDS

GROUNDING INSTRUCTIONS

In the event of a malfunction or breakdown

, grounding provides the path of least resistance for an electric

current and reduces the risk of electric shock. This tool is equipped with an electric cord that has an

equipment grounding conductor and a grounding plug. The plug MUST be plugged into a matching outlet

that is properly installed and grounded in accordance with ALL local codes and ordinances.

1. Do not modify the plug provided.

If it will not fit the outlet, have the proper outlet installed by a licensed

electrician.

2. Improper connection

of the equipment grounding conductor can result in electric shock. The conductor

with the green insulation (with or without yellow stripes) is the equipment grounding conductor. If repair or

replacement of the electric cord or plug is necessary, DO NOT connect the equipment grounding conductor

to a live terminal.

1. Examine extension cord before use. Make sure your extension cord is properly wired and in good condition.

Always replace a damaged extension cord or have it repaired by a qualified person before using it.

2. Do not abuse extension cord. Do not pull on cord to disconnect from receptacle; always disconnect by pulling on

plug. Disconnect the extension cord from the receptacle before disconnecting the product from the extension cord.

Protect your extension cords from sharp objects, excessive heat and damp/wet areas.

3. Use a separate electrical circuit for your tool. This circuit must not be less than a 12-gauge wire and should be

protected with a 15A time-delayed fuse. Before connecting the motor to the power line, make sure the switch is in

the OFF position and the electric current is rated the same as the current stamped on the motor nameplate. Running

at a lower voltage will damage the motor.

Fig. 1

When using an extension cord, be sure to use one heavy enough to carry the current your product will draw. An un-

dersized cord will cause a drop in line voltage resulting in loss of power and overheating. The table below shows the

correct size to be used according to cord length and ampere rating. When in doubt, use a heavier cord. The smaller

the gauge number, the heavier the cord.

9

UNPACKING & PACKING LIST

UNPACKING

With the help of a friend or trustworthy foe, carefully remove the Drill Press from the packaging. Make sure to take

out all contents and accessories. Do not discard the packaging until everything is removed. Check the packing list

below to make sure you have all of the parts and accessories.

PACKING LIST

ASSEMBLY / ADJUSTMENT TOOLS

The tools listed below are not included but are required for either assembly or adjustment:

• Adjustable wrench

• Hammer and block of wood or rubber mallet, or dead-blow hammer

WARNING! Do not plug in or turn on the tool until it is fully assembled according to the instructions. Failure

to follow the safety instructions may result in serious personal injury.

1

2

5

6

3

4

7

89

12

13

14

10

Head / Motor Assembly....................................1

Table Locking Handle.......................................1

Table Asssembly...............................................1

Base.............................................................1

Column Assembly............................................1

Chuck...............................................................1

Chuck Key........................................................1

Feed Handles...................................................3

Hex Wrench.....................................................2

Hex bolt M 8×20...............................................3

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

Depth gauge.....................................................1

11.

Column collar...................................................1

12.

Table adjustment handle...................................1

13.

Worm gear........................................................1

14.

11

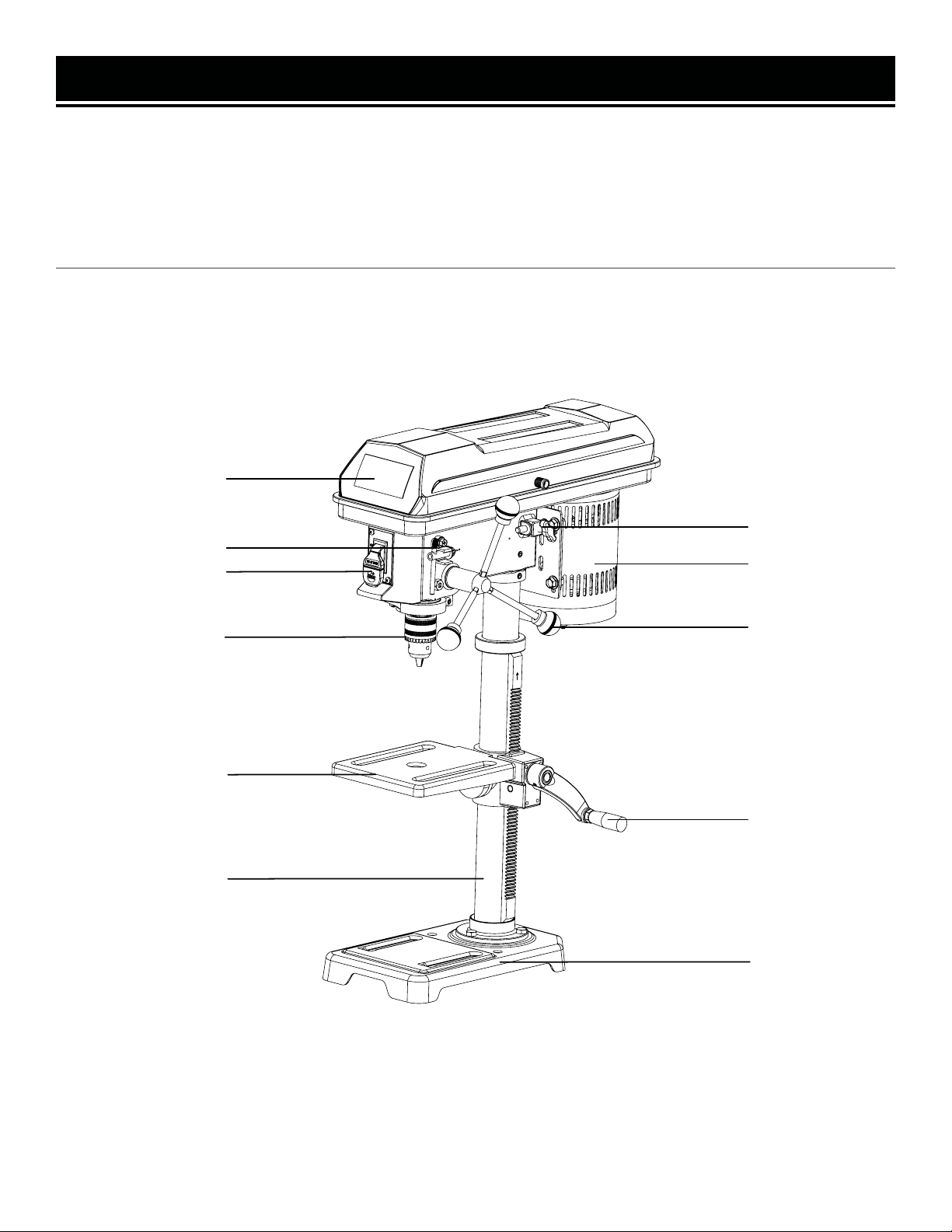

KNOW YOUR DRILL PRESS

TOOL PURPOSE

Drill clean, precise cylindrical holes into workpieces or enlarge existing holes with your Drill Press. Refer to the fol-

lowing diagrams to become familiarized with all the parts and controls of your Drill Press. The components will be

referred to later in the manual for assembly and operation instructions.

10

DRILL PRESS

Housing Cover

Chuck Key

Chuck

Motor

Feed Handle

Belt Tension

Base

Table assembly

Table Lock

ON/OFF Switch

Column

11

Table assembly

Worm gear

D-shaft

Table lock handle

Threaded hole

Slot

ASSEMBLY & ADJUSTMENTS

ATTACHING COLUMN ASSEMBLY TO BASE

1. Place the column tube on the base,aligning the column

support holes to the base holes.

2. Install a hex head bolt in each of the three column

support holes and tighten using the adjustable wrench

(not included).

INSTALLING TABLE ASSEMBLY

WARNING! Do not plug in or turn on the tool until it

is fully assembled according to the instructions. Failure

to follow the safety instructions may result in serious

personal injury.

Fig. 3

Fig. 4

Gear rack

Base

Hex bolt

Column Fig. 2

(Fig. 2)

(Fig. 3-6)

1. Loosen the set screw in the column collar. Remove the

column collar and gear rack from the column and set aside.

2. Clean the spindle with a degreaser before installing the

chuck into the head.

3. Locate the worm gear and feed the D-shaft through the

hole in the table assembly.

4. Install table adjustment handle over the end of the D-

shaft so that the flat side of the shaft aligns with the set

screw.Tighten the set screw using the hex key.

5. Feed the gear rack through the slot in the table assembly

so that the teeth are facing out and the longer smooth end

faces up. The worm gear should engage the gear rack.

6. Using both hands, slide the entire table assembly and

gear rack onto the column until the bottom of the gear rack

is positioned in the base collar and against the column.

7. Slide the column collar, bevel-side down, over the

column until the beveledside engages the beveled end ofthe

gear rack. Tighten the set screw in the collar using the hex

key. Do not overtighten.

Table assembly

Fig. 5

Gear rack

Column collar

Set screw

Base collar

NOTE: You should be able to move the table from side to

side.

Locate the table lock handle. Insert it into the threaded

hole at the rear of the table assembly and tighten by hand.

If the drill press is to be usedin a permanent location, secure

it to a workbench or other stable surface.

If the drill press is to be used as a portable tool, fasten it

permanently to a mounting board that can easily be clamped

to a workbench or other stable surface. The mounting board

should be of sufficient size to avoid tipping while drill press

is in use. Any good grade plywood or chipboard with a

3/4 in. thickness is recommended.

1. Mark holes on surface where drill press is to be mounted

using holes in drill press base as a template for hole

pattern.

1. Place the head assembly upside down on a level, flat

surface.

2. Position chuck on spindle. Chuck should be fully opened

to avoid damaging jaws.

3. Using a piece of scrap wood to protect the chuck, firmly

tap the chuck into place using a mallet or hammer.

4. Position the head assembly onto the column with the

chuck positioned over the table.

NOTE: This head assembly is heavy. Get help when needed.

5. Slide the head assembly down as far as it will go. Align

the table assembly with the base and then tighten the

two head set screws with the hex key.

6. Attach the three feed handles by screwing them into the

threaded holes in the hub.

12

ASSEMBLY & ADJUSTMENTS

(Fig. 7-8)

(Fig. 9)

Chuck

Scrap wood

Fig. 8

WARNING! Before any assembly of the chuck to the

drill press spindle, clean all mating surfaces with a non-

petroleum based product; such as acetone or lacquer

thinner. Any oil or grease used in the packing of these

parts must be removed; otherwise the chuck may come

loose during operation.

INSTALLING CHUCK, HEAD ASSEMBLY, AND

FEED HANDLES

MOUNTING THE DRILL PRESS

Fig. 7

Feed handle

Mallet

Fig. 6

Set screw

Hex key

2. Drill holes through mounting surface.

3. Place drill press on mountingsurface,aligning holes in

the base with holes drilledinthe mounting surface.

4. Insert bolts (not included) and tighten securely with lock

washers andhex nuts (not included).

5. If lag bolts are used, make sure they are long enough to

go through holes in drill press base and material thedrill

press is beingmounted to. If machine bolts are used, make

sure bolts are longenough to gothrough holes in drill press,

the material being mounted to, and the lock washers and hex

nuts.

NOTE: All bolts should be inserted from the top. Install the

lock washers and hex nuts from the underside of the

workbench.

Once the drill press is securely mounted on a sturdy surface:

1. Check for vibrationwhen the motor is switched ON.

2. Adjust and retighten the mounting hardware as necessary.

3. Check the table assembly toassure smooth movement

up anddownthe column.

4. Check toassure that the spindle shaft moves smoothly.

13

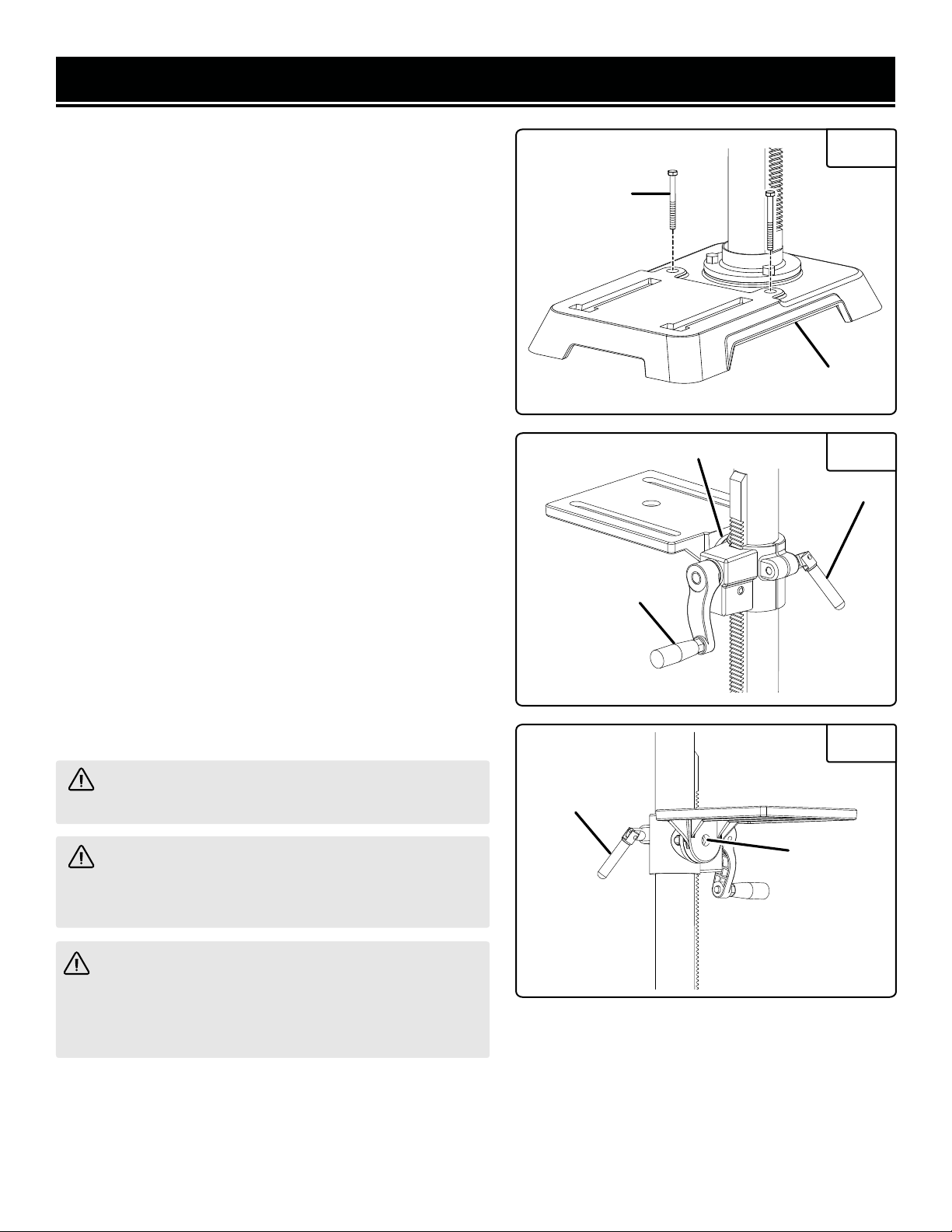

ASSEMBLY & ADJUSTMENTS

Fig. 9

Fig. 10

Fig. 11

(Fig. 10)

ADJUSTING TABLE HEIGHT

WARNING! Use of controls or adjustments or per-

formance of procedures other than those specified herein

could result in hazardous radiation exposure.

WARNING! Before performing any adjustment, make

sure the tool is unplugged from the power supply and the

switch is in the OFF ( O ) position. Failure to heed this

warning could result in serious personal injury.

WARNING! Laser radiation. Avoid direct eye contact

with light source.

Mounting bolts

Base

Bevel scale

Table lock handle

Table lock handle

Hex bolt

Table adjustment handle

1. Holdthe table with one hand and loosen the table lock handle.

2. Rotate the table adjustment handle clockwise to raise the table.

Fig. 12

Fig. 13

Fig. 15

(Fig. 11-12)

ADJUSTING TABLE BEVEL

(Fig. 12)

ADJUSTING DEPTH GAUGE

(Fig. 13-15)

CHANGING SPEEDS

Drive belt

Motor pulley

Pivot nut

Pivot bolt

Tension bolt

Motor

Depth stop

locking collar

Depth gauge

14

ASSEMBLY & ADJUSTMENTS

3. Rotate the table adjustment handle counterclockwise to

lower the table.

4. Position the table to the desired height and retighten the

table lock handle.

The drill press is equipped with a tilting table that allows

you to drill angled holes. The table can be tilted left or right,

from 0º to 45º.

To tilt the table:

1. Loosen the large hex bolt located underneath the table.

2. Use the bevel scale to tilt the table to the desired angle.

3. Retighten the hex bolt securely.

Adjust the depth gauge when you need to drill a number of

holes to exactly the same depth.

1. Loosen the depth stop locking collar.

2. Rotate depth gauge to desired setting.

3. Retighten depth stop locking collar, if needed.

The spindle speed is determined by the location of the belt

on the pulleys inside the head assembly. The speed chart

located on the cover inside the head assembly shows the

recommended speed and pulley configuration for each

drilling operation.

NOTE: The pivot bolts located on the side of the tool should

allow the motor to move freely once the tension bolt is

loosened.If themotor is difficult to move, it may benecessary

to loosen the pivot bolts slightly (1/4turn). Do not retighten.

1. Lift head assembly cover from side to open.

2. Loosen the tension bolt until there is enough slack in the

belt for it to be repositioned around the pulleys.

3. Reposition the belt according to the speed chart.

Fig. 14

Spindle pulley

(Fig. 16)

PULLEYS

15

ASSEMBLY & ADJUSTMENTS

(1)When decreasing speed, move the belt downthe motor

pulley first and then down the spindle pulley.

(2)When increasing speed, move the belt up the spindle

pulley first and then up the motor pulley.

4. Turn the belt by hand until you are certain it is properly

aligned on the grooves of the pulleys.

5. Move the motor away from the tool until there is tension

in the belt.

6. Hold the motor in place and retighten the tension bolt.

Should you feel an unusually high level of vibration, the

pulleys may not be tightly secured on the motor and/or

spindle shafts. To make surethe pulleys are properly seated

and tight, locate the set screw on each of the pulleys.

Tighten each set screw with the hex key.

Fig. 16

Pulley set

screws

OPERATION

WARNING! Do not allow familiarity with tools to

make you careless.Remember that a careless fraction

of a second is sufficient to inflict serious injury.

WARNING! Always wear eye protection with side

shields marked to comply with ANSI Z87.1. Failure to

do so could result in objects being thrown into your

eyes, resulting in possible serious injury.

WARNING! Do not use any attachments or

accessories not recommended by the manufacturer of

this tool. The use of attachments or accessories not

recommended can result in serious personal injury.

WARNING! ALWAYS remove the switch key

when the tool is not in use and keep it in a safe place.

In the event of a power failure, turn the switch OFF

(O)and remove the key.This action will prevent the

tool from accidentally starting when power returns.

WARNING! Always make sure the workpiece is

not in contact with the bit before operating the switch

to start the tool. Failure to heed this warning may

cause the workpiece to be kicked back toward the

operator and result in serious personal injury.

WARNING! To prevent the workpiece or the backup

material from being torn from your hand while drilling,

position them against the left side of the column. If the

workpiece or the backup material are not long enough

to reach the column, clamp them to the table. Failure to

do this could result in personal injury.

The drill press is equipped with a power switch that has a

built-in locking feature. This feature is intended to prevent

unauthorized and possible hazardous use by children and

others.

To turn the drill press on:

With the switch key inserted into the switch, lift the switch

to turn ON ( l ).

To turn the drill press off:

With the switch key inserted into the switch, push the

switch down to turn OFF ( O ).

To LOCK the drill press:

1. Place the switch in the OFF ( O ) position.

2. Remove the switch key from the switch and store in a

secure location.

Fig. 17

(Fig. 17)

POWER SWITCH

Power off

Switch key

Power on

APPLICATIONS

You may use this tool for the purposes listed below:

1. Drilling in wood.

2. Drilling in ceramics, plastics, fiberglass, and laminates.

3. Drilling in metals.

16

OPERATION

WARNING! Use only the self-ejecting chuck key

provided. Always remove chuck key. Failure to heed this

warning could result in serious personal injury.

WARNING! Donot insert drill bitinto chuck jaws and

tighten as shown in figure 20. This could cause drill bit to

be thrown from the drill press, resulting in possible

serious personal injury or damage to the chuck.

Fig. 18

Fig. 19

The self-ejecting chuck key ensures the chuck key is removed

from the chuck before the drill press is turned on.

In order to loosen or tighten the chuck using the chuck key,

push the key into the key hole located on the chuck. Rotate

the key clockwise to tighten the chuck or counterclockwise

to loosen the chuck.

(Fig. 18)

SELF-EJECTING CHUCK KEY

The table can be rotated out of the way when drilling large

objects.

1. Loosenthe table lock handle.

2. Rotate the table to the desired position.

3. Retighten the table lock handle.

(Fig. 19)

TABLE ROTATION

1. Unplug the drill press.

2. Open or close the chuck jaws to a pointwhere the opening

is slightly larger than the bit size youintend to use.

3. Insert drill bit into the chuck the full length of the jaws.

1. Using a clamping device, secure the workpiece to the work-

table. To protect the top surface of the workpiece,use a piece

of scrap wood between the clamping device and the workpiece.

(Fig. 20)

INSTALLING AND REMOVING BITS

(Fig. 21)

DRILLING

Chuck key

Table assembly

Table lock handle

Key hole

4. Unplug the drill press.

5. Open or close the chuck jaws to a point where the opening

is slightly larger than thebit size you intend to use.

6. Insert drill bit intothe chuck the full length ofthe jaws.

Fig. 20

17

OPERATION

Fig. 21

2. Select theproper drill bit based on the hole size desired.

For large holes, drill a pilot hole first, using a smaller diameter

bit.

3. Select and set the recommended spindle speed. Refer to

“Changing Speeds” in the Adjustments section of this manual.

4. Set table assembly to desired height. Refer to “Adjusting

Table” Height in theAdjustments section.

5. If desired,set feed shaft at desired spindle depth. Refer to

“Adjusting Depth Gauge” in the Adjustments section.

6. Make surethe work table is free of all loose objects and

the bit is not in contact with the workpiece.

7. Plug electrical cord into powersupply and turn switch ON.

Make sure spindle rotates freely.

8. Slowly lower drill bit into workpiece. Do not force the bit;

let the drill press do the work.

9. Once the hole is completed,allow the spindle to return to

its normal position. This will automatically raise the chuck

and bit.

If a large hole is needed,it’s a good idea to drill a smaller pilot

hole before drilling the final one. Your hole will be more

accurately positioned, rounder, and the bits will last longer.

If the hole is deeper than it is wide, back offoccasionally to

clear the chips.

When drilling metal, lubricate the bit with oil to improve drilling

action and increase bit life.

As you increase the drill size, you may need to reduce the

spindle speed.

If drilling a throughhole, make sure that the bit will not drill into

the table after moving through the workpiece.

DRILLING TIPS

Clamp

Scrap wood

Workpiece

18

OPERATION

DRILLING SPEEDS

There are a few important factors to keep in mind when determining the best drilling speed:

• Material type

• Hole size

• Drill bit or cutter type

• Quality desired

Smaller drill bits require greater speed than larger drill bits. Softer materials require greater speed than harder ma-

terials.

DRILLING WOOD

• Brad point bits are preferred. Metal-piercing twist bits may be used on wood.

• Do not use auger bits. Auger bits turn so rapidly that they can lift the workpiece off of the table and whirl it around.

• To prevent splintering, feed drill bit slowly right as the bit is about to cut through to the backside of the workpiece.

• To reduce splintering and protect the point of the bit, use scrap wood or a base block under the workpiece.

• Always protect the drill bit by positioning the table so that the drill bit will enter the center hole when drilling

through the workpiece.

FEEDING THE DRILL BIT

• Pull down on the feed handles with only enough force to allow the drill bit to cut.

• Feeding too rapidly might stall the motor, cause the belt to slip, damage the workpiece, or break the drill bit.

• Feeding too slowly will cause the drill bit to heat up and burn the workpiece.

MAINTENANCE

ROUTINE INSPECTION

Before each use, inspect the tool. If any of these following conditions exist, do not use until parts are replaced.

Check for:

• Loose hardware or improper mounting

• Misalignment

• Damaged cord / electrical wiring

• Cracked or broken parts

• Any other condition that may affect its safe operation

WARNING! To avoid accidents, turn OFF and unplug the tool from the electrical outlet before cleaning,

adjusting, or performing any maintenance or lubrication work.

WARNING! Any attempt to repair or replace electrical parts on this tool may be hazardous. Servicing of the

tool must be performed by a qualified technician. When servicing, use only identical replacement parts. Use of

other parts may be hazardous or induce product failure.

CAUTION! Most plastics are susceptible to damage from various types of commercial solvents. Do not use

any cleaning products that could damage plastic parts. Some of these include but are not limited to: gasoline,

carbon tetrachloride, chlorinated cleaning solvents, and household detergents that contain ammonia.

19

MAINTENANCE

CLEANING & STORAGE

1. After every operation, use a vacuum to remove sawdust or metal shavings from the tool surfaces, motor hous-

ing and work area. Keep the ventilation openings free from dust and debris to prevent the motor from overheating.

2. Wipe the tool surfaces clean with a soft cloth or brush. Make sure water does not get into the tool.

3. Apply a light coat of paste wax to the column and table to help keep these surfaces clean and rust free.

4. Store the tool in a clean and dry place away from the reach of children.

LUBRICATION

The ball bearings in the spindle and the V-belt pulley assembly are greased and permanently sealed, and require no

lubrication. Pull the spindle down and oil the quill moderately every three months.

Lubricate the table bracket and locking knobs if they become difficult to use.

PRODUCT DISPOSAL

Used power tools should not be disposed of together with household waste. This product contains electronic com-

ponents that should be recycled. Please take this product to your local recycling facility for responsible disposal and

to minimize its environmental impact.

Please recycle the packaging and electronic components where facilities exist.

20

Table of contents

Other BILT HARD Power Tools manuals

Popular Power Tools manuals by other brands

Bosch

Bosch GDR 14,4 V-LI Professional instructions

Cocraft

Cocraft ASYPHT04180 manual

Scheppach

Scheppach HMS850 Translation from the original instruction manual

Chicago Electric

Chicago Electric 94782 Assembly and operation instructions

Makita

Makita DTW190 instruction manual

Silverline

Silverline 430787 Original instructions

EINHELL

EINHELL SB 501 operating instructions

Bosch

Bosch DL 0 607 453 4 Series Original instructions

Moto Tork

Moto Tork MT70N operating instructions

Skil

Skil 1400 Operating/safety instructions

Schwamborn

Schwamborn BEF 204 Translation of the original operating manual

DeWalt

DeWalt DPN46RN-XJ Original instructions