Biotage Flash 400 User manual

Biotage®Flash 400

User Manual

Biotage®Flash 400 User Manual | © Biotage 2018

Contents

Biotage®Flash

User Manual

CONTENTS

Introduction

1 Speed

1 Safety

1 Performance

Description and Specifications

2 Biotage®Flash 400 Frame

2 Radial Compression Module

4 Biotage®Flash 400 Prepacked Cartridge

4 Radial Compression Fluid Reservoir

5 Control Panel

6 Side Connection Panel

6 Hoist

7 Start-Up Kit

8 System Dimensions and Valves,

Gauges, and Regulators

10 Specifications

Safety

11 Intended Use

11 Working Volume

11 Education, Training, and Competence

11 Warranty and Liability

11 Service

11 Labels

12 Safety Requirements

Installation

14 Site Requirements

14 Ground the System

15 Gas Supply Connections

16 Solvent Inlets (A and B)

16 Fraction Outlets (1 and 2)

16 Drain Valve and Exhaust Ports

16 Tube Connections

Operation

17 Install a Cartridge

22 Fill the Radial Compression Fluid Reservoir

22 Pressurize the Radial Compression

Module and Fluid Reservoir

23 Test the Cartridge Sealing

24 Test a Biotage®Flash 400 Cartridge

25 Equilibrate the Cartridge

25 Load the Sample

25 Collect Fractions

26 Purge and Flush the Cartridge

27 Depressurize and Drain the System

28 Remove and Handle the Used Cartridge

29 Clean the System

30 Lock the Hoist in the Storage Position

Troubleshooting

31 Biotage®Flash 400 Radial Compression Module

31 Solvent Compatibly of O-Rings

32 Radial Compression Fluid Reservoir

32 Operation

General Information

33 Patents

33 Price List and Ordering Information

33 Download User Documentation

33 Manufacturer

33 Contact Us

Appendix

34 Warranty and Liability

34 Essential Tools List

34 Biotage®Flash 400 Spare Parts

35 Biotage®Flash 400 Process

and Instrumentation Drawing

Notes

Introduction

Introduction

Biotage®Flash 400 is a flash purification system based

on prepacked cartridge technology that provides users of

traditional self-packed glass columns with three critical

operational benefits: speed, safety, and performance.

Speed

Unlike glass columns, which operate at low pressure and

have very poor flow distribution, Biotage flash cartridges are

optimized for high speed separations. Purifications that might

otherwise require a full working day can be run in one hour.

For a chemist running just a single reaction and separation

per day, the annual gain in productivity can be as high as 15

additional weeks each year; time that could be used to develop

new compounds or processes. With the rising cost of labor,

the efficiencies afforded by this alone can exceed the cost of

the flash system and a year’s supply of cartridges.

Safety

Laboratory and process safety is a growing concern, with

many companies carefully reviewing current procedures and

techniques to reduce the risk of chemical exposure, injury, and

consequently their liability. Biotage Flash systems eliminate the

concerns of using glassware under pressure by utilizing durable

polyethylene cartridges that are prepacked and completely

self-contained, eliminating user exposure to silica dust, HP-API,

or any contaminants left after a separation.

Figure 1.Radial compression module overview.

The Flash 400 system is designed and manufactured to meet

the requirements of the EC machinery directive and the ATEX

product directive, and contains ASME/CE rated pressure

vessels. The design, fabrication, and pressure testing are

reviewed and confirmed by an independent inspector.

The hoist mechanism, including associated pneumatics, valves,

switches, and lifting hardware, should be regularly inspected in

accordance with local regulations and directives. Contact your

Biotage representative for additional information.

Performance

In addition to speed and safety, Biotage flash cartridges

improve both the performance and the reproducibility of

separations. The use of Biotage patented radial compression

technology (see Figure 1) reduces interstitial spaces (void

volume) within the packed bed. The optimized bed density

means that compounds are collected in narrow bands, which

results in higher separation efficiency. Unlike glass columns,

each Biotage flash cartridge will perform in the same way, time

after time.

Head assembly

Prepacked

cartridge

Compression

barrel

Flow distribution

plate

Frit

Media

Radial

pressure

applied

Cartridge

wall

Biotage®Flash 400 User Manual | © Biotage 2018

Description and Specifications

Description and Specifications

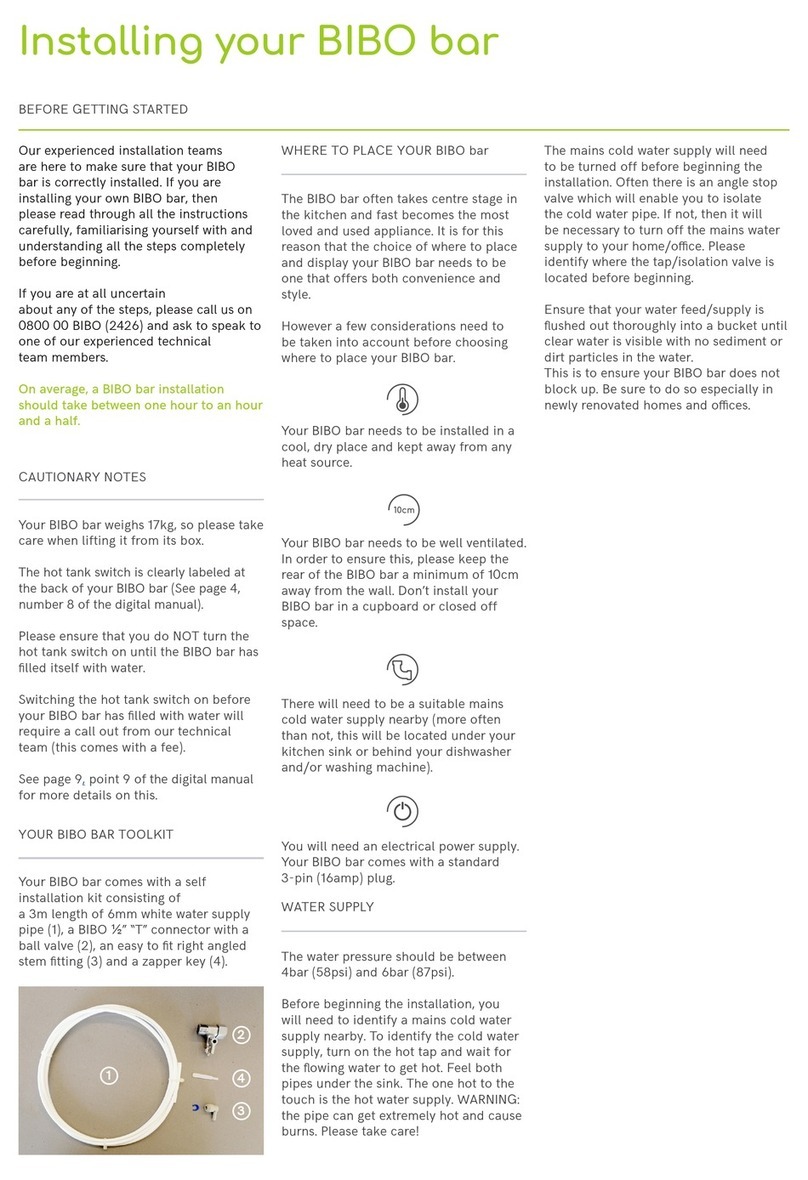

Figure 2

A

B

C

E

H

I

G

D

.Flash 400 system. A = hoist, B = hoist control box, C = cartridge

tool, D = prepacked cartridge, E = radial compression module, F = radial

compression fluid reservoir, G = control panel, H = solvent inlets and

fraction outlets, and I = air and nitrogen inlets.

Biotage®Flash Frame

The Flash 400 radial compression module is mounted on a

portable frame. The frame includes a side connection panel with

bulkhead compression fittings for connecting solvent reservoirs

(inlet A and B), collection vessels (outlet 1 and 2), a nitrogen

supply (radial compression fluid reservoir and module), and a

compressed air supply (solvent pump). The air supply for the

hoist is connected at the rear of the hoist. For more information

see “Installation” on page 14.

The system is fully plumbed and ready for installation.

Figure 14 on page 8 shows the overall dimensions.

Radial Compression Module

The Flash 400 radial compression module (see E in Figure 2)

is an ASME rated and CE marked pressure vessel. The barrel is

fabricated from 316L stainless steel while the top head, bottom

head, and clamps are machined from 316 stainless steel. The

interior and exterior surfaces have been mechanically polished.

The radial compression module is rated at 170 psig (11.7 bar)

maximum pressure. The system includes several pressure relief

valves to help ensure that the operating pressure does not

exceed this specification.

Note: The radial compression module’s polished surfaces must

be protected to minimize mechanical damage.

Additional Radial Compression Barrel

The system supports two interchangeable barrels for use with

either 400 mm x 300 mm (Flash 400M) or 400 mm x 600 mm

(Flash 400L) cartridges. One of the radial compression barrel

sizes is included in the system and the barrel of the other size

can be ordered.

O-Rings

The head assembly includes a two piece stainless steel

cartridge seal adapter with two Chemraz O-rings (A & B); see

5 and 6 in Figure 3. The cartridge seal adapter seals against

the seal adapter plate when the face O-ring (A) is compressed.

The radial O-ring (B) seals the adapter to the head.

The top and bottom head assemblies seal to a tapered surface

on the cartridge and to the radial compression barrel with either

Viton (as shipped) or EPDM (spares) O-rings (C & D); see 3 and 2

in Figure 3. These O-rings are non-product contact surfaces.

The Viton and EPDM O-rings are very compressible and will

seal reliably up to 100 psig (6.9 bar). EPDM is resistant to polar

solvents but will swell in many common aliphatic and aromatic

solvents. Viton is resistant to non-polar solvents, but will

swell in the typical polar modifiers. For solvent compatibility

information, see Table 1.

Table 1 only covers a limited number of commonly used

solvents. To check the compatibility of a particular solvent or

solvent mixture, soak an O-ring in the solvent/mixture for one

hour and then inspect it for swelling. If the O-ring swells in use,

allow it to dry out in a fume hood until it returns to its normal

size (typically overnight).

Inspect your O-rings before each run and replace any O-ring

that shows signs of wear or damage or that leaks at your typical

operating pressures. See Table 2 for part numbers and Figure 3

for location.

F

Description and Specifications

O-Ring Material Composition

Type Solvent

Polarity

Solvent Viton EPDM

(Ethylene

Propylene)

Chemraz

Normal

Phase

0.1 Hexane Good Poor Good

2.4 Toluene Fair Poor Good

2.5 MTBE Poor Poor Good

3.1 DCM Fair Fair Good

3.9 IPA Good Good Good

4.0 THF Poor Poor Good

4.4 Ethyl Acetate Poor Good Good

5.1 Methanol Poor Good Good

Reversed

Phase

5.8 Acetonitrile Poor Good Good

6.4 DMF Poor Fair Good

…Acids Poor Good Good

…Bases Poor Good Good

10.0 Water Good Good Good

Table 1.General solvent compatibility chart.

Figure 3

7

89

1

6

5

4 2

3

89

10

11

.Cut-away view of the top head assembly (left) and expanded view of the cartridge seal adapter (right).

1 = top head clamp, 2 = O-ring “D” size 387, Viton (as shipped) or EPDM (spares), 3 = O-ring “C” size 460, Viton (as shipped) or EPDM (spares),

4 = cartridge, 5 = O-ring “A” size 222, Chemraz, 6 = O-ring “B” size 223, Chemraz, 7 = top head assembly, 8 = cartridge seal adapter (adjustable),

9 = seal adapter housing (fixed), 10 = flow distribution plate (inside the cartridge), and 11 = frit.

Flash 400

Compression Module

Part

Number

No.

Above

Material Product

Contact

Size

Ref

Imp: CD, ID, OD

(Inches)

Std. Qty.

Installed

Spares In

Start-Up Kit

Barrel O-Rings (D) 03020 2 Viton No #387 2 2

Barrel O-Rings (D) 03019 2EPDM No #387 0 4

Barrel O-Rings (D) 03020-K 2Kalrez No #387 0 0

Top/Bottom Head (C) 02939 3 Viton No #460 1/4, 15½, 16 2 0

Top/Bottom Head (C) 03011 3EPDM No #460 1/4, 15½, 16 0 0

Top/Bottom Head (C) 08648 3 Chemraz No #460 1/4, 15½, 16 0 2

Top/Bottom Head (C) 02939-K 3Kalrez No #460 1/4, 15½, 16 0 0

Cart Seal Adapter (A) 06875 5 Chemraz Yes #222 1/8, 1½, 1¾ 2 2

Cart Seal Adapter (B) 03010 6 Chemraz No #223 2 2

Table 2.Radial compression module O-rings.

Biotage®Flash 400 User Manual | © Biotage 2018

Description and Specifications

Top Head Assembly Valves

The top head assembly has the following valves.

Valve Description

MV-02 Three-way injection valve. Selects the solvent or

sample inlet (see Figure 4). During cartridge removal,

compressed gas may be blown through this valve and

through the cartridge to remove solvent.

MV-03 Cartridge compression vent valve. Open the valve to

purge air from the radial compression chamber when

compressing the cartridge (see Figure 5).

MV-04 Vacuum break valve, top. Open the valve to break any

vacuum that develops when the cartridge is in use (see

Figure 5). Used when preparing to remove a cartridge

or testing if the cartridge seal adapter’s O-ring has

sealed properly.

Figure 4.The three-way injection valve (MV-02) with the handle pointing

toward the solvent inlet tube.

Figure 5.The cartridge compression vent valve (MV-03) and the top

vacuum break valve (MV-04) closed (left image) and opened (right image).

Biotage®Flash Prepacked Cartridge

The system supports two interchangeable barrels for use with

either 400 mm x 300 mm (Flash 400M) or 400 mm x 600 mm

(Flash 400L) cartridges, with the capacity to purify up to 8 kg*

of crude reaction mixture. One of the radial compression barrel

sizes is included in the system and the barrel of the other size

can be ordered.

A variety of pre-packed cartridges are available depending on

the purification goal and cartridges can be custom packed

with

the preferred chromatography media for your process. The media

in each cartridge is self-contained, improving

handling and

eliminating exposure to contamination and impurities or

HP-APIs (high potency active pharmaceutical ingredients).

The cartridges are shipped in a sealed polyethylene shipping

bag to minimize water vapor adsorption. Each cartridge includes

certificates of compliance and conformance with detailed

information for your records in GLP or cGMP environments.

Note: Biotage cartridges are optimized for single use.

All warranties are void if the cartridges are used multiple times.

Specification Flash 400M Flash 400L

Size D x H 400 x 300 mm 400 x 600 mm

Mass of Biotage®KP-Sil Silica 20 kg 40 kg

Column Volume 28 liters 56 liters

Sample Size 4 kg* 8 kg*

Flow Rate 1-6 L/min 1-6 L/min

Table 3.Flash cartridge specifications.

* The amount of sample that can be purified will depend on the stationary

phase and ease of separation. Our new advanced spherical silicas with

greater surface area routinely support purification using approximately

double the traditional silica sample loadings.

Radial Compression Fluid Reservoir

Biotage provides an electropolished 304 stainless-steel

fluid reservoir with the capacity of 12 liters (see F in Figure 2).

The oval lid has a clamp that screws shut and a solvent proof,

PTFE-encapsulated Viton O-ring to seal the lid in place.

The fluid reservoir is fitted with a pressure gauge (PG-03) and a

safety relief valve (PSV-03) that activates at pressures in excess

of 125 psi (8.6 bar).

Note: Biotage recommends using the same solvent for both the

eluent and the radial compression fluid.

Figure 6.The pressure gauge on the radial compression fluid reservoir.

Description and Specifications

Control Panel

The system includes a control panel with the following pressure

gauges and valves required to operate the system.

Label Description

PG-01 Pump pressure gauge. Monitors the solvent pump (P-01)

outlet pressure.

PG-02 Cartridge compression pressure gauge. Monitors the

pressure inside the radial compression module.

MV-01 Solvent select valve. Selects which of the two solvent

inlets (Aor B) that will be used.

MV-06 Fraction select valve. Selects which of the two outlets

(1or 2) the elution stream will exit through.

MV-07 Cartridge compression valve.

Opens the line between the radial compression

chamber and the radial compression fluid reservoir,

which compresses the cartridge if the fluid reservoir is

pressurized. PG-02 and PG-03 readings will equalize.

Closes the valve.

MV-08 Solvent pump valve. Turns the solvent pump on or off

(Oor I) by opening or closing the line between the air

supply and the pump.

MV-09 Reservoir pressure valve.

Pressurizes the radial compression fluid reservoir

by connecting it to the nitrogen supply.

Used when checking that the pressure in the radial

compression fluid reservoir can be maintained.

Vents the radial compression fluid reservoir by

opening it to the atmosphere. The exhaust port is

located on the side connection panel.

MV-11 Pump flow rate control. Regulates the compressed air

pressure to the solvent pump (P-01). Turn the knob

counterclockwise to increase the solvent flow rate and

clockwise to decrease it.

Table 4.The control panel.

Safety Positions

Before introducing compressed air or nitrogen into the system,

ensure that the following valves on the control panel are in their

safety position as listed in Table 5 below.

Valve Safety Position

MV-11 Clockwise until stopped

MV-08 O(closed)

MV-09 (vent)

MV-07 (open/compress)

Table 5.Valve safety positions.

Figure 7

MV-05

MV-10

1 2

2

MV-06

MV-09

MV-08

PG-01

MV-07

MV-01

A1

PG-02

BIOTAGE®FLASH 400

A B

B

MV-11

.The control panel.

Pump Valve Handle with Safety Latch

The pump valve handle has an automatic safety latch feature

to prevent accidental movement of the handle from one setting

to another.

To operate this valve, the safety latch must be pressed in and

held while the handle is moved. Upon release, the handle

becomes latched in its current position.

To secure the handle in a specific position and prevent anyone

from changing the setting, the latch mechanism includes an

opening for installing a padlock or other locking device (see

Figure 8).

Figure 8.Pump valve handle with safety latch.

Biotage®Flash 400 User Manual | © Biotage 2018

Description and Specifications

Hoist

The hoist (see A in Figure 2 on page 2) is used to move

and seal the top head assembly, insert and remove cartridges,

and when necessary, move the radial compression barrel.

The maximum working load is 125 kg (275 lbs).

The hoist is pneumatically operated and has a separate,

dedicated compressed air input connection with a maximum inlet

pressure of 100 psig (6.9 bar). The air pressure to the hoist motor

is set internally at the factory to approximately 30 psig (2.1 bar).

For safety reasons, this internal setting must not be changed.

When not in use, the hoist must be locked in the “storage”

position. See the instructions on page 30.

Figure 10.Hoist control box.

Cartridge Tool

The cartridge tool (see Figure 11) is used to insert and remove

cartridges with the hoist.

Grasp the eyebolt at the top of the cartridge tool with both

hands and lift the tool onto the top of the cartridge. Center the

cartridge tool on the top of the cartridge and hand turn the

knurled knob (below the eyebolt) clockwise until it will not turn

any more. This opens the four plates in the tool and forces them

to lock securely into the cartridge lifting groove.

Figure 11

A

B

C

D

.The cartridge tool. A = eyebolt, B= locking nut, C = knurled

knob, and D = moveable plate (4).

If the knurled knob tightens without the plates fully extending,

spread the plates by hand and push the spreader shaft down

until it is in the grooves of the plates. Ensure that the cartridge

tool outer ridge is fully engaged into the mating cartridge lifting

groove. Re-tighten the knurled knob.

Side Connection Panel

The side connection panel has the following ports and valves.

Label Description

Solvent inlets Aand B.

Fraction outlets 1and 2.

MV-10 Radial compression drain valve.

Closes the valve.

Drains the fluid from the radial compression

chamber. Used before removing the cartridge.

MV-05 Vacuum break valve, bottom.

Closes the valve.

Breaks any vacuum that develops when the

cartridge is in use. Used when preparing to remove

a cartridge or when testing if the cartridge seal

adapter’s O-ring has sealed properly.

Compressed air inlet for the solvent pump.

Nitrogen inlet. Used to pressurize the radial compression

fluid reservoir and the radial compression module.

Exhaust port for when venting the radial compression fluid

reservoir using the MV-09 valve.

Safety relief port for the radial compression module. The

module is rated at 170 psig (11.7 bar) maximum pressure.

Table 6.The side connection panel.

Figure 9

MV-05

MV-10

1 2

2

MV-06

MV-09

MV-08

PG-01

MV-07

MV-01

A1

PG-02

BIOTAGE®FLASH 400

A B

B

MV-11

.The side connection panel.

Description and Specifications

Ensure that the cartridge tool cannot be moved within the

cartridge top. If the tool can be moved, loosen the knurled knob

and repeat the tightening process to re-engage.

Move the hoist arm so that the safety hook is centered over the

cartridge tool and then fasten the hook to the tool’s eyebolt.

Head Sling Assembly

The head sling assembly (see Figure 12) is used to move and

seal the top head assembly with the hoist. It can also be used to

move the radial compression barrel to get access to the bottom

head assembly or to change the barrel (see “Additional Radial

Compression Barrel” on page 2).

To move the top head assembly, attach the pivot arms on the

head sling assembly to the eyebolts on the top head assembly

using the quick-release pins. Turn the pivot arms so that the end

attached to the sling cable faces inward, toward the center of

the head assembly, as shown in Figure 25 on page 18.

To seal the head assembly, attach the pivot arms on the head

sling assembly to the fulcrum arms using the quick-release pins.

Turn the pivot arms so that the end attached to the sling cable

faces outward as shown in Figure 12.

To lift the radial compression barrel, attach the pivot arms to

the fulcrum arms using the quick-release pins. Turn the pivot

arms so that the end attached to the sling cable faces inward,

toward the center of the barrel.

Attach the top ring of the head sling assembly to the hoist safety

hook. Ensure that the top ring is attached to the hook with the

narrow end up and the closure nut fully threaded and tightened.

Figure 12

A

B

C

D

F

E

.Sealing the head assembly. A = hoist safety hook, B = top ring,

C = sling cable, D =pivot arm (3), E = fulcrum arm (3), and F = quick-

release pin (3).

Start-Up Kit

Biotage provides a start-up kit consisting of the following items:

Description QTY UOM P/N

Cartridge tool 1Ea. 03468

Head sling assembly 1Ea. 08327

Wedge tool (see Figure 13) 1Ea. 05557

Barrel O-rings, size 387, Viton 2Ea. 03020

Barrel O-rings, size 387, ethylene

porpylene

4Ea. 03019

Top and bottom head assembly O-rings,

size 460, chemraz 505

2Ea. 08648

Cartridge seal adapter O-rings, size 222

chemraz

2Ea. 06875

Cartridge seal adapter O-rings, size 223

chemraz

2Ea. 03010

Tubing assembly 1.2" FLEX 4Ea. 07087

Tubing, 1/4" OD yellow LDPE 20 Ft. 01354

Tubing, 1/4" OD blue LDPE 20 Ft. 01487

Connector, male 1/4" tube x 1/4" MNPT 1Ea. 02184

Nut, hex 3/8"-16 UNC 18-8 SST 2Ea. 03286

Washer, flat 3/8" 18-8 SST 2Ea. 03287

Muffler, 3/8" 40µ POREX 1Ea. 01801

Quick guide 1Ea. 416118

User manual (this publication) 1Ea. 04149

For more information on the O-rings, see “O-Rings” on page 2.

Figure 13.The wedge tool.

Biotage®Flash 400 User Manual | © Biotage 2018

Description and Specifications

System Dimensions and Valves,

Gauges, and Regulators

All valves used on the Flash 400 system are fabricated from 316

stainless steel with a PTFE seat and rated by the manufacturer

to at least 200% of the maximum system working pressure.

The pressure gauges operate in contact with the radial

compression fluid. They are rated to at least 150% of the

Figure 14.Component location and system dimensions.

maximum working pressure and are graduated as appropriate

for convenient operation. The bodies are stainless steel with

glass lenses.

For details about each component, see Figure 14 below,

Table 7 on page 9, and the Flash 400 flow diagram located

on page 35. For information on the ports on the side

connection panel, see Table 6 on page 6.

Description and Specifications

Item Description

MV-01 Solvent select valve. Selects which of the two solvent

inlets (Aor B) that will be used.

MV-02 Three-way injection valve. Selects the solvent or sample

inlet (see Figure 4 on page 4). During cartridge

removal, compressed gas may be blown through this

valve and through the cartridge to remove solvent.

MV-03 Cartridge compression vent valve. Open the valve to

purge air from the radial compression chamber when

compressing the cartridge (see Figure 5 on page 4).

MV-04 Vacuum break valve, top. Open the valve to break any

vacuum that develops when the cartridge is in use

(see Figure 5 on page 4). Used when preparing

to remove a cartridge or testing if the cartridge seal

adapter’s O-ring has sealed properly.

MV-05 Vacuum break valve, bottom.

Closes the valve.

Breaks any vacuum that develops when the

cartridge is in use. Used when preparing to

remove a cartridge or when testing if the cartridge

seal adapter’s O-ring has sealed properly.

MV-06 Fraction select valve. Selects which of the two outlets

(1or 2) the elution stream will exit through.

MV-07 Cartridge compression valve.

Opens the line between the radial compression

chamber and the radial compression fluid

reservoir, which compresses the cartridge if the

fluid reservoir is pressurized. PG-02 and PG-03

readings will equalize.

Closes the valve.

MV-08 Solvent pump valve. Turns the solvent pump on or off

(Oor I) by opening or closing the line between the air

supply and the pump.

MV-09 Reservoir pressure valve.

Pressurizes the radial compression fluid reservoir

by connecting it to the nitrogen supply.

Used when checking that the pressure in the radial

compression fluid reservoir can be maintained.

Vents the radial compression fluid reservoir by

opening it to the atmosphere. The exhaust port is

located on the side connection panel.

MV-10 Radial compression drain valve.

Closes the valve.

Drains the fluid from the radial compression

chamber. Used before removing the cartridge.

MV-11 Pump flow rate control. Regulates the compressed

air pressure to the solvent pump. Turn the knob

counterclockwise to increase the solvent flow rate and

clockwise to decrease it.

Item Description

P-01 Pneumatic solvent pump. Moves solvent through

the system.

PG-01 Pump pressure gauge. Monitors the solvent pump

outlet pressure.

PG-02 Cartridge compression pressure gauge. Monitors the

pressure inside the radial compression module.

PG-03 Reservoir pressure gauge. Monitors the radial

compression fluid reservoir pressure.

PRR-01 Air pressure regulator (with filter and gauge). Regulates

the incoming compressed air pressure for the solvent

pump. Set to a maximum of 100 psig (6.9 bar).

PRR-02 Hoist air inlet. Compressed air supply inlet for the hoist,

max 100 psig (6.9 bar). Air pressure to the hoist motor

is set internally at the factory to approximately 30 psig

(2.1 bar). This internal setting must not be changed.

PSV-01 Safety relief valve, solvent pump. Relieves the radial

compression chamber if the pressure reaches 170 psig

(11.7 bar). ASME rated.

PSV-02 Safety relief valve, chamber. Relieves the radial

compression chamber if the pressure reaches 170 psig

(11.7 bar). ASME rated.

PSV-03 Safety relief valve, fluid reservoir. Monitors the radial

compression fluid reservoir pressure. When the

cartridge compression valve (MV-07) on the control

panel is set to on/compress, the reading on this gauge

(PG-03) will be equal to the reading on the cartridge

compression pressure gauge (PG-02).

Table 7.Flash 400 valves, gauges, and regulators.

Biotage®Flash 400 User Manual | © Biotage 2018

Description and Specifications

Specifications

Item Rating

Hoist load rating Working load rating is 125 kg (275 lbs)

Nitrogen inlet 100 psig (6.9 bar) maximum

Compressed air inlet

(solvent pump) 100 psig (6.9 bar) maximum

Compressed air inlet

(hoist) 100 psig (6.9 bar) maximum

Compressed gas supply

tubing

200 psig (13.8 bar) minimum working

rating

System weight Up to 650 kg (1433 lbs) typical

Installation floor load

requirement 732 kg/m2 (150 lbs/f t2) minimum

Head assembly weight 68 kg (149 lbs) each head

Head clamp weight 11.3 kg (25 lbs) each half

Radial compression

pressure 80 to 100 psig (5.5 to 6.9 bar)

Solvent pressure Set to at least 20 psig (1.4 bar) less than

radial compression pressure, 80 psig

(5.5 bar) maximum

Table 8.Specifications.

Chemical Resistance

The following chemicals can be used in the wetted parts of

the system:

»

Acetone

»

Dichloromethane (methylene chloride, DCM)

»

Toluene

»

Acetonitrile (MeCN)

»

Tetrahydrofuran (THF)

»

Triethylamine (TEA)

»

N,N-dimethylformamide (DMF)

»

Ethyl acetate (ethyl ethanoate, EtOAc)

»

N-methyl-2-pyrrolidone (NMP)

»

Dimethylsulfoxide (DMSO)

»

Ethanol (EtOH)

»

Methanol (MeOH)

»

2-propanol (isopropanol, IPA)

»

Formic acid (methanoic acid, HCOOH)

»

Acetic acid (Ethanoic acid, HOAc, AcOH)

»

Deionized water (H2O)

»

Trifluoroacetic acid (TFA), max 5 % (by volume)

»

n-Heptane

»

Piperidine (pip)

»

Pyridine (pyr)

»

Ammonia (NH3) conc.23-27 % (by weight)

»

tert-Butyl methyl ether (TBME)

»

Diethyl ether

»

10 mM phosphate buffered saline, pH= 7.4

»

50 mM phosphate-citrate buffer, pH= 5.0

»

Boric acid/NaOH/KCl buffer, pH=11

Note: Always check the O-rings’ compatibility with the solvent

or solvent mixture that you want to use. For more information,

see “O-Rings” on page 2.

Safety

Intended Use

Biotage Flash 400 system is intended solely for purification.

The system must be operated in a controlled environment with

an ambient temperature between 4°C and 32°C (39°F and 90°F)

by trained professionals. The system must not be installed or

used near a potential ignition source. It is the responsibility of

the customer to classify (zone) their particular environment in

order to verify that it meets the requirements of the directive

1999/92/EC. All operations must be performed:

»

According to the user documentation

delivered with the system.

»

According to instructions available at www.biotage.com.

»

According to instructions given by the

technical support staff from Biotage.

»

Within limits set by the system’s technical specification and

in line with user standard operating procedures (SOPs).

Failure to follow those instructions and operate within the limits

set by the technical specification may result in personal injury

and/or equipment damage.

Working Volume

The data plate on the radial compression module states a

working volume as required by the Pressure Equipment Directive

(PED) 2014/68/EU. In line with regulations, this is the available

volume after the cartridge and allowable permanent parts have

been excluded from the total theoretical volume. The volume is

therefore not the volume of a cartridge, or a purification metric

such as “column volume”. For further information on scale-up,

please contact your local Biotage representative.

Education, Training, and Competence

It is your responsibility to provide all applicable health and

safety regulations to your personnel. You must also ensure that

all personnel involved in the operation and maintenance of the

system fulfill the following criteria:

»

Have the necessary education, training, and competence

required for the intended use of the system.

»

Observe general and specific safety regulations for the

use of the system and its accessories at all times in order

to reduce the risk of personal injury, fire, and explosion.

Warranty and Liability

See the “Biotage Terms & Conditions of Sale” document at

www.biotage.com.

Service

All service must be performed by an authorized Biotage service

engineer. Before handing over the system for service, it should

be emptied of all liquid and cleaned from harmful residues.

It is the responsibility of the customer to inform Biotage®

1-Point Support™representatives if the system has been used

with hazardous biological, radioactive, or toxic samples and/

or solvents, prior to any service being performed. If returning

equipment to Biotage, this should be done in accordance with

the material return procedures supplied separately by Biotage.

Only genuine Biotage spare parts must be used in the system.

Labels

Labels used on the system:

In accordance with all the essential requirements of

all applicable European product directives; see the

Declaration of Conformity.

In accordance with the ATEX Product Directive,

2014/34/EU for Group II, Category 2G equipment.

The equipment is intended for use in areas in which

explosive atmospheres caused by gases, vapors, or

mists or air/dust mixtures are likely to occur.

Manufacturer.

Consult accompanying user documentation.

Note: The system is ASME rated and in accordance with both

U.S. and Canadian safety standards; see the Declaration of

Conformity.

Safety

Biotage®Flash 400 User Manual | © Biotage 2018

Safety

Safety Requirements

You must observe all safety requirements when installing and

operating the system. Failure to install or use the system in

a manner specified by Biotage may result in personal injury

and/or equipment damage.

If the system has been damaged or does not function properly,

turn off the gas supplies, depressurize the system (all pressure

gauges should read zero (0) bar/psig), open the vacuum break

valves (see MV-04 and MV-05 in Figure 14 on page 8), and

contact Biotage 1-Point Support (www.biotage.com).

Installation

»

The system must be unpacked and installed by an

authorized Biotage service engineer. Prepare the

installation site as described on page 14.

»

Follow regional safety practices when handling

and moving shipping boxes and containers,

and when moving the system.

»

The total weight of the package including the system is up to

1043 kg (2300 lbs) depending on the system configuration.

Use suitable lifting equipment when moving the package.

»

The system can weigh up to 650 kg (1433 lbs). It must

be installed on a level floor that can support the

system weight concentrated on the four wheels.

»

The system must be placed in a well-ventilated walk-in

fume hood or an equivalent enclosure that is capable

of exhausting 0.6 m3/min (21.2 ft3/min). Follow

local and national safety regulations for installing a

system inside a fume hood and the safety regulations

supplied by the fume hood manufacturer.

»

Never install or use the system near

a potential ignition source.

»

The system, when operated with non-polar solvents

such as hexane, methylene chloride, etc., can build up a

high static electricity charge, which in certain conditions

can be dangerous. To eliminate any risk of a static

discharge, the system and ancillary containers must

be grounded before use as described on page 14.

Failure to follow these grounding instructions may result

in equipment damage, personal injury, or death.

»

A trained person must verify that the system and

ancillary containers are grounded before each run.

Nominal resistance must be below 5 Ohm between

ground and each metal point in the system.

»

Only nitrogen must be used to move radial

compression fluid through its flow path due to the

risk of exothermal reaction and/or explosion.

»

Ensure that the inert gas tubing connected to the

system cannot come in contact with chemicals.

Corrosives and solvents can dissolve the tubing.

»

The outlets of the three safety relief valves (located on

the radial compression module, the air pressure regulator

to the solvent pump, and the radial compression fluid

reservoir) must be directed away from the operator.

»

To avoid injury to yourself or damage to the system,

never apply gas pressures greater than 100 psig

(6.9 bar) to the system inlet gas ports.

»

Do not over-tighten the fittings or the

tubing may become damaged.

»

Never modify the system components in any way

and always use spare parts supplied by Biotage.

Failure to follow this warning may result in serious

personal injury or death. Please contact your Biotage

representative for questions regarding this.

Operation

»

Use the system only for its intended purpose, as described

in the user documentation delivered with the system and

user documentation available at www.biotage.com. If the

system is used in a manner not specified by Biotage, the

safety features of the system may be compromised.

»

The system must not be operated unattended.

»

Never operate the system if damaged.

»

Only nitrogen must be used to move radial

compression fluid through its flow path due to the

risk of exothermal reaction and/or explosion.

»

Inspect the head clamps before and after each use.

If the clamp, threaded studs, nuts, or washers show

any sign of wear or damage, replace it/them. Only use

clamps, studs, nuts, and washers supplied by Biotage.

»

Confirm that the head clamps are tight before compressing

the radial compression module. Hand-tighten the clamps,

to a torque of 34 Nm (25 ft-lb). Ensure that the space

between the clamp halves is distributed evenly on both

sides. The gap should be approximately 10 mm (0.4")

on both sides. If the cartridge is not sealed properly,

replace the O-rings (see Figure 3 on page 3)

and retry, or contact Biotage 1-Point Support.

»

Ensure that all clamps are properly closed before

introducing pressure into the system.

»

Before removing the head assembly, ensure that

the system is depressurized (all pressure gauges

should read zero (0) bar/psig) and completely

drained, and the vacuum break valves (see MV-04

and MV-05 in Figure 14 on page 8) are open.

»

Ensure that the pump pressure gauge on the control

panel (see PG-01 in Figure 14 on page 8) reads

zero (0) bar/psig before disconnecting the stainless

steel overbraided solvent inlet tube from the three-way

injection valve, or the three-way injection valve.

»

Never remove a tube or system component

when it is under pressure.

Safety

»

The clamp halves must be held to prevent them from falling

when striking them with the wedge tool or a plastic-faced

mallet. Each half weighs approximately 11.3 kg (25 lbs).

»

When closing the radial compression fluid reservoir lid,

ensure that it is seated properly to ensure a secure seal.

»

Only use unmodified Biotage cartridges.

»

Never attempt to run the system without a

cartridge, or with the wrong size of cartridge.

»

Always equilibrate the cartridge.

»

Equilibrate the cartridge at a low flow rate

to avoid extreme temperature rise.

»

Only use waste containers and fraction collection

vessels that are grounded or made of glass.

»

A fume extractor must be used for open waste

containers and fraction collection vessels.

»

Do not place solvent reservoirs on top of any part of

the system. Any spillage can seriously damage the

equipment, resulting in potential safety hazards.

»

The system contains various exhaust ports. If the solvent

in use should not be released as a liquid or vapor into

the general atmosphere, contact Biotage for instructions

on how to safely vent these vapors and liquids.

»

To prevent spray hazards, the cartridge compression vent

port on the top head assembly (see MV-03 in Figure 14

on page 8) and the safety relief port for the radial

compression module on the side connection panel (see

Table 6 on page 6) must have the supplied frits

or appropriate tubing installed during operation.

»

Disposing of the used cartridge and media as a unit

reduces the exposure of plant personnel to the residual

solvent and any potentially hazardous by-products.

Biotage recommends prompt disposal of used cartridges.

»

The cartridge shipping containers are not considered

leak proof. The containers are resistant to most solvents

for 100 days when stored at 37.8°C (100°F) or less.

Some solvents may dissolve the plastic shipping bag.

»

Follow all applicable safety procedures

when working with bottled gas.

»

Follow all generally-accepted lab safety procedures

and applicable laws and regulations.

»

Always follow local and national safety

regulations related to storage, handling and

disposal of chemicals, samples and waste.

»

Read and understand the safety data sheet (SDS)

provided by the chemical manufacturer before

storing, handling, working with, or disposing

of any chemical or hazardous substance.

»

In many cases the system will be used in a Class I,

Division I, Group C/D hazardous area (equivalent to

EEx D IIc T4) as defined by the ANSI/NFPA 70, American

National Standards for Electrical Installations. Many

solvents are both flammable and toxic and must be

handled by trained operators who follow government

and corporate safety regulations and guidelines.

»

Personnel working with or near the system must

wear applicable safety clothing and gear (such as

solvent-resistant clothing and gloves, steel toe

shoes, and hearing, face, and eye protection) that

comply with local and national safety regulations.

Hoist

»

The hoist motor internal air pressure setting must

not be changed from the factory-set value.

»

When operating the hoist, do not attempt to lift loads

greater than 125 kg (275 lbs), and always wear steel

toe safety shoes, and hearing and eye protection.

»

Visually inspect the hoist, cartridge tool, and head

sling assembly before each use to ensure that no

parts are damaged or loose. If any problems are

found, solve them before using the equipment.

»

Confirm that the four plates of the cartridge

tool are fully extended and engaged with the

cartridge lifting groove, the knurled knob is fully

tightened (clockwise), and the locking nut is in

place before attempting to raise the cartridge.

»

Ensure that the top ring on the head sling assembly is

attached to the hoist with the narrow end up and the

closure nut fully threaded and tightened, and that the

cables are not twisted and are clear of obstacles.

»

To avoid cable damage, do not raise the cable so

high that the cable safety wrap (above the hoist

hook eyelet) is drawn into the hoist pulley.

»

Use caution when moving the head assembly

while attached to the hoist; the weight of the head

assembly (68 kg; 149 lbs) can cause it to swing

excessively if the hoist is rotated at a high speed.

»

Do not perform any maintenance tasks on the hoist unless

it is completely disconnected from the inlet air supply.

Biotage®Flash 400 User Manual | © Biotage 2018

Installation

Warning

»

The system must be unpacked and installed by an authorized

Biotage service engineer.

»

Follow regional safety practices when handling and moving

shipping boxes and containers, and when moving the system.

»

The total weight of the package including the system is up to

1043 kg (2300 lbs) depending on the system configuration.

Use suitable lifting equipment when moving the package.

»

Observe general and specific safety regulations for the use of

the system and its accessories at all times in order to reduce

the risk of personal injury, fire, and explosion; see the “Safety”

chapter on page 11.

Site Requirements

Before the system is installed, the installation site should be

prepared as follows:

Fume Hood/

Ventilation

System

The system must be placed in a well-ventilated

walk-in fume hood or an equivalent enclosure

that is appropriate for safe handling and

exhausting large quantities of sample, solvent, and

fractions and capable of exhausting 0.6 m3/min

(21.2 ft3/min). Follow local and national safety

regulations for installing a system inside a fume

hood and the safety regulations supplied by the

fume hood manufacturer.

A fume extractor must be used for open waste

containers and fraction collection vessels.

Never install or use the system near a potential

ignition source.

Floor Load

Capacity

The system can weigh up to 650 kg (1433 lbs).

It should be installed on a level floor that has a

minimum floor load rating of 732 kg/m2(150 lb/f t2).

The system is stable under normal usage.

Note: If the system will be moved from one area

to another, carefully evaluate the floor condition

between each point to ensure that the load ratings

are adequate.

Dimensions Review Figure 14 on page 8 to determine the

space allowances needed to set up and operate

the system. Consider the following clearance

recommendations:

»

A minimum of 25 cm (10") clearance on the

sides of each unit for solvent/air connections.

»

A minimum height clearance of 250 cm

(100") for the hoist to reach full extension.

»

Enough space behind the system

to allow operator access.

»

A minimum clear radius of approximately 60 cm

(24") is required in front of the system to

provide clearance for the range of motion of the

hoist when inserting and removing cartridges.

Operating

Temperature

4°C to 32°C (39°F to 90°F)

Nitrogen

Supply

100 psig (6.9 bar), dry and clean.

Compressed

Air Supply

100 psig (6.9 bar), clean and dry; however, slightly

lubricated is allowable.

Note: If lubricated air is used, appropriate

safety precautions must be taken to prevent the

lubricant in the air exhaust from contaminating the

surrounding area.

Ground the System

Warning

»

The system, when operated with non-polar solvents such as

hexane, methylene chloride, etc., can build up a high static

electricity charge, which in certain conditions can be dangerous.

To eliminate any risk of a static discharge, the system and

ancillary containers must be grounded before use as described

below. Failure to follow these grounding instructions may result

in equipment damage, personal injury, or death.

»

A trained person must verify that the system and ancillary

containers are grounded before each run. Nominal resistance

must be below 5 Ohm between ground and each metal point in

the system.

Whenever organic solvents flow from one point to another there

is the possibility of dangerous static electric buildup along the

path. To eliminate any risk of a static discharge, the systems

and ancillary containers must be grounded before use.

To ground the system, connect a ground wire between the

3/8"-16 UNC threaded ground stud on the system (see Figure 15)

and a grounding point, such as a metal cold water pipe.

Figure 15.Electrical ground stud location.

Installation

Installation

Note: To be an acceptable grounding point, the entire run of

pipe must be made of metal. Have a qualified person, such as

an electrician, verify that the point is grounded before operating

the system.

Verify that the system and ancillary containers are grounded using

an electrical multimeter (DVM). Nominal resistance must be below

5 Ohm between ground and each metal point in the system.

Gas Supply Connections

Warning

»

To avoid injury to yourself or damage to the system, never apply

gas pressures greater than 100 psig (6.9 bar) to the system inlet

gas ports.

»

Only nitrogen must be used to move radial compression fluid

through its flow path due to the risk of exothermal reaction

and/or explosion.

»

Ensure that the inert gas tubing connected to the system cannot

come in contact with chemicals. Corrosives and solvents can

dissolve the tubing.

»

Do not perform any maintenance tasks on the hoist unless it is

completely disconnected from the inlet air supply.

Recommended Tubing

Biotage recommends stainless steel or brass tubing or

stainless steel overbraided PTFE tubing for the gas supply

lines. The tubing must be rated to at least 200 psig (13.8 bar)

at the maximum working temperature. The gas tubing must be

protected from abrasion, kinking, or mechanical damage.

Before connecting gas tubing to the system:

1. Blow the gas tubing clean with clean, dry gas.

2. Ensure that the pump valve (MV-08) and the reservoir

pressure valve (MV-09) on the control panel are in the

following positions:

Valve Position

MV-08 O(closed)

MV-09 (vent)

3. Ensure that the air pressure regulator (see PRR-01 in

Figure 14 on page 8) is turned down to zero.

Nitrogen

Nitrogen is used to pressurize the radial compression fluid

reservoir and the radial compression module.

Connect a dry and clean nitrogen gas supply to the nitrogen port

on the side connection panel (see Figure 16). Set the pressure to

100 psig (6.9 bar).

Figure 16

MV-05

MV-10

1 2

2

MV-06

MV-09

MV-08

PG-01

MV-07

MV-01

A1

PG-02

BIOTAGE®FLASH 400

A B

B

MV-11

.The side panel connections.

=Nitrogen inlet for cartridge compression.

=Compressed air inlet for the solvent pump.

Compressed Air

Both the solvent pump and the hoist need compressed air to

operate:

»

Solvent Pump: Connect a compressed air supply to the

air port on the side connection panel (see Figure 16).

Set the pressure to a maximum of 100 psig (6.9 bar).

»

Hoist: Connect a compressed air supply to the hoist air

inlet (see Figure 17). Set the pressure to a maximum of

100 psig (6.9 bar). Note that the actual air pressure supplied

internally to the hoist motor is factory-set to approximately

30 psig (2.1 bar) to ensure hoist safety. For safety

reasons, this internal setting must not be changed.

Use clean and dry compressed air; however, slightly lubricated

is allowable. If lubricated air is used, appropriate safety

precautions must be taken to prevent the lubricant in the air

exhaust from contaminating the surrounding area.

Figure 17.The hoist air inlet (PRR-02).

Biotage®Flash 400 User Manual | © Biotage 2018

Installation

Solvent Inlets (A and B)

Warning

»

Take appropriate measures to protect against static discharge

by ensuring that the system and ancillary containers are

grounded (see page 14).

»

Do not place solvent reservoirs on top of any part of the system.

Any spillage can seriously damage the equipment, resulting in

potential safety hazards.

It is possible to connect up to two solvent reservoirs (eluent)

to the system. The solvent reservoirs must be slightly

pressurized (2 to 5 psig; 0.1 to 0.3 bar) so that the solvent pump

will have a sufficient supply of solvent and not cavitate while

drawing the solvent from a reservoir. Mounting the solvent

reservoirs at a height above the solvent pump (P-01) inlet

should satisfy this requirement. The solvent reservoirs must be

grounded and the distance from the reservoirs to the Flash 400

system should be minimized.

Connect a solvent reservoir to one of the inlet ports (Aor B)

on the side connection panel (see Figure 16 on page 15)

using one of the supplied two meter long stainless steel

overbraided tubes.

=Solvent inlets on the side connection panel.

Fraction Outlets ( and )

Warning

»

Only use waste containers and fraction collection vessels that

are grounded.

Connect two of the supplied two meter long stainless steel

overbraided tubes to the outlet ports (1and 2)on the side

connection panel (see Figure 16 on page 15). Collect the

eluting fractions in grounded vessels that are suitable for the

separated compounds.

A slight draw on the outlet may be beneficial to prevent

unnecessary strain on the solvent pump.

=Fraction outlets on the side connection panel.

Drain Valve and Exhaust Ports

Warning

»

Only use waste containers and fraction collection vessels that

are grounded.

The radial compression drain valve (MV-10) on the side

connection panel (see Figure 16 on page 15) is used to drain

the 10 liters of radial compression fluid from the chamber

during the cartridge removal procedure. Place a grounded waste

container of a suitable size underneath the drain tube; see

Figure 18.

The system contains various exhaust ports. If the solvent in

use should not be released as a liquid or vapor into the general

atmosphere, contact Biotage for instructions on how to safely

vent these vapors and liquids.

Figure 18.The drain tube connected to the radial compression drain valve

(MV-10) on the side connection panel is located underneath the Flash 400

frame, on the right side.

Tube Connections

The dual-ferrule type fittings (1/2" fittings) should be

assembled to the tubing as described below:

1. Slide the nut and ferrules onto the tube as shown in Figure 19.

2. Push the tube into the fitting until it seats and then

finger-tighten the nut. Use a 7/8" wrench to turn the nut

1 to 1¼ turn past finger-tight (the first time, after that less is

required). Do not over-tighten.

3. Test the seal by gently pulling on the tube.

Figure 19.How to slide the nut and ferrules onto the tubing.

Operation

Warning

»

Before operating the system, please read and observe the

safety requirements in the “Safety” section on page 11.

Note: As part of GLP, we recommend that you keep a logbook of

runs performed on the system (with the date, time, user, used

solvent or solvent mixture, and pressure settings for each run).

Install a Cartridge

Remove the Top Head Assembly

Warning

»

Before removing the head assembly, ensure that the system

is depressurized and completely drained (all pressure gauges

should read zero (0) bar/psig), and the vacuum break valves

(MV-04 and MV-05) are open.

Note: Refer to Figure 14 on page 8 for component locations

when performing this procedure.

Retract the Cartridge Seal Adapters

1. Ensure that the system is depressurized and completely

drained (all pressure gauges should read zero (0) bar/psig),

and the vacuum break valves (MV-04 and MV-05) are open;

see the instructions on page 27.

2. Disconnect the three-way valve from the cartridge seal

adapter using a 7/8" open-end wrench; see Figure 20.

Figure 20.Removing the three-way injection valve.

3. Disconnect the stainless steel overbraided outlet tube from

the outlet fitting in the middle of the bottom head assembly

using a 7/8" open-end wrench; see Figure 21.

Figure 21.The outlet tube at the bottom head assembly.

4. To avoid damaging the cartridge seal adapters on the top

and bottom head assemblies and the new cartridge, retract

both the adapters fully by turning them counterclockwise

(see Figure 22) until you feel resistance. This may require a

3/4" open-end wrench.

Figure 22.Retracting the top cartridge seal adapter.

Remove the Top Head Clamp

Warning

»

The clamp halves must be held to prevent them from falling

when striking them with the wedge tool or a plastic-faced

mallet. Each half weighs approximately 11.3 kg (25 lbs).

»

Inspect the head clamps before and after each use. If the

clamp, threaded studs, nuts, or washers show any sign of wear

or damage, replace it/them. Only use clamps, studs, nuts, and

washers supplied by Biotage.

5. Remove the top head clamp by loosening the nuts on the sides

of each threaded stud using a pair of appropriate wrenches

(see Figure 23) or one wrench and a deep-socket and ratchet.

Slide the nuts and washers off and remove the studs.

Figure 23.Removing the top head clamp.

6. Carefully slide both halves of the top head clamp off the

head assembly and place them on a clean, smooth surface

where they will not fall and get damaged.

Note: If necessary, use the wedge tool provided (see

Figure 13 on page 7) and/or a plastic-faced mallet to

gently strike and loosen the clamp halves. The clamp halves

must be held to prevent them from falling when striking

them with the wedge tool or a plastic-faced mallet.

Operation

Biotage®Flash 400 User Manual | © Biotage 2018

Operation

Lift the Top Head Assembly from the

Radial Compression Barrel

Warning

»

When operating the hoist, do not attempt to lift loads greater

than 125 kg (275 lbs).

»

Visually inspect the hoist and head sling assembly before

each use to ensure that no parts are damaged or loose. If any

problems are found, solve them before using the equipment.

»

Ensure that the top ring on the head sling assembly is attached

to the hoist with the narrow end up and the closure nut fully

threaded and tightened, and that the individual cables are not

twisted and are clear of obstacles.

»

To avoid cable damage, do not raise the cable so high that the

cable safety wrap (above the hoist hook eyelet) is drawn into the

hoist pulley.

»

Use caution when moving the head assembly while attached to the

hoist; the weight of the head assembly (68 kg; 149 lbs) can cause

it to swing excessively if the hoist is rotated at a high speed.

7. Move the hoist arm so that the safety hook is centered over

the top head assembly.

8. Attach the top ring of the head sling assembly to the hoist

safety hook. Ensure that the top ring is attached to the hook

with the narrow end up and the closure nut fully threaded

and tightened (see Figure 24).

Figure 24.The hoist control box and the head sling assembly attached to

the hoist safety hook.

9. Attach the pivot arms on the head sling assembly to the

eyebolts on the top head assembly:

a. If required, raise or lower the head sling assembly to

allow the pivot arms to reach the head eyebolts.

b. Place the pivot arm’s slotted leg over a head eyebolt.

Turn the pivot arm so that the end attached to the

sling cable faces inward, toward the center of the head

assembly, as shown in Figure 25A. Ensure that the cable

is not twisted and clear of obstacles.

c. Press and hold the release button on the pivot arm’s

quick-release pin, insert the pin through the aligned

holes in the pivot arm leg and the eyebolt loop, and then

release the button. This locks the pivot arm to the head

eyebolt; see Figure 25B.

d. Repeat steps b through c for the two remaining pivot arms.

Figure 25

A B

.A: The pivot arms on the head sling assembly are attached to

the eyebolts on the top head assembly. B: The quick-release pin locks the

pivot arm to the head eyebolt.

10. Once the pivot arms are secure, press and hold the button

on the hoist control box (see Figure 24) until the head

assembly is clear of the radial compression barrel.

11. Slowly move the head assembly while attached to the hoist

toward the front of the Flash 400 frame until it is completely

clear of the frame and the radial compression module.

Use caution as the weight of the head assembly (68 kg;

149 lbs) can cause it to swing excessively if the hoist is

rotated at a high speed.

12. Align the head assembly over a clean, padded surface

capable of supporting its weight (68 kg; 149 lbs).

13. Press and hold the button on the hoist control box until

the head assembly comes to rest on the padded surface and

there is slack in the head sling assembly.

14. Remove the head sling assembly from the hoist safety hook.

Leave the head sling assembly attached to the head assembly.

Insert a Cartridge into the Radial Compression Barrel

Warning

»

Only use unmodified Biotage cartridges.

»

When operating the hoist, do not attempt to lift loads greater

than 125 kg (275 lbs).

»

Visually inspect the hoist and cartridge tool before each use to

ensure that no parts are damaged or loose. If any problems are

found, solve them before using the equipment.

»

Confirm that the four plates of the cartridge tool are fully

extended and engaged with the cartridge lifting groove, the

knurled knob is fully tightened (clockwise), and the locking nut

is in place before attempting to raise the cartridge.

»

To avoid cable damage, do not raise the cable so high that the

cable safety wrap (above the hoist hook eyelet) is drawn into the

hoist pulley.

When inserting a cartridge, it is critical to ensure that it stays

level and aligned in the vertical axis. The bottom head O-ring

should be sufficiently lubricated with solvent. A dry O-ring may

cause the cartridge to tilt to one side while seating, resulting in

incomplete sealing.

1. Fully retract the upper and lower cartridge seal adapters and

remove the head assembly as described on page 17 to

page 18.

Other manuals for Flash 400

1

Table of contents

Other Biotage Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Santevia

Santevia Alkaline user manual

BWT

BWT Multipur AP Series Installation and operating manual

ITT

ITT WEDECO Aquada Installation and maintenance instructions

Bauer

Bauer FAN Separator Green Bedding Service manual

Judo

Judo EASY FILT-BP Installation and operating instructions

GE

GE GX1S50R Owner's manual and installation instructions

Vortex

Vortex 85-1448-10 (10 GPM) Installation and service manual

Hitachi

Hitachi PQF Quick start up guide

ROSEDALE

ROSEDALE DUPLEX 6 Installation, operation and maintenance manual

Bibo

Bibo BIBO bar manual

Greiner Vibrograf

Greiner Vibrograf ACS 900 Manual and instruction

Kemppi

Kemppi PFU 210e operating manual