Redline Operating Manual RE / RF / RI 12/2010 page 9/46

Content

EC – Declaration of Conformity redLINE RE ................................................................................................2

EC – Declaration of Conformity redLINE RF ................................................................................................4

EC – Declaration of Conformity redLINE RI..................................................................................................6

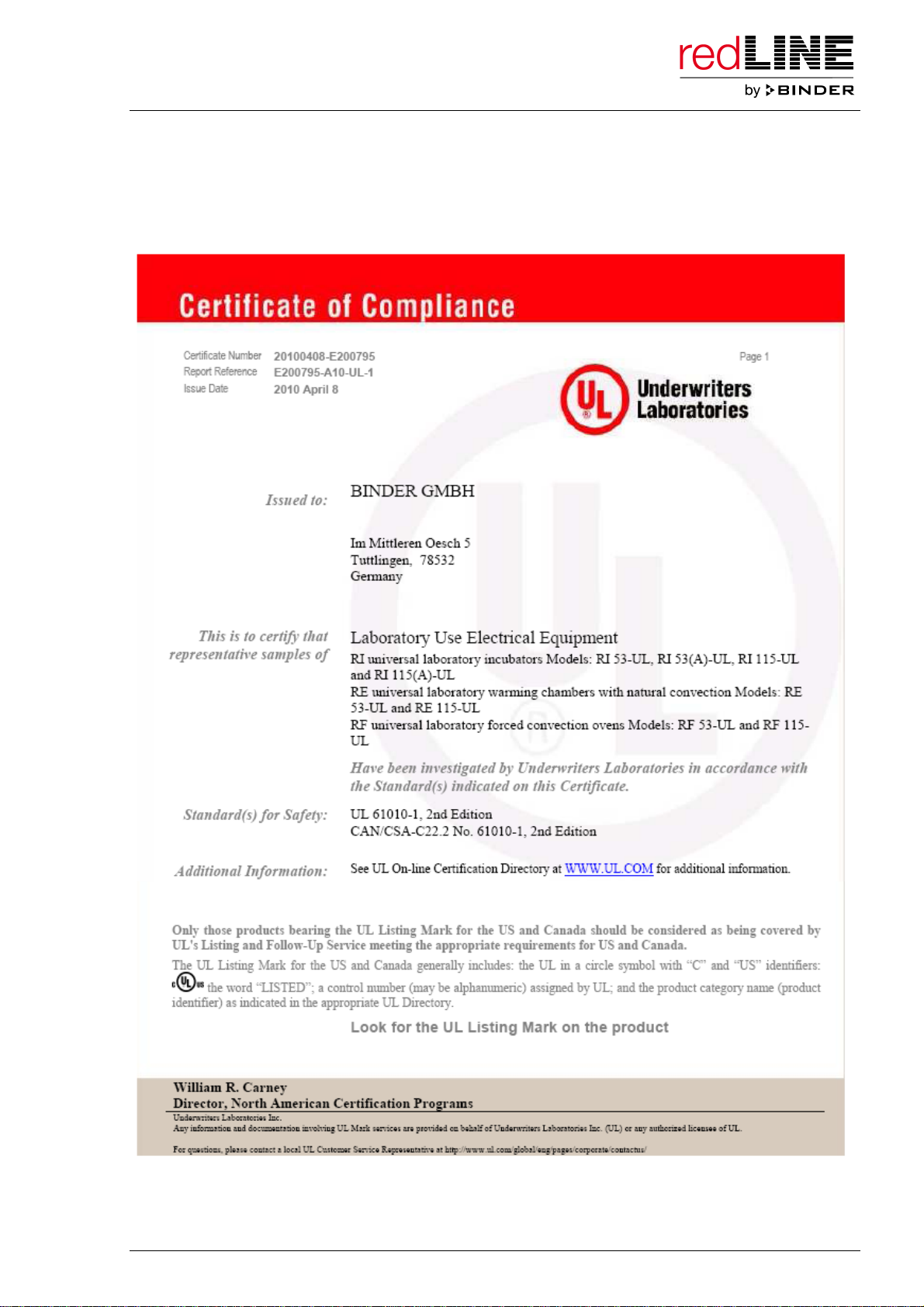

UL certificate, valid for redLINE-UL units......................................................................................................8

1. SAFETY................................................................................................................11

1.1 Legal considerations .........................................................................................................................11

1.2 Structure of the safety instructions....................................................................................................11

1.2.1 Signal word panel ........................................................................................................................11

1.2.2 Safety alert symbol ......................................................................................................................12

1.2.3 Pictograms ...................................................................................................................................12

1.2.4 Word message panel structure....................................................................................................13

1.3 Localization / position of safety labels on the unit.............................................................................13

1.4 Type plate .........................................................................................................................................14

1.5 General safety instructions on installing and operating the redLINE chambers...............................15

1.6 Intended use .....................................................................................................................................16

2. UNIT DESCRIPTION............................................................................................17

2.1 Scope of delivery...............................................................................................................................17

2.2 Equipment overview..........................................................................................................................18

2.3 Control panel.....................................................................................................................................19

3. SCOPE OF DELIVERY, TRANSPORTATION, STORAGE, AND INSTALLATION19

3.1 Unpacking, and checking equipment and scope of delivery.............................................................19

3.2 Guidelines for safe lifting and transportation ....................................................................................20

3.3 Storage..............................................................................................................................................20

3.4 Location of installation and ambient conditions ................................................................................20

3.5 Stacking ............................................................................................................................................21

4. INSTALLATION OF THE EQUIPMENT ...............................................................22

4.1 Electrical connection .........................................................................................................................22

4.2 Connection to a suction plant (optional) ...........................................................................................23

5. START UP............................................................................................................24

5.1 Adjusting the air change ...................................................................................................................24

5.2 Controller overview ...........................................................................................................................25

5.3 Turning on the unit ............................................................................................................................27

6. OPERATING THE CONTROLLER.......................................................................27

6.1 Operating modes...............................................................................................................................27

6.2 Operating mode Automatic Mode – entering the set-point ...............................................................29

6.3 Operating mode Manual Mode .........................................................................................................30

6.4 Timer operation.................................................................................................................................30

6.5 Setting the temperature unit..............................................................................................................32

7. CALIBRATING AND ADJUSTING THE TEMPERATURE CONTROLLER.........33

7.1 Required measuring equipment........................................................................................................33

7.2 Check (calibration) ............................................................................................................................33

7.3 Two-point adjustment procedure ......................................................................................................33

8. CLEANING AND DECONTAMINATION..............................................................37

8.1 Cleaning ............................................................................................................................................37

8.2 Decontamination ...............................................................................................................................38