Glossary

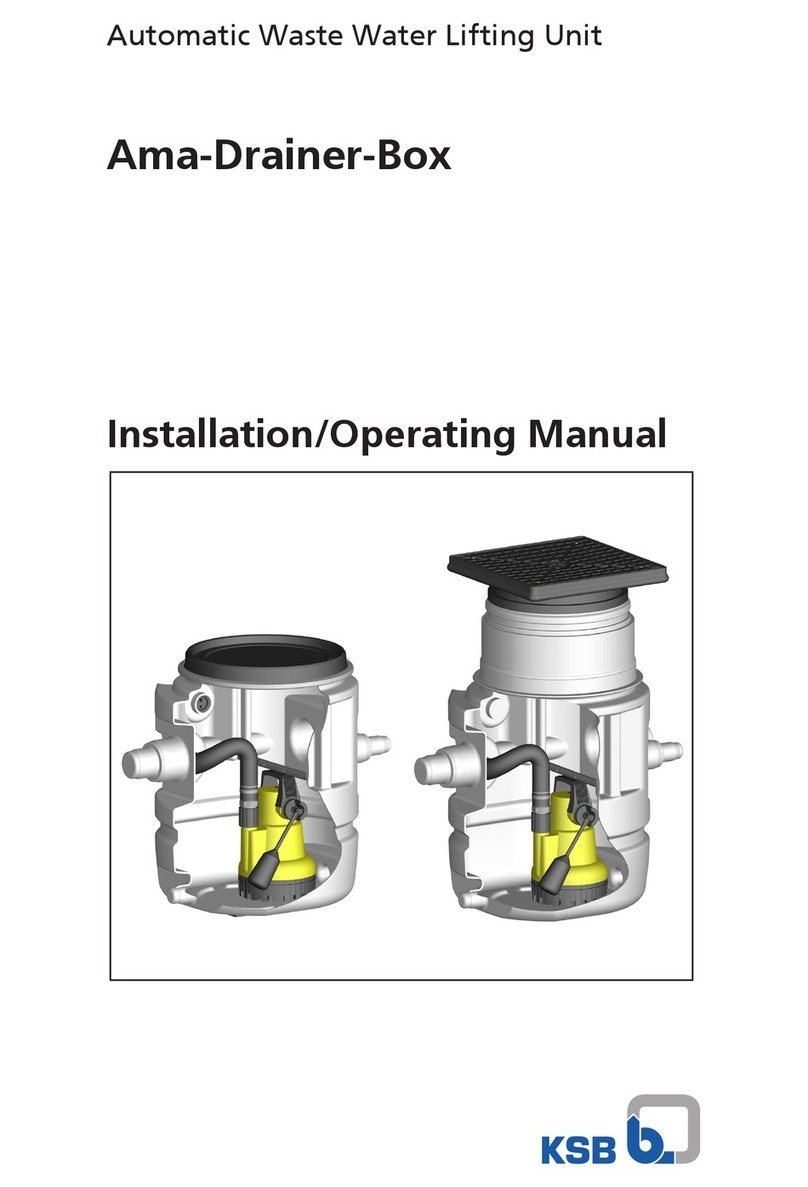

Above-floor box

Automatic waste water lifting unit for above-

floor installation

Backflow loop

The section of the discharge pipe of a waste

water lifting unit that is located above the

flood level

Backflow loop

The section of the discharge pipe of a waste

water lifting unit that is located above the

flood level

Certificate of Decontamination

A certificate of decontamination is enclosed by

the customer when returning the product to

the manufacturer to certify that the pump (set)

has been properly drained to eliminate any

environmental and health hazards arising from

components in contact with the fluid handled.

Check valve

Element of a waste water lifting unit which

prevents waste water from flowing back from

the discharge line into the lifting unit.

Collecting tank

Component of a waste water lifting unit in

which the incoming waste water is stored in

unpressurised condition prior to automatic

lifting.

Domestic waste water

Faecal-free waste water (grey water) from

washbasins, showers, washing machines, etc.

Dual-pump unit

Waste water lifting unit containing a duplicate

pumping device which starts up automatically

as necessary.

EN 12050-2

European Standard for waste water lifting units

which are used to dispose of faeces-free waste

water occurring below the flood level of

buildings and land. It defines general

requirements as well as principles of

construction and testing.

Inlet line

Pipe used for draining waste water from

sanitary installations into the lifting unit

Noise characteristics

The noise emission to be expected, indicated as

sound pressure level LpA in dB(A)

Nominal diameter DN

Identifier (inside diameter) used for

characterising mating components such as

pipes, pipe connections and fittings

Stormwater

Water from natural precipitation which has not

been contaminated by any form of use

Submersible motor pump

Submersible motor pumps are floodable, close-

coupled units which are not self-priming. The

pumps are usually operated completely

submerged. They may be operated outside the

fluid for short periods of time, until the

minimum fluid level has been reached.

Underfloor box

Automatic waste water lifting unit for

underfloor installation in substructures and

foundations.

Waste water

Faecal-free waste water (grey water) from

washbasins, showers, washing machines, etc.

Waste water

Water which has been changed by some type

of use, e.g. domestic waste water

Waste water lifting unit

Device for collecting and automatically lifting

faecal-free waste water above the flood level

White tank

Waterproof concrete structure. Water-

impermeable concrete is used to produce a

waterproof "tank".

Glossary

Ama-Drainer-Box 5 of 62