VAP 5 02/2022 Page 2/94

Contents

1. OPERATING MANUAL AND CLASSIFICATION .................................................. 5

1.1 Operating manual................................................................................................................................5

1.2 Legal considerations ...........................................................................................................................6

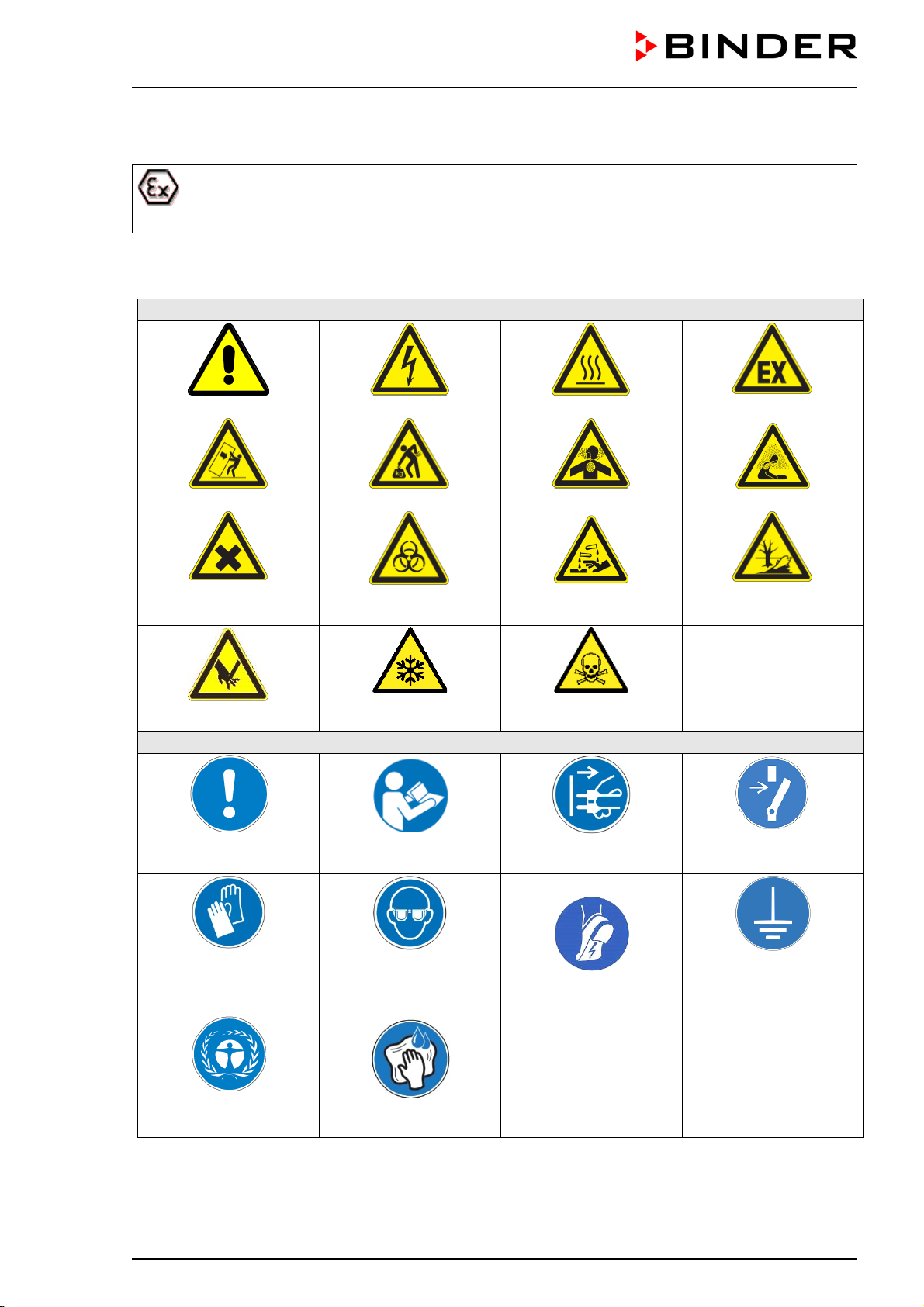

1.3 Structure of the safety and warning notices........................................................................................7

1.3.1 Warning levels ..........................................................................................................................7

1.3.2 Representation of safety and warning notices..........................................................................7

1.3.3 Safety alert symbol ...................................................................................................................7

1.3.4 Explosion protection symbol .....................................................................................................8

1.3.5 Pictograms in this manual.........................................................................................................8

1.4 Localization / position of safety labels on the device ..........................................................................9

1.5 Type plates and classifications .........................................................................................................10

1.5.1 Type plate of the entire device VAP 5 ....................................................................................10

1.5.2 Type plate of the electric motor ..............................................................................................12

1.5.3 Type plate of the mechanical pump unit .................................................................................12

1.5.4 Classification on the cable gland ............................................................................................12

1.6 Ex classification of the device and immediate surroundings ............................................................13

1.6.1 Classification of the assembly “VAP 5 vacuum pump” ...........................................................13

1.6.2 Parts of the assembly “VAP 5 vacuum pump”........................................................................14

2. SAFETY................................................................................................................ 15

2.1 Personnel Qualification .....................................................................................................................15

2.2 Intended use .....................................................................................................................................17

2.3 Foreseeable Misuse..........................................................................................................................20

2.4 Residual Risks ..................................................................................................................................21

2.5 Operating instructions .......................................................................................................................22

2.6 Safety regulations .............................................................................................................................22

2.6.1 General information ................................................................................................................22

2.6.2 Safety instructions on installation ...........................................................................................23

2.6.2.1 Measures against overheating ..................................................................................................23

2.6.2.2 No installation in potentially explosive areas of Zone 1 or 0 .....................................................23

2.6.2.3 Technical ventilation (extraction ................................................................................................24

2.6.2.4 Equipotential bonding according to the grounding concept ......................................................25

2.6.2.5 Accessibility to the disconnection from the power supply .........................................................25

2.6.3 Safety instructions on operating the vacuum pump................................................................26

2.6.3.1 Measures against hazards caused by voltage ..........................................................................26

2.6.3.2 Measures against hazards caused by hot surfaces ..................................................................26

2.6.3.3 Measures against hazards from cold surfaces..........................................................................27

2.6.3.4Observe the maximum gas suction temperature ......................................................................27

2.6.3.5 Measures against condensation by pumping vapors ................................................................28

2.6.3.6 Ventilation precautions ..............................................................................................................28

2.6.4 Safety instructions on inert gas supply ...................................................................................29

2.6.5 Safety instructions on the aspirated media.............................................................................29

2.7 Operator responsibility, documentation, and measures ...................................................................30

2.7.1 Risk assessment / explosion protection document.................................................................30

2.7.2 Employee training and protocols ............................................................................................31

2.7.3 Operating instructions issued by the operator ........................................................................31

2.7.4 Personal protective equipment ...............................................................................................32

2.7.5 Standard Operating Procedures (SOP) ..................................................................................32

2.7.6 Testing and maintenance .......................................................................................................32

2.7.7 Operation log ..........................................................................................................................32

3. DEVICE DESCRIPTION ....................................................................................... 33

3.1 Device overview ................................................................................................................................33

3.2 Description and equipment ...............................................................................................................35

3.3 Manufacturer's safety plan: Protective measures and equipment ....................................................36