Biotech AB-40010 User manual

BIOTECH LIQUID

FLOW METER

User Manual

AB-40010

2

CONTENT

1. NOTICES 3

2. WARRANTY 3

3. IMPORTANT USER INFORMATION 4

4. CE CERTIFYING 4

5. RECYCLING 5

6. WARNING! 5

7. FEATURES 6

7.1. INTRODUCTION 6

7.2. CALIBRATION 6

7.3. A NEW TECHNICAL APPROACH 7

7.4. SELECTABLE INTEGRATION TIME 8

7.5. TIME FACTOR 9

7.6. NOTICE

10

7.7. SITE SELECTION

10

7.8. UNPACKING

10

7.9. PACKING LIST

10

8. FLUID CONNECTIONS 11

8.1. LEFT SIDE 11

8.2. RIGHT SIDE 11

9. OPERATING 13

9.1. POWER-ON AND START 13

9.2. MAIN SCREEN 13

9.3. DATA ACQUISITION 14

10. HOW TO INSTALL THE FLOW METER APP 14

11. USING THE FLOW METER APP 14

11.1 MAIN SCREEN 14

11.2 SETTINGS 16

11.3 EXPORT GRAPH 19

11.4 EXPORT DATA 19

12. TROUBLESHOOTING 19

13. CONTACT

20

3

1. NOTICES

© Biotech AB 2022

No part of this manual may be reproduced in any form or by any means (including

electronic storage and retrieval or translation into a foreign language) without prior

agreement

and written consent from Biotech AB as governed by Swedish

and inter-

national copyright laws.

Printed in Sweden.

Biotech AB

Råövägen 300

SE-439 92 Onsala

Sweden

Research Use Only.

Not for use in Diagnostic Procedures.

2. WARRANTY

Biotech AB makes no warranty, included but not limited to the common warranty

legislation, for Quality and tness of the product to a determined purpose.

In no event shall Biotech AB be liable for direct, indirect, special and consequent

damages connected to the delivery, use or application of the product or its compo-

nents.

Biotech AB guarantees that the product is free from hardware

defects within the

Warranty validity time. Should, within this time, a defect occurs, we will correct it free

of charge.

All servicing will be handled by:

Biotech AB

Råövägen 300

439 92 Onsala

Sweden

Phone: +46 300 56 91 80

info@biotechuidics.com

Freight expenses for the safe transport of the product to Biotech AB and back, must

be carried by the customer.

4

Biotech AB grants no warranty for: Routine checks,

Maintenance, Repair or

Parts Replacement after normal wear; Consumables; Damages caused by total or

partial blockage

of tubings; Any type of Software; Damages caused by

modi-

cation of the product without consent of Biotech AB;

Warranty repair is void when

the damages or errors where caused by: Unqualied or wrong handling like

fall or

strong Vibration of the Product. Accidents, natural

catastrophe and all other caus-

es which cannot be foreseen or controlled by Biotech AB, including but not limited

to Storm, Water, Fire, Riot and abnormal Climate conditions.

Warranty validity Time

The validity Time of the Warranty is, if not otherwise agreed, one years from the day

of purchase according to the

Biotech

General Terms, found on www.biotechuidics.com/

general-terms/

Safety

Safety rules according to the Swedish and European

guidelines 89/3 92/EWG

§1.1.2.b have been taken into

account during design of the instrument. All electron-

ic In- and

Outputs are very sensitive to electrostatic discharge (ESD).

The use of

strong electromagnetic sources like Cellular

Telephones or Radio Transmitters near

the instrument should be avoided.

3. IMPORTANT USER INFORMATION

All users must read this manual to fully understand the safe use of the Liquid Flow

Meter.

WARNING!

The WARNING! Sign highlights instructions that must be followed to avoid

damage. Do not proceed until all stated conditions are clearly understood

and met.

4. CE CERTIFYING

This product meets all requirements of applicable CE-directives.

A copy of the corre-

sponding Declaration of Conformity

is available on request. The CE symbol and cor-

responding declaration of conformity, is valid for the instrument when it is:

• Used as a stand-alone unit, or

• Connected to other CE-marked Biotech AB instruments,

or

• Connected to other products recommended or described in this manual, and

• Used in the same state as it was delivered from Biotech AB

except for alterations

described in this manual.

55

5. RECYCLING

This symbol indicates that the waste of electrical and electronic

equipment

must not be disposed as unsorted

municipal waste

and must be collected separately.

Please contact an authorized

representative

of the manufacturer for information concerning

the decommissioning of equipment.

6. WARNING!

This is a Class A product. In a domestic environment,

it might cause radio

interference, in which

case the user might be required to take appropriate

measures.

By using the Liquid Flow Meter AB-40010 our tips/

warnings as well as our terms of

delivery are accepted.

1. Only use in laboratory! The use for medical purposes, in

the food- or beverage

processing, plant breeding or

something else is expressly required or permit-

ted. Any

type of use and the related specic suitability of the

product for this

purpose is to be checked by the user.

2. This product may be used only by trained personal. Correct

behavior in the labo-

ratory are presupposed by trained personal. We accept no liability for improper

use of the product. If in doubt, ask the competent commissioner for laboratory

safety.

3. Notes on environmental and health hazards and also the handling and disposal

of the solvent used must be

taken from the safety data sheets of the solvent sup-

pliers.

4. We advise the customer orally, writing or by trials, this must be done in good

faith but without liability for us, and does not exempt the customer from testing

the goods to their suitability for the intended processes and uses.

IN ORDER TO UTILIZE THE INSTRUMENT’S FULL POTENTIAL,

WE STRONGLY RECOMMEND YOU TO

DOWNLOAD AND

INSTALL OUR PC-APP.

DOWN

LOAD

APP

7. FEATURES

7.1. INTRODUCTION

The AB-40010 is specically designed for continuous

measurement of ow rate

without interference in Fluidic systems. Compatible with all HPLC and GPC/SEC

solvents,

it is conveniently sized and powers itself from a USB

connection. A

modern PC based app allows continuous recording

and storage of the measured ow

rates. The current ow

r

ate is also displayed on the Flow Meter’s integral high-resolution

OLED Display, allowing easy control of current ow value.

Extraordinary high resolution and wide dynamic range makes

the BIOTECH AB Liquid

Flow Meter the perfect ow monitoring

tool for the most demanding HPLC and GPC/

SEC systems.

7.2. CALIBRATION

6

Factory settings with calibration for water and 4 additional solvents

• Water (Default)

• Tetrahydrofuran “THF”

• Methanol

• Ethanol-Water 1:9

• Acetonitrile – Water 40:60

Easily select the calibration factor to be used (via the app)

• New calibration factors and solvent names can be stored

7.3. A NEW TECHNICAL APPROACH

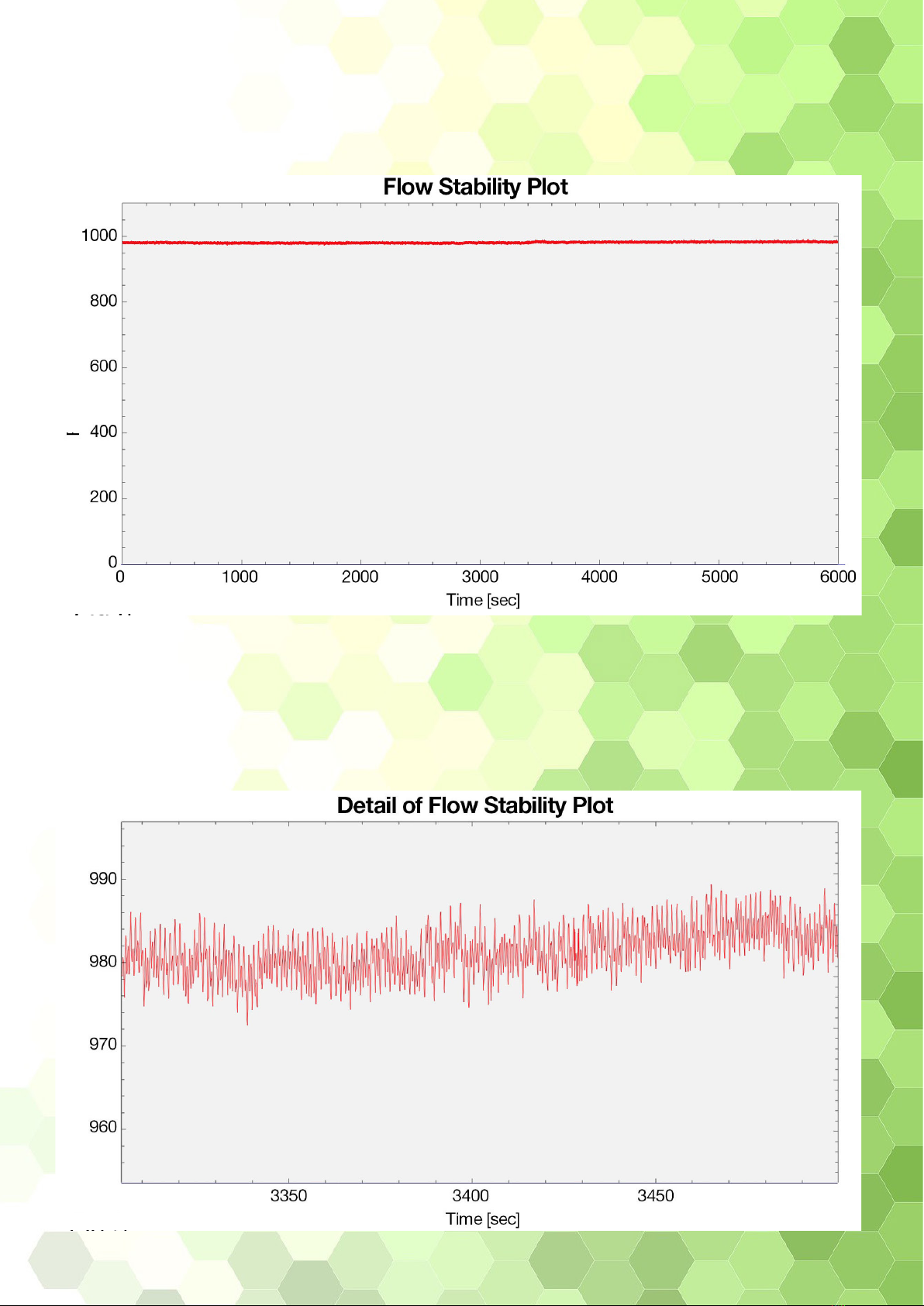

It may look like you have a stable ow….

But when you take a closer look…

Fig. 2

Fig.1

Flow [µl/min]

Flow [µl/min]

7.4. SELECTABLE INTEGRATION TIME - TIME FACTOR SETTINGS

MADE VIA THE APP

78 msec (No Integration)

• Real time measurement. Useful for tracking high frequency pulsation of the

pump and detecting defective seal rings and/or check valves

300 msec

• Equivalent to traditional volumetric owmeters

• Useful for detecting overall performance of pumps

1 sec

• This integration time targets system validation applications where pulsation of

the pump is not relevant and long term stability is desired

2 sec

• Same as for 1 sec integration time but targeted to owrate of 1 mL/min and

above

10 sec

• Extremely useful for absolute calibration of ow rate of the pump

• This ensures that no sporadic eects inuence the calibration

8

9

9.8 sec integration time

310 m sec integration time

78 m sec integration time

Fig.3

Fig. 4

Fig.5

7.5.

TIME FACTOR — HOW YOU MEASURE DECIDES WHAT YOU GET

10

By using the Liquid Flow Meter AB-40010 our tips/

warnings as well as our

terms of delivery are accepted.

1. Only use in laboratory! The use for medical purposes, in

the food- or beverage

processing, plant breeding or

something else is expressly required or permit-

ted. Any

type of use and the related specic suitability of the

product for this

purpose is to be checked by the user.

2. This product may be used only by trained personal. Correct

behavior in the labora-

tory are presupposed by trained personal. We accept no liability for improper use

of the product. If in doubt, ask the competent commissioner for laboratory safety.

3. Notes on environmental and health hazards and also the handling and disposal

of the solvent used must be

taken from the safety data sheets of the solvent sup-

pliers.

4. We advise the customer orally, writing or by trials, this must be done in good faith

but without liability for us, and does not exempt the customer from testing the

goods to their suitability for the intended processes and uses.

7.7. SITE SELECTION

The Flow Meter should be installed in an area free of extreme

temperature, humidity,

sunlight, shocks and vibration. Use delivered Sticky Pads to place the Flow Meter

correctly.

7.8. UNPACKING

Please check immediately after delivery the content of the package for transport

damages.

Please also check after unpacking if all components are present. Should anything

miss, please contact our Support Department

7.9. PACKING LIST

A complete delivery consists of:

• 1 Biotech Liquid Flow Meter

• 1 Mini-USB cable, 1m

• 2 PFA Plug, ¼-28 Flat Bottom

• 2 FEP Tubing, 1/16’’ OD, 0.75 mm ID 0,4m

• 3 P-249 One-Piece Super FlangelessTM PEEK nut

1/4’’- 28 Flat Bottom for 1/16’’ OD

• 1 F-120 One-Piece 10-32 coned PEEK tting 1/16’’

• 2 Sticky pads

1 User Instruction Manual.

7.6. NOTICE

11

8. FLUID CONNECTIONS

First, remove the caps.

Note! As the thru-hole of the ow meter is 1.8mm, be sure that tubing with OD 1/16”

or smaller is not pushed into the ow meter cell. Nothing will be destroyed but the

measurement will not work.

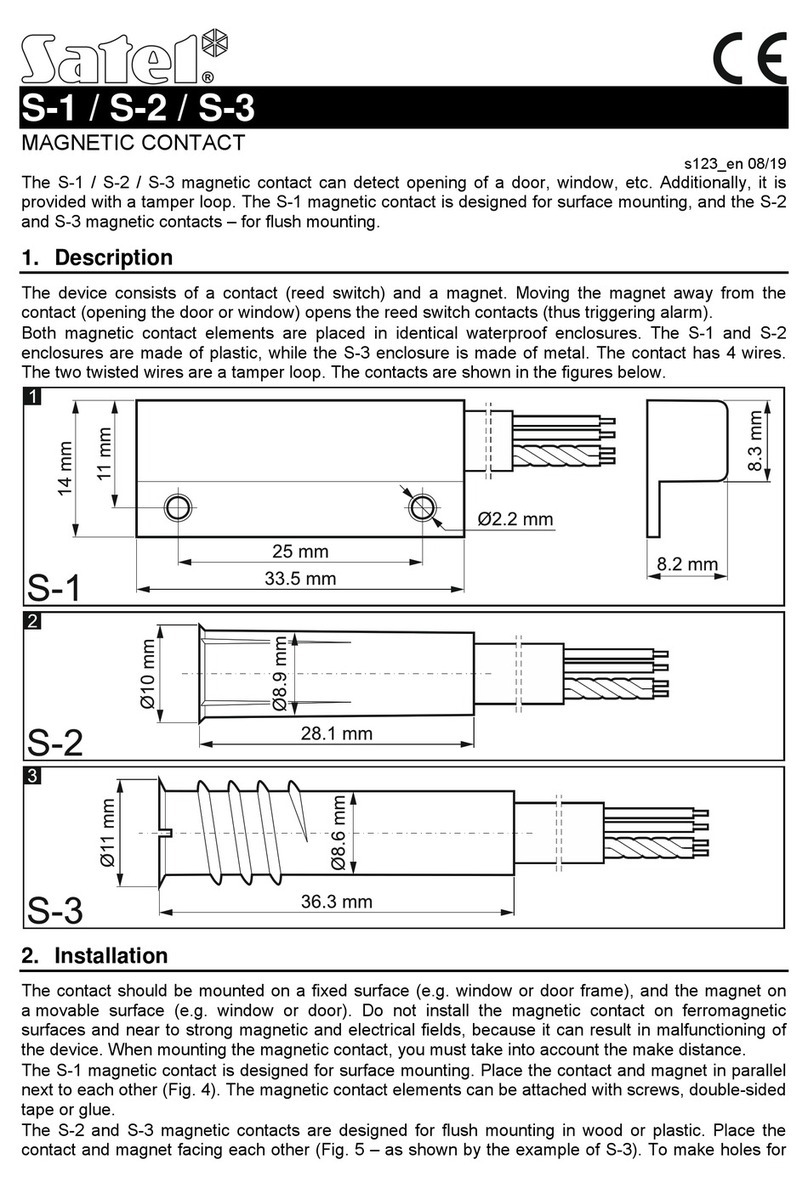

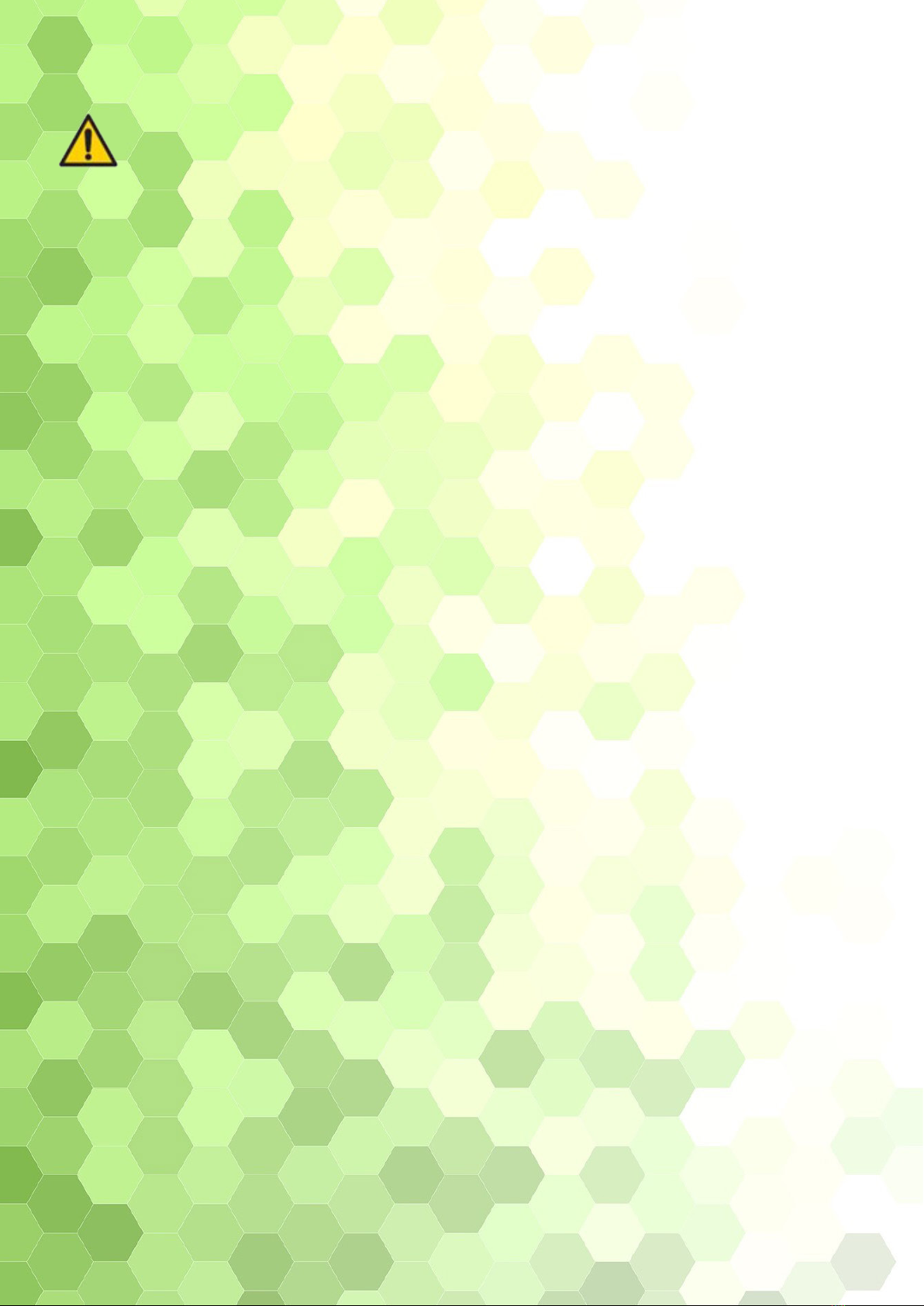

Fig. 6 Left Side, INLET Port Flow Meter

8.2. RIGHT SIDE

Route the other side of the capillary

to a waste bottle or connect it to

your uidic

system with a suitable

tting,

see Figure 7.

Fig. 7 Right Side, OUTLET Port Flow Meter

8.1. LEFT SIDE

Connect the FEP capillary

with the

Flat Bottom

tting at the left side

of the Flow Meter. For the other side

of the capillary take the Flat Bottom

or the coned tting, see Figure 6.

12

If everything is connected properly, the Flow Meter should look Figure 8 (descripted

picture, color of Fittings may change).

Fig. 8 Connection of the Flow Meter

The Flat Bottom ttings may only be tightened nger tight!

13

9. OPERATING

9.1. POWER-ON AND START

The Flow Meter AB-40010 is easy to use with USB-powered plug. Connect the delivered

USB cable to the ow meter and a computer. Upon powering up the instrument the

display will shortly presents the Biotech AB logo.

Figure 9 Flow Meter Start Screen

9.2. MAIN SCREEN

0.000

H2O mL/min

Fig.10 Flow Meter Main Screen

Value Current Flow Rate

H2O Show calibrated eluent [H2O;

MeOH; THF; etcetera]

mL/min Flow rate unit

14

9.3. DATA ACQUISITION

1. Start the app (see Chapter 10) or open a Terminal like HTERM and enter following

settings:

Port COM X -> nd at device manager

BaudRate 9600

Data 8

Stop 1

Parity None

CTS Flow con-

trol No

Newline at CR+LF

2. Press the connect button and data acquisition starts automatically

.

10. HOW TO INSTALL THE FLOW METER APP

1. Start the Flowmeter_Vx.x.x.x_Setup.exe and follow the installation menu.

2. Connect the Flow Meter USB cable to a computer and start the App.

11. USING THE FLOW METER APP

11.1 MAIN SCREEN

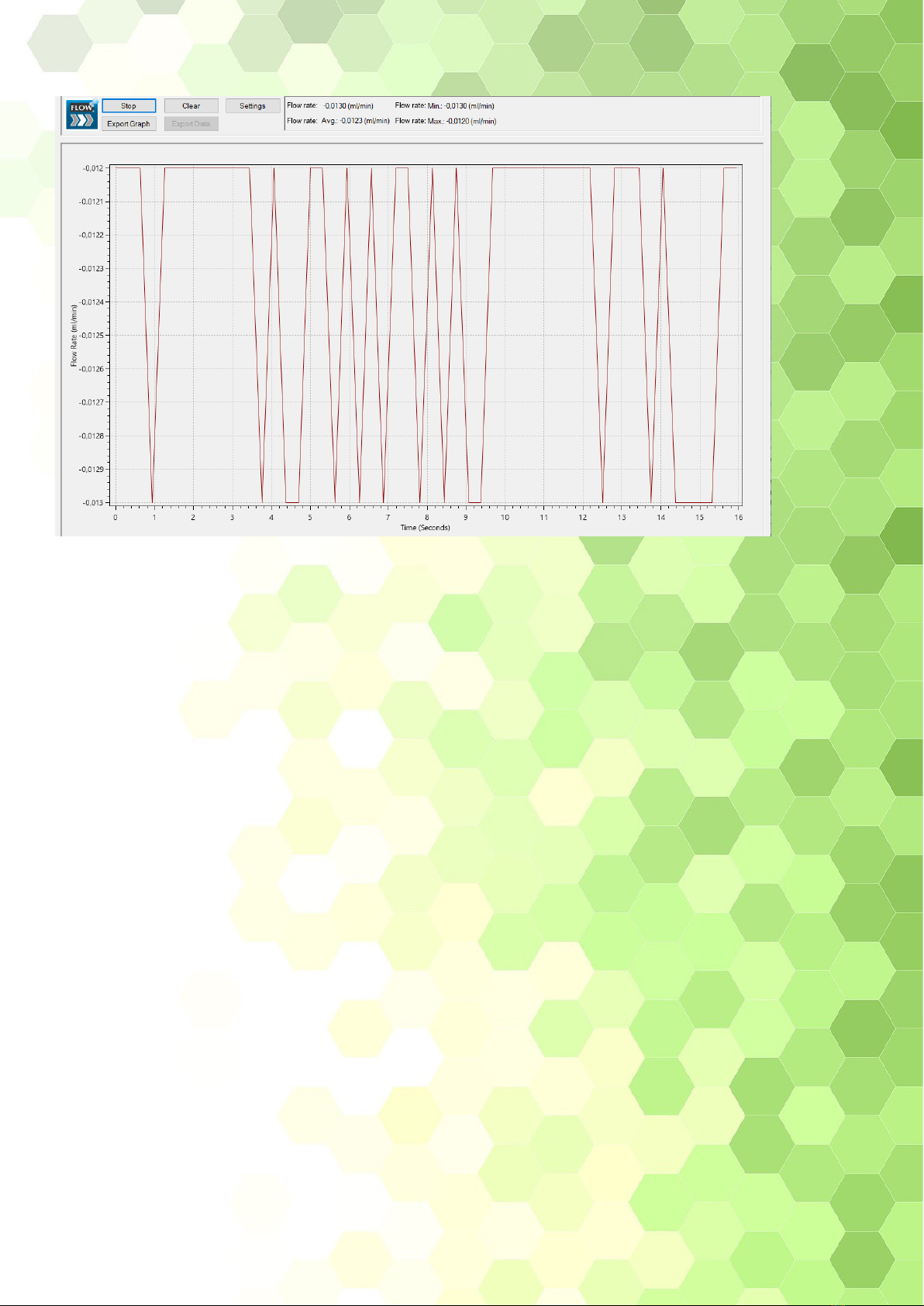

Fig. 11 Main Screen

After installing and connecting the Flow Meter, the main screen shows the status

connected and the serial number of the connected device.

15

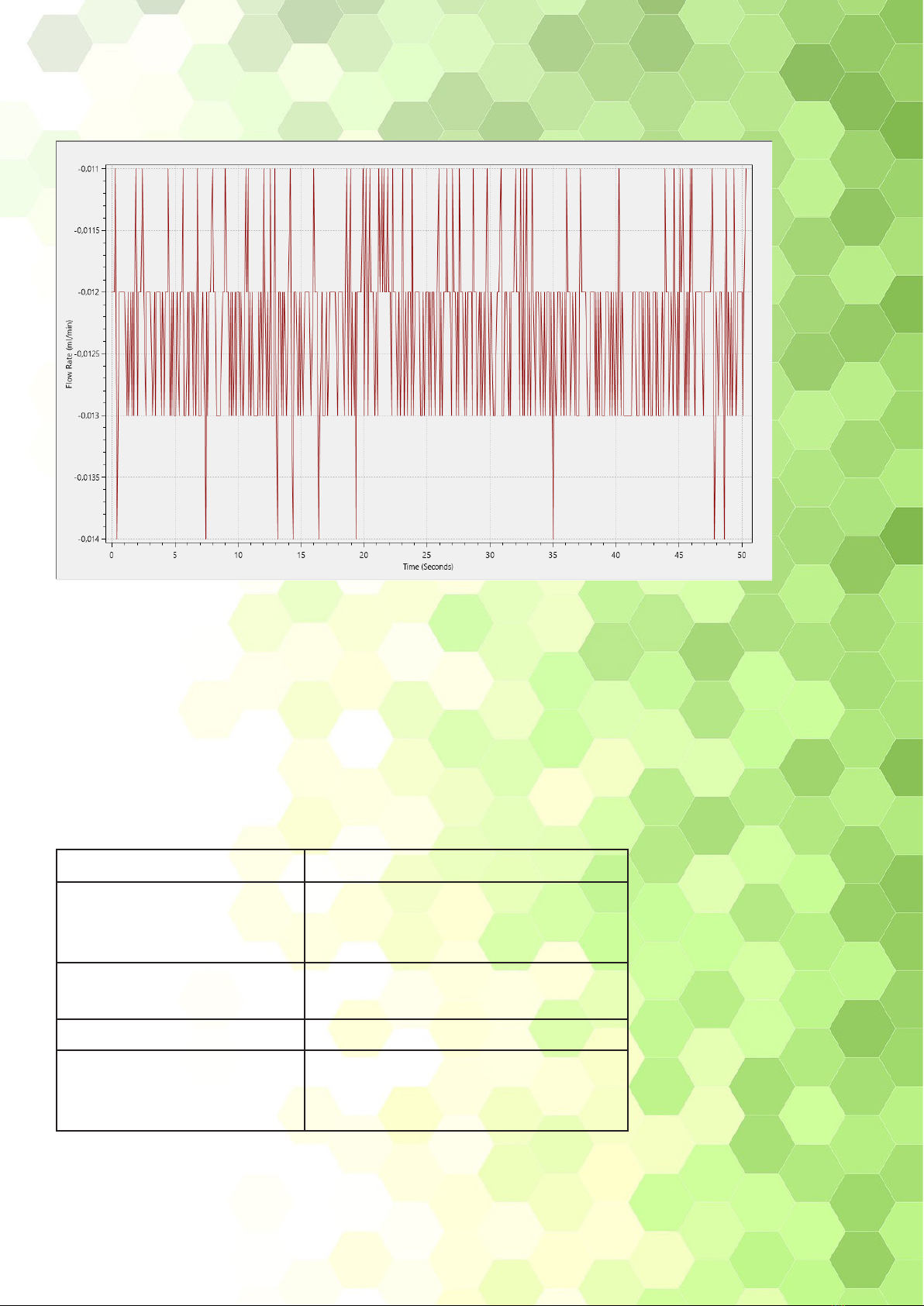

Press START to begin the data collection.

Fig. 12 Data Collection

Starting the data collection information about actual

Minimum, Maximum and

Average Flow Rate. By scrolling the mouse wheel, you can zoom in and out.

Press STOP to discontinue the data collection. The data will be saved automatically

(default, change in settings -> logles).

To start a new sequence, press CLEAR rst and then START.

11.2 SETTINGS

In settings menu are the three registers: Device, Logles and About.

16

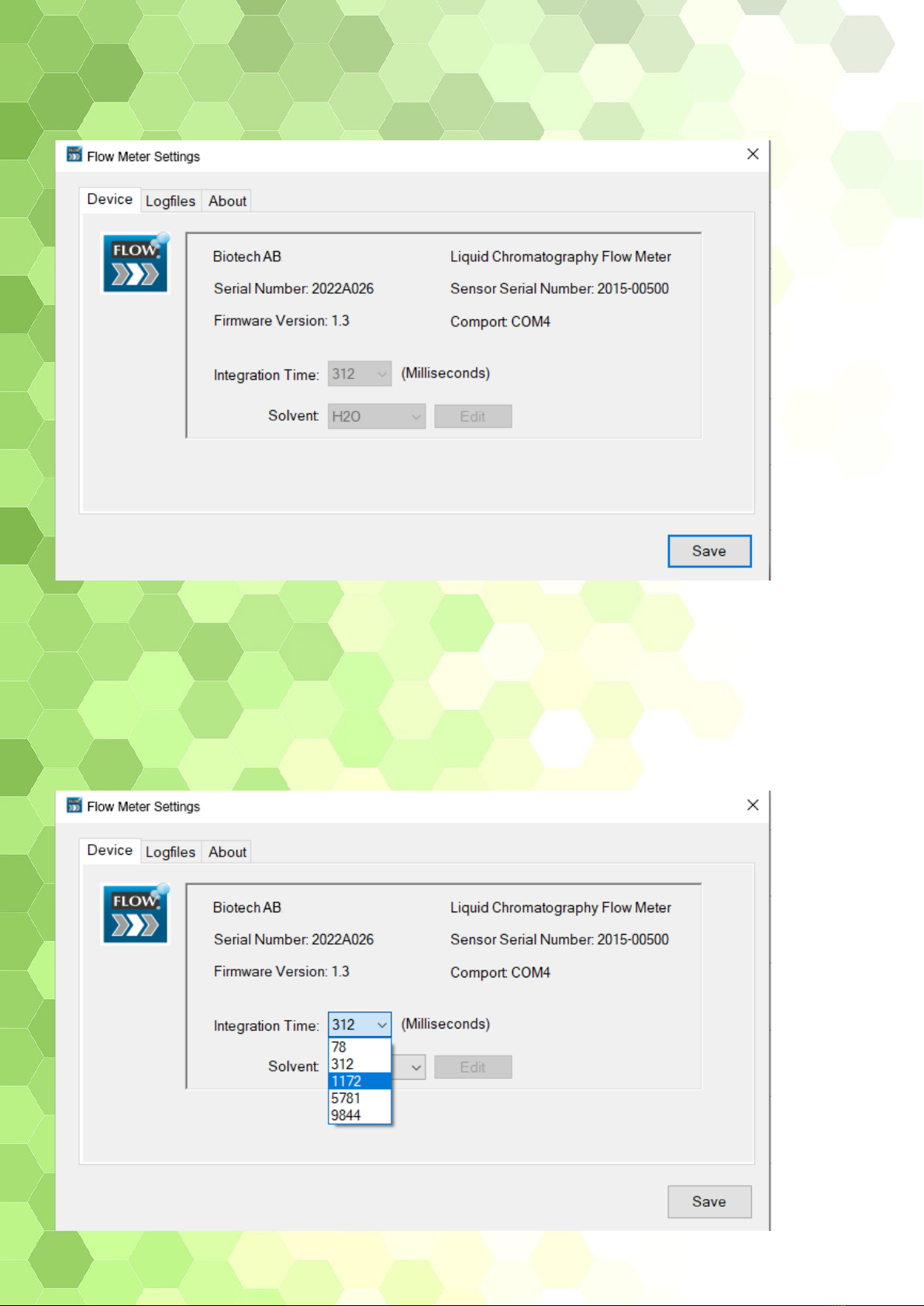

11.2 SETTINGS

In settings menu are the three registers: Device, Logles and About.

Fig. 13 Settings

DEVICE: Provides Information about the Serial Number, Firmware Version and Com port.

Fig. 14 Integration time Settings

Set the Integration Time in Milli Seconds (default 312 ms)

17

NOTE: All changes are stored in the device itself

Fig. 15 Solvent Settings

Set the solvent in use (default H2O)

Fig. 16 Change THF Calibration Factor

EDIT: Change the Solvent Calibration Factor (make sure to use the correct one)

18

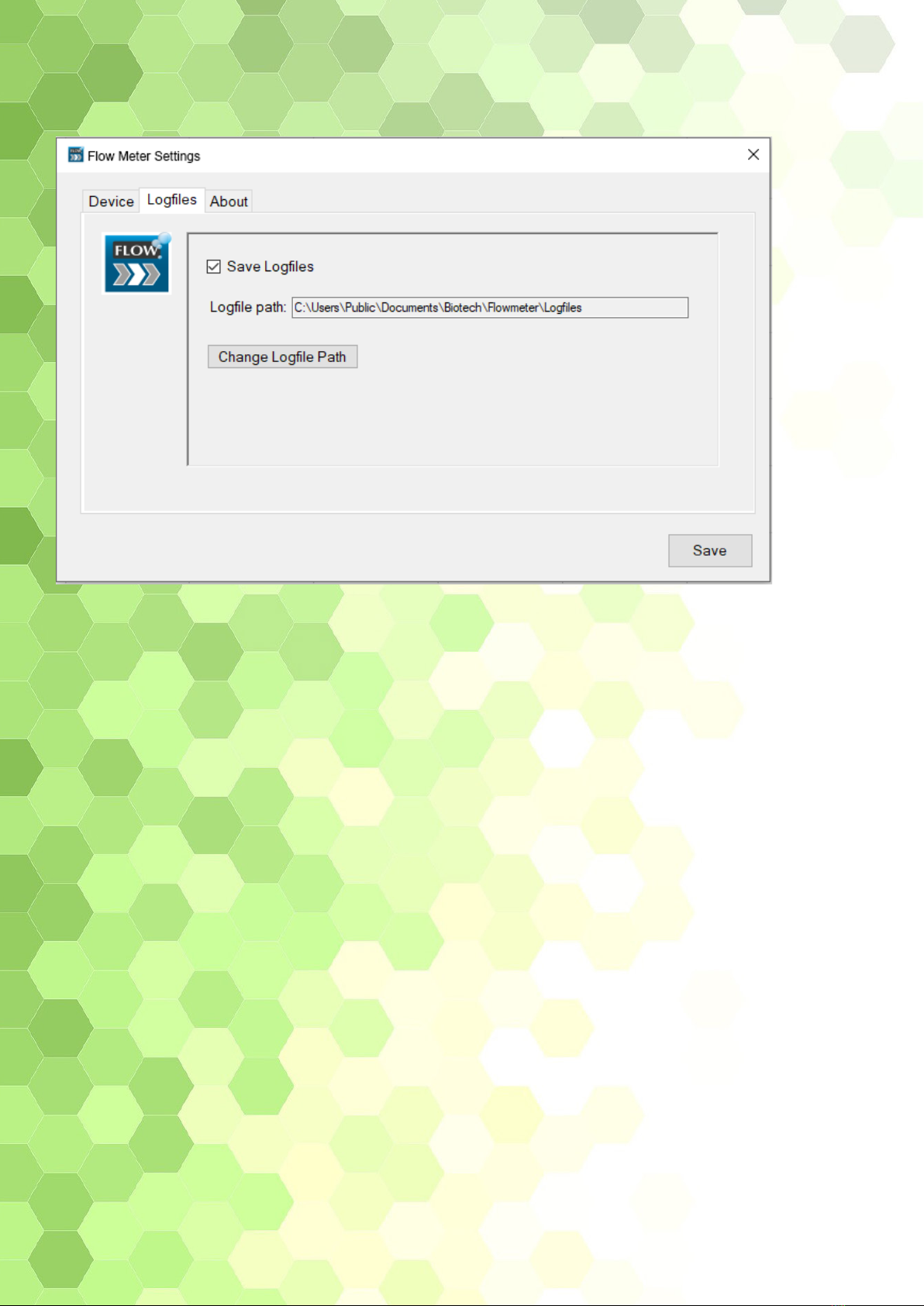

LOGFILES: Provides information about data storage location

.

Save Log Files:

Automatically save CSV logle when measurement stops

or at 100 000 data

points (then a new sequence starts

automatically).

Change Log File Path:

Change path for automatic log le storage.

ABOUT: Provides information about the manufacturer.

Fig. 17 Log File Path

19

11.3 EXPORT GRAPH

Save the measurement as a PNG le.

Fig. 18 PNG Data

11.4 EXPORT DATA

Export the measurement as CSV data. Measurements cannot be reloaded

into the app.

12. TROUBLESHOOTING

Error What to do

The Flow Meter initial-

ization failed.

Status: Not connected

Check the USB connection

with the computer and the Flow

Meter

Make sure that no other soft-

ware blocked the comport

Restart the App

Make sure that there is no pow-

er-safe modus (USB ports) set on

the computer

Table 1 Troubleshooting

20

Biotech AB

Råövägen 300

439 92 Onsala

Sweden

Phone: +46 300 56 91 80

info@biotechuidics.com

Biotech USA LLC

PO Box 18796

Minneapolis

MN 55418, USA

Phone: +1 612-703-5718

sales@biotechuidics.com

www.biotechuidics.com

© Copyright Biotech AB 2022

All rights reserved. No part of this publication may be

reproduced, stored in

a retrieval system or transmitted, in any form by any means, electronic, mechani-

cal, magical, photocopying, recording, or otherwise as well as translated into any

human, computer or alien language, without the prior written permission of the

manufacturer.

All information included in this document may change without any notice.

13. CONTACT

Table of contents