BioCool BIO Series User manual

BIOseries

ASSAMBLED IN SPAIN

Version v. /

YEARS

GUARANTEE

STRUCTURAL

YEARS

GUARANTEE

COMPONENTS

YEARS

GUARANTEE

ANTI-CORROSION

INSTALLATION GUIDE

EVAPORATIVE COOLER

BIOCOOLERS

* More languages: see last page

*Altre lingue: vedi ultima pagina

* Mais idiomas: ver última página

ECO Cooling Soluons

ECO Cooling SoluonsINSTALLATION GUIDE

ENG

2

>3

>

INDEX

General Information................................................................................................................................4

Precautions and Safety............................................................................................................ .............4

Diagrams/cuing.......................................................................................................................................7

Technical characteristics.................................................................................................................... 10

Installation types example ................................................................................................................ 14

Internal Connections.............................................................................................................................22

Electrovalve...................................................................................................................................22

Drain valve ......................................................................................................................................23

Electronic connection ..........................................................................................................................24

Start-up.......................................................................................................................................................27

Connection diagrams............................................................................................................................28

Water and power supply ......................................................................................................................31

Duct design.................................................................................................................................................31

Opening and season closure.............................................................................................................33

Problems and solutions...................................................................................................................... 36

Q&A-Installation.....................................................................................................................................38

Installation Checklist...........................................................................................................................40

ECO Cooling SoluonsINSTALLATION GUIDE

ENG

4

>5

>

GENERAL INFORMATION

Evaporative cooler manual

Thank you for your support and confidence choosing our air conditioning

evaporative, which will provide you with comfort and health.

The evaporative air conditioner operates with the most advanced technology of

evaporation, using the most advanced electronic management. This manual is only

for the series BIO evaporative air conditioners.

Please read these instructions carefully before use.

Observations for the installation instructions.

• This manual is based on the current state of approval and testing.

• The evaporative must be located in a well ventilated, dry place to ensure 100%

performance.

• Before introducing fresh air in a closed environment, be sure there is adequate

ventilation or extraction. Natural extraction and forced can be combined.

• We reserve the right to realize technical modifications.

PRECAUTIONS AND SAFETY

DANGER: Not follow these instructions, may cause serious injuries.

Before operating with the machine make sure that the main switch of the

equipment is OFF.

Keep the voltage stable with variations not exceeding 10v, so that the evaporative

cooler does not repeatedly switch on and off if the voltage is very low. This could

easily be damaged if too low or too high a voltage is used continuously.

PRECAUTIONS AND SAFETY

Responsibility of the worker

The installation and maintenance of the evaporative has a high probability of

causing serious injuries if its installation is not correct.

All the work with this product, both as to its installation in the evaporative and

internal connections must be carried out through a qualified person in accordance

with local and state regulations.

The rules and regulations for safe working at heights must be always consulted.

This product is single-use for adiabatic evaporative systems.

The use of this product is not applied to the use of persons (including children) with

physical and mental limitations or people with lack of experience and knowledge,

unless there is a direct supervision or instructions for use by a person who will be

responsible for their safety.

Children must be supervised to make sure they do not use the product with

recreational use.

For technical information consult this instruction manual.

Installation and operation

• The installation of the evaporative must be performed in a place with

power supply, water supply network and places according to the applicable

standards legislation.

• Safe clothing.Wear slip-resistant shoes all the time. Sandals, open shoes and

barefoot are prohibited for work with machines and tools.

• Do not wear loose clothing or accessories during installation as they can

remain inside or falling from high heights, causing damage.

• Do not install the evaporative during rainy days, wind gusts or adverse

weather conditions.

• Carry protective clothing with the use of power tools.

• Always make sure the use of electric cables according to regulations.

• Always raise the evaporative media insurance.

• Never drain water directly from the evaporative to the cover, use flexible

rubber tubes up to a point of discharge.

ECO Cooling SoluonsINSTALLATION GUIDE

ENG

6

>7

>

PRECAUTIONS AND SAFETY

• Any maintenance or repair installation must be performed by a person or

qualified firm.

• The packaging of the evaporative may be a danger to the security of the

storage. Please place them in areas according to local laws and regulations.

• Maximum load capacity allowed for loading equipment or lis must be taken

into account .

• Use in all the installations raise elements (erecting cranes, electrical arms)

and loading equipment such as controlled pulleys and with the fulfillment of

the regulation.

Other important requirements

Please read this manual carefully. Failure to do so may result in an injury or damage

to the evaporative, the evaporative or the property of the costumer.

• Do not force any part of the evaporative to enter because everything is

designed for an easy handling and placement.

•

• Never pierce the boom of the tank or the side panels unless otherwise

indicated, as they directly affect the functioning of the evaporative causing its

replacement.

•

• Check the area of placement of the evaporative, to ensure that the structure is

safe and capable of supporting the weight of the evaporative.

•

• Always comply with the standards and local regulations.

DIAGRAMS/CUTTING

1. Cover

2. Water distributor

3. Ozone

4. CPMD electronics

5. Water sensor

6. Drainage

7. Water tank

8. Corner post

9. Axial Motor

10. Fixation set

11. Water pump

12. Filter

13. Water Inlet Valve

14. Side Panell

15. Impulsion internal probe

BIO

12

8

4

5

6

3

9

10

7

11

12

13

14

15

ECO Cooling SoluonsINSTALLATION GUIDE

ENG

8

>9

>

DIAGRAMS/CUTTING

1. Water distributor

2. Cooling pads

3. Helicoid

4. Water pump

5. Draining valve

6. Vent valve

7. Tank

8. Corner Post

9. Motor

10. Centrifugal Fan

11. Lid

BIO -DC

DIAGRAMS/CUTTING

BIO

1. Cover

2. Water distributor

3. Corner post

4. Filter

5. Panel Fixation set

6. Water pump

7. Motor Fixation set

8. Water level inlet

9. Water level probe

10. Float

11. Drenaje

12. External disconnector

13. Axial Motor

14. CPMD Motor Electronics

15. Ozone

16. Side panel

1

2

3

4

5

67

8

9

10

11 1

3

2

5

4

6

7

8

9

10

11

12

13

14

15

16

ECO Cooling SoluonsINSTALLATION GUIDE

ENG

10

>11

>

TECHNICAL CHARACTERISTICS BIO AIV

Dimensions in mm.

* impeller mouth dimension

A B C D E F G H I J K L*

1110 1110 950 920 730 620 220 830 210 50 240 660

UNITS BIO-18D AIV BIO-18T AIV BIO-18DCV DC

AIR FLOW NOMINAL (m3/h)

EFFECTIVE (m3/h)

18.000

17.847

18.000

17.847

18.000

16.612

COOLING

CAPACITY WATTS (w) 19.652 19.652 18.290

ENERGY

CONSUMPTION

MAX (w)

MIN (w)

1.200

360

1.200

360

1.500

360

TOTAL

CURRENT MAXIMUM (amp) 8 8 9

FAN

DIAMETER (mm)

MAX SPEED (rpm)

TOTAL PRESSURE Pa

610

1.390

160

610

1.390

160

650

Centrifugal-Direct Action

180

MOTOR

POWER (kw)

VOLTAGE / PHASE / FREQ.

SPEED

RANGE (rpm)

TYPE

1.1

220 V / 1 / 50

Hz170-1390

Axial - Inverter

1.1

220 V / 1 / 50

Hz170-1390

Axial - Inverter

1.5

220 V / - / 50-60 Hz

10 speeds

Brushless DC motor

PUMP

POTENCIA

(w)

FLOW(L/MIN)

VOLTAGE / PHASE / FREQ.

30 W

23

220 V / 1 / 50 Hz

30 W

23

220 V / 1 / 50 Hz

30 W

23

220 V / 1 / 50 Hz

FILTER

UNITS

SIZE (mm)

MAX AIR SPEED (m/s)

SATURATION EFFICIENCY

4

825x620x100

1,36

89,1

4

825x620x100

1,36

89,1

4

825x620x100 / (625x820x75)

1,36

89,1

NOISE MAX. LEVEL (dB) <70 <70 <69

WATER SUPPLY WATER CAPACITY (L)

25 25 30

DIMENSIONS

SHIPMENT [LxWxH] (mm)

SHIPPING WEIGHT (Kg)

OPERATIVE

AIR OUTPUT DUCT (mm)

1110x1110x1020

77 kg

92 kg

660x660

1110x1110x1142

92 kg

107 kg

660x660

1110x1110x1100

87 kg

102 kg

660x660

ECO Cooling SoluonsINSTALLATION GUIDE

ENG

12

>13

>

BIO

Dimensions in mm.

* impeller mouth dimension

A B C D E* F G H I J

1290 1290 1310 1230 770 62 980 770 715 100

TECHNICAL CHARACTERISTICS

UNITS BIO DAV BIO TAV

AIR FLOW NOMINAL (m3/h)

EFFECTIVE (m3/h)

30.000

26.242

30.000

26.242

COOLING CAPA-

CITY WATTS (w) 28.800 28.800

ENERGY

CONSUMPTION

MAX (w)

MIN (w)

3.000

1.600

3.000

1.600

TOTAL

CURRENT MAXIMUM (amp) 7,1 7,1

FAN

DIAMETER (mm)

MAX SPEED (rpm)

TOTAL PRESSURE Pa

710

930-1490

270

710

930-1490

270

MOTOR

POWER (kw)

VOLTAGE / PHASE / FREQ.

SPEED

S

TYPE

3,0

380 / 3 / 50-60

10

Transmision direc-

ta-Axial

3,0

380 / 3 / 50-60

10

Transmision direc-

ta-Axial

PUMP

POTENCIA

(w)

FLOW(L/MIN)

VOLTAGE / PHASE / FREQ.

30

33

220 V / 1 / 50 Hz

30

30

220 V / 1 / 50 Hz

FILTER

UNITS

SIZE (mm)

MAX AIR SPEED (m/s)

SATURATION EFFICIENCY

4

890 x 970 x 100

2,81

89,1

4

890 x 970 x 100

2,81

89,1

NOISE MAX. LEVEL (dB) <80 <80

WATER SUPPLY WATER CAPACITY (L)

45 45

DIMENSIONS

SHIPMENT [LxWxH] (mm)

SHIPPING WEIGHT (Kg)

OPERATIVE

AIR OUTPUT DUCT (mm)

1.290x1.290x1.470

120

165

770 x 770

1.250x1.250x1.586

115

1650

770 x 770

ECO Cooling SoluonsINSTALLATION GUIDE

ENG

14

>15

>

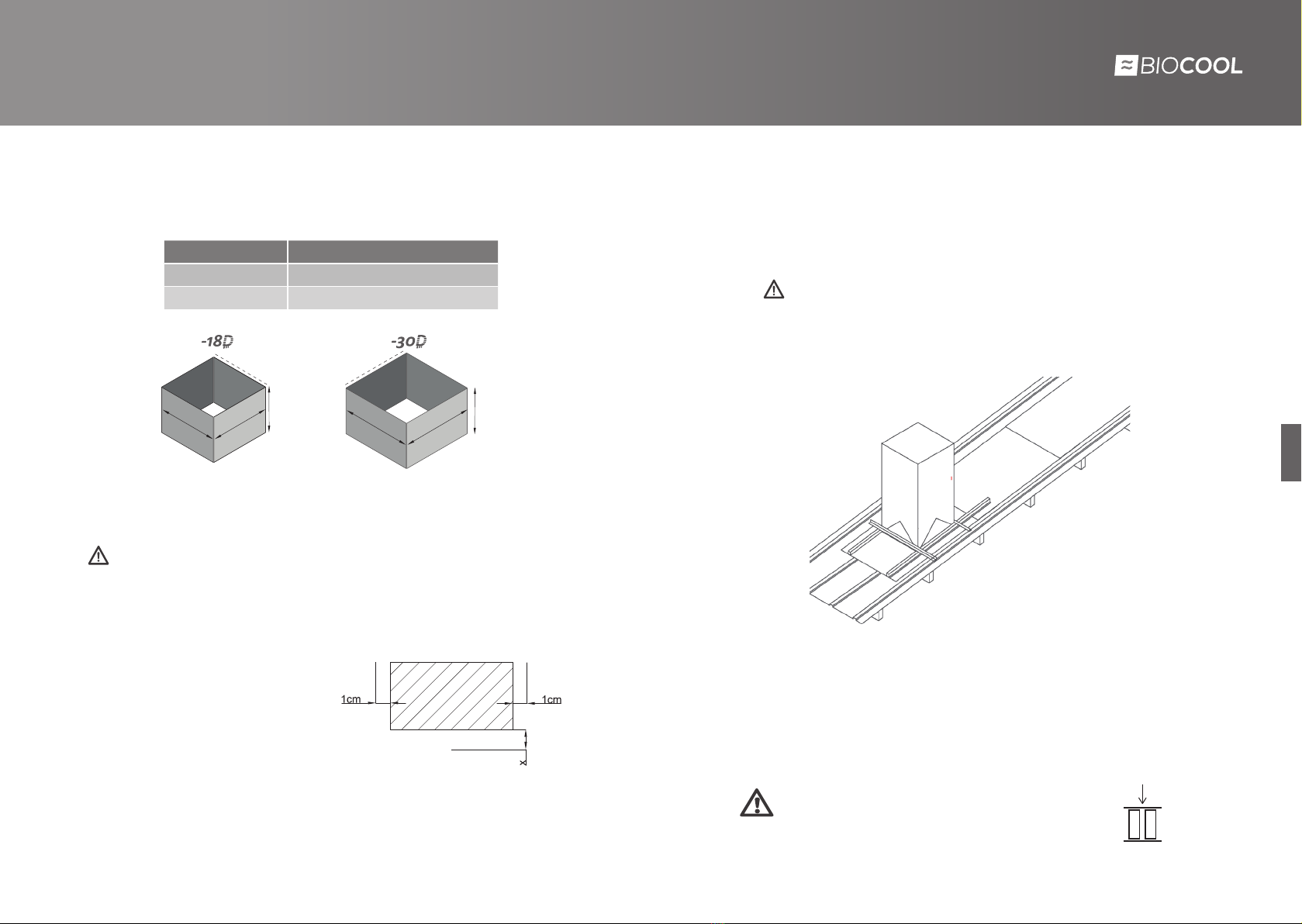

MODEL DUCTS DIMENSIONS

BIO-18D 660x660 mm. / 0,6-0,8 mm. espesor

BIO-30D 770x770 mm. / 0,6-0,8 mm. espesor

INSTALLATION

Ducts installation

Gap Cover Opening

ATTENTION! Before making a cut in the cover make sure that the weather

conditions are good and in no case with rain. On the other hand you must check

for the installation time required and sealing. NEVER LEAVE A OPENING IN THE

COVER, ITMAY CAUSE DAMAGETOTHE CLIENT.

Make the drill on the cover as shown in

the image. with the indicated margins.

The value of x is dependent on the type

of cover and its slope. The minimum

value recommended for “x” is 2 cm.

BIO

BIO

660

660

770

770

min. 300 mm

sobre cubierta

min. 300 mm

sobre cubierta

INSTALLATION

Remember:

• Minimumdistanceof cross-metalsheetbeding ofcm to maintainthesafety

margin of cm above the cover.

• For proper installation must be level.

• Sealing: With these sealing we will prevent the possible leakage of water into

the interior of the zone to climate

Once the duct sealed, you must use a li as a creane boom or any tool the rules of

evaporative liing to the cover.

The evaporative must be properly insured for their transport to the cover or in the

installation area.

You willneedan operatorin thecover abletodisengage andrelocatethe equipment.

You must ensure that the equipment is level for a

maxium performance and screw the evaporative.

ECO Cooling SoluonsINSTALLATION GUIDE

ENG

16

>17

>

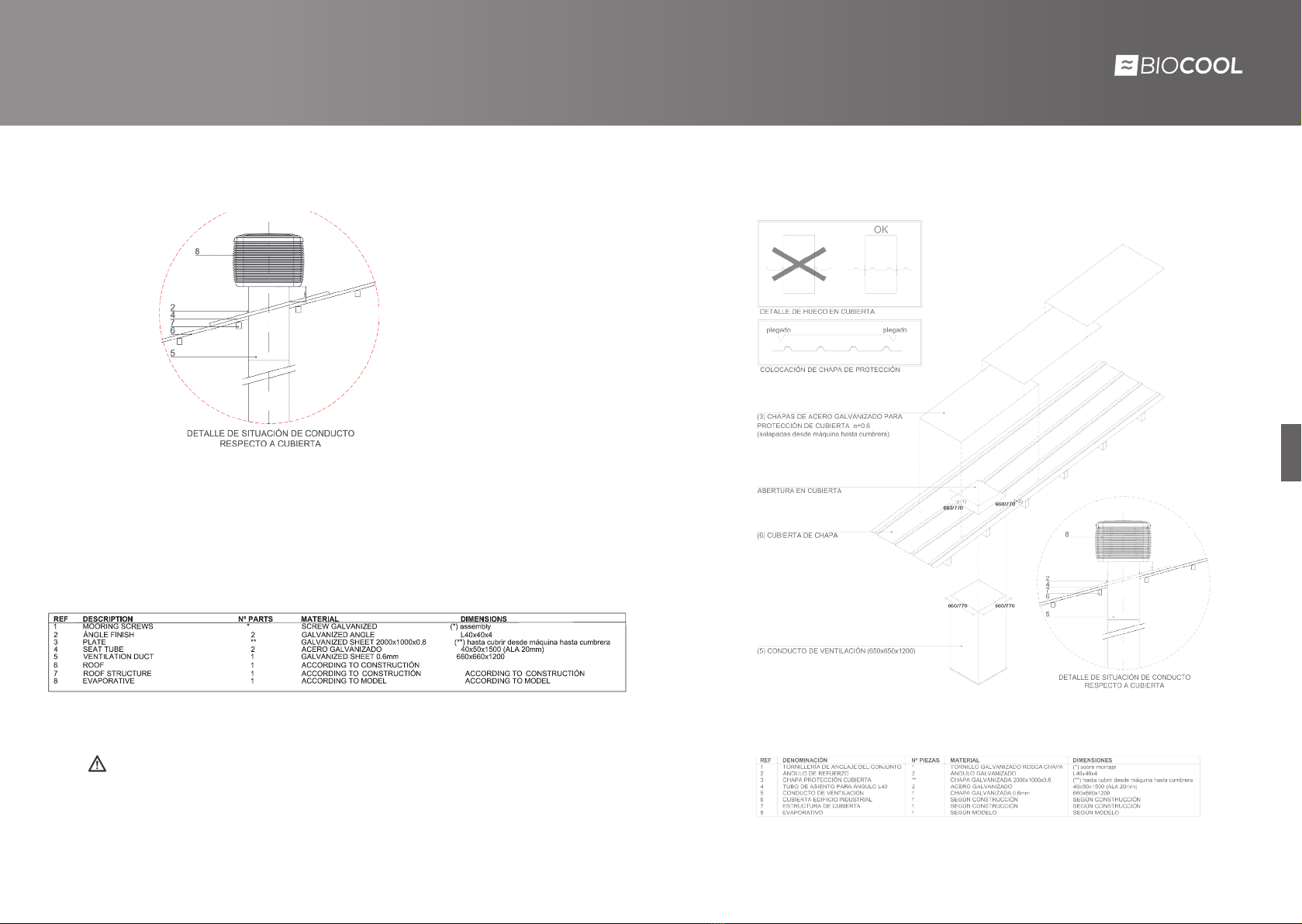

Example Installation type roof

(6) CUBIERTA DE CHAPA

ABERTURA EN CUBIERTA

(5) CONDUCTO DE VENTILACIÓN (650x650x1200)

(3) CHAPAS ACERO GALVANIZADO PROTECCIÓN DE CUBIERTA e=0.6

(solapadas desde máquina hasta cumbrera)

(4) TUBO DE ASIENTO PARA ÁNGULO L40x4 (40x50x2000;ala 20mm)

(2) ÁNGULO DE REFUERZO (L40x40x4)

PLEGADO DE CHAPAS (90º)

a b

a b

a b

Modelo A B

BIO 18 660 660

BIO 30 770 770

ÁNGULO DE REFUERZO (L40x40x4)

ÁNGULO DE REFUERZO (L40x40x4)

2 TUBOS DE ACERO 40X50X2000

ESTRUCTURA DE CUBIERTA

CUBIERTA DE CHAPA DE ACERO

CONDUCTO (660x660x1200)

660 a 550

CONDUCTO (550x550x1500)

550x500 45 ºC

DIFUSOR 2 CARAS

Example Installation type roof - Example BIO 18

ECO Cooling SoluonsINSTALLATION GUIDE

ENG

18

>19

>

Depending on the weather and the remaining time on the day of installation, it will

proceed to perform another installation of other evaporative unit or to perform

interior equipment assembly.

WARNING!

Never leave any area of open cover with a non complete installation.

Example Installation type roof Example Deck installation

ECO Cooling SoluonsINSTALLATION GUIDE

ENG

20

>21

>

1150 - 1250

950 - 1310

DISTANCIA MÍNIMA

INSTALLATION EXAMPLE

Example Installation type roof

SOPORTE

PERNOS DE SUJECCIÓN

MURO

1150 - 1250

950 - 1310

PERNOS DE SUJECCIÓN

DISTANCIA MÍNIMA

Generic frontage Installation example

INSTALLATION EXAMPLE

BIO BIO

1150 - 1250

950 - 1310

SOPORTE

CODO 90º

PERNOS DE SUJECCIÓN

MURO

DISTANCIA MÍNIMA

Generic frontage Installation example

CUBIERTA IMPERMEABLE

1150 - 1250

950 - 1310

BIO

BIO

Example Installation type roof

ECO Cooling SoluonsINSTALLATION GUIDE

ENG

22

>23

>

Internals Evaporative Assembly

1. First disengage the 3 side panel

clips

2. Hold the panel with both hands

and pull towards you.

3. Repeat with each of the panels.

Electrovalve

The electrovalve assembly will be on the inside of IP65

protection box, to protect from low temperatures and

prevent damage from freezing.

Electrovalve Connections

1/2 “

´

´

´

*

*

Llave de paso para cada máquina

Llave vaciado

Llave de paso principalLlave de suministro mínima

Entrada a 1/2”

* Electroválvula de

voltaje pulgadas

24 V

220 V

3/4“ - 3/4 ”

1/2“ - 1/2 ”

INTERNAL CONNECTIONS

Therewillbe aninstallationofakeystep foreachevaporativeunitandinaddition

to a key principal step for all the untis installed. You also install an emptying key to

the season closure.

SEE EXAMPLETYPE SCHEME ANNEX

Drain Valve

Water drained from the drain valve must be carried to the point of appropriate

download in the building or building installation, according to the regulations. It is

recommended that you do not drain the water never directly to the cover.

The drain valve comes from within the evaporative, you will have to put in its

corresponding zone and thread with the cap thread the projecting part of the lower

tank to ensure its stability.

The electrovalve prevents the entry of water when the drainage is open or the

machine is idle.

Once threaded drainage, ensure you drained by gluing a diameter PVC tube 32 mm

and length 1 meter.

Take this tube to the water discharge area or rain cover.

Model mm CAP to 32 mm

BIO 18 48 mm YES

BIO 30 32 mm NO

FOR BIO AND BIO DCVDC

Install the solenoid valve cap in the correct direction according to the position of

the cables, other type of installation can damage the solenoid valve.

Water supply

Water input Water output

Electronic

power supply

#1

#2

N

MODELS voltage inches

BIO18 axial 24 V 3/4 ” -

3/4 ”

BIO 30

BIO18 centrifugal 220 V 1/2 ” - 1/2 ”

*Solenoid valve of

ECO Cooling SoluonsINSTALLATION GUIDE

ENG

24

>25

>

ELECTRONIC CONNECTION

The control connection

Standard wall control connection

Maxium distance of m supply

Protect the control wire on the cover with a

corrugated cable to prevent damageo.

Biocool Control

BIO AXIAL

Biocool Control

BIO CENTRIFUGAL FAN

ELECTRONIC CONNECTION

The control connection

BIOCOOL MODEL BIO VARIABLE SPEED

Biocool Control

ECO Cooling SoluonsINSTALLATION GUIDE

ENG

26

>27

>

Control placement

Place the control in the area specified by the

client.

It is recommended that you place the control

at a minimum distance of the evaporative

connected,and ensure good communication.

Ifthedistanceis >m, will haveto be to crimp the

wire by adding a shielded x mm2 cross-section

wire cable and its corresponding RJ.

1. Connect the power and water supply and turn on the evaporative

from the remote control.

2. Turn on the evaporative from the remote control.

3. Check the exterior of the evaporative if there is any equipment with

loss of water or malfunction.

Any element not well connected to the electric panel will be reflected in the control.

The electric panel has a green LED which informs that it has power.

START-UP

Before to starting up all equipment follow the instructions in order for safety:

Safety box

Inside the equipment, in the accessory box is the electrical safety box. It is a three-

poles 20 A box with protection IP65.

1. Connect the power supply of the equipment to the input of the safety box. (three- phase for

BIO30 and single-phase for BIO18).

2.Connect output power wiring to the general low-voltage switchboard marked by the

customer.

3. Place the magnetic disconnect box in the duct as shown on the back picture.

- Safety box location -

Place here

Safety box General electric

table

Biocool Electronic

BIO x mm2

BIO x mm2

BIO x, mm2

BIO x, mm2

INTERIOR VIEW BIO18

INTERIOR VIEW BIO30

Safety box

Mechanical extractor connection

Consult the different options with BIOCOOL’s technical department.

General electric

table

Biocool electronic T’

N

F

T’

N

F

General electric

table

Biocool electronic

N -Neutral

T’ - Ground

R

S

T

N

T’

N

T’

R

S

T

ECO Cooling SoluonsINSTALLATION GUIDE

ENG

28

>29

>

Water scheme example

Considerations to take into account in the installation of plumbing:

• Place a shut-off valve to all machines.

• Place a draining shut-off valve to prevent accumulation of water in winter and

freezing problems.

• Makeuseofashut-offvalveforeachinstalledunitandbe able to cut the supply

in specific equipment.

• Use polyethylene pipe diameter corresponding to water supply connections.

• Entry to the evaporative will be /” and the electrovalve located before the

evaporative will be a /” female input and output.

• Check if the supply pressure is the necessary for supplying the full installation.

• Checking the plumbing connection of the entire installation to avoid losses and

leaks that can cause damage.

CONNECTION DIAGRAMS

MODELO WIRING TYPE

BIO-D wires of , mm2 section ( A)

BIO-D Three-phase cable(N+3F+Ground)

Connection diagram example

ECO Cooling SoluonsINSTALLATION GUIDE

ENG

30

>31

>

EachelectronicpanelhasaLEDsystemthatindicatesthemachineissupplied

with power.

The general panel must contain thermomagnetic switches with the expected

In=1,25xImax referred in the UNE .

Connection to the electric board WATER AND POWER SUPPLY

1. The water must always be clean, and the pressure must be between . to .

Mpa (. kgf/cm2)

2. There should be a valve (DN) near the entrance of the water inlet and a

cleaning duct.

3. Do not use untreated well-water, or low pH osmotic water

4. Ensure that the single phase voltage is / / / //±V, three-phase

voltage is ± V.

Water quality

Water type:

• The water supply for the equipment must be clean and from the mains,

guaranteeing a minimum water pressure at the entrance of each equipment.

• Do not use well water because of the high dissolved substances it may contain

(bicarbonates, carbonates, calcium ion, magnesium ion, boron, potassium ion

which tends to form clays...). If this is not possible, the water must be treated

according to the European Directive //CE.

• The temperature of the incoming water must be less than 45 degrees.

• The ph range should be between 6-9.

Hardness:

In very hard waters, a descaler will improve the performance of the equipment by

avoiding lime incrustations.

The water must have a hardness of ºhF, free of boron, salts,

carbonates, bicarbonates and other impurities.

In case the water hardness is considered hard or very hard, the automatic self-

cleaning of the equipment must be programmed at 4 h.

To carry out the electrical installation, the following considerations should be

taken into account:

• First make sure you have made a good connection to the safety box (located

at the boom of the machine as indicated above).

• An electrical sub panel must be made in each installation for the evaporative

unit system.

• Use the electrical wiring in the table above for all installations.

• It is recommended to connect each evaporative unit to each circuit breaker,

complying with current regulations. Each line is sized with the Imáx(A)

according to UNE 20460-5-523:2004

Recommendations for electrical and communication wiring.

Electrical connection

It is recommended to use this type of wiring according to the equipment installed.

This wiring must be on suitable conduit according to local regulations in force and

covered on a tray or cover. Otherwise, RZI-K halogen-free hose should be installed.

MODBUS communication connection

In Smart City Cooler installations with Modbus communication, shielded and

twisted communication cable of the BELDEN brand must be used.

ThiscablehasashieldedwirewhichmustbeconnectedtotheRS485communication

GND, never connected to the electrical earth.

MODEL TYPE OF ELECTRIC CABLE

BIO-18D 3 x2,5 mm2 section

BIO-30D Three-phase cable (N+3F+Earth)

The electrical wiring should NEVER go on the same tray/lid as the

communication one, in any type of BIOCOOL installation.

ECO Cooling SoluonsINSTALLATION GUIDE

ENG

32

>33

>

CHECK BEFORE

USE

1. The machine is leveled

2. Drain pipe is installed .

3. No Water dripping in operation.

4. Water level is normal.

5. The evaporative is well connected to the power.

6. Control lines are well fixed

7. Check nothing obstructs the tank or the fan

8. Check voltage and the current are normal.

9. Check the machine is operating under the required power

level

MANTEINANCE

10. To achieve maximum efficiency, cooling pads should be clea-

ned continuously. Do not use water pressure or hot water

more than 40 ° C. Clean with a so brush.

11. To avoid freezing in winter, you should empty the tank and

cut water. In case of snow or dust cover it when not using.

CLEANING This series has its own cleaning system. We recommend using

the cleaning function at least once a month

DUCT DESIGN

1. Duct material must be of galvanized metal sheet, steel, plastic, aluminum, etc.

2. The grilles or diffusers should be installed where refrigeration is necessary.

Grilles characteristics will be determined depending on the speed of the air.

The material could be aluminum, wood etc. Doubled air deflection grilles

m/s,flow rate of the air, are recommended.

3. The duct must be designed to 6-8 m/s speed air in the main duct, 4-5 m/s in

the pipes, and m/s at the end.

4. It is advisable an economical duct design, without excessively noise.To

reduce resistance, the duct curvature radius should not be less than 1.5 times

of its width.

5. Ductwork should not exceed metres in length.

6. It is advisable that the layout of the duct is straight, no curves or angles, to

prevent resistance.

7. According to the different air flows, duct should be designed with different

sections; the longer the duct is the minor the section must be .

8. If there are ramifications, these should be set to adjust the air flow.

OPENING AND SEASON CLOSURE

SERVICE SCOPE MAINTENANCE

You must ensure a technical assistance in the case as required at any time of the

season, including labour for solving any kind of fault. Does not include the price

of the rest of the component need to be replaced (unless they are covered by

warranty).

The tasks to be performed in teams evaporative should be divided in two ways:

Technical maintenance.

These equipments require technical routine maintenance , if not done, can cause

inefficient operation or even not working.

Tasks carried out follow the indications of the manufacturer for both opening and

closure. So:

1.In spring and summer we check equipment function is acting properly aer

a prolonged stop proceeding to a cleaning work and in the event of failure or

malfunction detection informs the client to proceed with their replacement.

2. in autumn the status of the equipment is reviewed reporting detected anomalies

to solve them before the start of the following season

Hygienic Maintenance.

Although opening tasks perform a cleaning of the evaporative, they are subject to

a national regulations for the control and the prevention of legionella (still being

a classified equipment with less probability of proliferation and dispersal of the

Legionella). Therefore, they should perform an annual cleaning and disinfection

(to start) and subsequently a water analysis for the detection of Legionella (aer

between and days aer treatment) in accordance with the R. D. /.

Companies authorized to carry out this type of services to third parties are those

listed in the Register Official of Establishments and services Biocides ROESB.

ECO Cooling SoluonsINSTALLATION GUIDE

ENG

34

>35

>

Aer each of the maintenance operations, a technical report on the condition of

the equipment is prepared so they may have a greater control of their installations.

This report would be aached to the Record Book of the installation for the control

of Legionnaire’s disease along with the certificate of cleaning and disinfection and

analytical results to comply with the regulations in force.

Point out that equipment have an automatic cleaning of tray and drain system .This

system will allow also leave the tray without water when the appliance is unused

during a season, reducing most if possible, the risk of proliferation of Legionnaire’s

disease to empty the tray both when the equipment is not used as when it reaches

high values of suspended solids.

Review the following points :

REVIEWPOINTS:

• Draining and cleaning tray and equipment.

• Water pump.

• Automatic gate closure.

• External panels (housing evaporative panels)

• Evaporative cellulose filters.

• Review irrigation water (water dispenser)

• Eye examination of electrical lines, water and sanitation.

• Motor fan.

• Water detector.

• Solenoid electrovalve.

• Automatic drain w.

• Automatic filling.

OPENING AND SEASON CLOSURE

SEASON OPENING WORKS:

• Disconnect the power supply.

• Remove the filter panels to give access to the interior.

• Wash the filters to remove the dust accumulated during the winter. Change

filters if they are in bad condition.

• Turn on the electricity switch inside of the air conditioner.

• Connect the water supply and electrical supply.

• Put the filters panels to close the unit.

• Start-up of the air conditioner.

OPENING AND SEASON CLOSURE

SEASON CLOSURE WORKS

• Disconnect the power supply.

• Close the water supply.

• Remove the filter panels to give access to the interior.

• Disconnect the power switch inside of the air conditioner.

• Check and clean the guers of water from the tap.

• Allow water to drain from the tank through the drain valve that is automatic.

• Aer draining all the tank, clean the tank and the pump filter.

• Put the filter panels to close the unit

PROBLEM COMMON CAUSES POSSIBLE SOLUTION

The evaporative cooler doesn’t work

and the buons do not respond

External switch (machine base) or interior switch off, power failure,

bad connection, blown fuse, loss of connection between the control

box and the machine, faulty remote controls..

Check that the switches are on, measure the voltage, and connect properly, reset or replace it, check connections,

replace the control panel. If it happens again, you should check again if there has been an overload.

No airflow Warming up the engine, loss of electrical connections, damaged

contact, pre-cooling mode on, faulty remote controls .

If overheating engine will start aer 20 m. If the connection failures, check all electrical connections, if the contact

isbroken,replace it,if pre-cooling functionis ON,turn offthis functiontemporarily,if the remotecontrol isdefective

must be replaced, if the engine is damaged must be changed. Check the parameters of voltage and current.

Pump is working but doesn’t cool well. The cooling pads are dirty, insufficient air supply, dry pads or lack of

water, excessive moisture in the atmosphere..

If the problem are the pads, clean or replace, install grilles for the air in the places that need cooling, if the pads are

dry, check water distribution and the tank for possible obstruction, if there is excessive humidity in the atmosphere,

the evaporative doesn’t work at 100% because it works beer with drier climate. If desired, turn off cooling mode

in such days and turn on fan only..

Pump fails Broken water pump, loss of electrical connection, water level sensor

is broken or damaged, faulty remote controls.

If the pump is broken must be replaced, failed connection, if there is no water check valves and tank, if your remote

control is defective must be replaced.

Pump is working but no water flows Water pumpisblocked, watervalveislocked,watersupplierislocked. If there is a pump blockage should be cleaned, if there is a valve blockage clean it, if the water supplier is locked

clean it..

Cleaning mode is activated too many

times or too much water flows.

Self-cleaning function is activated, faulty valve, the drain valve is

leaking, faulty remote controls.

If the self-cleaning function is enabled, temporarily disable, if the valve is obstructed or faulty, cleaning or changing,

if the drain valve leaks, check or replace the valve, if the remote control does not work, replace it.

Water drips on the inside The pads are broken or blocked, excessive amount of water in the

pads.

If the pads are dirty or damaged, clean or replace, if there is excess water probably the water distributor is

unbalanced, balance it.

Smells The evaporative is with dirt. Clean the evaporative cooler completely

White residue High levels of salt in water. Drain water more frequently.

Red flashing on the remote control.

Erro de comunicação

Check the instructions in the BIOCOOL Control manual.

Erro de preenchimento

Erro de esvaziamento

Erro de motor

The communication green LED on the

electronics does not light up

Short-circuit in the communication cable, damage to the electrical

system and lack of power supply.

Change communication cable, check power supply or replace electronics.

PROBLEMS AND SOLUTIONS ECO Cooling Soluons

36

>37

>

ECO Cooling SoluonsINSTALLATION GUIDE

ENG

38

>39

>

Q&A-Installation

BIOCOOL ESTANDARD COOLERS

Communication errors in installation

• Why did not detect some coolers?

1. Reviewlocationof connectionofBioCool Standardcontrol andconnected

coolers

2. Make sure you have good contact with the RJ wiring -electronic tab HUBB

3. By using the crimper : CAUTION! Because if we press a lot you can join

wiring and lose communication .

4. Makeuseofanaccessory such as a flange forpressure connection RJ with

electronic tab HUBB ensuring a good connection.

5. To ensure it is resolved and there is good communication, see BioCool

control in the solid line in the right corner that it is fixed.Otherwise,

change the HUBB.

Electric installation errors

• What is the wiring recomended in the power supply of the cooler?

The electrical wiring must be protected on electric tray.In other case can be

installed follow the UNE 21123 UNE designation W - K 0.6 / 1 kW with flexible

conductor.

NEVER! Place the communication cable and power supply in the same tray

MODELO TIPO DE CABLE ELECTRICO

BIO-18D 3 x2,5 mm2 de sección(Imax=10 A)

BIO-30D Cable trifasico (N+3F+Tierra)

Q&A-Installation

• Should I put some kind of protection??

In the case BIOCOOL coolers , it is recommended to place each evaporative

coolerto acircuitbreakerboxdistribution boardor generalstress.Onegeneral

low-tension should have the MCB’s with In> =1,25 x Iprevista contemplated by

the UNE 20460-4-43.

Water installation

• What PH should I use?

PH between -.

• What water main should I use to pipe water supply ?

We recommend using pipe polietilieno to hold well pressure ( 8-10 kg / cm2).

NEVER use a drainage pipe as it cannot withstand sufficient pressure

• Can I make the water supply from a tank ? And the water treatment?

Yes, if the supply is made from a tank , it is recommended that the pressure at

the end of the line installation is 1.5-3 kg / cm2 .. In addition , you must perform

maintenance on the valves cleaning the grids of these for cases with water

with gravel.

• ¿How many valves should be placed?

Se recomienda una llave de paso de cada equipo y luego una general, además

de una llave de paso para desagüe. See previous scheme.

This manual suits for next models

8

Table of contents