VAP 1 / VAP 2 06/2020 Page 2/52

Contents

1. SAFETY..................................................................................................................4

1.1 Personnel Qualification.......................................................................................................................4

1.2 Operating manual................................................................................................................................4

1.3 Legal considerations...........................................................................................................................4

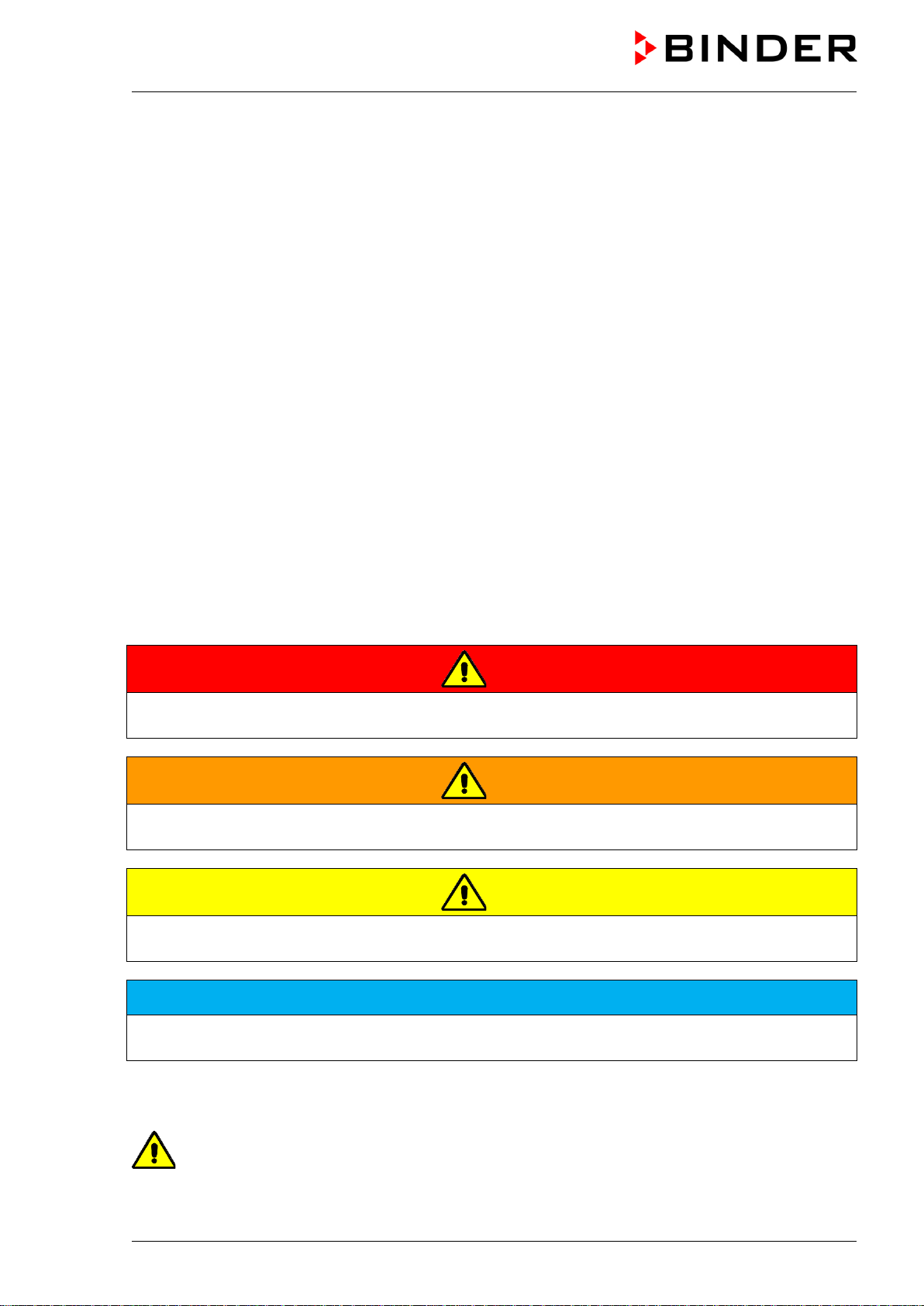

1.4 Structure of the safety instructions......................................................................................................5

1.4.1 Signal word panel .....................................................................................................................5

1.4.2 Safety alert symbol ...................................................................................................................5

1.4.3 Pictograms................................................................................................................................6

1.4.4 Word message panel structure.................................................................................................6

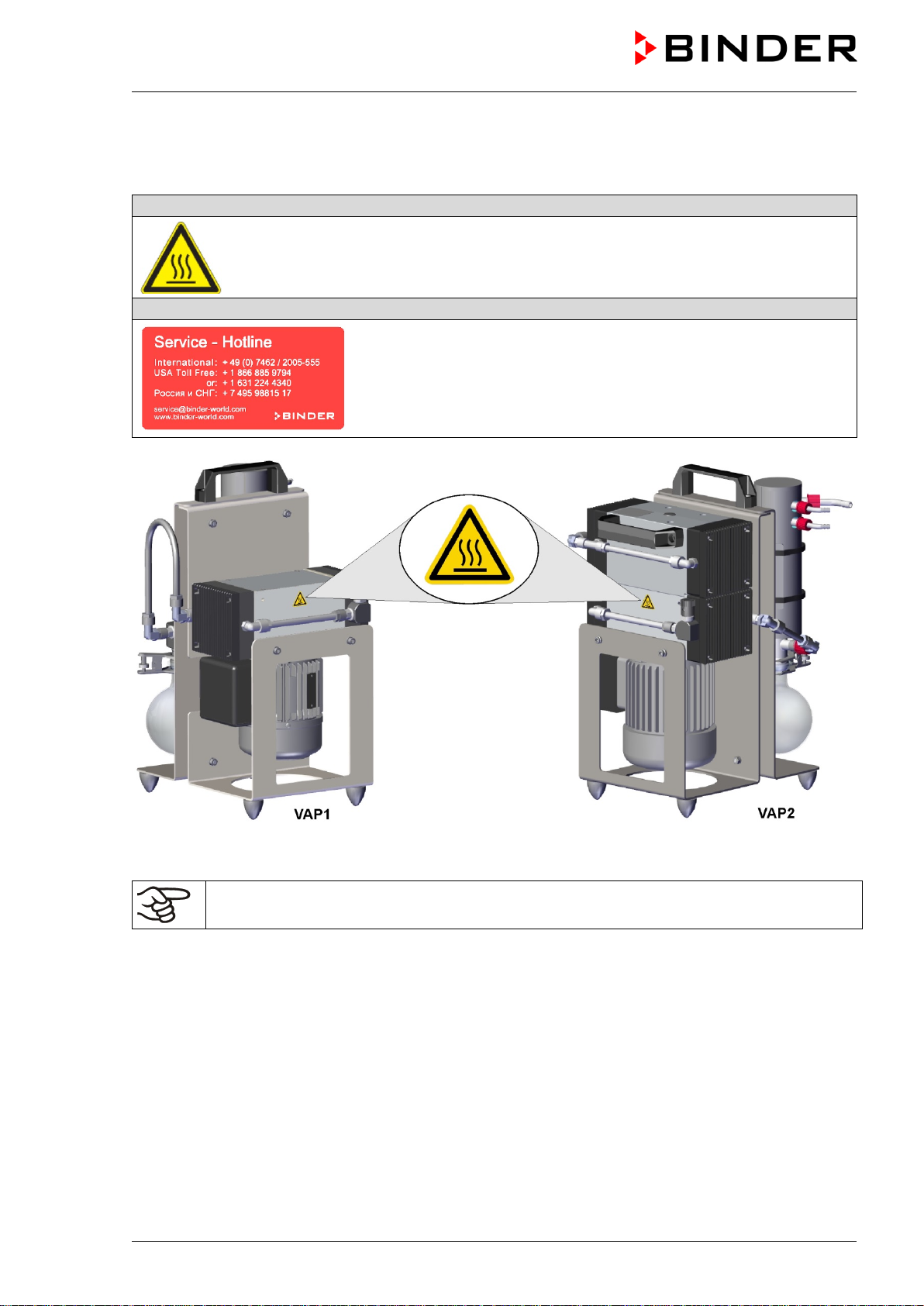

1.5 Localization / position of safety labels on the device..........................................................................7

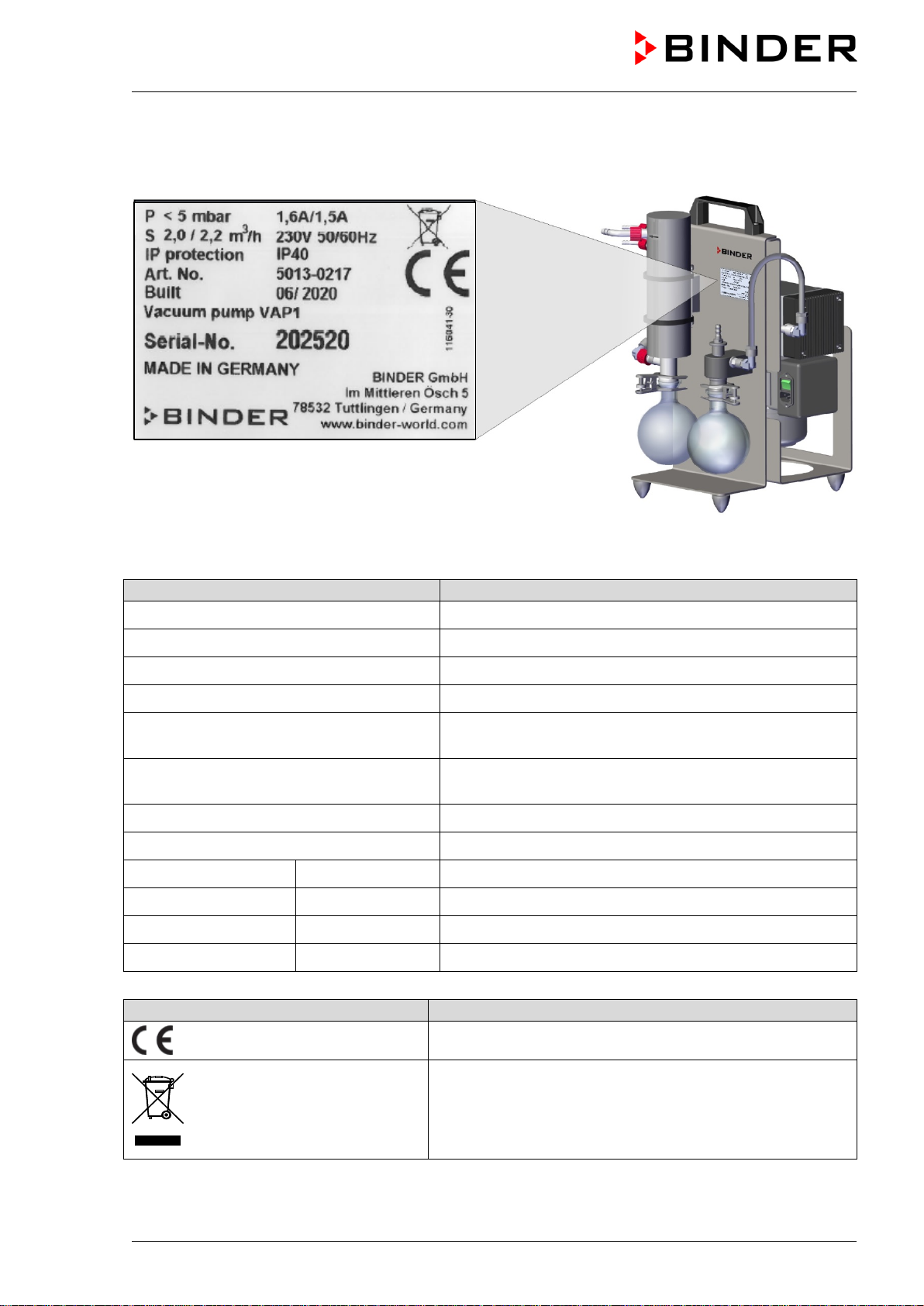

1.6 Type plate............................................................................................................................................8

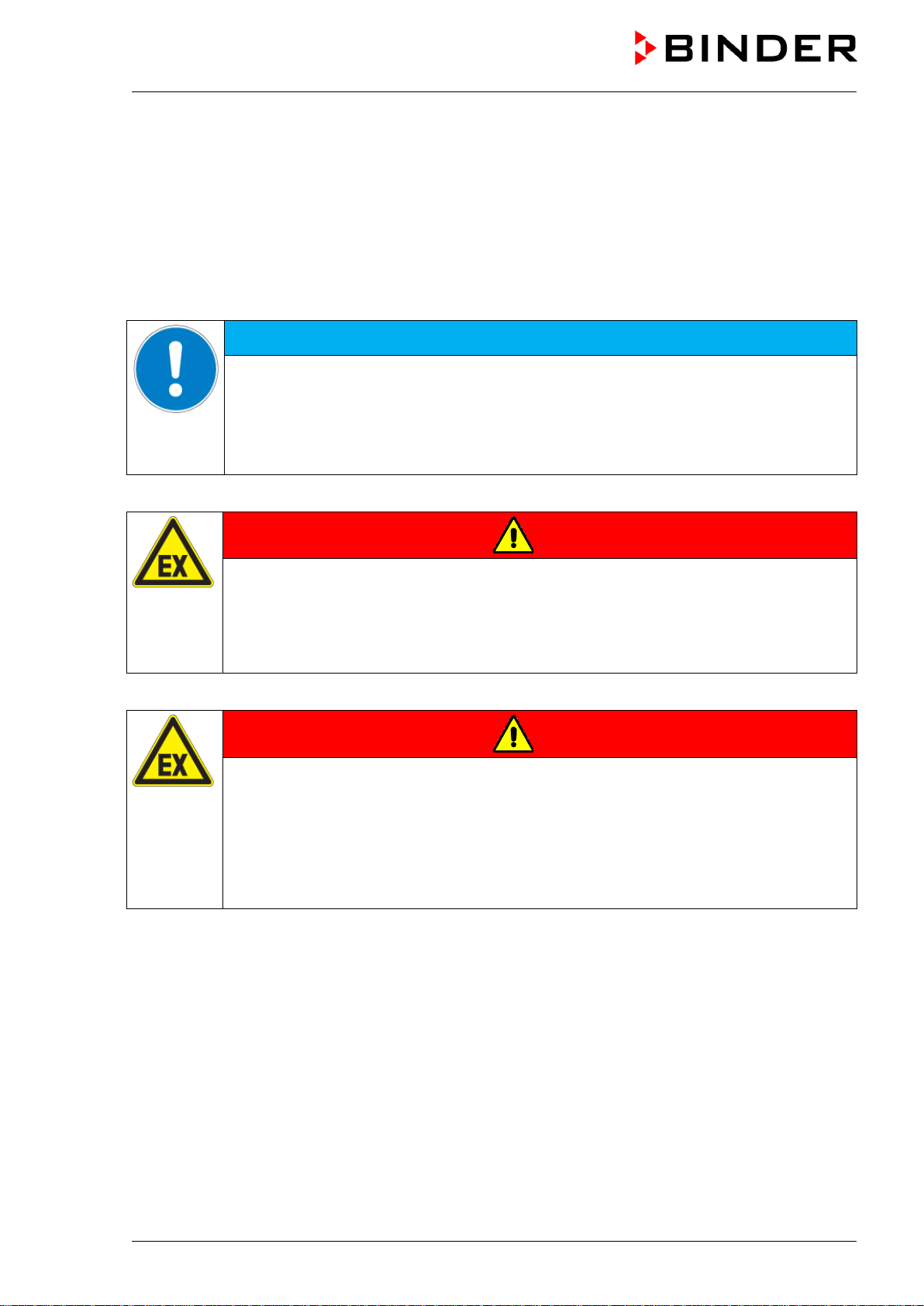

1.7 General safety instructions on installing and operating......................................................................9

1.8 Intended use .....................................................................................................................................11

1.9 Foreseeable Misuse..........................................................................................................................12

1.10 Residual Risks ..................................................................................................................................13

1.11 Operating instructions .......................................................................................................................14

1.12 Measures to prevent accidents.........................................................................................................15

2. DEVICE DESCRIPTION.......................................................................................16

2.1 Device overview................................................................................................................................17

3. COMPLETENESS OF DELIVERY, TRANSPORTATION, STORAGE, AND

INSTALLATION....................................................................................................18

3.1 Scope of delivery...............................................................................................................................18

3.2 Unpacking, and checking the equipment..........................................................................................18

3.3 Assembly...........................................................................................................................................19

3.4 Guidelines for safe transportation.....................................................................................................20

3.5 Storage..............................................................................................................................................20

3.6 Location of installation and ambient conditions ................................................................................20

4. INSTALLATION AND CONNECTIONS ...............................................................21

4.1 Vacuum connection...........................................................................................................................21

4.2 Electrical connection.........................................................................................................................23

5. START UP............................................................................................................24

5.1 Turning on the device........................................................................................................................24

5.2 Adjusting the gas ballast...................................................................................................................25

6. OPERATION.........................................................................................................25

6.1 Daily inspection.................................................................................................................................25

6.2 Removing and emptying the condensate catchpot...........................................................................26

7. CLEANING AND DECONTAMINATION..............................................................26

7.1 Cleaning............................................................................................................................................27

7.2 Decontamination / chemical disinfection of the device .....................................................................28

8. MAINTENANCE AND SERVICE, TROUBLESHOOTING, REPAIR, TESTING...29

8.1 General information, personnel qualification.....................................................................................29

8.2 Maintenance intervals, service..........................................................................................................30

8.3 Simple troubleshooting......................................................................................................................30

8.4 Maintenance by the operator ............................................................................................................31

8.4.1 Replacing the form diaphragm, valves, and O-rings ..............................................................32

8.4.2 Function test ...........................................................................................................................34

8.5 Sending the device back to BINDER GmbH.....................................................................................34