If nitrogen removal is needed the system (The BioBarrier®0.5-N, 1.0-N, 1.5-N) consists of a tankwith three compartments, or two

tanks totaling at least three compartments, with exactly two compartments in the second or final tank. The first compartment or

tank provides primary treatment - sedimentation and separation offloatables and solids, and is equipped with an outlet screening

device called SaniTEE®. The second and third compartments must be in the same tank, and the second compartment is where

denitrification takes place under anoxic conditions. The third compartment, the aeration/membrane zone, is separated from the

anoxic zone by a baffle wall between the two zones to allow nitrified waste to enter into the anoxic area for denitrification.

NSF Standard 350 Class R Restricted Indoor Urban Reuse Water

The BioBarrier®system has been tested under NSF Standard 350 Class R (Residential) and is capable of treating residential

wastewater for restricted indoor urban water reuse, which is toilet and urinal flushing. The system design requires a holding tank

and plumbing system for reuse water and shall meet all applicable codes; have proper backflow prevention and protection against

cross connections; and is the responsibility of the local designer/installer. When the reuse water is used for toilet and urinal

flushing, additional disinfection should be considered to provide adequate assurance in preventing microorganism growth in the

treated reuse water storage tank and as required by applicable codes.

Thereuse tank shallbelocatedafterthe BioBarrier®system. Thistankshall alsoincorporatean overflow thatallows excess reuse

water to be dispersed in a locallyapproved soil dispersal system or released into a sanitary sewer system. A potable water make

up system shall also be available to supply water when treated reuse water is not available. This potable water make up system

shall include a properly designed backflowpreventer that meets all applicable codes.

NSF Standard 350 Class R Unrestricted Outdoor Urban Reuse Water

The BioBarrier® system has been tested under NSF Standard 350 Class R (Residential) and is capable of treating residential

wastewater for unrestricted outdoor urban water reuse, which is acceptable for use in surface and subsurface irrigation, including

irrigation of edible crops without the edible portion being in direct contact with the treated water. A reuse tank may be required if

the irrigation system requires it. The holding tank and plumbing system for reuse water shall meet all applicable codes; have

proper backflow prevention and protection against cross connections; and is the responsibility of the local designer/installer.

Additional disinfection should be considered to provide adequate disinfection to prevent microorganism growth in the treated

reuse water storage tank and as required by applicable codes.

Ifa reuse tankis required for irrigation,itshallbelocatedaftertheBioBarrier®system. Thistank shallalsoincorporateanoverflow

that allows excess reuse water to be dispersed in a locally approved soil dispersal system or released into a sanitary sewer

system. If a potable water make up system is required for irrigation, it shall include a properly designed backflow preventer that

meets all applicable codes.

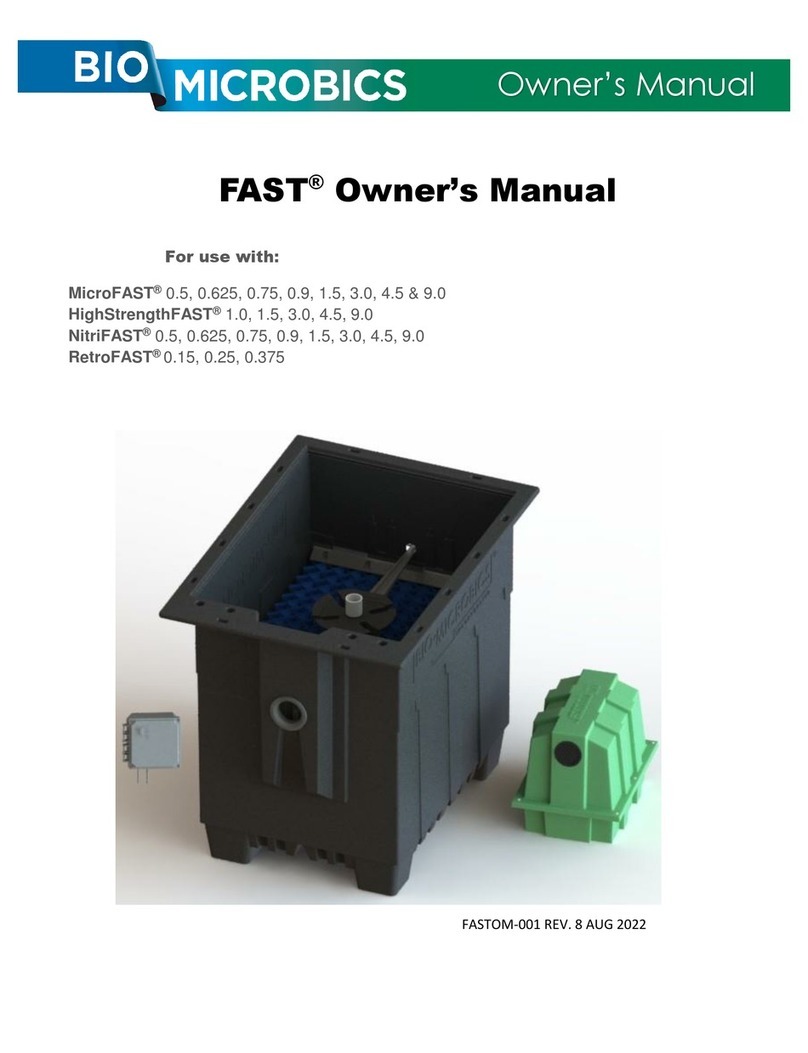

INSTALLATION PROCEDURE

Always have all utility lines and equipment marked by a locating service prior to performing any work. Failure to do so

could result in severe bodily injury or death.

Hazards exist in confined spaces such as a septic tank. All confined space precautions must be followed if entering a

tank. Always keep tank openings covered during storage and installation

MATERIALS REQUIRED FOR INSTALLATION

A. Septic tank that meets all applicable requirements andstandards.

B. Recognized,safe lifting mechanismfor treatmentmodule (e.g. a tripod).

C. Non-corrosivestrut channel or equivalentmaterial that is able to hold down atleast 550pounds [250 kg] of

buoyant force (see step 29).

D. Stainless steel anchor bolts to secure strut channel to tank riser and blower housing toconcrete base.

E. Piping for allair and vent lines. Check the install procedure all specs, and plans to determine what sizes

and types of pipe you may need.

F. PVC saw

G. Pipe joint lubricant/soap.

H. PVC primer and glue.

I. Concrete base for blower assembly.

J. Mounting screws for control panel.

K. Electrical conduit, fittings and wire for required wiring.

L. Hammer Drill and concrete bits.