Biotage Flash 75 User manual

Biotage®Flash 75/150

User Manual

Biotage®Flash 75/150 User Manual | © Biotage 2018

Contents

Biotage®Flash /

User Manual

CONTENTS

Introduction

1 Speed

1 Safety

1 Performance

System Components

2 Prepacked Biotage®Flash Cartridge

2 Radial Compression Module

3 AM-190 Manifold

4 Solvent Reservoir

4 Sample Injection Module (Biotage®SIM) Kit

5 Grounding Kit

5 Start-Up Kit

5 Cartridge Extraction Tool

6 Chemical Resistance

Safety

7 Intended Use

7 Education, Training, and Competence

7 Warranty and Liability

7 Service

7 Labels

7 Safety Requirements

Installation

9 Set Up the Radial Compression Module

9 Set Up the AM-190 Manifold

9 Set Up the Sample Injection Module (Biotage®SIM)

10 Set Up the Solvent Reservoir

10 Attach the Inert Gas Supply and Solvent Lines

12 Ground the System

How to Use the system

14 Fill the Solvent Reservoir

14 Insert a Flash Cartridge

15 Pressurize the Radial Compression

Module and the Solvent Reservoir

15 Equilibrate the Cartridge

16 Load Sample and Collect Fractions

18 Refill the Solvent Reservoir

18 Empty the Solvent Reservoir

18 Depressurize the Radial Compression Module

and Remove the Used Cartridge

19 Clean the Sample Injection Module (Biotage®SIM)

Troubleshooting

20 AM-190 Manifold

20 Biotage®Flash 75/150 Radial Compression Module

21 Operation

21 Sample Injection Module (Biotage®SIM)

21 Solvent Reservoir

Optimizing Flash Separations

22 Column Separations are Governed by CV, not Rf

22 Vary Solvent Strength to Maintain

RfValues Between 0.15 and 0.40

23 Vary Solvent Selectivity to Maintain

RfValues Between 0.15 and 0.40

24 The Relationship Between the Size of a Column

and the Sample Load is Dependent on CV

Flash Chromatography Workbook

General Information

31 Price List and Ordering Information

31 Download User Documentation

31 Manufacturer

31 Contact Us

Notes

Introduction

Introduction

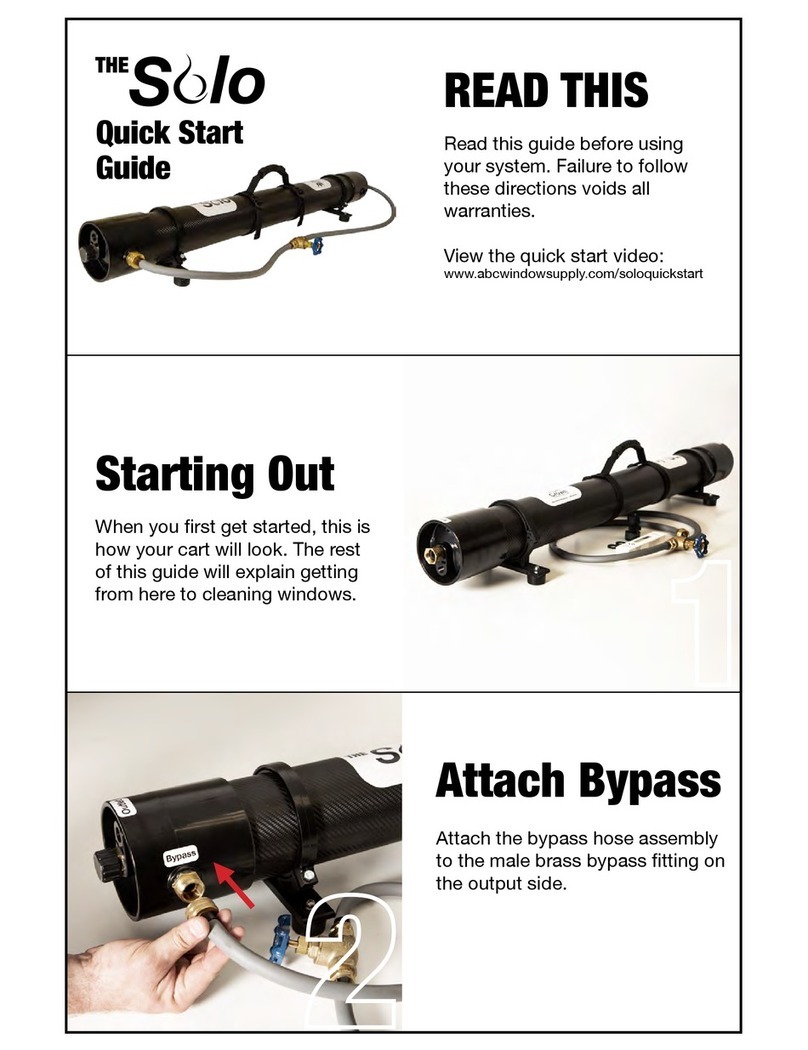

Biotage®Flash 75 and Biotage®Flash 150 are flash purification

systems based on prepacked cartridge technology that provide

users of traditional self-packed glass columns with three critical

operational benefits: speed, safety, and performance.

Speed

Unlike glass columns, which operate at low pressure and

have very poor flow distribution, Biotage flash cartridges are

optimized for high speed separations. Purifications that might

otherwise have used up half a working day can be run in 15 to

45 minutes. For a chemist running just a single reaction and

separation per day, the annual gain in productivity can be as

high as 15 additional weeks each year; time that could be used

to develop new compounds or processes. With the rising cost

of labor, the efficiencies afforded by this alone can exceed the

cost of the flash system and a year’s supply of cartridges.

Safety

Laboratory and process safety is a growing concern with

many companies carefully reviewing current procedures and

techniques to reduce the risk of chemical exposure, injury, and

consequently their liability. Biotage Flash systems eliminate the

concerns of using glassware under pressure by utilizing durable

polyethylene cartridges that are prepacked and completely

self-contained, eliminating user exposure to silica dust, HP-API,

or any contaminants left after a separation.

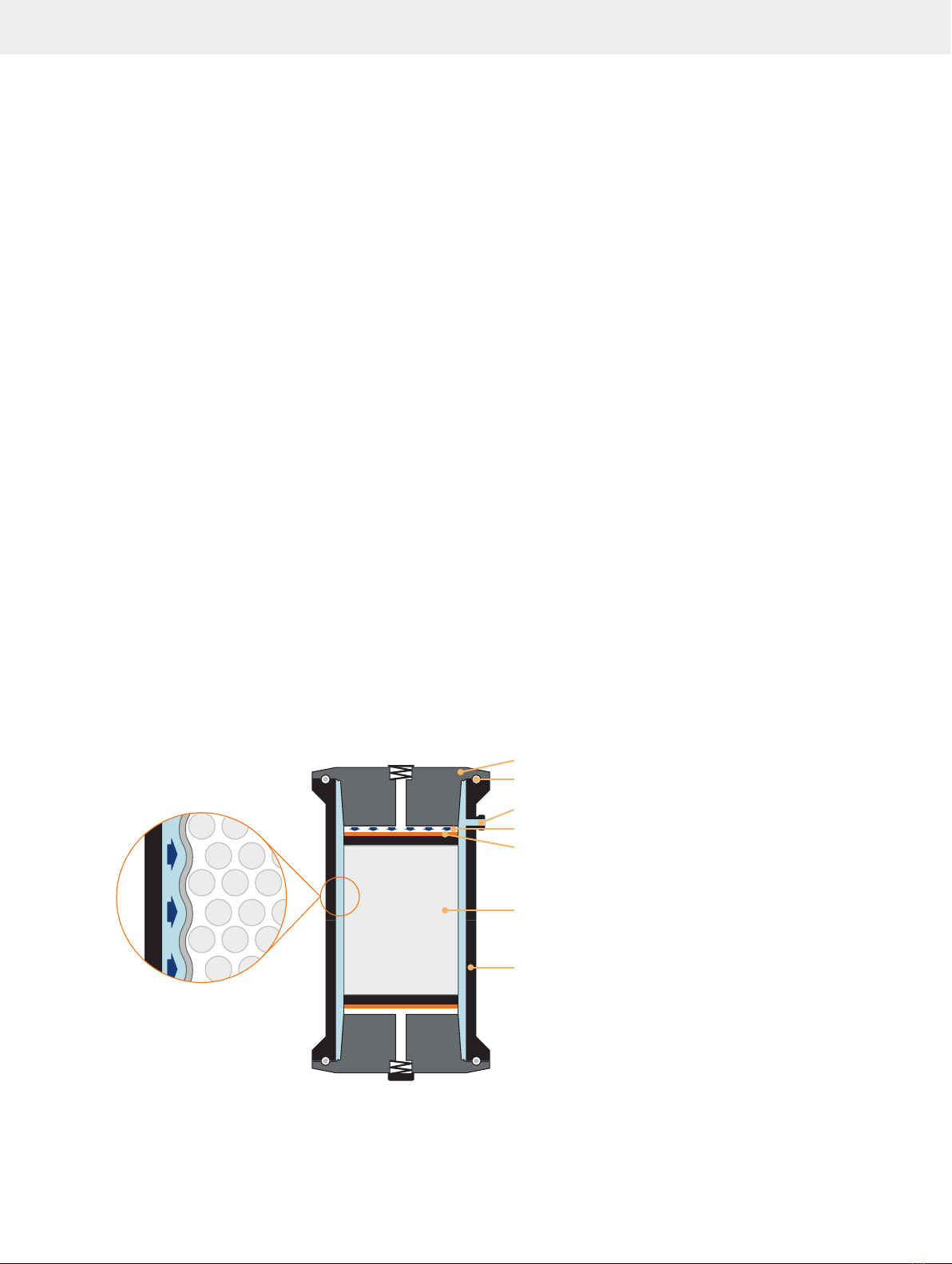

Figure 1.Biotage patented radial compression technology improves flash separation performance and increases separation speed.

Distribution plate (only Flash 75)

O-ring

10 µm porosity frit

Prepacked, disposable flash cartridge

Compression barrel

Radial compression inert gas supply

316 stainless steel head

External

pressure

applied

Media

Performance

In addition to speed and safety, Biotage flash cartridges improve

both the performance and the reproducibility of separations.

The use of Biotage patented radial compression technology (see

Figure 1) reduces interstitial spaces (void volume) within the

packed bed. The optimized bed density means that compounds

are collected in narrow bands, which results in higher separation

efficiency. Unlike glass columns, each Biotage flash cartridge

will perform in the same way, time after time.

Flash 75/150 systems include everything you need to separate

compounds in a fume hood with standard laboratory mounting

bars, clamps, and an inert gas such as nitrogen. A typical

Flash 75/150 system can be assembled in minutes and be ready

to run samples in less than an hour.

Biotage®Flash 75/150 User Manual | © Biotage 2018

System Components

System Components

Prepacked Biotage®Flash Cartridge

The prepacked flash cartridge from Biotage is the key to the

radial compression module’s improved performance. Flash

cartridges are available in a wide variety of sizes for optimum

separation of samples ranging from 50 mg to 8 kg. Biotage

offers Flash 75 and Flash 150 cartridges and radial compression

modules for samples up to 1000 grams; see Table 1 below.*

Each flash cartridge is prepacked as standard with normal

phase silica, C18-bonded silica, amine-functionalized silica,

or activated carbon, and is individually wrapped with a water

repelling plastic film to minimize water vapor adsorption.

Each case of cartridges includes certificates of compliance and

conformance with detailed information for your records in GLP

or cGMP environments.

The flash cartridge itself is made from FDA compliant, medium

density polyethylene. The flow distribution plate and 10 m

porosity frits are also fabricated from FDA compliant polyethylene.

*This user manual deals specifically with the Flash 75 and 150 cartridge

series. For information on additional cartridge diameters, contact Biotage.

See contact information on the back of this document or visit our website

www.biotage.com.

Radial Compression Module

The radial compression module (see Figure 3), together with

the flash cartridge, is the heart of the system. It is an anodized

aluminum barrel with an instant-tight fitting for connection to

the inert gas outlet on the AM-190 manifold (see page 3).

The safety features on the barrel include a safety relief valve that

activates at pressures in excess of 110 psi (7.6 bar) for Flash 75

and 150 psi (10.3 bar) for Flash 150, and a red pressure indicator

that sticks out when there is more than 20 psi (1.4 bar) of inert

gas pressure inside the radial compression module (see Figure 2).

Figure 2.The pressure indicator sticks out when the pressure inside the

radial compression module is more than 20 psi (1.4 bar).

Figure 3

Safety relief valve

Viton O-ring

Anodized aluminum barrel

Pressure indicator

Radial compression inert gas inlet

Stainless steel head assembly

Fraction collection outlet

Portable cart

(only Flash 150)

V-band clamp

V-band clamp

Stainless steel head assembly

Three-way valve

Prepacked cartridge

Viton O-ring

.The components of the Flash 150 radial compression module.

The Flash 75 module has the same features but instead of being delivered

with a portable cart it has mounting pads on the side of the barrel for easy

connection to lab scaffolding or support bars.

A Viton O-ring sits inside a groove in the top lip of the barrel and

seals the radial compression module against leakage of gas.

The bottom opening of the barrel has an identical groove and

O-ring. Two replacement O-rings are provided with the start-up

kit (see page 5).

The Flash 150 radial compression module comes with a portable

cart with casters. The Flash 75 barrel is easily attached to standard

½" (12.7 mm) Flex-Frame type laboratory mounting bars using

a pair of standard mounting rods that screw into the mounting

pads on the side of the barrel. With the rods in place, the module

can be secured with standard mounting clamps (not included).

Specification Flash 75M Flash 75L Flash 150M Flash 150L

Size D x H 75 x 150 mm (3" x 6") 75 x 300 mm (3" x 12") 150 x 300 mm (6" x 12") 150 x 600 mm (6" x 24")

Mass of Biotage®KP-Sil Silica (approx.) 0.4 kg 0.8 kg 2.5 kg 5.0 kg

Column Volume (approx.) 0.5 liter 1.0 liter 4.3 liters 8.6 liters

Sample Size Up to 80 grams Up to 160 grams Up to 500 grams Up to 1000 grams

Table 1.The specifications of the Flash 75 and Flash 150 cartridges.

System Components

Head Assemblies

Two stainless steel head assemblies, with knife-edges for

sealing the cartridge, attach to the top and bottom of the barrel

by means of V-band clamps, which can be easily hand-tightened

to seal the flash cartridge inside the barrel. The top head

assembly is fitted with a three-way valve that connects to the

solvent reservoir and the outlet of the Biotage sample injection

module (Biotage®SIM). The bottom head assembly has a tube

compression fitting; this is the fraction collection outlet of the

radial compression module.

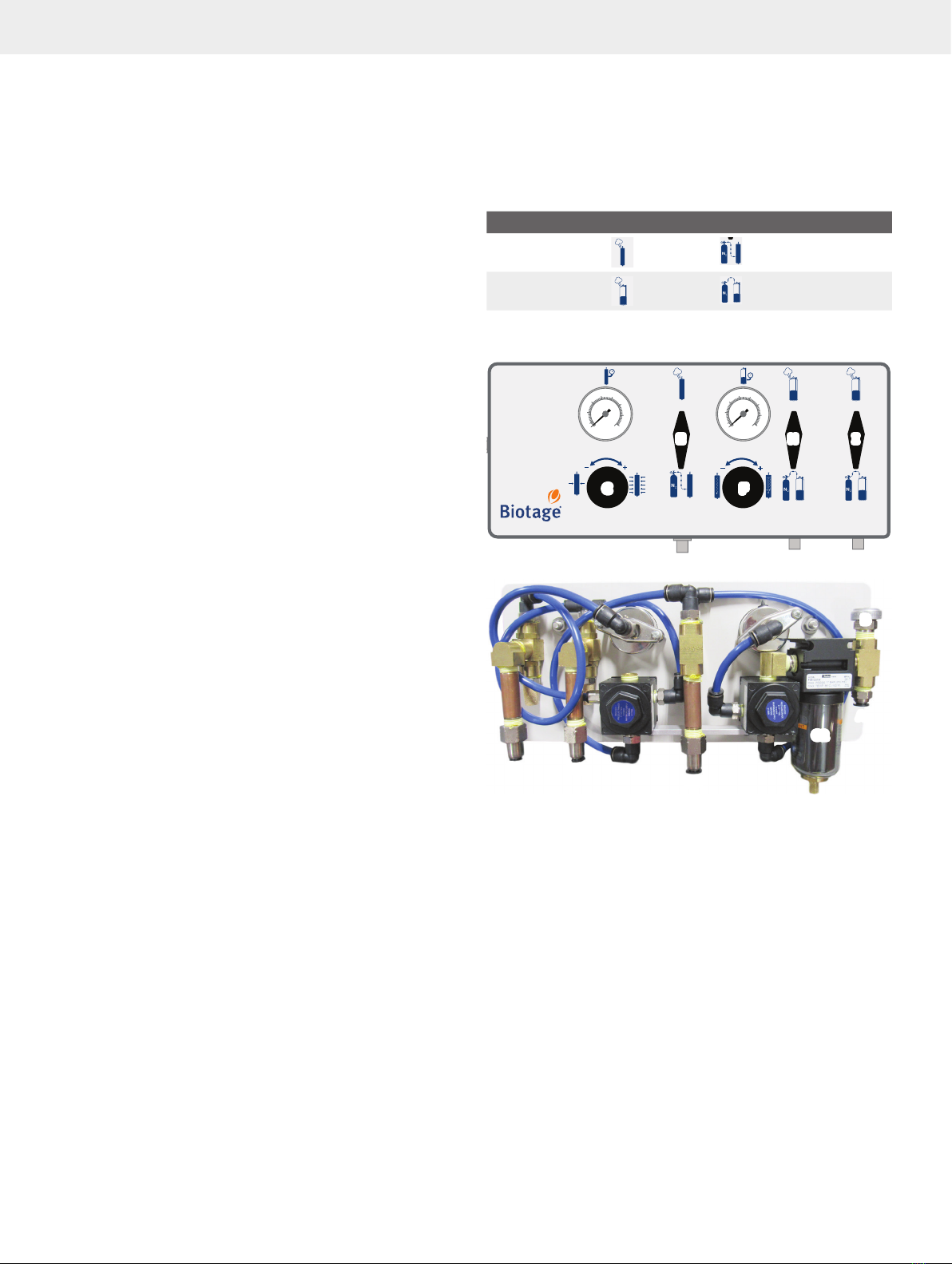

AM- Manifold

The AM-190 manifold (see Figure 4) regulates the radial

compression pressure and the flow of sample and solvent into

the radial compression module. The manifold is easily attached

to standard fume hood mounting bars using the two mounting

rods supplied with the manifold; see “Set Up the AM-190

Manifold” on page 9.

The AM-190 manifold comes equipped with the following

features. See the corresponding letters in Figure 4.

A. An inlet for pressurized inert gas, with an instant-tight fitting

for attaching tubing.

B. A safety relief valve that activates at pressures in excess of

150 psi (10.3 bar).

C. A locking pressure regulator (labeled PRR-01), with a water

trap (C2), for increasing or decreasing the inert gas pressure

to the radial compression module.

D. A pressure gauge (labeled PG-01) for monitoring the inert

gas pressure delivered to the radial compression module.

E. A valve (labeled MV-01) for turning the flow of compressed

inert gas to the radial compression module on or off (see

Table 2), with an instant-tight fitting for attaching tubing (E2).

F. A locking pressure regulator (labeled PRR-02) for increasing

or decreasing the inert gas pressure to the solvent reservoir

and sample injection module (SIM).

G. A

pressure

gauge (labeled

PG-02)

for monitoring the inert

gas pressure delivered to the solvent reservoir and SIM.

H. A valve (labeled MV-03) for turning the flow of compressed

inert gas to the SIM on or off (see Table 2), with an instant-

tight fitting for attaching tubing (H2).

I. A valve (labeled MV-02) for turning the flow of compressed

inert gas to the solvent reservoir on or off (see Table 2), with

an instant-tight fitting for attaching tubing (I2).

Valve Positions

Valve Off/Vent On/Pressurize

MV-01

PRR-01

BIOTAGE

®

FLASH 75/150

CHROMATOGRAPHY

AM-190 MANIFOLD

PRR-02

MV-01

PG-01 PG-02

MV-03 MV-02

N

2

N

2

N

2

A B

PRR-01

BIOTAGE

®

FLASH 75/150

CHROMATOGRAPHY

AM-190 MANIFOLD

PRR-02

MV-01

PG-01 PG-02

MV-03 MV-02

N

2

N

2

N

2

A B

MV-02 and

MV-03

PRR-01

BIOTAGE

®

FLASH 75/150

CHROMATOGRAPHY

AM-190 MANIFOLD

PRR-02

MV-01

PG-01 PG-02

MV-03 MV-02

N

2

N

2

N

2

A B

PRR-01

BIOTAGE

®

FLASH 75/150

CHROMATOGRAPHY

AM-190 MANIFOLD

PRR-02

MV-01

PG-01 PG-02

MV-03 MV-02

N

2

N

2

N

2

A B

Table 2.The positions for the three valves on the AM-190 manifold.

Figure 4

PRR-01

BIOTAGE®FLASH 75/150

CHROMATOGRAPHY

AM-190 MANIFOLD

PRR-02

MV-01

PG-01 PG-02

MV-03 MV-02

N2N2

N2

A B

E H I

C F

A

C2

B

D G

E2

I2 H2

.The AM-190 manifold (bottom) regulates the flow of inert gas

into the radial compression module, solvent reservoir, and sample

injection module (SIM). The front panel of the AM-190 manifold (top) offers

easy-to-use switches to set all flows.

A = pressurized inert gas inlet, B = safety relief valve, C = regulator

for the gas pressure to the radial compression module, C2 = water

trap, D = gauge for the pressure delivered to the radial compression

module, E = compress/vent valve for the radial compression pressure,

E2 = instant-tight fitting for connecting a gas tube between the manifold

and the radial compression module, F = regulator for the gas pressure

to the solvent reservoir and sample injection module (SIM), G = gauge

for the inert gas pressure delivered to the solvent reservoir and SIM,

H = compress/vent valve for the solvent pressure, H2 = instant-tight

fitting for connecting a gas tube between the manifold and the solvent

reservoir, I = compress/vent valve for the SIM pressure, and I2 = instant-

tight fitting for connecting a gas tube between the manifold and the SIM.

Biotage®Flash 75/150 User Manual | © Biotage 2018

System Components

Solvent Reservoir

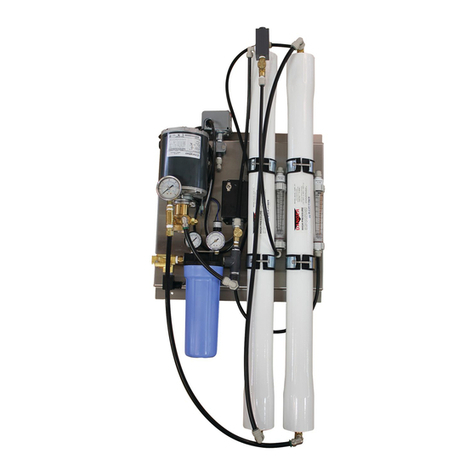

Biotage provides an electropolished 316 stainless-steel solvent

reservoir, available in a 12-liter capacity for the Flash 75 system

and 37-liter and 60-liter capacities for the Flash 150 system.

The solvent reservoir is fitted with an instant-tight fitting for

pressurized inert gas, an on/off valve for solvent flow, and

a safety relief valve that activates at pressures in excess of

109 psi (7.5 bar).

The oval lid of the reservoir is fitted with a clamp that screws

shut, and has a solvent proof, PTFE-encapsulated Viton O-ring

to seal the lid in place. See “Set Up the Solvent Reservoir” on

page 10 for safety precautions on how to secure the lid once

the reservoir has been filled with solvent.

Figure 5

Fitting for

inert gas

On/off valve

Safety relief

valve

Lid with clamp

.The 60-liter solvent reservoir with the two-way valve open.

Sample Injection Module (Biotage®SIM) Kit

Biotage provides a sample injection module (SIM) kit, available

in 500 mL, 1000 mL, and 2000 mL sizes, to simplify the handling

of routine samples as well as viscous oils and samples with

poor solubility that need to be adsorbed directly onto silica.

SIM 500 is optimized for Flash 75M and 75L, SIM 1000 for

Flash 150M, and SIM 2000 for Flash 150L.

Illustrated in Figure 6, the SIM body is constructed of a welded

316 stainless steel tube with a sanitary clamp at the top and a

stainless steel 1/8" (Flash 75) or 1/4" (Flash 150) tube fitting at

the bottom. The top lid comes with a three-way valve. One port

supplies inert gas to drive liquid sample onto the cartridge.

The other port supplies solvent through the SIM when using a

pre-adsorbed sample loading technique.

The SIM is supplied with six sanitary gaskets (two of each type,

see “Sanitary Gaskets” below), one chain clamp (P/N 01520),

25 top frits (P/N FTF-0225), 25 bottom frits with sealing rings

(P/N FBS-1025), and one frit insertion tool (P/N 01596 for

SIM 500 and 1000 and P/N 03339 for SIM 2000).

Figure 6

Three-way valve

Solvent flow

Inert gas

Sanitary

clamp

Frit holder

316 stainless

steel tube

Pour in liquids, oils,

or coated samples

To the radial compression module

Nut

.The sample injection module (SIM) simplifies the handling of

routine samples as well as viscous oils and samples with poor solubility.

Sanitary Gaskets

The SIM includes three different types of sanitary gaskets;

PTFE/EPDM, Viton, and EPDM (see Figure 7). Biotage recommends

the black and gray PTFE/EPDM gasket for most applications, as

it is resistant to most normal phase solvents and mixtures. The

gasket is moderately soft and seats when the sanitary clamp is

firmly tightened. The PTFE/EPDM gasket may leak a small amount

of solvent initially if the SIM is completely full of liquid.

The black Viton and EPDM gaskets are very compressible and

will seal reliably up to 100 psi (6.9 bar), even with a finger-tight

sanitary clamp. EPDM, which has a green color dot on the edge,

is resistant to polar solvents but will swell in many common

aliphatic and aromatic solvents. Viton, which has yellow and

white color dots on the edge, is resistant to non-polar solvents,

but will swell in the typical polar modifiers. For solvent

compatibility information, see Table 3 below.

Solvent PTFE/EPDM Viton EPDM

Hexane FAIR GOOD POOR

Toluene GOOD GOOD POOR

Ethyl acetate GOOD POOR GOOD

Dichloromethane FAIR FAIR FAIR

Methanol GOOD POOR GOOD

Table 3.Solvent compatibility.

Table 3 shows a limited number of commonly used solvents.

To check the compatibility of a particular solvent or solvent

mixture, soak a gasket in the solvent/mixture for one hour and

then inspect it for swelling. If the gasket swells in use, allow

it to dry out in a fume hood until it returns to its normal size

System Components

(typically overnight). Perform a periodic check of your gaskets

and replace a gasket that shows sign of wear or damage or that

leaks at your typical operating pressures.

Figure 7.There are three sanitary gaskets for the SIM: 1) the black and

gray PTFE/EPDM gasket (P/N 415891SP), 2) the black Viton gasket with

yellow and white color dots on the edge (P/N 01615), and 3) the black

EPDM gasket with green dots on the edge (P/N 01616).

Grounding Kit

The system can build up high static charges as non-polar

solvents flow through PTFE tubing, membrane filters, and/or

across a bed of dry silica. To eliminate any risk of a static

discharge, the systems and ancillary containers must be

grounded before use.

The pre-wired grounding kit that is supplied with the system

includes a complete wiring harness assembly (see Figure 8)

and a pair of fraction collection assemblies (a smaller one for

the Flash 75 system and a larger one for the Flash 150 system,

see Figure 9). For instructions on how to install the grounding

kit, see “Ground the System” on page 12.

Figure 8.The wiring harness assembly included in the grounding kit.

Figure 9.The fraction collection assembly for the Flash 75 system (left)

and the Flash 150 system (right).

Start-Up Kit

Biotage provides a start-up kit consisting of the following items:

»

For supplying inert gas, the kit includes four (4)

six-foot lengths (1830 mm) of polyethylene tubing,

1/4" O.D., 0.04" wall thickness, color-coded

in BLUE (P/N 01487), YELLOW (P/N 01354),

GREEN (P/N 00547), and RED (P/N 00546).

»

For supplying solvent, the kit includes:

»

Flash 75: one (1) three-foot (914 mm) and one (1)

one-foot length (305 mm) of 1/8" O.D. CLEAR PTFE tubing

(P/N 00088), and one (1) six-foot length (1830 mm)

of 1/4" O.D. CLEAR PTFE tubing (P/N 00089).

»

Flash 150: one (1) twelve-foot length (3658 mm)

of 1/4" O.D. CLEAR PTFE tubing (P/N 00089).

»

Two (2) spare O-rings for the radial compression module

(P/N 00778 for Flash 75 and P/N 01420 for Flash 150).

»

One (1) two-part inert gas supply fitting, a 3/8" NPT

reducing bushing with a 1/4" (M) NPT attached to

an instant-tight tubing connector (P/N 03072).

»

One (1) three-way valve for the radial

compression module (P/N 04562).

»

One (1) grounding kit (P/N FGD-15075).

»

One (1) cartridge extraction tool (P/N 02131 for

Flash 75 and P/N 01428 for Flash 150).

»

Two (2) disposable 10 mL syringes (P/N 01656).

»

One (1) Luer injection port (P/N02838). Only Flash 150.

»

One (1) user manual (P/N 02140).

For detailed information on how tubing and fittings are attached

and assembled, refer to the section “Installation” on page 9.

Cartridge Extraction Tool

A cartridge extraction tool is provided to simplify the removal of

used flash cartridges from the barrel of the radial compression

module. The tool consists of a machined stainless steel rod with

a handle on one end and two swinging, bladed “leaves” on the

other (see Figure 10). A sliding ring on the shaft locks the leaves

into a position perpendicular to the shaft of the tool.

Figure 10

Sliding

lock ring

Bladed

“leaves”

.The cartridge extraction tool simplifies the removal of a used

cartridge from the radial compression module.

To use the tool, slip the lock ring to the bottom of the shaft so

that the leaves are held in place. Hold the tool by the handle

and push the tool firmly into the top of the cartridge. The bladed

surface of the leaves will “bite” into the plastic edge of the

cartridge, allowing it to be easily pulled out. Moving the sliding

lock ring up will release the leaves so the tool can be removed.

Biotage®Flash 75/150 User Manual | © Biotage 2018

System Components

Chemical Resistance

The following chemicals can be used in the wetted parts of the

system:

»

Acetone

»

Dichloromethane (methylene chloride, DCM)

»

Toluene

»

Acetonitrile (MeCN)

»

Tetrahydrofuran (THF)

»

Triethylamine (TEA)

»

N,N-dimethylformamide (DMF)

»

Ethyl acetate (ethyl ethanoate, EtOAc)

»

N-methyl-2-pyrrolidone (NMP)

»

Dimethylsulfoxide (DMSO)

»

Ethanol (EtOH)

»

Methanol (MeOH)

»

2-propanol (isopropanol, IPA)

»

Formic acid (methanoic acid, HCOOH)

»

Acetic acid (Ethanoic acid, HOAc, AcOH)

»

Deionized water (H2O)

»

Trifluoroacetic acid (TFA), max 5 % (by volume)

»

n-Heptane

»

Piperidine (pip)

»

Pyridine (pyr)

»

Ammonia (NH3) conc. 23–27 % (by weight)

»

tert-Butyl methyl ether (TBME)

»

Diethyl ether

»

10 mM phosphate buffered saline, pH= 7.4

»

50 mM phosphate-citrate buffer, pH= 5.0

»

Boric acid/NaOH/KCl buffer, pH=11

Note: The sample injection module (SIM) is delivered with three

types of sanitary gasket. Always check the gaskets' compatibility

with the solvent or solvent mixture that you want to use. For more

information, see “Sanitary Gaskets” on page 4.

Safety

Intended Use

Biotage Flash 75 and Flash 150 systems are intended solely

for purification. The systems must be operated in a laboratory

environment with an ambient temperature between 4°C and

32°C (39°F and 90°F) by trained professiona

ls. The system must

not be installed or used near a potential ignition source. It is the

responsibility of the customer to classify (zone) their particular

environment in order to verify that it meets the requirements of

the directive 1999/92/EC. All operations must be performed:

»

According to the user documentation

delivered with the system.

»

According to instructions available at www.biotage.com.

»

According to instructions given by the

technical support staff from Biotage.

»

Within limits set by the system’s technical specification and

in line with user standard operating procedures (SOPs).

Failure to follow those instructions and operate within the limits

set by the technical specification may result in personal injury

and/or equipment damage.

Education, Training, and Competence

It is your responsibility to provide all applicable health and

safety regulations to your personnel. You must also ensure that

all personnel involved in the operation and maintenance of the

system fulfill the following criteria:

»

Have the necessary education, training, and competence

required for the intended use of the system.

»

Observe general and specific safety regulations for the

use of the system and its accessories at all times in order

to reduce the risk of personal injury, fire, and explosion.

Warranty and Liability

See the “Biotage Terms & Conditions of Sale” document at

www.biotage.com.

Service

All service must be performed by an authorized Biotage service

engineer. Before handing over the system for service, it should

be emptied of all liquid and cleaned from harmful residues.

It is the responsibility of the customer to inform

Biotage®1-Point Support™

representatives if the system has been

used with hazardous biological, radioactive, or toxic samples

and/or solvents, prior to any service being performed.

If returning equipment to Biotage, this should be done in

accordance with the material return procedures supplied

separately by Biotage.

Only genuine Biotage spare parts must be used in the system.

Labels

Labels used on the system:

In accordance with all the essential requirements of

all applicable European product directives; see the

Declaration of Conformity.

In accordance with the ATEX Product Directive,

2014/34/EU for Group II, Category 2G equipment.

The equipment is intended for use in areas in which

explosive atmospheres caused by gases, vapors, or

mists or air/dust mixtures are likely to occur.

Manufacturer.

Consult accompanying user documentation.

Note: The system is ASME rated and in accordance with both

U.S. and Canadian safety standards.

Safety Requirements

You must observe all safety requirements when installing and

operating the system. Failure to install or use the system in

a manner specified by Biotage may result in personal injury

and/or equipment damage.

If the system has been damaged or does not function

properly, turn off the inert gas supply, depressurize the radial

compression module and the solvent reservoir, and contact

Biotage 1-Point Support (www.biotage.com).

Installation

»

The system must be unpacked and installed

as described on page 9.

»

Follow regional safety practices when handling

and moving shipping boxes and containers,

and when moving the system.

»

The total weight of the package including the

system is between 16 and 84 kg (35 and 185 lbs)

depending on the system configuration. Use suitable

lifting equipment when moving the package.

Safety

Biotage®Flash 75/150 User Manual | © Biotage 2018

Safety

»

The system must be placed in a well-ventilated fume hood

or an equivalent enclosure that is capable of exhausting

2.5 m3/min (90 ft3/min). Follow local and national safety

regulations for installing a system inside a fume hood and the

safety regulations supplied by the fume hood manufacturer.

»

Never install or use the system near

a potential ignition source.

»

The system, when operated with non-polar solvents

such as hexane, methylene chloride, etc., can build up a

high static electricity charge, which in certain conditions

can be dangerous. To eliminate any risk of a static

discharge, the systems and ancillary containers must

be grounded before use as described on page 12.

Failure to follow these grounding instructions may result

in equipment damage, personal injury, or death.

»

A trained person must verify that the system and

ancillary containers are grounded before each run.

Nominal resistance must be below 5 Ohm between

ground and each metal point in the system.

»

Always connect inert gas such as nitrogen to

the gas inlet on the AM-190 manifold.

»

Ensure that the inert gas tubing connected to the

system cannot come in contact with chemicals.

Corrosives and solvents can dissolve the tubing.

»

The AM-190 manifold must be mounted horizontally

so that the water trap can function correctly.

»

The outlets of the three safety relief valves (located on the

radial compression module, AM-190 manifold, and solvent

reservoir) must be directed away from the operator.

»

Ensure that the tubes are not longer than

necessary for your setup so that there is no

risk of stepping or tripping over them.

»

To avoid injury to yourself or damage to the

system, set the inert gas supply pressure to

between 100 and 125 psi (6.9 to 8.6 bar).

»

Do not over-tighten the fittings or the

tubing may become damaged.

»

Never modify the system components in any way

and always use spare parts supplied by Biotage.

Operation

»

Use the system only for its intended purpose, as described

in the user documentation delivered with the system and

user documentation available at www.biotage.com. If the

system is used in a manner not specified by Biotage, the

safety features of the system may be compromised.

»

The system must not be operated unattended.

»

Never operate the system if damaged.

»

The system is operated using pressurized inert

gas. Ensure that all seals are properly mounted

and that all clamps are properly closed before

introducing pressurized gas into the system.

»

Confirm that the upper V-band clamp is tight before

compressing the radial compression module. Only

hand-tighten the clamp, to a maximum torque of 11.3 Nm

(100 lbf-in). If the cartridge is not sealed properly, replace

the O-ring and retry, or contact Biotage 1-Point Support.

»

Inspect the V-band clamps before and after each use.

The clamp must be replaced when it shows any signs of

wear and tear, or at 500 pressure cycles, whichever comes

first. Only use clamps and screws supplied by Biotage.

»

Never loosen the V-band clamps when the radial

compression module is under pressure. A red

pressure indicator on the radial compression

module sticks out when the pressure is above

20 psi (1.4 bar); see Figure 2 on page 2.

»

Never remove a tube or system component

when it is under pressure.

»

Reduce the pressure using the solvent pressure

regulator (labeled PRR-02)to less than 50 psi

(3.5 bar) before blowing down the Flash 150

radial compression module with inert gas.

»

When closing the solvent reservoir lid, ensure that

it is seated properly to ensure a secure seal.

»

Never run the system without a cartridge,

or with the wrong size of cartridge.

»

Always equilibrate the cartridge.

»

Equilibrate the cartridge at a low flow rate

to avoid extreme temperature rise.

»

Only use waste/fraction collection vessels

that are grounded or made of glass.

»

If the system is placed in a walk-in fume

hood, a fume extractor must be used for open

waste/fraction collection vessels.

»

Follow all applicable safety procedures

when working with bottled gas.

»

Follow all generally-accepted lab safety procedures

and applicable laws and regulations.

»

Always follow local and national safety

regulations related to storage, handling and

disposal of chemicals, samples and waste.

»

Read and understand the safety data sheet (SDS)

provided by the chemical manufacturer before

storing, handling, working with, or disposing

of any chemical or hazardous substance.

»

Personnel working with or near the system must

wear applicable safety clothing and gear (such as

solvent-resistant clothing and gloves, steel toe

shoes, and face and eye protection) that comply

with local and national safety regulations.

Installation

Installation

Warning

»

Follow regional safety practices when handling and moving

shipping boxes and containers, and moving the system.

»

The system must be placed in a well-ventilated fume hood or an

equivalent enclosure that is capable of exhausting 2.5 m3/min

(90 f t3/min). Follow local and national safety regulations

for installing a system inside a fume hood and the safety

regulations supplied by the fume hood manufacturer.

»

Never install or use the system near a potential ignition source.

»

If the system is placed in a walk-in fume hood, a fume extractor

must be used for open waste/fraction collection vessels.

»

The total weight of the package including the system is

between 16 and 84 kg (35 and 185 lbs) depending on the

system configuration. Use suitable lifting equipment when

moving the package.

Note: We recommend that the boxes and packing materials are

retained in case the system needs to be returned for service

or moved to another location. If you need to ship the system,

please contact Biotage 1-Point Support for instructions.

Set Up the Radial Compression Module

Warning

»

The outlet of the safety relief valve must be directed away from

the operator.

1. Remove the assembled radial compression module (see D in

Figure 13 on page 11) from the shipping container.

2. Attach the three-way valve supplied in the start-up kit onto

the top head assembly using a 9/16" wrench.

3. Determine the best installation location for the radial

compression module. Consider the following:

»

The outlet of the safety relief valve

(see Figure 3 on page 2) must be

directed away from the operator.

»

There must be sufficient space above the radial

compression module to insert and remove cartridges.

4. If using a Flash 75 radial compression module:

a. Screw the two mounting rods into the mounting pads

located on the side of the barrel.

b. Attach the barrel to the fume hood’s mounting bars

using mounting clamps (not supplied).

5. If using a Flash 150 radial compression module, roll the cart

with the module into a walk-in fume hood.

Set Up the AM- Manifold

Warning

»

The AM-190 manifold must be mounted horizontally so that the

water trap can function correctly.

»

The outlet of the safety relief valve must be directed away from

the operator.

1. Remove the AM-190 manifold (see A in Figure 13 on

page 11) from the shipping container.

2. Attach the two mounting bars to the manifold using a 5/32"

Allen key.

3. Determine the best mounting location for the manifold.

Consider the following:

»

Choose a location that allows you to easily access both

the manifold and the radial compression module.

»

The outlet of the safety relief valve (see B in Figure 4 on

page 3) must be directed away from the operator.

4. Attach the AM-190 manifold to the fume hood’s mounting

bars using mounting clamps. Ensure that the manifold is

mounted horizontally.

Set Up the Sample Injection

Module (Biotage®SIM)

Note that the use of the sample injection module (SIM) is optional.

1. Remove the SIM (see B in Figure 13 on page 11) from the

shipping container.

2. Open the bag of bottom frits and push one plastic frit into a

sealing ring. Save the other frits and sealing rings for use later.

3. Unscrew the lower half of the stainless steel frit holder

and drop the sealing ring and frit into the lower half; see

Figure 22 on page 16.

Note: Ensure that the plastic frit is at the bottom of the

frit holder.

4. Screw the lower half of the frit holder back in place. Finger-

tight is normally adequate.

5. Determine the best mounting location for the SIM. Consider

the following:

»

Typically, the SIM should be mounted so that

the bottom tube fitting is 1" to 3" (25 to 76 mm)

above the radial compression module.

»

Ensure to leave enough space to insert and remove

cartridges from the radial compression module.

»

The SIM should be in a convenient location

for pouring in liquid or solid sample.

6. Attach the SIM to the fume hood’s mounting bars using the

chain clamp provided.

Biotage®Flash 75/150 User Manual | © Biotage 2018

Installation

Set Up the Solvent Reservoir

Warning

»

The outlet of the safety relief valve must be directed away from

the operator.

»

When closing the solvent reservoir lid, ensure that it is seated

properly to ensure a secure seal.

1. Remove the solvent reservoir (see C in Figure 13 on

page 11) from the shipping container.

2. If the two-way on/off valve is not installed:

a. Remove the on/off valve from the inside of the reservoir.

b. Install the on/off valve into the 1/4" NPT fitting on the

solvent reservoir. Turn the valve clockwise by hand.

Use a wrench (not provided) on the hex section of the

adapter to fully tighten it into the solvent reservoir.

c. Install the lid on the solvent reservoir by tilting and

lowering it into the mouth of the reservoir. Hand-tighten

the clamp to secure the lid and ensure that the lid is

seated properly to ensure a secure seal.

3. Place the solvent reservoir in a convenient spot on the

benchtop or floor of the fume hood. Ensure that you leave

enough space for your fraction collection vessels and

that the outlet of the safety relief valve (see Figure 5 on

page 4) is directed away from the operator.

Attach the Inert Gas Supply

and Solvent Lines

Warning

»

Always connect inert gas such as nitrogen to the gas inlet on the

AM-190 manifold.

»

Follow all applicable safety procedures when working with

bottled gas.

»

Set the inert gas supply pressure to between 100 and 125 psi

(6.9 to 8.6 bar).

»

Ensure that the inert gas tubing connected to the system cannot

come in contact with chemicals. Corrosives and solvents can

dissolve the tubing.

»

Ensure that the tubes are not longer than necessary for your

setup so that there is no risk of stepping or tripping over them.

»

Do not over-tighten the fittings or the tubing may become

damaged.

The start-up kit includes all of the tubing necessary for

operation (see page 5).

1. Ensure that:

a. The inert gas supply is turned off.

b. The two-way valve on the solvent reservoir is closed.

c. The three valves on the AM-190 manifold are set to their

off/vent positions (see Table 2 on page 3)

2. Install a pressure regulator set to a maximum of 125 psi

(8.6 bar) to your inert gas supply.

3. Install the brass fitting supplied with the start-up kit (the

two-part assembly with a 3/8" NPT reducing bushing and

a 1/4" NPT instant-tight tubing connector):

»

If using an inert gas supply in the fume hood, remove the

standard hose barb and replace it with the brass fitting.

»

If using bottled inert gas, remove the 3/8" NPT reducing

bushing and then thread the 1/4" instant-tight tubing

connector directly onto your pressure regulator.

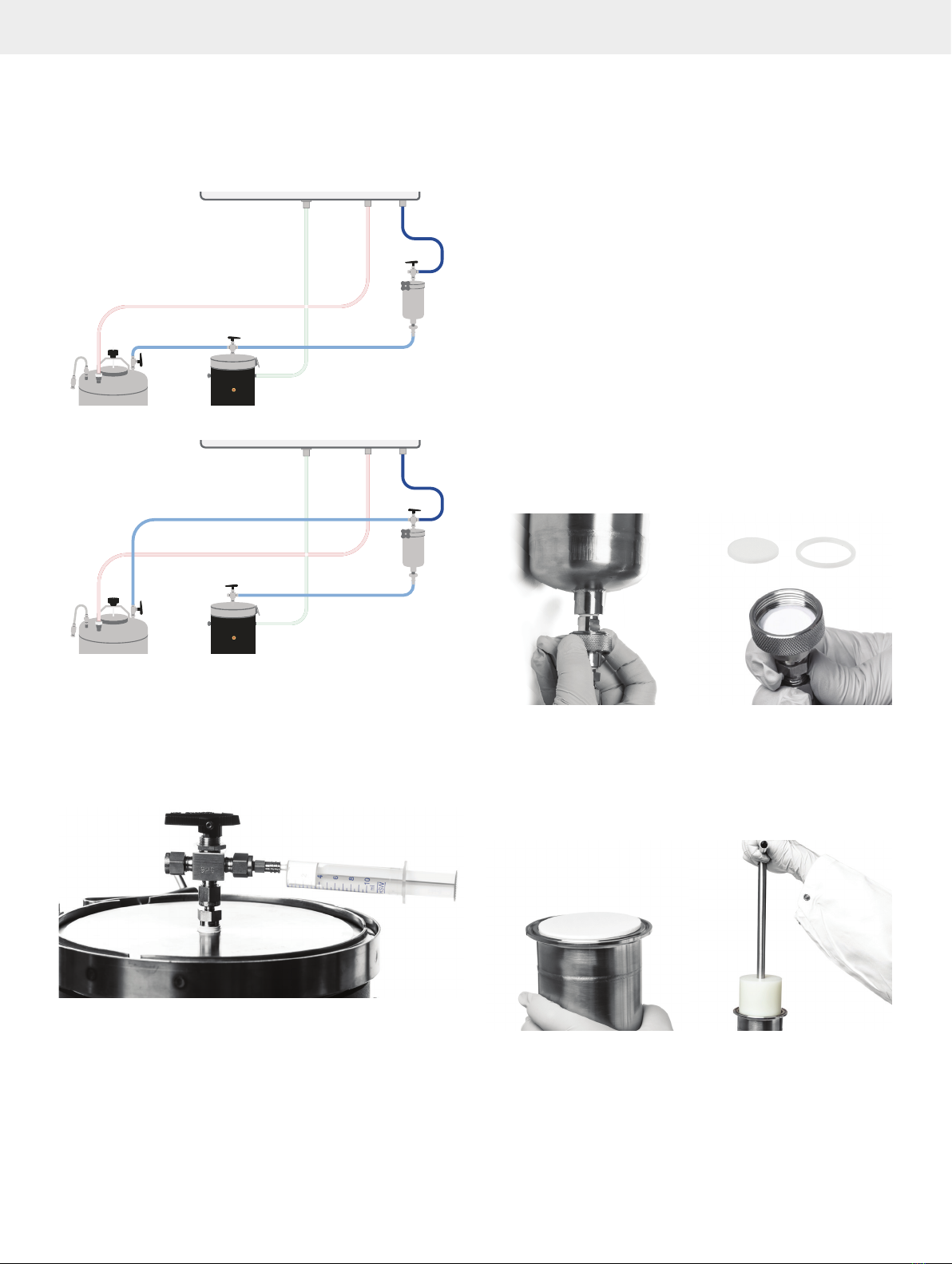

4. Connect all the tubing, except the fraction collection tube,

as shown in the left schematic in Figure 13 or, if not using

a SIM, as shown in Figure 12. The fraction collection tube is

supplied with the grounding kit and is connected during the

grounding of the system; see the instructions on page 12.

Cut the tubing so that they are long enough for your setup.

The system has both instant-tight fittings and fittings with

nuts and ferrules, see the instructions below. Test the seal

by pulling on the tubing.

Note: All tubing should be cut with square ends using a tube

cutter. Do not use scissors as they tend to flatten the tubing

and leave a rough edge.

Note: If using a SIM, the clear PTFE tubing attached to the

solvent reservoir must be long enough to reach both to the

radial compression module (for when equilibrating and

loading liquid samples, see the left schematic in Figure 13)

and the SIM (for when loading solid samples, see the right

schematic in Figure 13).

Note: The Flash 75 start-up kit contains both 1/4" and 1/8"

clear PTFE tubing. The 1/8" tubing is to be used between the

SIM and the radial compression module.

Fitting with Nut and Ferrules

1. Slide the nut and ferrules onto the tube as shown in Figure 11.

2. Push the tube into the fitting until it seats and then finger-

tighten the nut. Use a 7/16" or 9/16" wrench to turn the nut

1 to 1¼ turn past finger-tight (the first time, after that less is

required). Do not over-tighten.

3. Test the seal by gently pulling on the tube.

Figure 11.How to slide the nut and ferrules onto the tubing.

Installation

Figure 12

PRR-01

BIOTAGE®FLASH 75/150

CHROMATOGRAPHY

AM-190 MANIFOLD

PRR-02

MV-01

PG-01 PG-02

MV-03 MV-02

N2N2

N2

A B

A

C

Inert gas supply

D

E

.Schematics of a system without the sample injection module (SIM).

Figure 13

PRR-01

BIOTAGE®FLASH 75/150

CHROMATOGRAPHY

AM-190 MANIFOLD

PRR-02

MV-01

PG-01 PG-02

MV-03 MV-02

N2N2

N2

A B

A

C

Inert gas supply

B

D

E

PRR-01

BIOTAGE®FLASH 75/150

CHROMATOGRAPHY

AM-190 MANIFOLD

PRR-02

MV-01

PG-01 PG-02

MV-03 MV-02

N2N2

N2

A B

A

C

Inert gas supply

B

D

E

.

Schematics of a system ready-for-use when equilibrating the system and loading liquid sample (left) and when loading solid sample (right).

A = AM-190 manifold, B = sample injection module (SIM), C = solvent reservoir, D = radial compression module, and E = fraction collection vessel.

Yellow tube = pressurized inert gas inlet, green tube = inert gas to the radial compression module, red tube = inert gas to the solvent reservoir,

blue tube = inert gas to the sample injection module, and clear PTFE tubes (light blue in the schematics) = solvent supply, SIM outlet, and fraction collection.

Biotage®Flash 75/150 User Manual | © Biotage 2018

Installation

Ground the System

Warning

»

The system, when operated with non-polar solvents such as

hexane, methylene chloride, etc., can build up a high static

electricity charge, which in certain conditions can be dangerous.

To eliminate any risk of a static discharge, the systems and

ancillary containers must be grounded before use as described

below. Failure to follow these grounding instructions may result

in equipment damage, personal injury, or death.

»

A trained person must verify that the system and ancillary

containers are grounded before each run. Nominal resistance

must be below 5 Ohm between ground and each metal point in

the system.

The pre-wired grounding kit that is supplied with the system

includes a complete wiring harness assembly (see Figure 14)

and a pair of fraction collection assemblies (see Figure 15).

Figure 14.The wiring harness assembly included in the grounding kit.

Figure 15.The fraction collection assembly for the Flash 75 system (left)

and the Flash 150 system (right).

Note: All the alligator clips must be connected to metal

fittings/objects, not to the plastic tubing.

Note: Before installing the grounding kit, ensure that the system

tubing has been installed in accordance with the instructions in

“Attach the Inert Gas Supply and Solvent Lines” on page 10.

1. Connect the first alligator clip (item 1 in Figure 16) to a

grounded point, such as a metal cold water pipe.

Note: To be an acceptable grounding point, the entire run of

pipe must be made of metal. Have a qualified person, such

as an electrician, verify that the point is grounded before

operating the system.

2. Connect the next alligator clip (item 2 in Figure 16) to the

on/off valve on the top of the solvent reservoir, at the point

where the metal tubing connector is located.

3. Connect the next alligator clip (item 3 in Figure 16) to the

three-way valve on the top of the sample injection module,

at the point where the metal tubing connector is located.

4. Connect the next alligator clip (item 4 in Figure 16) to the

bottom of the sample injection module, at the point where

the metal tubing connector is located.

5. Connect the next alligator clip (item 5 in Figure 16) to the

three-way valve on the top of the radial compression module,

at the point where the metal tubing connector is located.

6. Connect the last alligator clip (item 6 in Figure 16) to the

metal fitting on the bottom of the radial compression

module.

7. Connect the fraction collection assembly tube (item 7

in Figure 16) to the fitting on the bottom of the radial

compression module as described in “Fitting with Nut and

Ferrules” on page 10.

Note: The grounding kit contains two fraction collection

assemblies. The one with the smaller nozzle and a tube with

an outer diameter of 1/8" is for Flash 75 and the one with the

larger nozzle and a tube with an outer diameter of 1/4" is for

Flash 150; see Figure 15.

8. Wrap the uninsulated wire (item 8 in Figure 16) that connects

to the last alligator clip (item 6 in Figure 16) around the

fraction collection tube (item 7 in Figure 16) and then

securely tighten the terminal ring on the uninsulated wire

(item 9 in Figure 16) between the two hex nuts on the

fraction collection nozzle (item 10 in Figure 16).

9. Verify that the system is grounded using an electrical

multimeter (DVM). Nominal resistance must be below 5 Ohm

between ground and each metal point in the system.

Installation

Figure 16

PRR-01

BIOTAGE®FLASH 75/150

CHROMATOGRAPHY

AM-190 MANIFOLD

PRR-02MV-01

PG-01 PG-02

MV-03 MV-02

N2N2

N2

A B

.System grounding schematic. Note that all the alligator clips must be connected to metal fittings/objects, not to the plastic tubing.

1

Connect

to earth

ground

2

3

4

5

6

7

10

8

9

Biotage®Flash 75/150 User Manual | © Biotage 2018

How to Use the System

Warning

»

Before operating the system, please read and observe the

safety requirements in the “Safety” section on page 7.

Note: We recommend that you keep a logbook of all the runs

performed on the system (with the date, time, user, used

solvent or solvent mixture, and pressure settings for each run)

to keep track of the pressurized cycles.

Fill the Solvent Reservoir

1. Ensure that the two-way valve on the top of the solvent

reservoir is closed; see Figure 17.

2. Ensure that the inert gas supply is turned off and that the

three valves on the AM-190 manifold are set to their off/vent

positions (see Table 2 on page 3).

3. Take the necessary precautions to avoid exposure to harmful

gases and open the lid by loosening the clamp screw and

then tilting the lid.

4. Ensure that the system is grounded; see “Ground the

System” on page 12.

5. Fill the solvent reservoir with the desired solvent.

Note: If the solvent reservoir is not empty, ensure that you

fill it with the same solvent or solvent mixture.

6. Put the lid back in place by tilting and lowering it into the

mouth of the solvent reservoir. Hand-tighten the clamp to

secure the lid.

Figure 17

ClosedOpen

.The two-way on/off valve on the solvent reservoir open (left)

and closed (right).

Insert a Flash Cartridge

Warning

»

Never run the system without a cartridge, or with the wrong

size of cartridge.

»

Never loosen the V-band clamps when the radial compression

module is under pressure. A red pressure indicator on the radial

compression module sticks out when the pressure is above

20 psi (1.4 bar); see Figure 2 on page 2.

»

Inspect the V-band clamp before and after each use. The clamp

must be replaced when it shows any signs of wear and tear, or

at 500 pressure cycles, whichever comes first. Only use clamps

and screws supplied by Biotage.

»

Confirm that the V-band clamp is tight before compressing the

radial compression

module. Only hand-tighten the clamp to a

maximum torque of 100 lbf-in (11.3 Nm). If the cartridge is

not sealed properly, replace the O-ring and retry, or contact

Biotage 1-Point Support.

1. Ensure that the three-way valve on the radial compression

module and the two-way valve on the top of the solvent

reservoir are closed.

2. Ensure that the inert gas supply is turned off and that the

three valves on the AM-190 manifold are set to their off/vent

positions (see Table 2 on page 3).

3. Remove any outer plastic wrapping from the cartridge.

You may wish to keep label information for your records.

4. Remove the end caps from the cartridge and keep them.

5. Loosen the upper and lower V-band clamps.

6. Remove the top head assembly from the radial compression

module.

7. Lower the cartridge into the radial compression module and

confirm that it is level with the top of the barrel.

Note: If the cartridge does not go all the way into the radial

compression module, loosen the lower V-band clamp until

the cartridge top is level with the top of the barrel.

8. When the cartridge is level with the top of the barrel, ensure

that the O-ring is secure inside the groove in the top lip of the

barrel and that it is not damaged; see Figure 26 on page 19.

Note: If the O-ring shows any signs of wear or damage,

replace it. Two spare O-rings are supplied with the system.

9. Place the top head assembly back in place and hand-tighten

the V-band clamps alternating between the upper and lower

until secure.

Tightening the V-band clamp will engage the knife-edge seal

into the cartridge and engage the O-ring to seal the inert

gas pressure within the barrel. Note that the V-band clamp

should not be over-tightened. Maximum recommended

tightening torque is 100 lbf-in (11.3 Nm).

How to Use the System

How to Use the System

Figure 18.Inserting a flash cartridge into the radial compression module.

Pressurize the Radial Compression

Module and the Solvent Reservoir

Warning

»

The system is operated using pressurized inert gas. Ensure that

all seals are properly mounted and that all clamps are properly

closed before introducing pressurized gas into the system.

»

To avoid injury to yourself or damage to the system, set

the inert gas supply pressure to between 100 and 125 psi

(6.9 to 8.6 bar).

»

Follow all applicable safety procedures when working with

bottled gas.

1. Ensure the system is grounded; see “Ground the System” on

page 12.

2. Ensure that the three-way valve on the radial compression

module and the two-way valve on the solvent reservoir are

closed.

3. Ensure that all the lines are properly connected as described

in “Attach the Inert Gas Supply and Solvent Lines” on

page 10 and that there is solvent in the solvent reservoir.

Note: If using a SIM, the solvent tube must be connected

between the solvent reservoir and the radial compression

module as shown in the left schematic in Figure 13 on

page 11 for you to be able to equilibrate the cartridge.

The solvent tube may contain solvent; please ensure to

take the necessary precautions to avoid spillage when

disconnecting the tube.

4. Turn on the inert gas supply that is connected to the AM-190

manifold (see A in Figure 4 on page 3). Confirm that the

gas pressure is between 100 and 125 psi (6.9 to 8.6 bar).

5. Pressurize the radial compression module by turning the

MV-01 valve on the AM-190 manifold to the on/pressurize

position (see Table 2 on page 3).

6. Set the radial compression pressure to 100 psi (6.9 bar) by

adjusting the PRR-01 regulator on the AM-190 manifold.

7. Confirm that the cartridge is compressed; the red pressure

indicator on the front of the radial compression module

sticks out (see Figure 2 on page 2).

8. Pressurize the solvent reservoir by turning the MV-03 valve

on the AM-190 manifold to the on/pressurize position (see

Table 2 on page 3).

9. Set the equilibration flow rate/solvent pressure by adjusting

the PRR-02 regulator on the AM-190 manifold as follows:

»

Flash 75M: approx. 30 psi (2.1 bar)

»

Flash 75L and Flash 150M: approx. 45 psi (3.1 bar)

»

Flash 150L: approx. 45 to 60 psi (3.1 to 4.1 bar)

Note: These solvent pressure settings are approximate

guidelines. Your particular mobile phase, depending on its

viscosity, may require a higher or lower pressure.

Note: Ensure that the solvent pressure is at least 20 psi

(1.4 bar) lower than the radial compression pressure.

Equilibrate the Cartridge

Warning

»

Always equilibrate the cartridge.

»

Equilibrate the cartridge at a low flow rate to avoid extreme

temperature rise.

»

Only use waste/fraction collection vessels that are grounded or

made of glass.

»

If the system is placed in a walk-in fume hood, a fume extractor

must be used for open waste/fraction collection vessels.

1. Ensure that the fraction collection nozzle is inserted into a

collection vessel that is grounded or made of glass. If the

system is placed in a walk-in fume hood, a fume extractor

must be used for open collection vessels.

2. Turn the three-way valve on the radial compression module

toward the tube connected to the solvent reservoir.

3. Open the two-way valve on the solvent reservoir and allow

solvent to flow through the cartridge.

4. When solvent exits from the fraction collection nozzle, close

the two-way valve on the solvent reservoir and empty the

collection vessel.

Biotage®Flash 75/150 User Manual | © Biotage 2018

How to Use the System

Load Sample and Collect Fractions

A liquid sample or a solid sample that has been pre-adsorbed

on silica can be loaded onto the equilibrated cartridge using

a sample injection module (SIM); see Figure 19 and Figure 20.

Figure 19

PRR-01

BIOTAGE®FLASH 75/150

CHROMATOGRAPHY

AM-190 MANIFOLD

PRR-02

MV-01

PG-01 PG-02

MV-03 MV-02

N2N2

N2

A B

.Liquid sample loading using a sample injection module (SIM).

Figure 20

PRR-01

BIOTAGE®FLASH 75/150

CHROMATOGRAPHY

AM-190 MANIFOLD

PRR-02

MV-01

PG-01 PG-02

MV-03 MV-02

N2N2

N2

A B

.Solid sample loading using a sample injection module (SIM).

Alternatively, if the sample is soluble in a small volume of

solvent, it can be injected with a syringe through a Luer-lock

injection port on the radial compression module; see

Figure 21. The port is fitted by disconnecting the SIM outlet

tube from the radial compression module and replacing it with

the Luer-lock injection port (supplied with Flash 150 systems).

Figure 21.Alternatively, if the sample is soluble in a small volume of

solvent, it can be injected with a syringe through a Luer-lock injection

port on the radial compression module.

Load the Sample into the SIM

1. Ensure that the MV-02 valve on the AM-190 manifold is set

to its off/vent position (see Table 2 on page 3) and the

two-way valve on the solvent reservoir is closed.

2. If loading a solid sample, close the three-way valve on the

radial compression module and disconnect the solvent tube

connected between the solvent reservoir and the radial

compression module from the module and connect it to the

SIM; see Figure 20.

Note: The solvent tube contains solvent; please ensure

to take the necessary precautions to avoid spillage when

disconnecting the tube.

3. Insert a bottom frit into the SIM's frit holder:

a. Push one bottom frit into a sealing ring.

b. Unscrew the lower half of the frit holder and insert the

sealing ring and frit into the lower half; see Figure 22.

Note: Ensure that the plastic frit is at the bottom of the

frit holder.

c. Screw the lower half of the frit holder back in place.

Finger-tight is normally adequate.

Figure 22.Inserting a bottom frit into the lower half of the frit holder.

4. Loosen the clamp on the SIM and remove the top assembly

(clamp, lid with the three-way valve, and sanitary gasket).

5. Insert a top frit of the correct diameter into the SIM and push

it down to the bottom using the frit insertion tool included in

the SIM kit; see Figure 23.

Figure 23.Inserting a frit into the SIM 2000 body using its frit insertion

tool. Note that the insertion tool for SIM 500 and SIM 1000 does not have

a handle.

How to Use the System

6. Pour the liquid sample or the silica with the adsorbed

sample into the SIM. See Table 4 for maximum volumes.

Note: When working with oils, dilute the sample with elution

solvent until it will flow freely down a glass rod.

SIM Max Volume

(mL)

Max Silica Mass

(gram/SIM Unit*)

500 350 175

1000 900 450

2000 1800 900

Table 4.Maximum volume and nominal mass of silica for the SIM modules.

*This is the maximum amount of silica that fits into the SIM; the actual

amount of silica used will depend on the sample being loaded.

7. If loading a solid sample:

a. Tap the silica down using the frit insertion tool.

b. Insert a second top frit into the SIM and push it down

using the frit insertion tool.

Note: The top frit must be installed or the separation

efficiency will be low.

8. Ensure that the gasket grooves of the lid and SIM body are

free from any particulates.

9. Place the top assembly back in place and tighten the clamp.

Ensure that the sanitary gasket is captured in the grooves of

the lid and SIM body; see Figure 24.

Note: Use a sanitary gasket that compatible with the used

solvent; see “Sanitary Gaskets” on page 4.

Note: If the gasket shows any signs of wear or damage,

replace it.

Note: It is sometimes useful to apply a small amount of

solvent to the groove and gasket to ensure a good seal.

10. To load the sample onto the equilibrated cartridge and elute

fractions, see “Load the Sample onto the Cartridge and

Collect Fractions” below.

Figure 24.The sanitary gasket must be captured in the grooves of the lid

and the SIM body.

Load the Sample onto the Cartridge and Collect Fractions

Collect your fractions in flasks that are grounded or made of glass.

The following are guidelines for vessel types by cartridge volume:

»

Flash 75M (400g): 125-mL flasks

»

Flash 75L (800g): 250-mL flasks

»

Flash 150M (2.5 kg): 1-liter flasks

»

Flash 150L (5.0 kg): 2-liter flasks

Since your compound will not elute in less than one column volume

(CV), you may wish to collect the first 0.5, 1, or 3 to 6 liters in

a larger flask or carboy. As you approach the point where your

compound will elute, use the smaller fraction collection vessels

(see the bullet list above) to maximize your yield and purity.

Note: Based on the predicted retention volume (CP) of the first

compound, the initial solvent volume could be collected in one

large flask to minimize glassware usage.

Warning

»

Only use waste/fraction collection vessels that are grounded or

made of glass.

11. If the SIM contains a liquid sample:

a. Ensure that the fraction collection nozzle is inserted into

a collection vessel that are grounded or made of glass.

b. Turn the three-way valve on the radial compression

module toward the tube connected to the SIM

c. Turn the MV-02 valve on the AM-190 manifold to its

on/pressurize position (see Table 2 on page 3) to

drive your sample onto the cartridge.

d. When the sample has been loaded onto the cartridge,

i.e. when the SIM outlet tubing is dry, turn the MV-02

valve on the AM-190 manifold to its off/vent position

(see Table 2 on page 3).

12. Turn the three-way valve on the SIM toward the tube

connected to the solvent reservoir.

13. Ensure that the solvent reservoir is pressurized, i.e. the

MV-03 valve on the AM-190 manifold is turned to its

on/pressurize position (see Table 2 on page 3).

14. Set the solvent flow rate/solvent pressure by adjusting the

PRR-02 regulator on the AM-190 manifold as follows:

»

Flash 75M: approx. 40 psi (2.8 bar)

»

Flash 75L and Flash 150M: approx. 60 psi (4.1 bar)

»

Flash 150L: approx. 60 to 80 psi (4.1 to 5.5 bar)

Note: These solvent pressure settings are approximate

guidelines. Your particular mobile phase, depending on its

viscosity, may require a higher or lower pressure. For flash

cartridges packed with KP-Sil silica, Biotage recommends a

solvent flow rate between 100 and 250 mL/min for Flash 75

and between 400 and 1000 mL/min for Flash 150.

Note: Ensure that the solvent pressure is at least 20 psi

(1.4 bar) lower than the radial compression pressure.

Biotage®Flash 75/150 User Manual | © Biotage 2018

How to Use the System

15. Ensure that the fraction collection nozzle is inserted into a

collection vessel of a suitable size. See the guidelines above.

Note: If using a solid sample, the sample has not yet been

loaded onto the cartridge. It will be loaded when you open

the two way valve on the solvent reservoir in the next step.

16. Open the two-way valve on the solvent reservoir. Solvent

will then flow through the SIM and cartridge (solid sample)

or cartridge (liquid sample) and out of the fraction collection

nozzle.

17. Once your separation is finished, stop the solvent flow by

closing the two-way valve on the solvent reservoir.

18. Turn the MV-03 valve on the AM-190 manifold to its off/vent

position (see Table 2 on page 3).

19. Close the three-way valve on the radial compression module.

Refill the Solvent Reservoir

If you need to refill the solvent reservoir during a run:

1. Close the two-way valve on the solvent reservoir.

2. Depressurize the solvent reservoir by turning the MV-03

valve on the AM-190 manifold to its off/vent position (see

Table 2 on page 3).

3. When the pressure has been released, open the lid by

loosening the clamp screw and then tilting the lid.

4. Ensure that system is grounded; see “Ground the System”

on page 12.

5. Take the necessary precautions to avoid exposure to

harmful gases and then fill the solvent reservoir with the

desired solvent.

Note: If changing solvent, the new solvent must be miscible

with the previous solvent.

6. Put the lid back in place by tilting and lowering it into the

mouth of the solvent reservoir. Hand-tighten the clamp to

secure the lid.

Empty the Solvent Reservoir

Warning

»

Only use waste/fraction collection vessels that are grounded or

made of glass.

If you want to empty the solvent reservoir after the run, this is

preferably done before depressurizing the radial compression

module.

1. Ensure that the three-way valve on the radial compression

module and the two-way valve on the solvent reservoir are

closed.

2. Disconnect the solvent tube from the radial compression

module and insert it into a collection vessel of a suitable size.

3. Turn the MV-03 valve on the AM-190 manifold to its

on/pressurize position (see Table 2 on page 3).

4. Lower the solvent pressure to 15 psi (1 bar).

5. Take the necessary precautions to avoid exposure to

harmful gases.

6. While firmly holding down the solvent tube into the

collection vessel, slowly open the two-way valve on the

solvent reservoir.

Depressurize the Radial Compression

Module and Remove the Used Cartridge

Warning

»

Never loosen the V-band clamps when the radial compression

module is under pressure. A red pressure indicator on the radial

compression module sticks out when the pressure is above

20 psi (1.4 bar); see Figure 2 on page 2.

»

Only use waste/fraction collection vessels that are grounded or

made of glass.

1. If using a Flash 150 system, reduce the solvent pressure to

less than 50 psi (3.5 bar) by adjusting the PRR-02 regulator

before blowing down the radial compression module.

2. Insert the fraction collection nozzle into a collection vessel

that are grounded or made of glass.

3. Turn the three-way valve on the radial compression module

toward the tube connected to the SIM.

4. Turn the three-way valve on the SIM toward the BLUE tubing

that is connected to the AM-190 manifold.

5. Turn the MV-02 valve on the AM-190 manifold to its

on/pressurize position (see Table 2 on page 3)to blow

inert gas through the SIM and cartridge and drive out any

remaining solvent.

6. When the last of the solvent drains out of the radial

compression module, turn the MV-02 and MV-01 valves on

the AM-190 manifold to their off/vent positions (see Table 2

on page 3).

7. When the radial compression module is not under pressure,

i.e. the red pressure indicator on the front of module is not

sticking out (see Figure 2 on page 2), turn off the inert

gas supply to the system and allow any pressure to dissipate

through the system.

8. Loosen the upper V-band clamp and remove the top head

assembly from the radial compression module.

9. Remove the cartridge using the cartridge extraction tool

supplied with the system; see Figure 25.

10. Put the end caps back on the cartridge and dispose of it in a

safe manner.

This manual suits for next models

1

Table of contents

Other Biotage Water Filtration System manuals