Sea Recovery SRC Aqua Matic 450-1 User manual

Aqua Matic Modular 450-1800

Owner’s Manual

Initial Release - 1 December 2008

Manual PN B651140002 | Revision: 0//1

SRC Aqua Matic 450-1

SRC Aqua Matic 700-1

SRC Aqua Matic 900-1

SRC Aqua Matic 900-2

SRC Aqua Matic 1400-2

SRC Aqua Matic 1800-2

FOR DECEMBER 2008 MODELS

Aqua Matic Modular 450-1800

Owner’s Manual

Aqua Matic Modular 450-1800

Page i

PREFACE

Thank you for your purchase of a Sea Recovery Aqua Matic

Reverse Osmosis Desalination System. This manual contains

instructions for the installation, operation, maintenance,

and repair of the Sea Recovery Desalination System. This

information is provided to ensure extended life and safe

operation of your Sea Recovery system.

Please read this manual thoroughly before installation

or operation, and keep it for future reference. A better

understanding of the system ensures optimum performance

and longer service life.

Sea Recovery’s Reverse Osmosis Desalination Systems are

designed and engineered to function as a complete working

unit. Generally speaking, the performance of each component

within the System is dependent on the component prior to it

and governs the performance of all components after it. Proper

performance of the system is thus dependent upon proper

operation of every single component within the system.

The intent of this manual is to allow the operator to become

familiar with each component within the Sea Recovery system.

By understanding the function, importance, and normal

operation of each component within each subsystem of the

unit, the operator can readily diagnose minor problems, which

if detected early are usually easily corrected. However, if left

unattended, a problem in one component eventually affects the

rest of the system and leads to further repairs.

The manual is divided into sections that address different

subject matter. Each section should be reviewed before

operating the Reverse Osmosis Desalination system.

The major documented cause of failures and problems are

from the use of third party, non Sea Recovery, parts, from

improper installation, and from improper operation:

The use of third party, non Sea Recovery, consumable, spares,

and assemblies will damage the Sea Recovery system and/

or specific components within the system. Do not use parts,

components from any source other than Sea Recovery. Use of

third party, non Sea Recovery, components will void any and

all warranty of the system and/or void the effected component

within the system.

Sea Recovery maintains inventory for immediate shipment and

our Service Dealers throughout the world maintain stock of Sea

Recovery parts. Always insist on Sea Recovery supplied parts

for your system in order to avoid failures, eliminate problems,

and maintain your Sea Recovery Warranty.

Follow the Installation and Operation Instructions in this manual.

From time to time, Sea Recovery may make programming

changes to the Control Logic.

Other physical production changes may also be made from

time to time and are tracked by Sea Recovery through the

System Serial Number.

Troubleshooting and repair method results can vary

depending on the information that is displayed at the SYSTEM

INFORMATION screen.

• SERIAL NUMBER helps us to determine the latest

physical version and configuration of your system

which is necessary to ensure that we provide you with

the correct information or parts.

• TYPE tells us the production capacity of your system

which gives us a bench mark in diagnosing product

water flow and pressure concerns.

• TIME RUNNING assists us in diagnosing abnormalities

that can occur at given operational time intervals such

as required pump maintenance, or R.O. membrane

element condition.

• VERSION allows us to determine the specific sequential

operation of the system based on the version of the

programmed control logic.

When requesting assistance from Sea Recovery

or Sea Recovery’s service dealers, always:

PROVIDE ALL INFORMATION DISPLAYED

AT THE SYSTEM INFORMATION SCREEN.

Aqua Matic Modular 450-1800

Page ii

COPYRIGHT NOTIFICATION

Copyright 2008-2009®Sea Recovery Corporation. All content

included within this manual, such as text, graphics, logos,

and images, is the property of Sea Recovery Corporation and

protected by U.S. and international copyright laws.

The compilation (meaning the preparation, collection,

arrangement, and assembly) of all content within this manual

is the exclusive property of Sea Recovery Corporation and

protected by U.S. and international copyright laws.

All software used in the design and manufacture of the

Sea Recovery Reverse Osmosis Desalination System is the

property of Sea Recovery Corporation and protected by U.S.

and international copyright laws. All computer and logic

programming used in the design and manufacture of the Sea

Recovery Reverse Osmosis Desalination System the property

of Sea Recovery Corporation and protected by U.S. and

international copyright laws.

The content of this manual and the software, programming,

and graphic designs used in the design and manufacture of

the Sea Recovery Reverse Osmosis Desalination System is for

the purpose of operation, maintaining, and repair of the Sea

Recovery Reverse Osmosis Desalination System. Any other

use, including the reproduction, modification, distribution,

transmission, republication, display, or performance, of the

content within this manual is strictly prohibited.

TERMS AND CONDITIONS

The use of this manual acknowledges acceptance of the terms

and conditions provided herewith and the agreement to comply

with all applicable laws and regulations pertaining to the use of

this manual.

In addition, the use of this manual forms an agreement

that Sea Recovery’s trademarked name or Sea Recovery’s

trademarked logo mark are not to be used in any form or

manner except with Sea Recovery Corporation’s written

permission. Sea Recovery Corporation holds all rights to its

copyrights and trademarks, and to the material contained in

this manual. Any use of such requires the written permission

from Sea Recovery Corporation.

PATENT INFORMATION

Certain aspects of the Sea Recovery Reverse Osmosis

Desalination System are protected by U.S. and International

Patent Laws.

NOTICE OF LIABILITY

The information contained in the manual is distributed on an

“As is” basis, without warranty. While every effort has been

taken in the preparation of this manual, Sea Recovery Corp.

shall not be held liable with respect to any liability, loss, or

damage caused by the instructions contained in this manual.

The information contained in this manual is subject to change

without notice.

TRADEMARKS

The Sea Recovery®logo mark is a U.S. Registered Trademark

and belongs to Sea Recovery Corporation with all rights

reserved. Sea Recovery®is a US Registered trademark of

Sea Recovery Corporation. Aqua Matic™is a trademark of

Sea Recovery Corp.

Aqua Matic Modular 450-1800

Page i

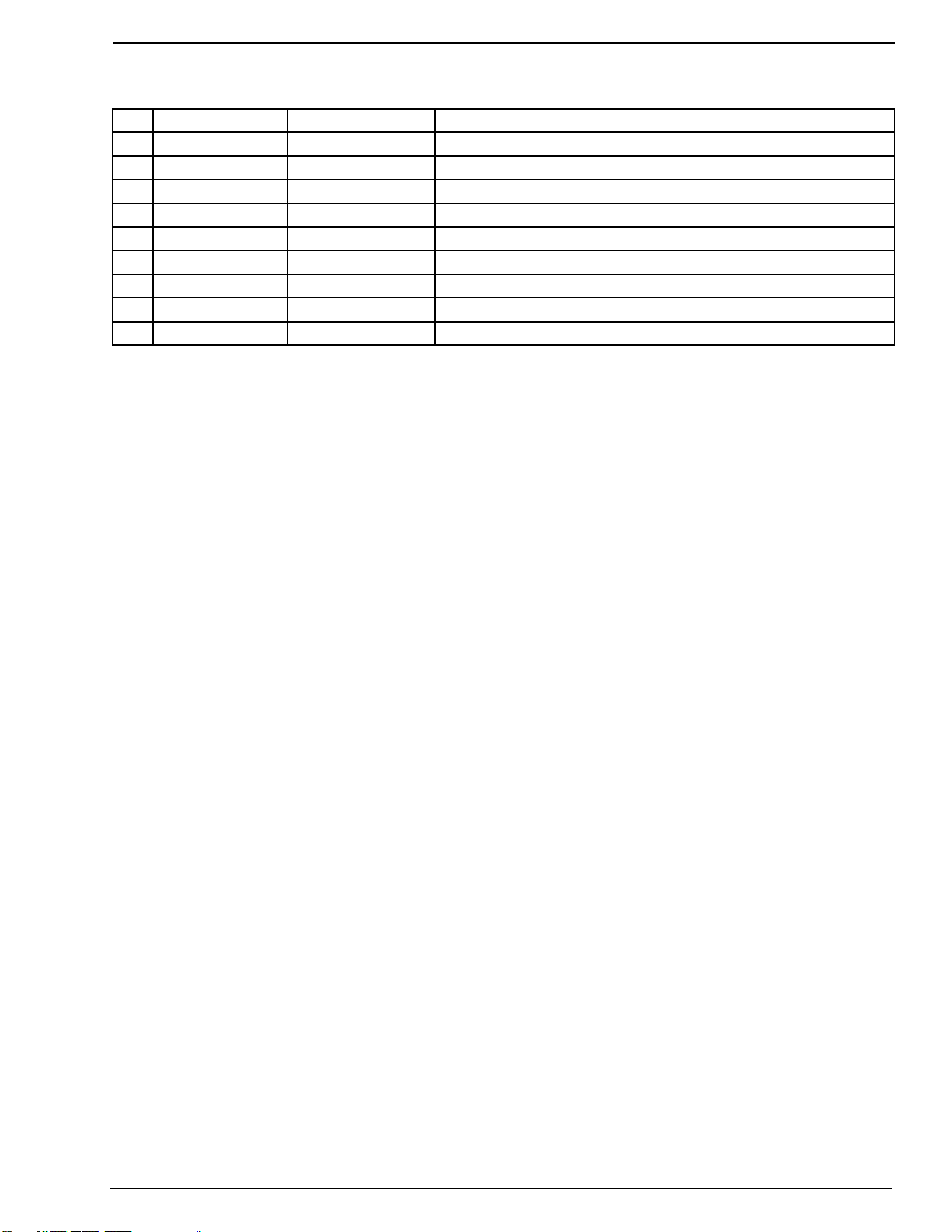

REVISION HISTORY

Rev. Date Affected Pages Description

Ø 1 December 2008 - Initial Release of the 2008 Models.

1 9/23/09 Pg.4-11 & FoldOut Revised Electrical Diagrams

2 11/18/09 - General Re-formatting

3 11/23/09 Pg. 5-2 Multi Media Installation Instructions revision

4 6/23/10 Section 10 Updated Parts / Added NMEA kit

5. 6/23/10 Pg. 2-1, 2-12, & 2-15 AQM modular with new GP pump

6. 6/23/10 Cover New AQM modular with plunger pump

7 5-30-13 Parts View Added HP 75, and Soft Start

8 5-30-13 Electrical & Certificates New Diagrams, New Certificates

Aqua Matic Modular 450-1800

Page iv

TABLE OF CONTENTS

1 INTRODUCTION 1-1

1.1 PURPOSE 1-1

1.2 SAFETY IN GENERAL 1-1

1.3 USING THIS MANUAL 1-1

1.4 TERM USED 1-1

1.5 REFERENCES 1-1

1.6 SAFETY NOTES 1-1

1.7 GRAPHICS 1-1

1.8 GLOSSARY 1-1

2 SYSTEM DESCRIPTION 2-1

2.1 MODELS 2-1

2.2 SPECIFICATIONS 2-1

2.3 COMPLIANCE 2-1

2.4 WARRANTY 2-1

2.5 REGISTRATION 2-1

2.6 PACKING LIST 2-1

2.7 COMPONENT DIMENSIONS 2-1

2.8 DAILY SYSTEM READING 2-1

2.9 CHEMICAL SAFETY 2-1

2.10 TEMPERATURE & PRESSURE EFFECTS 2-1

3 PRE-INSTALLATION NOTES 3-1

3.1 PRECAUTIONS 3-1

3.2 SPECIAL CONSIDERATIONS 3-1

3.3 DISTANCE BETWEEN COMPONENTS 3-2

3.5 COMPONENTS SUPPLIED BY INSTALLER 3-2

3.6 PIPING AND INTERCONNECT DIAGRAMS 3-3

3.7 EXPLANATION OF PRESSURE TRANSDUCERS 3-16

3.8 RO MEMBRANE ELEMENT NOTES 3-17

3.9 COMPONENT DESCRIPTIONS 3-17

4 ELECTRICAL INFORMATION 4-1

4.1 ELECTRICAL REQUIREMENTS AND INFORMATION 4-1

4.2. ELECTRICAL MOTOR SPECIFICATIONS 4-2

4.3. RECOMMENDED CIRCUIT BREAKER 4-2

4.4. RECOMMENDED POWER WIRE SIZE 4-3

4.5. WIRE INSERTION TO TERMINAL STRIPS 4-4

4.6. WIRE SIZE REFERENCES 4-4

4.7. MODULAR MODEL ELECTRICAL INFORMATION 4-6

4.8 MODULAR MODEL WIRING DIAGRAMS 4-11

5 INSTALLATION REQUIREMENTS 5-1

5.1 SYSTEM CONTROL BOX 5-1

5.2 COMPONENTS 5-1

Aqua Matic Modular 450-1800

Page v

5.3 INTERCONNECTING COMPONENTS 5-5

5.4 WATER TANK 5-6

5.5 REMOTE TOUCH SCREEN 5-6

5.6 ELECTRICAL CONNECTIONS 5-6

5.7 LAND FEED WATER PICK-UP 5-6

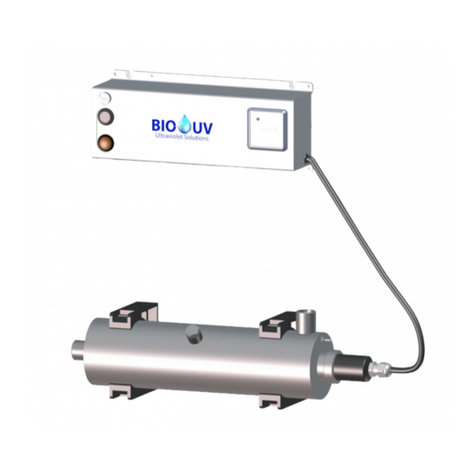

5.8 UV STERILIZER INSTALLATION 5-8

6 COMMISSIONING 6-1

6.1 CHECK INSTALLATION 6-1

6.2 CHECK R.O. MEMBRANE 6-1

6.3. SETUP CONTROLLER 6-1

6.4 CHECK SYSTEM MANUALLY 6-2

6.5 OPERATION NOTES 6-3

6.6 INITIAL STARTUP 6-4

6.6.1. POSITION SYSTEM VALVES 6-4

6.6.2. APPLY POWER TO THE SYSTEM 6-5

6.6.3. START THE SYSTEM 6-5

6.6.4. LOG SYSTEM READINGS 6-6

6.6.5. SHUTDOWN THE SYSTEM 6-6

6.7 WARNINGS AND CAUTIONS 6-6

7 OPERATION 7-1

7.1 DAILY OPERATION 7-3

7.1.1 POSITION VALVES 7-3

7.1.2 APPLY POWER TO THE SYSTEM 7-3

7.1.3 START THE SYSTEM 7-3

7.1.5. LOG SYSTEM READINGS 7-4

7.1.6. SHUTDOWN THE SYSTEM 7-4

7.2 SYSTEM STORAGE AND CLEANING 7-4

7.3 SHORT-TERM SHUTDOWN 7-8

7.4 LONG TERM SHUTDOWN 7-8

7.5 WINTERIZING PROCEDURE 7-9

7.6 R.O. MEMBRANE CLEANING 7-9

8 MAINTENANCE AND REPAIR 8-1

8.1 WEEKLY QUICK CHECK 8-2

8.2 OPERATOR MAINTENANCE INTERVALS 8-2

8.3 INDIVIDUAL COMPONENT MAINTENANCE AND REPAIR 8-2

8.4 UV STERILIZER MAINTENANCE 8-18

9 TROUBLESHOOTING 9-1

9.1 ALARM AND ERROR SCREENS 9-1

9.2 TROUBLESHOOTING COMPONENTS 9-2

9.3 ELECTRICAL TROUBLESHOOTING 9-18

Aqua Matic Modular 450-1800

Page vi

10 EXPLODED PARTS VIEW 10-1

10.1. WHEN ORDERING 10-1

10.3 AVAILABLE TUBES AND FITTINGS 10-2

10.4 INSTALLATION KIT B001990001 10-5

10.5 MAJOR PARTS 10-6

1. SEA STRAINER ASSY 3/4-B B006080002 10-6

2. BOOSTER PUMP ASSY N200 50/60/1 B016120001 10-7

3. BOOSTER PUMP ASSY N200 50/60/3 B016120002 10-8

4. BOOSTER PUMP HEAD N200 1221515772 10-9

5. MEDIA FILTER ASSY -4 HS/AW/UW B071080002 10-10

6. MULTI MEDIA FILTER PLUMBING ASSY B075000001 10-12

7. PLANKTON FILTER ASSY-SINGLE B008800001 10-13

8. PLANKTON FILTER ASSY-DOUBLE B008800002 10-14

9. PREFILTER DUAL AQM II B108140001 10-16

10. COMMERCIAL PREFILTER ASSY 32.5 SQ FT SRC AQM B109120001 10-18

11. OIL / WATER SEPARATOR ASSY SRC 32.5 SQ FT B111120001 10-19

12. HP PUMP MOTOR ASSY, 1 PHASE B156150001 (Optional) 10-20

13. HP PUMP MOTOR ASSY 3 PHASE B156150002 (Optional) 10-21

14. HP PUMP/MOTOR ASSY PGR 110/220/1 - B156930003 (Standard) 10-22

15. HP PUMP/MOTOR PLGR 110/220/60/1 - B156930006 (Standard) 10-23

16. HP PUMP/MOTOR PLGR 220/60/3 - B156150007 (Standard) 10-24

17. HP PUMP ASSY-12180513CO (Standard) 10-26

18. HP HOSE ASSEMBLY 10-28

19. MEMBRANE RACK 450-1 - B198000032 10-29

20. MEMBRANE RACK 700-1 - B198000033 10-30

21. MEMBRANE RACK 900-1 - B198000034 10-31

22. MEMBRANE RACK 900-2 - B198000035 10-32

23. MEMBRANE RACK 1400-2 - B198000036 10-33

24. MEMBRANE RACK 1800-2 - B198000037 10-34

25. CONTROLLER BOX A15M 10-36

26. CONTROLLER CHASSIS 1 PH B619940001 10-37

27. CONTROLLER CHASSIS 3 PH B619940002 10-38

28. BACK PRESSURE REGULATOR ASSY B476160003 10-39

29. LP BACK PRESSURE PLATE ASSY B515150002 10-40

30. LP TRANSDUCER ASSY B147130002 10-41

31. PH NEUTRALIZER / CHARCOAL DUAL AQMC II / MOD B114140001 10-42

32. CLEAN AND RINSE KIT AQM B591120001 10-43

33. FRESH WATER FLUSH (.50 INCH) B598000008 10-44

34. UV STERILIZER 12VDC 2GPM B5262000CV 10-46

35. SOFT START ASSY B596800006 10-47

36. REMOTE KIT DISPLAY 80FT STD AQMII B610140008 10-48

37. NMEA 2000 ENABLED B610140004 10-49

11 FOLDOUT 11-1

Introduction

Aqua Matic Modular 450-1800

Section 1 - INTRODUCTION

Introduction

Aqua Matic Modular 450-1800

Page 1-1

Introduction

1.6 SAFETY NOTES

Safety issues that require users attention are highlight

through out this manual as follows.

WARNING: A Warning note provides

critical information users must comply

within order to prevent the possibility of

injuries and/or death.

CAUTION: A Caution note provides

important information users must know

to prevent the possibility of damaging the

device or equipment.

NOTE: A Note provides additional

information users should know to properly

and safely operate the equipment.

1.7 GRAPHICS

Graphics used are for reference and illustration

purposes only, and may not represent the actual part or

arrangement of parts in a customized system.

1.8 GLOSSARY

Following terms are helpful in becoming familiar with the

Sea Recovery Reverse Osmosis System.

BOUNDARY LAYER / CONCENTRATION POLARIZATION

When water permeates through the membrane, nearly

all the salt is left behind in the brine channel. In any

dynamic hydraulic system, the fluid adjacent to the wall

of the vessel is moving relatively slow. Even though the

main body of the stream is turbulent, a thin film adjacent

to the wall (membrane) is laminar. This thin film is called

the boundary layer.

At the boundary layer the salts are saturated and can

readily adhere to and pack into the R.O. membrane

element surface if the Feed Water Flow is insufficient.

For this reason it is important to maintain sufficient Feed

Water flow, to prevent Concentration Polarization, through

the R.O. membrane element.

BRINE VELOCITY

The brine flow over the membrane surface is very

important to both product water quality and quantity. At

low flows, concentration polarization occurs, causing the

water quality to decline.

1 INTRODUCTION

1.1 PURPOSE

This manual is intended for Sea Recovery’s system

technicians, technical support, and training personnel.

This manual contains technical information & instructions

for the installation, operation, maintenance, and

troubleshooting of the Sea Recovery Desalination System.

1.2 SAFETY IN GENERAL

Anyone responsible for the installation, operation,

and maintenance of the Sea Recovery Desalination

System must read this manual thoroughly and

comply with the instructions, guidelines, and safety

requirements at all times.

1.3 USING THIS MANUAL

Reading this manual in its entirety will help users to

become familiar with each component within the system.

By understanding the function, importance, and normal

operation of each component, users can readily operate

and diagnose problems.

Aside from this section, this manual is divided into ten

majors sections.

•Section 2: System Description

•Section 3: Pre-installation Notes

•Section 4: Electrical Information

•Section 5: Installation Requirements

•Section 6: Commissioning

•Section 7: Operation

•Section 8: Maintenance & Repair

•Section 9: Troubleshooting

•Section 10: Exploded Parts View

•Section 11: Foldouts

Each section should be reviewed in the order provided

before performing any system operations.

1.4 TERM USED

The term System refers to Aqua Matic System in general

and will be used throughout this manual.

1.5 REFERENCES

All references in this manual refers to other sections

within this manual unless specifically defined.

Aqua Matic Modular 450-1800

Page 1-2

Introduction

SPIRAL-WOUND MEMBRANE

The spiral-wound membrane consists of multiple

membrane envelopes each formed by enclosing a

channelized product water carrying material between two

large flat membrane sheets. The membrane envelope

is sealed on three edges with a special adhesive and

attached with the adhesive to a small diameter pipe.

A polypropylene screen is used to form the feed water

channel between the membrane envelopes. A wrap

is applied to the membrane element to maintain the

cylindrical configuration. The center tube is also the

permeate (product water) collecting channel. Several

elements may be connected in series within a single or

multiple pressure vessels).

WATER TEMPERATURE EFFECT

The product water flow through the membrane is

significantly affected by the water temperature. At any

given pressure this flow increases with increasing water

temperature and is reduced at lower temperatures.

The System over comes this factor by self adjusting

the operating pressure to maintain a precise amount of

Product Water Flow.

In addition to inferior product water quality, low brine

flows can increase the precipitation of sparingly soluble

salts which will foul the R.O. membrane element surface

(concentration polarization). If this occurs, the product

water flux (production) will decline.

The Feed Pump integrated design provide a relatively

smooth and continual flow of Feed Water across and

through the R.O. membrane element.

COMPACTION

Some densification of the membrane structure may

take place while operating at elevated pressures, above

1000 PSI. The change is known as compaction and is

accompanied by a reduction in the water permeation rate.

When the R.O. membrane element is subjected to

elevated pressures beyond 1000 PSI the Product Water

Channel becomes squeezed which results in restriction

and in turn product water recovery reduction.

OSMOTIC PRESSURE

The transfer of the water from one side of the membrane

to the other will continue until the head (pressure) is

great enough to prevent any net transfer of the solvent

(water) to the more concentrated (feed water) solution.

At equilibrium, the quantity of water passing in either

direction is equal, and the head pressure is then defined

as the ”Osmotic Pressure” of the solution having that

particular concentration of dissolved solids.

PRESSURE

The operating pressure has a direct affect on product

water quality and quantity. Both factors will increase

as the system pressure increases (higher quantity and

higher quality within design limits).

The system must be operated at the lowest pressure

required to achieve the designed product water flow

rate. This parameter also minimizes compaction, which

proceeds at a faster rate at higher pressures as well as

at higher temperatures.

The System self adjusts its operating pressure to maintain

a precise amount of Product Water Flow. However in

so doing, at low temperatures and or high salinity feed

water conditions the system will operate at higher than

normal pressure in maintaining the specified amount of

product water flow. This is normal, to be expected, and is

due to the design characteristics of the system.

Description

Aqua Matic Modular 450-1800

Section 2 - SYSTEM DESCRIPTION

Description

Aqua Matic Modular 450-1800

Page 2-1

Description

2 SYSTEM DESCRIPTION

Since 1981, Sea Recovery Corporation has been

producing water desalination systems for various

applications to customers all around the world.

Since then Sea Recovery has become one of the top

leaders in advanced water desalination systems for

leisure marine applications.

2.1 MODELS

Aqua Matic Modular series are available in six models.

SRC Aqua Matic 450-1• SRC Aqua Matic 700-1• SRC Aqua Matic 900-1• SRC Aqua Matic 900-2• SRC Aqua Matic 1400-2• SRC Aqua Matic 1800-2• 2.2 SPECIFICATIONS

Refer to Page 2-2 for System Specification details.

2.3 COMPLIANCE

Sea Recovery’s Reverse Osmosis Desalination

Systems are Type Accepted by the American Bureau

of Shipping, ABS.

Sea Recovery’s Reverse Osmosis Desalination Systems

comply with FCC § 15.105

Sea Recovery’s Reverse Osmosis Desalination Systems

have been independently tested and determined to be in

compliance with European CE (Conformité Européne).

Refer to Page 2-5 for compliance certificates.

2.4 WARRANTY

Sea Recovery guarantees its product, components, and

replacement parts and recommends customers to use

only Sea Recovery parts. The majority of RO system

problems derive from premature failure of unauthorized

third party replacement parts.

Using unauthorized third party components will lead to

higher operating costs and maintenance costs and labor.

Most importantly, using unauthorized parts will void

Sea Recovery Warranty.

Refer to Page 2-11 for Limited Warranty.

2.5 REGISTRATION

Sea Recovery recommends all customers to register

their System immediately after delivery to ensure and

guarantee product technical support and warranty.

2.6 PACKING LIST

For visual packing list and optional accessories refer

to Page 2-13.

2.7 COMPONENT DIMENSIONS

Refer to Page 2-15 for system and component dimensions.

2.8 DAILY SYSTEM READING

Refer to Page 2-17 for daily system reading log sheet.

2.9 CHEMICAL SAFETY

Refer to Page 2-18 for chemical safety and first aid

recommendations.

2.10 TEMPERATURE & PRESSURE EFFECTS

Refer to Page 2-20 for temperature and pressure effects

on RO membrane performance.

Aqua Matic Modular 450-1800

Page 2-2

Description

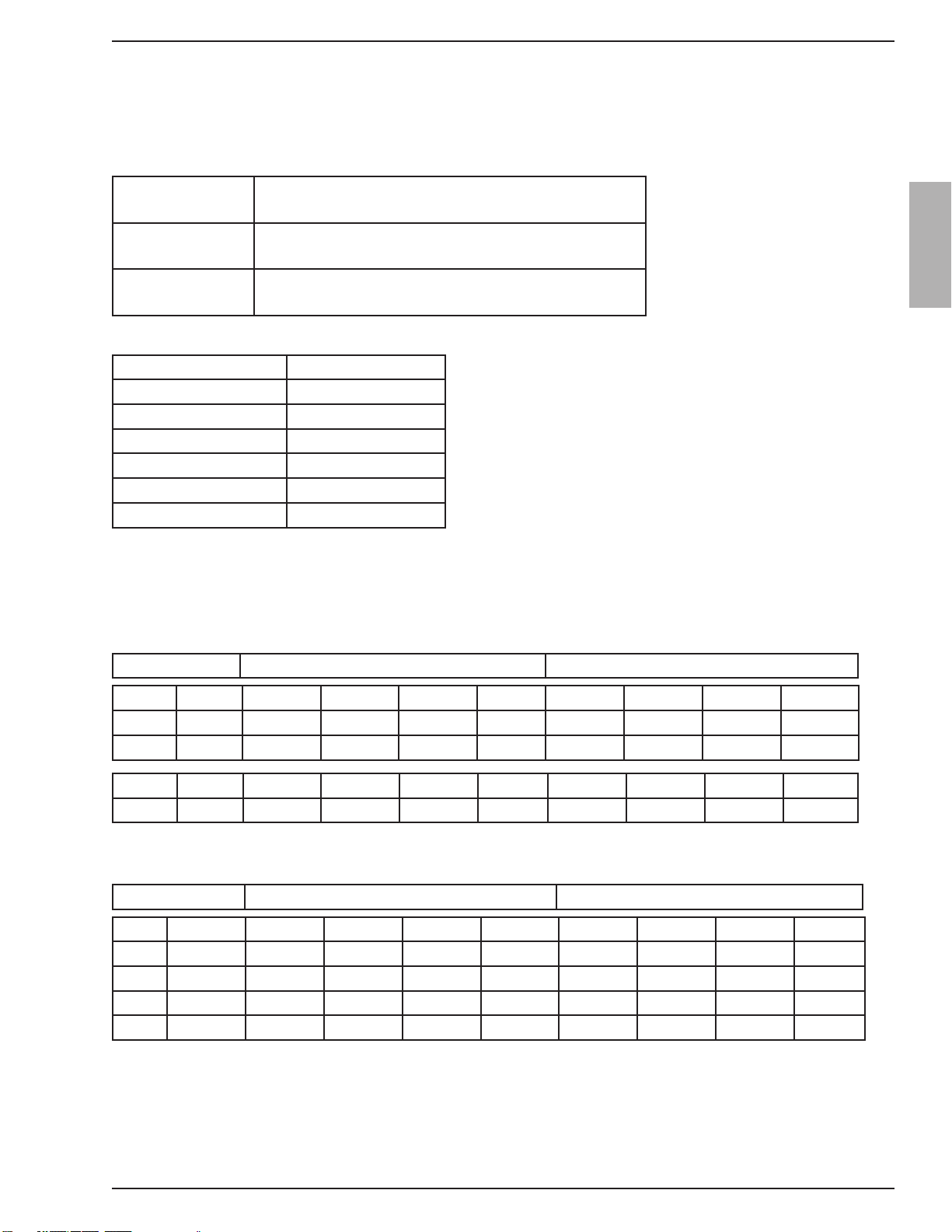

SYSTEM SPECIFICATIONS

PERFORMANCE:

PRODUCT WATER PRODUCED PER HOUR AND PER DAY OF OPERATION:

( +-15% at 850 psig / 56 BAR, 77°F / 25°C & 35,000 PPM TDS Feed Water Salinity )

Model Number per 1 hour of operation: per 24 hours of operation:

U.S. Gallons / Liters U.S. Gallons / Liters

SRC Aqua Matic 450-1 19 71 450 1703

SRC Aqua Matic 700-1 29 110 700 2650

SRC Aqua Matic 900-1 38 142 900 3407

SRC Aqua Matic 900-2 38 142 900 3407

SRC Aqua Matic 1400-2 58 221 1400 5300

SRC Aqua Matic 1800-2 75 284 1800 6814

SALT REJECTION (CHLORIDE ION): 99.4%

PRODUCT WATER TEMPERATURE: Ambient to feed water temperature

SPECIFICATIONS:

SALINITY MONITORING: Automatic computer controlled electronic monitoring.

The salinity monitoring components of the system give a continuous readout in micro ohms per cubic centimeter, are

temperature compensated and of a fail-safe design.

SALINITY RANGE OF FEED WATER:

Seawater up to 50,000 PPM TDS (NaCl) (typical seawater salinity is 35,000 PPM)

TEMPERATURE RANGE: Max. 122°F / 50°C, Min. 33°F / .5°C

SYSTEM FEED WATER:

Alternating Current 50 Hz Alternating Current 60 Hz

Feed Water Flow Per Hour: 225 U.S. Gallons / 852 Liters 270 U.S. Gallons / 1,022 Liters

REVERSE OSMOSIS MEMBRANE:

TYPE: Specifically selected High Rejection / High Yield aromatic tri-polyamide, thin film composite, spiral wound,

single pass reverse osmosis membrane element.

CHLORINE TOLERANCE: 0.1 PPM.

pH RANGE: 3-11 (typical seawater pH is 8)

SYSTEM PRESSURE:

FEED WATER: Minimum 6 psi / .42 Kg/cm2. / 41.4 kPa Maximum 40 psi / 2.8 Kg/cm2 / 275.8 kPa

OPERATION: Seawater @ 35,000 PPM & 77º F / 25º C: Nominal 800 psi / / 56.25 Kg/cm2 / 5516 kPa

Aqua Matic Modular 450-1800

Page 2-3

Description

EXTERNAL INSTALLATION WATER CONNECTIONS:

Pipe sizes to be supplied by the installer for connection of the Sea Recovery supplied components

Aqua Matic

Feed Inlet: 3/4 in. (19 mm) MNPT Male National Pipe Thread U.S.

Standard

Brine Discharge 3/4 in. (19 mm) MNPT Male National Pipe Thread U.S.

Standard

Product 1/2 in. (12.7 mm) FNPT Female National Pipe Thread U.S.

Standard

WEIGHT:

MODEL Modular Style

Aqua Matic 450-1 149 lbs / 68 kg

Aqua Matic 700-1 152 lbs / 69 kg

Aqua Matic 900-1 154 lbs / 70 kg

Aqua Matic 900-2 161 lbs / 73 kg

Aqua Matic 1400-2 167 lbs / 76 kg

Aqua Matic 1800-2 172 lbs / 78 kg

ELECTRICAL MOTOR SPECIFICATIONS:

(H.P. = Horse Power; RPM = Revolutions Per Minute; FLA = Full Load Amperes; LRA = Locked Rotor Amperes @ Start Up)

ALTERNATING CURRENT SYSTEMS:

Single Phase Alternating Current:

High Pressure Pump Motor Booster Pump Motor

VAC Hz H.P RPM FLA LRA H.P RPM FLA LRA

110 50 3 2850 23 89 .5 2850 7.4 20

220 50 3 2850 11.5 44 .5 2850 3.7 10

115 60 3 3450 25.4 86 .5 3450 9.4 20

230 60 3 3450 12.7 43 .5 3450 4.7 10

Three Phase Alternating Current:

High Pressure Pump Motor Booster Pump Motor

VAC Hz H.P RPM FLA LRA H.P RPM FLA LRA

220 50 2.5 2850 7.9 24.9 .5 2850 2.5 8.2

380 50 2.5 2850 4.6 14.4 .5 2850 1.5 4.7

230 60 3 3450 7.6 23.8 .5 3450 2.4 7.9

460 60 3 3450 3.8 11.9 .5 3450 1.2 3.9

Aqua Matic Modular 450-1800

Page 2-4

Description

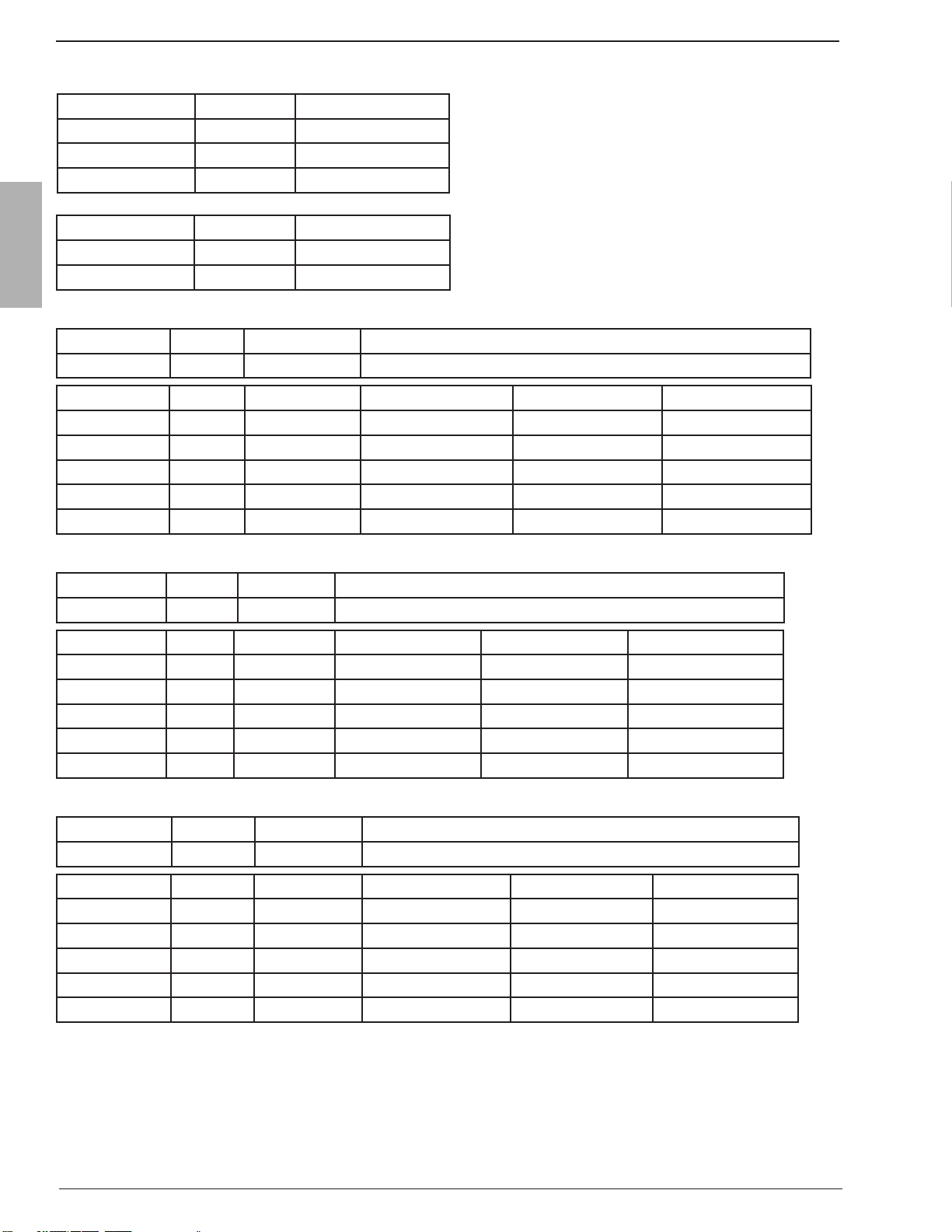

RECOMMENDED CIRCUIT BREAKER SUPPLYING POWER TO SYSTEM AMPERAGE RATING:

Operating Recommended

AC Voltage Phase Circuit Breaker

110 - 115 VAC Single 50 Ampere

220 - 230 VAC Single 25 Ampere

220 VAC Three 15 Ampere

380 VAC Three 10 Ampere

460 VAC Three 10 Ampere

RECOMMENDED POWER WIRE SIZE TO AQUA MATIC SYSTEM:

Operating Phase Maximum Recommended Minimum Wire Size for Length of run

Voltage Load

10 Ft / 3 meter 25 Ft / 8 meter 50 Ft / 15 meter

110-115 VAC Single 34.8 Ampere 10 AWG / 6 mm2 8 AWG / 10 mm2 8 AWG / 10 mm2

220-230 VAC Single 17.4 Ampere 12 AWG / 4 mm2 12 AWG / 4 mm2 12 AWG / 4 mm2

220-230 VAC Three 10.4 Ampere 14 AWG / 2.5 mm2 14 AWG / 2.5 mm2 14 AWG / 2.5 mm2

380 VAC Three 6.1 Ampere 14 AWG / 2.5 mm2 14 AWG / 2.5 mm2 14 AWG / 2.5 mm2

460 VAC Three 5 Ampere 14 AWG / 2.5 mm2 14 AWG / 2.5 mm2 14 AWG / 2.5 mm2

RECOMMENDED POWER WIRE SIZE TO AQUA MATIC BOOSTER PUMP:

Operating Phase Maximum Recommended Minimum Wire Size for Length of run

Voltage Load

10 Ft / 3 meter 25 Ft / 8 meter 50 Ft / 15 meter

110-115 VAC Single 9.4 Ampere 14 AWG / 2.5 mm2 14 AWG / 2.5 mm2 14 AWG / 2.5 mm2

220-230 VAC Single 4.7 Ampere 14 AWG / 2.5 mm2 14 AWG / 2.5 mm2 14 AWG / 2.5 mm2

220-230 VAC Three 2.5 Ampere 16 AWG / 1.5 mm2 16 AWG / 1.5 mm2 16 AWG / 1.5 mm2

380 VAC Three 1.5 Ampere 16 AWG / 1.5 mm2 16 AWG / 1.5 mm2 16 AWG / 1.5 mm2

460 VAC Three 1.2 Ampere 16 AWG / 1.5 mm2 16 AWG / 1.5 mm2 16 AWG / 1.5 mm2

RECOMMENDED POWER WIRE SIZE TO AQUA MATIC HIGH PRESSURE PUMP:

Operating Phase Maximum Recommended Minimum Wire Size for Length of run

Voltage Load

10 Ft / 3 meter 25 Ft / 8 meter 50 Ft / 15 meter

110-115 VAC Single 25.5 Ampere 12 AWG / 4 mm2 10 AWG / 6 mm2 10 AWG / 6 mm2

220-230 VAC Single 12.7 Ampere 14 AWG / 2.5 mm2 12 AWG / 4 mm2 12 AWG / 4 mm2

220-230 VAC Three 7.9 Ampere 14 AWG / 2.5 mm2 14 AWG / 2.5 mm2 14 AWG / 2.5 mm2

380 VAC Three 4.6 Ampere 14 AWG / 2.5 mm2 14 AWG / 2.5 mm2 14 AWG / 2.5 mm2

460 VAC Three 3.8 Ampere 14 AWG / 2.5 mm2 14 AWG / 2.5 mm2 14 AWG / 2.5 mm2

Other manuals for SRC Aqua Matic 450-1

1

This manual suits for next models

5

Table of contents

Other Sea Recovery Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Eltroplan

Eltroplan Revcon RHF Series operating instructions

Tetra

Tetra Whisper 10-30 manual

Duo-Therm

Duo-Therm GENESIS 3308120.XXX Installation and operating instructions

VGE

VGE XCLEAR user manual

Enpress

Enpress CTA0840BBBKP5-04C00 Installation & operation manual

BestWater

BestWater Jungbrunnen 66-00 Ultimate user manual